1076

Since chocolate is made. Russia - a generous soul!

Photos lot. Finish will tell.

Sweet tooth and more ... Excursion to the factory "Russia»

Eating chocolate and walked through the factory Vladimir Sverkalov

So go.

Factory "Russia" was built in 1970, designed by the Italian company "Carlo Montanari." In 1995 he began a collaboration with the Swiss company Nestle. Currently, the product range includes dozens of names of Russian chocolate.

All chocolate products company Nestle produced in Russia is produced here in the factory in Samara. It is a lot of chocolate bars, candy bars Nuts, hot chocolate and Nestle cocoa Nesquik.

3. The factory is a symbol of the dome.

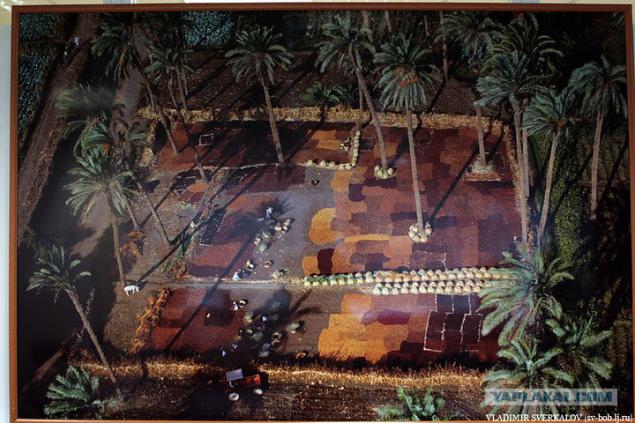

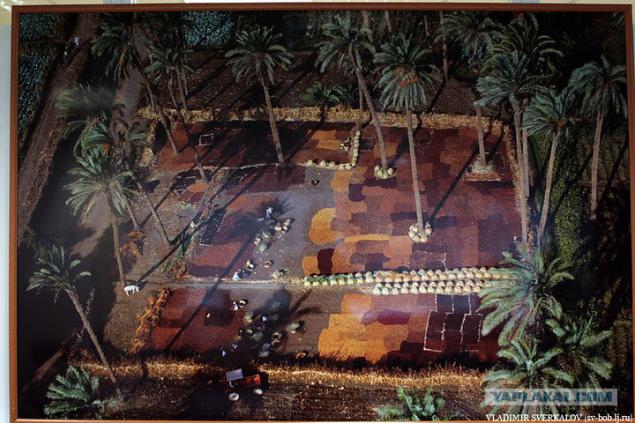

4. In favorable conditions evergreen cocoa tree blooms and bears fruit all year round throughout the year. The first flowers appear on the tree at the age of 5-6 years. Fruits are formed within 30-80 years. Ripening, yellow-green or red, depending on the variety, the fruit up to 30 cm in length and weight up to 500 grams. In the pulp of the fruit contains up to 50 cocoa beans. High yields of the tree gives, starting from 12 years of life. Harvested twice a year, for the first time at the end of

5. Somehow it looks like a plantation where they grow cocoa beans.

6. I tasted dozens of different candies

7. Ekaterina Burtsev, Manager of Corporate Affairs branch of LLC "Nestle Russia" in Samara, told about the factory and Nestlé.

8. Then we were instructed on safety in the factory. I must say that it pays great attention to this, and I've been to more hazardous occupations, not to mention nuclear power, and no one had not asked to sign a log teh.bezopasnosti.

9. Actually something similar I expect to see

10. All staff should be required to wash their hands thoroughly. Also, each employee receives a bathrobe, ear plugs, cap and shoes with metal toes.

12. Go up to the third floor, where the crushing process cocoa beans. Note grating on the stairs, another reminder of safety.

13. Inside is very noisy, so Catherine tells us the main points that need to be addressed. Also look at the abundance of various tablets and inscriptions. They are very much in the enterprise.

14. Forgot to tell the factory not wear jewelry, except for smooth engagement rings, as women may not use nail polish and artificial nails, in general, everything that could break away.

15. roasted cocoa beans.

16. Crusher - output of cocoa nibs

17. From the cocoa nibs obtained cocoa liquor, which is fed to the press, which squeezed turns cocoa butter.

18. This bars of 20kg, in the grinding of the cocoa powder.

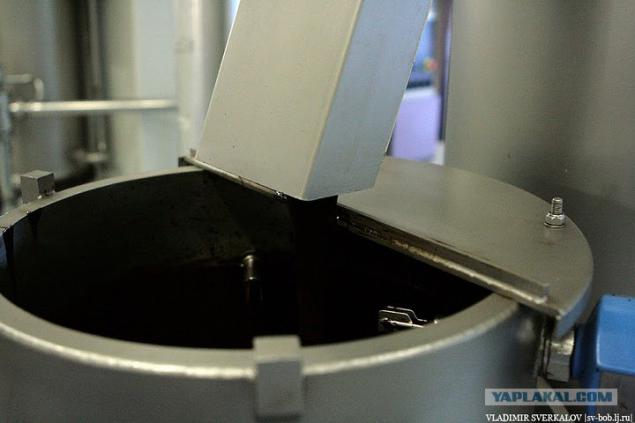

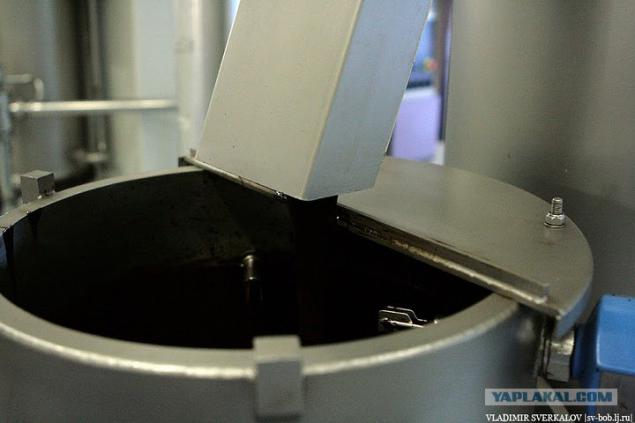

19. Storage cocoa liquor

20. Poor seen, but it runs the most cocoa liquor.

21. Cocoa beans - cocoa nibs - cocoa liquor - cocoa butter - cocoa powder. Total cocoa beans are ground cocoa nibs, used to make chocolate liquor. From cocoa liquor squeeze cocoa butter and cocoa powder is a waste.

Milk chocolate is made on the basis of cocoa butter, cocoa powder, sugar and powdered milk.

White chocolate does not contain cocoa powder.

Black does not contain dry-milk.

22

23

24. Mix all the ingredients of chocolate.

25. In other words, very cool equipment.

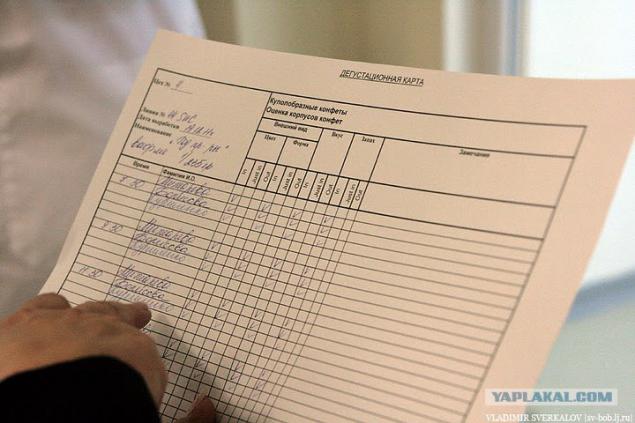

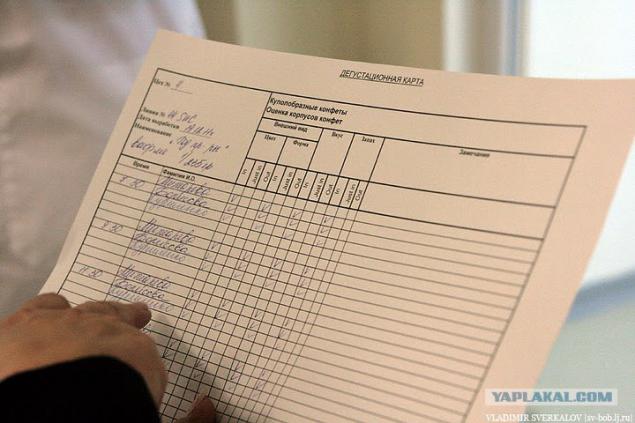

The coolest position in the factory - a taster! Yes, there are!

Each batch of the product tasted and checked by a team of taste, smell and appearance.

Then go to the line for the production of cocoa Nesquik, more precisely is going on packaging, as production is quite simple and consists in mixing of cocoa powder, sugar and powdered milk.

Wrapping.

Packing. This and other pallets to the largest sorting warehouse for Kinel, from chocolate to "scatter" around the country.

In the next room making hot chocolate

We are approaching the production of chocolates.

Forms for the production of tiles

Candy, "Variety»

...

40. Komilfo

...

...

But the tiles themselves. Everything is simple, chocolate is poured into molds, cooled and knocked out of the molds.

It is a large closet with chocolate, because Production is faster packaging, excess tiles are stored in the cabinet. There are a lot of pallets that are in constant motion.

With pallets of tiles are on the packaging.

...

On the last and most delicious.

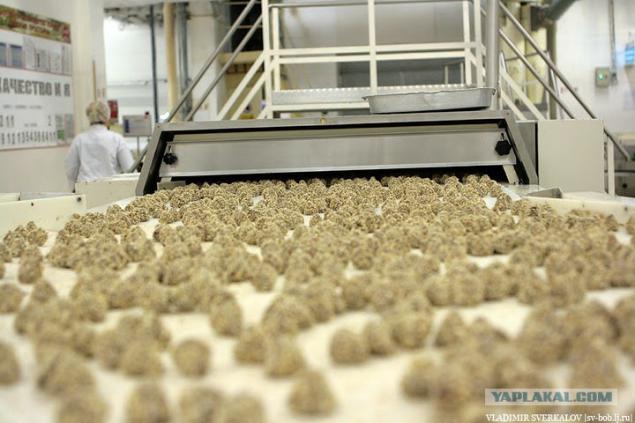

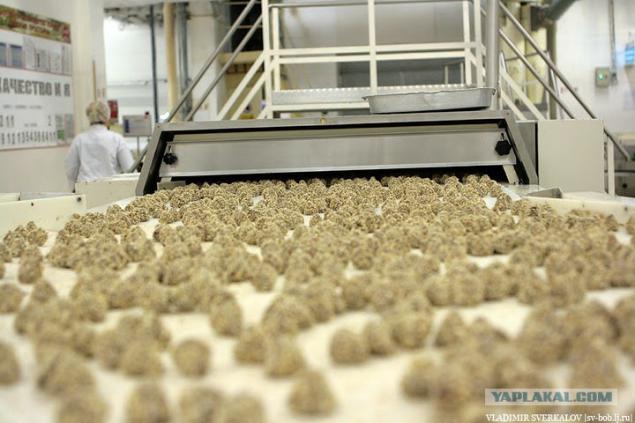

Praline make cones.

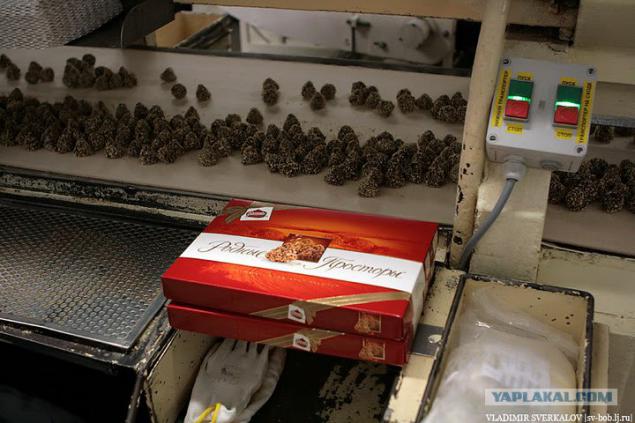

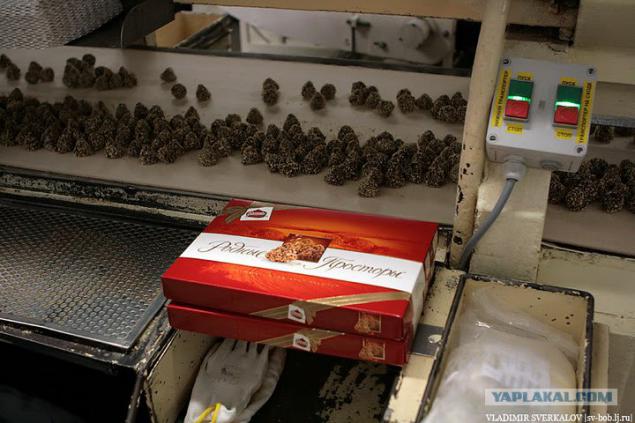

Watering chocolate

...

...

Cool

Once again, pour chocolate

And sprinkled with wafer crumb.

River from their scope.

Further fed to the packaging candy. We arrived at lunchtime, so did not find the packer.

...

After the tour, the director of the branch of "Nestle Russia" in Samara James Geddes answered our questions and told me that he loves "Very milk" chocolate.

Source:

Sweet tooth and more ... Excursion to the factory "Russia»

Eating chocolate and walked through the factory Vladimir Sverkalov

So go.

Factory "Russia" was built in 1970, designed by the Italian company "Carlo Montanari." In 1995 he began a collaboration with the Swiss company Nestle. Currently, the product range includes dozens of names of Russian chocolate.

All chocolate products company Nestle produced in Russia is produced here in the factory in Samara. It is a lot of chocolate bars, candy bars Nuts, hot chocolate and Nestle cocoa Nesquik.

3. The factory is a symbol of the dome.

4. In favorable conditions evergreen cocoa tree blooms and bears fruit all year round throughout the year. The first flowers appear on the tree at the age of 5-6 years. Fruits are formed within 30-80 years. Ripening, yellow-green or red, depending on the variety, the fruit up to 30 cm in length and weight up to 500 grams. In the pulp of the fruit contains up to 50 cocoa beans. High yields of the tree gives, starting from 12 years of life. Harvested twice a year, for the first time at the end of

5. Somehow it looks like a plantation where they grow cocoa beans.

6. I tasted dozens of different candies

7. Ekaterina Burtsev, Manager of Corporate Affairs branch of LLC "Nestle Russia" in Samara, told about the factory and Nestlé.

8. Then we were instructed on safety in the factory. I must say that it pays great attention to this, and I've been to more hazardous occupations, not to mention nuclear power, and no one had not asked to sign a log teh.bezopasnosti.

9. Actually something similar I expect to see

10. All staff should be required to wash their hands thoroughly. Also, each employee receives a bathrobe, ear plugs, cap and shoes with metal toes.

12. Go up to the third floor, where the crushing process cocoa beans. Note grating on the stairs, another reminder of safety.

13. Inside is very noisy, so Catherine tells us the main points that need to be addressed. Also look at the abundance of various tablets and inscriptions. They are very much in the enterprise.

14. Forgot to tell the factory not wear jewelry, except for smooth engagement rings, as women may not use nail polish and artificial nails, in general, everything that could break away.

15. roasted cocoa beans.

16. Crusher - output of cocoa nibs

17. From the cocoa nibs obtained cocoa liquor, which is fed to the press, which squeezed turns cocoa butter.

18. This bars of 20kg, in the grinding of the cocoa powder.

19. Storage cocoa liquor

20. Poor seen, but it runs the most cocoa liquor.

21. Cocoa beans - cocoa nibs - cocoa liquor - cocoa butter - cocoa powder. Total cocoa beans are ground cocoa nibs, used to make chocolate liquor. From cocoa liquor squeeze cocoa butter and cocoa powder is a waste.

Milk chocolate is made on the basis of cocoa butter, cocoa powder, sugar and powdered milk.

White chocolate does not contain cocoa powder.

Black does not contain dry-milk.

22

23

24. Mix all the ingredients of chocolate.

25. In other words, very cool equipment.

The coolest position in the factory - a taster! Yes, there are!

Each batch of the product tasted and checked by a team of taste, smell and appearance.

Then go to the line for the production of cocoa Nesquik, more precisely is going on packaging, as production is quite simple and consists in mixing of cocoa powder, sugar and powdered milk.

Wrapping.

Packing. This and other pallets to the largest sorting warehouse for Kinel, from chocolate to "scatter" around the country.

In the next room making hot chocolate

We are approaching the production of chocolates.

Forms for the production of tiles

Candy, "Variety»

...

40. Komilfo

...

...

But the tiles themselves. Everything is simple, chocolate is poured into molds, cooled and knocked out of the molds.

It is a large closet with chocolate, because Production is faster packaging, excess tiles are stored in the cabinet. There are a lot of pallets that are in constant motion.

With pallets of tiles are on the packaging.

...

On the last and most delicious.

Praline make cones.

Watering chocolate

...

...

Cool

Once again, pour chocolate

And sprinkled with wafer crumb.

River from their scope.

Further fed to the packaging candy. We arrived at lunchtime, so did not find the packer.

...

After the tour, the director of the branch of "Nestle Russia" in Samara James Geddes answered our questions and told me that he loves "Very milk" chocolate.

Source: