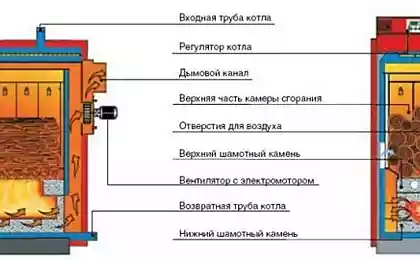

1559

How to get out of wood max: 9 ways to extend the combustion to increase heat and reduce consumption

The same amount of wood can burn at different speeds and to allocate a different amount of heat. The article discusses ways to extend the burning time of firewood to increase the heat and reduce consumption without significant cost.

Change the way of stacking wood

Usually the wood on fire: build a pyramid of logs, in the center put the paper pieces and set on fire. First flare up the chips, and eventually firewood. The disadvantage of this method is that you do not control the combustion. The wood is all light up at once and entirely, burn unevenly and quickly. When a part of the logs burn through, you will throw up new ones that will ignite and burn.

The burning time of firewood can be increased by changing the way they lay in the furnace. For example:

First lay the bottom row of firewood. Put the second row offset to the right or to the left by 5-10cm, to form a ledge. Put the third and following rows. At the edge of a ledge, place a paper or chips and burn them.

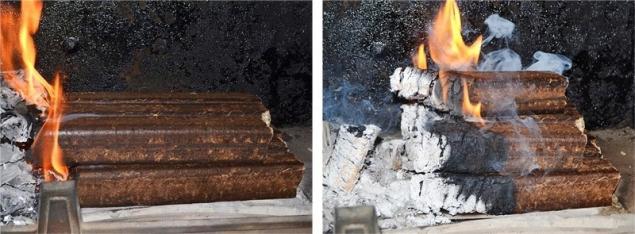

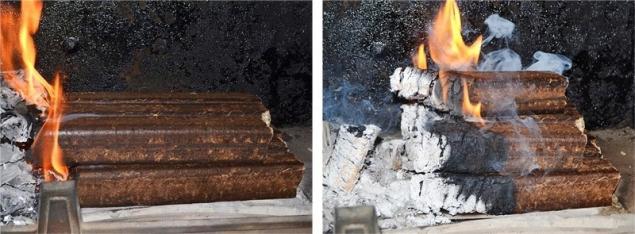

Laying on the example of fuel briquettes. Briquettes do not light up completely and burn evenly with the flame gradually moves from left to right. Laying the wood burns for a long time, and allocates a sufficient amount of heat.

Details:

Before ignition, open the choke heater on high, to provide good traction for kindling wood. When the wood will flare up start to gradually close the valve. If the wood will begin to fade – slightly open the valve and increase traction. Over time, you will select the optimum valve position. The drier and denser the wood, the less air required for their combustion.

Use a dense hardwoodAt the cellular level, wood is composed of a plurality of empty cells with walls of wood substance. The density of the wood substance (wall) all wood the same, but the size of the cells is different.

The smaller the cell size, the higher the density of wood and every square inch contains a lot of combustible wood material. And Vice versa: the larger the cells, the less the density of the wood. It contains a lot of air and little fuel wood substance.

Imagine that the circle is a 1 square inch of wood. In the first case the cells are small and the walls between them a lot. In the second case, the number of cells and walls less, and voids, which are air-filled – more. The density of this wood is low.

What conclusions can be made:

Less dense wood burn quickly. When burning firewood releases the air that feeds combustion. The more air, the wood burns faster and less evenly. Dense wood produce more heat, as per unit volume of fuel they contain more wood substance. Dense wood leave more coals that smolder long. Soft wood is worse keep their shape, to crumble into small embers and quickly extinguished. All the wood is divided into three categories of density: low, medium, high.

Density

Wood Small density of 0.15 – 0.55 g/cm3, Spruce, Willow, Aspen, Pine, Linden, Alder, Fir, poplar the Average density of 0.56 – 0.70 g/cm3 Maple, Walnut, Birch, cherry, Larch, Beech, Oak, sycamore, Pear, Apple High density of 0.75 – 1.08 g/cm3 Ash, Plum, Boxwood, Persimmon ebony, acacia firewood, Prepare in advance, Store the wood in a warm room for 2-3 days prior to ignition to increase their initial temperature.

Warmer than wood initially, however:

Pre-heat the furnaceWhen the wood starts to burn in cold furnace, then:

Use hearth burningThere are two ways of burning firewood: grate (bottom) and the bottom (top burning).

Lower combustion – traditional, when the air on the wood is coming from the bottom and the flame gradually moves up. At the upper combustion air to the wood served on top, the fire is lit at the top and gradually descends.

At the hearth burning at the bottom of the stacked large logs and put on top of the paper and the wood smaller.

Advantages:

Increases completeness of combustion of wood, due to which they produce more heat. You reduce the emission of volatile substances that pollute the chimney with soot. This is a more environmentally friendly method of combustion. How to do it

Hearth for burning firewood stacked pyramid: put down the big logs and the top is smaller. At the top, ignite chips and paper.

While burning wood chips and paper, furnace heated. The flame then begins to descend and set fire to the main wood. At this point, the combustion temperature and flame strength enough to begin to burn the volatile substances contained in the wood. Due to the completeness of combustion of wood produce more heat, and due to the uniform combustion long burning and economical.

Don't let the increased combustion of woodHas three modes of burning wood: low, high and optimum.

In degraded wood not burn completely and form a lot of soot. With increased reduces wood waste: the portion of the heat leaves through the chimney as the heat exchanger and the room did not have time to take it away completely. This occurs in two cases: you use too much wood or it can be served much air. You need to reduce the amount of laying or traction.

The best option when wood burns in an optimal mode: not weak and not strong. The easiest way to determine the mode of combustion is to use the indicator of combustion, which in real time show the current mode. If the flue gas temperature more than 320 degrees, the wood burning in elevated mode.

The indicator of combustion in real-time detects the temperature of the flue gases and the combustion mode

Change the volume of laying the wood on the outside temperaturethe warmer it is outside, the less the building is losing heat. Accordingly, it is need less wood for heating. If you put the same amount of wood at 0C or -10C, in the first case, consume more wood than necessary.

The indicator of combustion allows real-time tracking mode burning and over time empirically required amount of wood depending on the outside temperature.

Promptly remove sootSoot you need to uninstall not only when the chimney clogged and lost traction, but regularly. Carbon black not only impairs the draught of the chimney, but also serves as thermal insulation. It covers the inner wall of the heater and the heat exchanger, which reduces their heat. If it fails to remove the soot, then burning firewood can be reduced without a loss in heating capacity.

Obviously, but it's worth mentioning: the wood must be dry. Wet wood is bad erupted, fleeting and highlights in 2-2,5 times less heat than dry.

Remember toStack the wood carefully, so that they burn evenly and for a long time. Time to close the valve for air. The wood should be the minimum required combustion air quantity. Dense wood burn longer and leave more dolgelley coals. Use the wood of hard deciduous wood species: maple, walnut, birch, cherry, larch, beech, oak, sycamore, pear, Apple, Store firewood in the house for 2-3 days prior to their ignition and put in the furnace for an hour before ignition. Pre-heat the furnace using a small number of torches. If you have a fireplace or stove use hearth burning. Maintain optimal combustion mode. If the wood burns too much, then part of the heat flies up the chimney, and does not remain in the room. Change the volume load of logs depending on the outside temperature. Promptly remove soot. Soot is a thermal insulation and reduces heat transfer of the heating device and heat exchanger. The wood must be dry.

published

Source: term.od.ua/blog/9-sposobov-poluchit-bolshe-tepla-ot-drov/

Change the way of stacking wood

Usually the wood on fire: build a pyramid of logs, in the center put the paper pieces and set on fire. First flare up the chips, and eventually firewood. The disadvantage of this method is that you do not control the combustion. The wood is all light up at once and entirely, burn unevenly and quickly. When a part of the logs burn through, you will throw up new ones that will ignite and burn.

The burning time of firewood can be increased by changing the way they lay in the furnace. For example:

First lay the bottom row of firewood. Put the second row offset to the right or to the left by 5-10cm, to form a ledge. Put the third and following rows. At the edge of a ledge, place a paper or chips and burn them.

Laying on the example of fuel briquettes. Briquettes do not light up completely and burn evenly with the flame gradually moves from left to right. Laying the wood burns for a long time, and allocates a sufficient amount of heat.

Details:

- Don't stack firewood close to each other. Leave between them a small gap for air movement.

- The denser and drier the wood, the more evenly they are burning and easier to ignite.

Before ignition, open the choke heater on high, to provide good traction for kindling wood. When the wood will flare up start to gradually close the valve. If the wood will begin to fade – slightly open the valve and increase traction. Over time, you will select the optimum valve position. The drier and denser the wood, the less air required for their combustion.

Use a dense hardwoodAt the cellular level, wood is composed of a plurality of empty cells with walls of wood substance. The density of the wood substance (wall) all wood the same, but the size of the cells is different.

The smaller the cell size, the higher the density of wood and every square inch contains a lot of combustible wood material. And Vice versa: the larger the cells, the less the density of the wood. It contains a lot of air and little fuel wood substance.

Imagine that the circle is a 1 square inch of wood. In the first case the cells are small and the walls between them a lot. In the second case, the number of cells and walls less, and voids, which are air-filled – more. The density of this wood is low.

What conclusions can be made:

Less dense wood burn quickly. When burning firewood releases the air that feeds combustion. The more air, the wood burns faster and less evenly. Dense wood produce more heat, as per unit volume of fuel they contain more wood substance. Dense wood leave more coals that smolder long. Soft wood is worse keep their shape, to crumble into small embers and quickly extinguished. All the wood is divided into three categories of density: low, medium, high.

Density

Wood Small density of 0.15 – 0.55 g/cm3, Spruce, Willow, Aspen, Pine, Linden, Alder, Fir, poplar the Average density of 0.56 – 0.70 g/cm3 Maple, Walnut, Birch, cherry, Larch, Beech, Oak, sycamore, Pear, Apple High density of 0.75 – 1.08 g/cm3 Ash, Plum, Boxwood, Persimmon ebony, acacia firewood, Prepare in advance, Store the wood in a warm room for 2-3 days prior to ignition to increase their initial temperature.

Warmer than wood initially, however:

- They use less heat on your own warm-up and more on heating the room. You use heat more useful.

- Firewood faster achieve the best combustion mode, which increases their calorific value and reduces the amount of emitted soot. This is because part of the wood tar, creosote, tar, essential oils and other substances is not burned at a low temperature and deposited on the walls in the form of soot. While optimally the combustion temperature sufficient to burn completely and provide extra warmth.

Pre-heat the furnaceWhen the wood starts to burn in cold furnace, then:

- part of the heat you spend for heating the furnace and not space heating (as in the previous paragraph).

- they are harder to ignite, as the warm air overcomes the resistance of cold air in the chimney.

Use hearth burningThere are two ways of burning firewood: grate (bottom) and the bottom (top burning).

Lower combustion – traditional, when the air on the wood is coming from the bottom and the flame gradually moves up. At the upper combustion air to the wood served on top, the fire is lit at the top and gradually descends.

At the hearth burning at the bottom of the stacked large logs and put on top of the paper and the wood smaller.

Advantages:

Increases completeness of combustion of wood, due to which they produce more heat. You reduce the emission of volatile substances that pollute the chimney with soot. This is a more environmentally friendly method of combustion. How to do it

Hearth for burning firewood stacked pyramid: put down the big logs and the top is smaller. At the top, ignite chips and paper.

While burning wood chips and paper, furnace heated. The flame then begins to descend and set fire to the main wood. At this point, the combustion temperature and flame strength enough to begin to burn the volatile substances contained in the wood. Due to the completeness of combustion of wood produce more heat, and due to the uniform combustion long burning and economical.

Don't let the increased combustion of woodHas three modes of burning wood: low, high and optimum.

In degraded wood not burn completely and form a lot of soot. With increased reduces wood waste: the portion of the heat leaves through the chimney as the heat exchanger and the room did not have time to take it away completely. This occurs in two cases: you use too much wood or it can be served much air. You need to reduce the amount of laying or traction.

The best option when wood burns in an optimal mode: not weak and not strong. The easiest way to determine the mode of combustion is to use the indicator of combustion, which in real time show the current mode. If the flue gas temperature more than 320 degrees, the wood burning in elevated mode.

The indicator of combustion in real-time detects the temperature of the flue gases and the combustion mode

Change the volume of laying the wood on the outside temperaturethe warmer it is outside, the less the building is losing heat. Accordingly, it is need less wood for heating. If you put the same amount of wood at 0C or -10C, in the first case, consume more wood than necessary.

The indicator of combustion allows real-time tracking mode burning and over time empirically required amount of wood depending on the outside temperature.

Promptly remove sootSoot you need to uninstall not only when the chimney clogged and lost traction, but regularly. Carbon black not only impairs the draught of the chimney, but also serves as thermal insulation. It covers the inner wall of the heater and the heat exchanger, which reduces their heat. If it fails to remove the soot, then burning firewood can be reduced without a loss in heating capacity.

Obviously, but it's worth mentioning: the wood must be dry. Wet wood is bad erupted, fleeting and highlights in 2-2,5 times less heat than dry.

Remember toStack the wood carefully, so that they burn evenly and for a long time. Time to close the valve for air. The wood should be the minimum required combustion air quantity. Dense wood burn longer and leave more dolgelley coals. Use the wood of hard deciduous wood species: maple, walnut, birch, cherry, larch, beech, oak, sycamore, pear, Apple, Store firewood in the house for 2-3 days prior to their ignition and put in the furnace for an hour before ignition. Pre-heat the furnace using a small number of torches. If you have a fireplace or stove use hearth burning. Maintain optimal combustion mode. If the wood burns too much, then part of the heat flies up the chimney, and does not remain in the room. Change the volume load of logs depending on the outside temperature. Promptly remove soot. Soot is a thermal insulation and reduces heat transfer of the heating device and heat exchanger. The wood must be dry.

published

Source: term.od.ua/blog/9-sposobov-poluchit-bolshe-tepla-ot-drov/