705

Five men and four robot

It so happened that recently I got a second job. Money is not the last three months of study was not enough and I even wanted to leave the school, but the director said - why do you need, then pay, then, in fact, suggested that this second job. The place was a small factory, or rather even say a workshop producing a variety of small plastic stamping - housing units, buttons, switches ...

23 photos via ralphmirebs

1. The factory building is located in a residential area and is surrounded by the usual Japanese private houses, and inside there are four automatic press machine is cast plastic parts.

2. From the staff, in addition to me, it was as the same four people - two Japanese women directors and Chinese.

3.

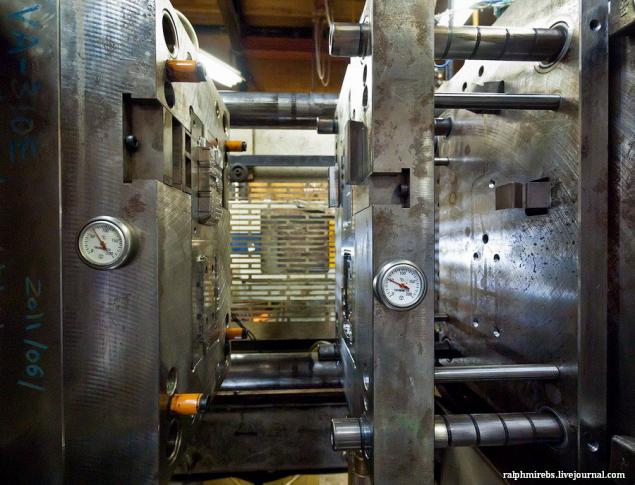

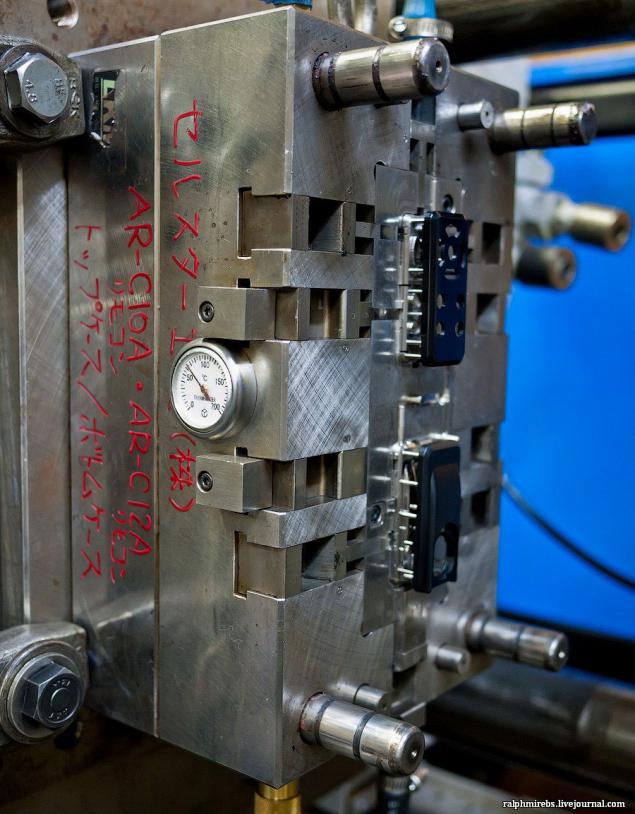

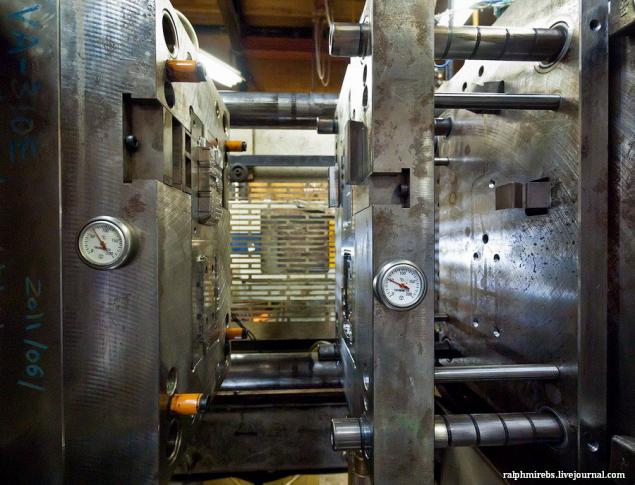

4. When an order for the production of a particular detail in the machine is loaded metal mold. Automatic, like a vacuum cleaner, tighten plastic pellets out of the bag, which comes in the warming unit. There pellets are heated up to 98 degrees, melted, hot mass portions enters the mold, whereby the finished products are produced.

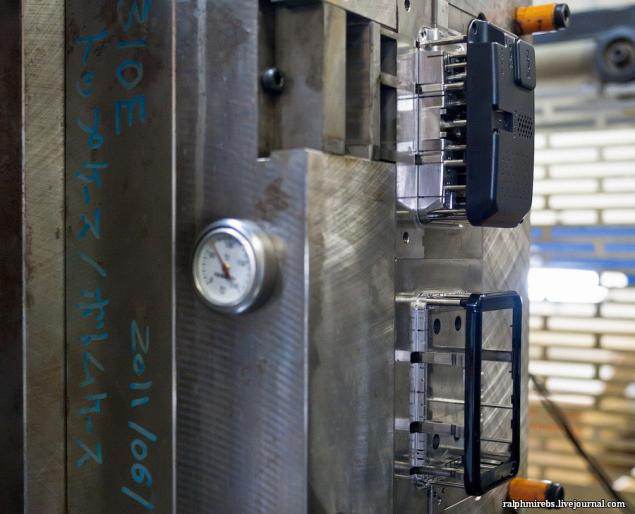

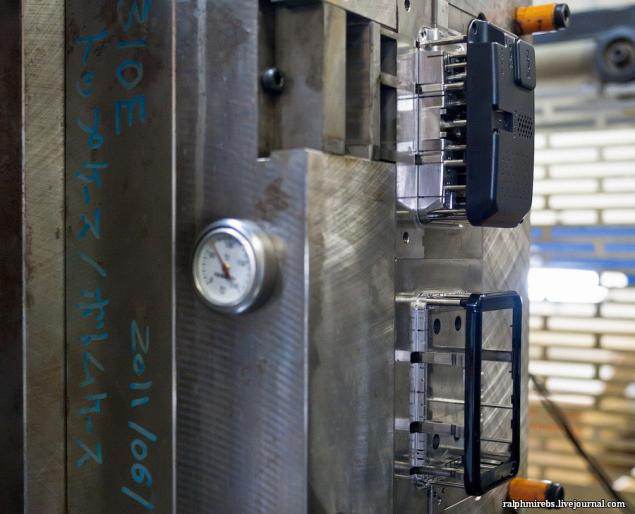

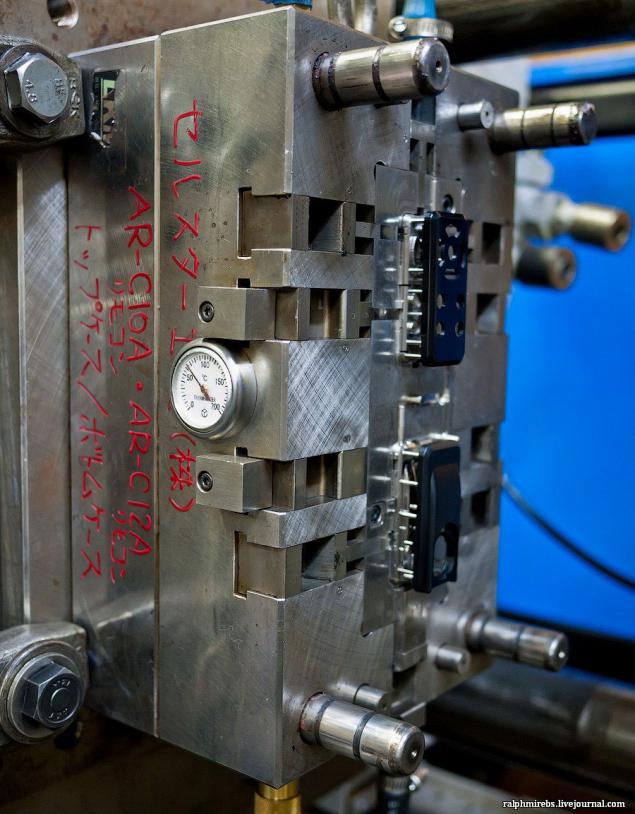

5. On the photo is visible mold with both finished products and without them. At the last stage of the form put forward the "needle" kicking moldings. Thermometers magnets show the temperature, the details are born heated to about 60-degrees, therefore we work gloves.

6.

7.

8.

9.

10. All the machines can operate in two modes - fully automatic or semi-automatic. In automatic mode, manufactured parts fall into a box, the gate is removed robotic arm, falls on the conveyor belt goes into the shredder and then punching operation is repeated.

11

12. In the semi-automatic version, the product extracted from the machine manually and the method is used when you need to protect moldings from scratches. Requirements on the appearance we have enough hard - if the item for any reason, falls to the floor, despite the appearance (ie, the presence or absence of scratches), immediately rejected and destroyed.

13

14

15. Thus, my job is that removing the finished parts, run the machine for the next cycle of punching, folding finished parts in boxes and service equipment - lubrication, cleaning. Perhaps someone such work may seem monotonous, but it is not so. First of all, I love technology and tinker with it, it gives me joy. In the second place, it is, I define the speed of the machine and I do not have to keep up with him. And, thirdly, at work and on the breaks you can chat with colleagues in all sorts of matters. For example, working next to me turned out to be a Japanese photographer with experience who prefer medium format, and even having a couple of Soviet cameras.

16. I also really like that gave a beautiful and easy-to-form. Generally, there is in this work something romantic for in Russia, I would be unlikely to ever become to get a similar plant, and knew about them (and such work for the machine) mainly of Soviet films about the workers.

17. Now we carry a large order for the production of car GPS-navigator - housing, buttons, battery cover. Here are some examples of finished products.

18.

19

20

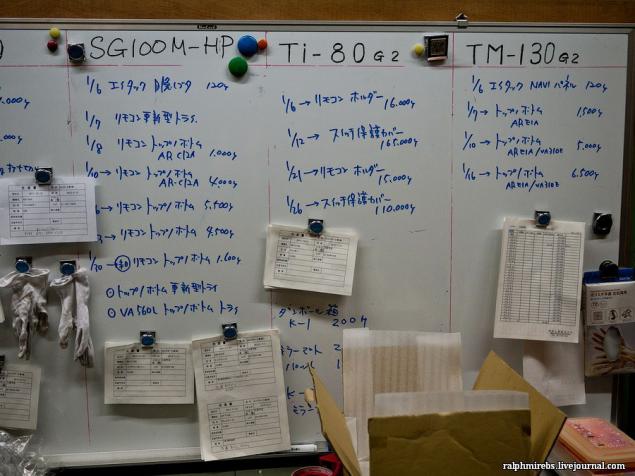

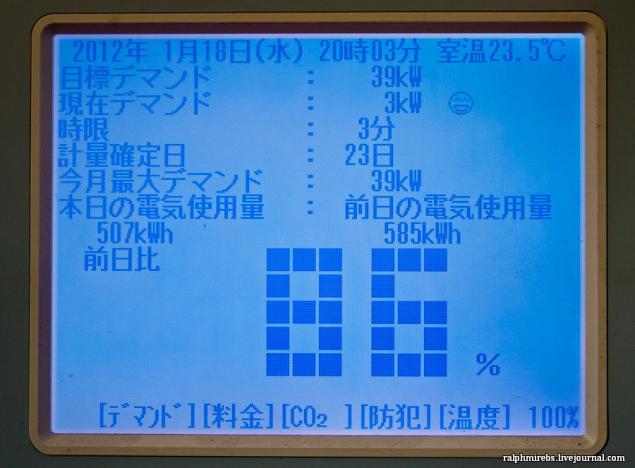

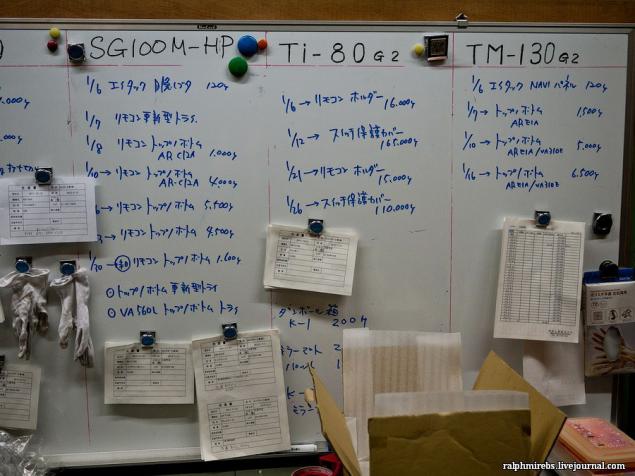

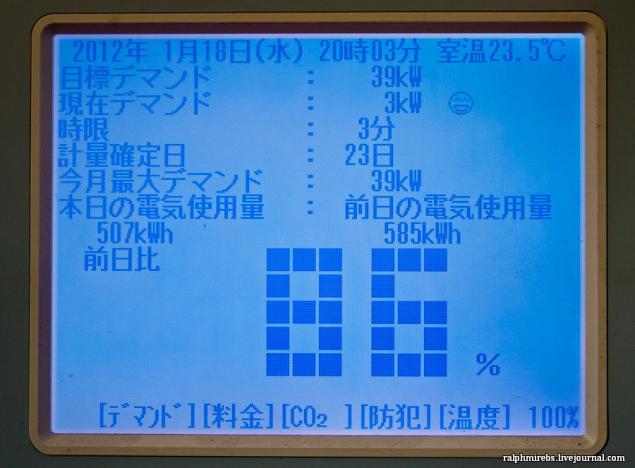

21. Here warehouse molds, stand with the description of current work and daily power consumption - a day to 585 kilowatts.

22

23. So now I'm coming home after school, have a snack and food immediately to the factory where I work from 3 to 6 hours. After that, go back, change clothes and run on a second job in ramen.

Source:

23 photos via ralphmirebs

1. The factory building is located in a residential area and is surrounded by the usual Japanese private houses, and inside there are four automatic press machine is cast plastic parts.

2. From the staff, in addition to me, it was as the same four people - two Japanese women directors and Chinese.

3.

4. When an order for the production of a particular detail in the machine is loaded metal mold. Automatic, like a vacuum cleaner, tighten plastic pellets out of the bag, which comes in the warming unit. There pellets are heated up to 98 degrees, melted, hot mass portions enters the mold, whereby the finished products are produced.

5. On the photo is visible mold with both finished products and without them. At the last stage of the form put forward the "needle" kicking moldings. Thermometers magnets show the temperature, the details are born heated to about 60-degrees, therefore we work gloves.

6.

7.

8.

9.

10. All the machines can operate in two modes - fully automatic or semi-automatic. In automatic mode, manufactured parts fall into a box, the gate is removed robotic arm, falls on the conveyor belt goes into the shredder and then punching operation is repeated.

11

12. In the semi-automatic version, the product extracted from the machine manually and the method is used when you need to protect moldings from scratches. Requirements on the appearance we have enough hard - if the item for any reason, falls to the floor, despite the appearance (ie, the presence or absence of scratches), immediately rejected and destroyed.

13

14

15. Thus, my job is that removing the finished parts, run the machine for the next cycle of punching, folding finished parts in boxes and service equipment - lubrication, cleaning. Perhaps someone such work may seem monotonous, but it is not so. First of all, I love technology and tinker with it, it gives me joy. In the second place, it is, I define the speed of the machine and I do not have to keep up with him. And, thirdly, at work and on the breaks you can chat with colleagues in all sorts of matters. For example, working next to me turned out to be a Japanese photographer with experience who prefer medium format, and even having a couple of Soviet cameras.

16. I also really like that gave a beautiful and easy-to-form. Generally, there is in this work something romantic for in Russia, I would be unlikely to ever become to get a similar plant, and knew about them (and such work for the machine) mainly of Soviet films about the workers.

17. Now we carry a large order for the production of car GPS-navigator - housing, buttons, battery cover. Here are some examples of finished products.

18.

19

20

21. Here warehouse molds, stand with the description of current work and daily power consumption - a day to 585 kilowatts.

22

23. So now I'm coming home after school, have a snack and food immediately to the factory where I work from 3 to 6 hours. After that, go back, change clothes and run on a second job in ramen.

Source: