640

Buttons in St. Petersburg.

Has anyone wondered where are the buttons?

I now know exactly !!! ))

30 pictures.

1. The proper material for buttons can serve as anything, plastic, metal, wood, rubber, glass ...

Our factory produces plastic fittings and nuts, actually pictured a regular Rondel (logs).

2. roundels is not difficult to guess various diameters, thicknesses, colors, composition, density, selection of some general

Only plastics is huge ...

3. The material does not always come roundel is often that we get the plate,

This miracle machine ... 19 years old shaggy cuts of plates rods of the required diameter.

4. Labuda also cuts roundels, but model year less hairy))

5. then (or immediately), these are rods fall on the turning station, where such devices here mechanically

(incisors, poligonali, drills, and so on) make buttons, for example, the machine is able to peel about 150-200

buttons per minute, but of course the speed greatly depends on the shape and size of the product.

6 is an older unit, but the appointment is also that of the previous one.

7. Another representative relic technology))

8. The general view of the turning section.

9. After shaping the product get to the grinding section, pictured barrel for sludge water.

10. General view of the polishing station.

11. The drum sander - essentially a concrete mixer, just inside the rubber, used for grinding

Ceramic stones are of different size,

as well as various additives usually obrazivnye.

12. This hrenovina need to wash / unloading of the drum, the pressure of the water washed out the buttons and collect in

drive.

13. If needed polishing buttons, then fill up here in "pieces of wood", inside it is not difficult to guess

of wood)) and polishing paste.

14. The inside.

15. themselves of wood))

16. The polishing of the product take out with the help of such a device, which napodobii vacuum sucks all that is,

and along the right weeds.

17. The washing and drying once, ordinary centrifuge, as in the old stiralka

18. A separator as buttons polished peremeshku this vibrating conveyor separates them by size

19. Further painting, everything is clear, hot water, the desired paint and soap as a catalyst

20. All this is all just))

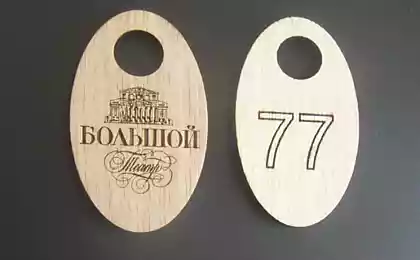

21. The area on which I actually work and laser station, then buttoned applied laser drawings and inscriptions,

if necessary, are burnt hole desired shape, pictured a regular 50-padded CO2.

22. This box is needed for burning laser buckles, in fact just the turntable.

23. extractor filter, for "exhaust pollutants.

24. next, but already 100 cotton laser, unfortunately only supports vector logos.

25. The refrigeration unit 100 of his jacket when running at full Power steering, all flying at the site))

26. My favorite, most expensive, but not the moschny, cotton 75 unit allows you to make a lot of any relevant

navrode trinkets pieces))) By the way the most "correct" laser with a normal software, support for over 30 file types,

lack of just one, does not understand the splines.

27. necessary for each software.

28. After marking all products pass through the caring hands pereborschits, or who have, at this crocodile selected marriage.

29. But the pride of the developers of the 21st century, this crap puts grommets in the hole buttons (such metallic insert), but unfortunately

without an operator does not work ...))

30. ultimately give the product presentation with the help of this ... here's how to call it, I do not know, actually inside the special sand,

which added a bit of chemistry, and after half an hour of shaking in a sand (semalin) button is already packaged, and sent to Clint.

Posted in [mergetime] 1307543647 [/ mergetime]

Actually I)))

Source:

I now know exactly !!! ))

30 pictures.

1. The proper material for buttons can serve as anything, plastic, metal, wood, rubber, glass ...

Our factory produces plastic fittings and nuts, actually pictured a regular Rondel (logs).

2. roundels is not difficult to guess various diameters, thicknesses, colors, composition, density, selection of some general

Only plastics is huge ...

3. The material does not always come roundel is often that we get the plate,

This miracle machine ... 19 years old shaggy cuts of plates rods of the required diameter.

4. Labuda also cuts roundels, but model year less hairy))

5. then (or immediately), these are rods fall on the turning station, where such devices here mechanically

(incisors, poligonali, drills, and so on) make buttons, for example, the machine is able to peel about 150-200

buttons per minute, but of course the speed greatly depends on the shape and size of the product.

6 is an older unit, but the appointment is also that of the previous one.

7. Another representative relic technology))

8. The general view of the turning section.

9. After shaping the product get to the grinding section, pictured barrel for sludge water.

10. General view of the polishing station.

11. The drum sander - essentially a concrete mixer, just inside the rubber, used for grinding

Ceramic stones are of different size,

as well as various additives usually obrazivnye.

12. This hrenovina need to wash / unloading of the drum, the pressure of the water washed out the buttons and collect in

drive.

13. If needed polishing buttons, then fill up here in "pieces of wood", inside it is not difficult to guess

of wood)) and polishing paste.

14. The inside.

15. themselves of wood))

16. The polishing of the product take out with the help of such a device, which napodobii vacuum sucks all that is,

and along the right weeds.

17. The washing and drying once, ordinary centrifuge, as in the old stiralka

18. A separator as buttons polished peremeshku this vibrating conveyor separates them by size

19. Further painting, everything is clear, hot water, the desired paint and soap as a catalyst

20. All this is all just))

21. The area on which I actually work and laser station, then buttoned applied laser drawings and inscriptions,

if necessary, are burnt hole desired shape, pictured a regular 50-padded CO2.

22. This box is needed for burning laser buckles, in fact just the turntable.

23. extractor filter, for "exhaust pollutants.

24. next, but already 100 cotton laser, unfortunately only supports vector logos.

25. The refrigeration unit 100 of his jacket when running at full Power steering, all flying at the site))

26. My favorite, most expensive, but not the moschny, cotton 75 unit allows you to make a lot of any relevant

navrode trinkets pieces))) By the way the most "correct" laser with a normal software, support for over 30 file types,

lack of just one, does not understand the splines.

27. necessary for each software.

28. After marking all products pass through the caring hands pereborschits, or who have, at this crocodile selected marriage.

29. But the pride of the developers of the 21st century, this crap puts grommets in the hole buttons (such metallic insert), but unfortunately

without an operator does not work ...))

30. ultimately give the product presentation with the help of this ... here's how to call it, I do not know, actually inside the special sand,

which added a bit of chemistry, and after half an hour of shaking in a sand (semalin) button is already packaged, and sent to Clint.

Posted in [mergetime] 1307543647 [/ mergetime]

Actually I)))

Source: