949

How to make bread in Russia

1.

It is said that people close to the wrong side of a production for the product are cool: sausage makers do not like sausage, staff restaurants prefer to eat at home. To learn how to make bread in Russia, we visited the "Baker" - the largest producer of corn in the Smolensk region. It was founded in 1933, and its production has increased three generations of townspeople. Today the plant is included in the agricultural holding "Stoylenskaya Niva».

Photo report consists of 10 photographs.

The original text.

Original photo essay.

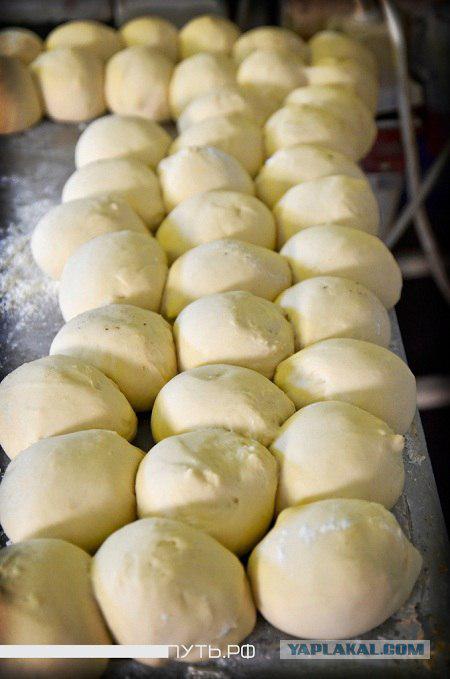

2.

This is a modest-looking building is feeding bread almost the entire Smolensk. If all issued here over the years drying glue in a single chain, you get a garland can be three times girdle the planet's equator. And this is just drying.

3.

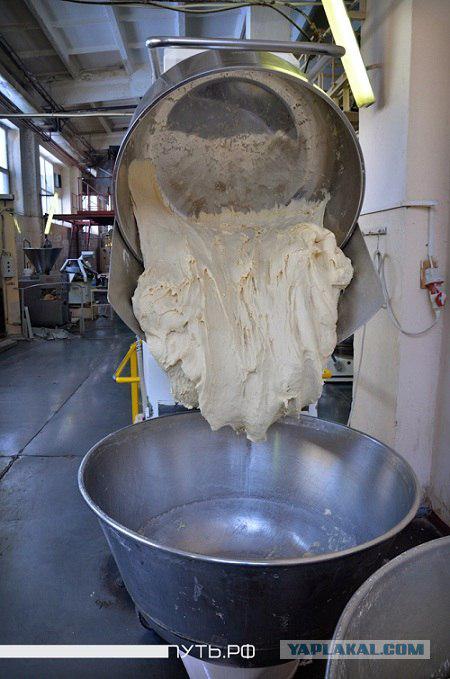

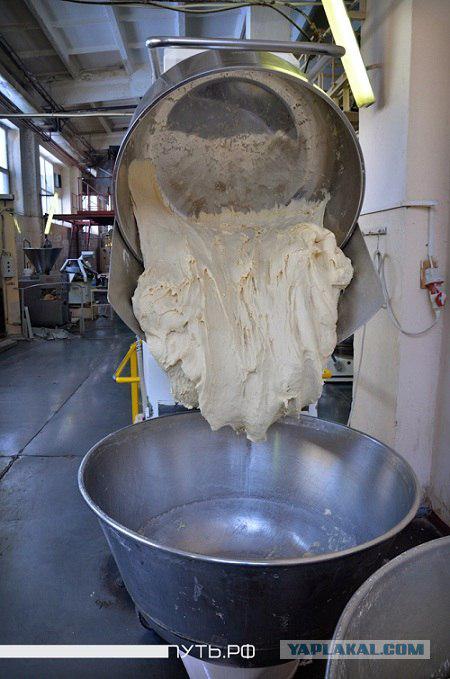

In total, "Hlepopeke" produced as many as 52 kinds of bakery products. The dough is mixed here in such huge vats. Once it reaches the desired consistency, it is loaded into the machine, which are cut white mass into billets of appropriate size.

4.

In the first decades of his work, "Baker" is not a high level of technology: the bread in the oven planted by hand shovel with a long handle, and in the shops was wet heat as in the jungle. The bread was mainly rye. Now everything is different: the work carried out in the spacious ventilated rooms, and a large part of the machines operate.

5.

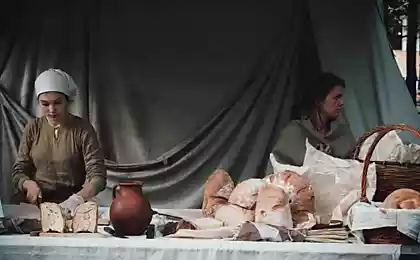

Still, not all the machines are able to. Paradox: the production of bread lends itself to mechanization worse than, for example, the production of electronics. Computer motherboard immeasurably harder bagel, but it makes automatic, but may take the form of a bagel only human hands.

6.

When the plant operates a laboratory, where specialists are engaged in improving the composition of bread, and his invention of new varieties. But the new is often a well-forgotten old: those favorite childhood products like black "Borodino", white bread, Easter cakes, made according to traditional recipes, which are more than 50 years.

7.

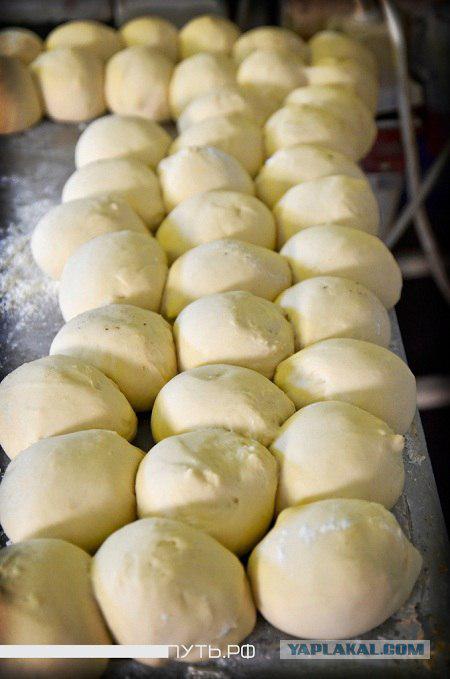

Future loaves are ready to attend the stove. The daily output of the plant is 109 tons. A baked bread for a month will be enough to feed the inhabitants of the whole week rather big French city of Toulouse.

8.

In addition to the bread factory and produce packaging for bakery products: set the line outputs of 45 plastic bags per minute. The size varies depending on the particular product.

9.

In 2011, "baker" was launched nearly 20 new products. Some of them, the company has positioned as indispensable attributes of celebrations: the employees of the plant argue that the wedding in a rare complete without "Russian Karavai." However, walking around the factory, I have not found where it is made.

10.

Bakers have done everything that depended on them. The case for logistics. The company has its own convoy of 50 new machines, which delivers bread every day on 80 routes. In all, "Baker '900 customers - mostly in the Smolensk region.

Source:

It is said that people close to the wrong side of a production for the product are cool: sausage makers do not like sausage, staff restaurants prefer to eat at home. To learn how to make bread in Russia, we visited the "Baker" - the largest producer of corn in the Smolensk region. It was founded in 1933, and its production has increased three generations of townspeople. Today the plant is included in the agricultural holding "Stoylenskaya Niva».

Photo report consists of 10 photographs.

The original text.

Original photo essay.

2.

This is a modest-looking building is feeding bread almost the entire Smolensk. If all issued here over the years drying glue in a single chain, you get a garland can be three times girdle the planet's equator. And this is just drying.

3.

In total, "Hlepopeke" produced as many as 52 kinds of bakery products. The dough is mixed here in such huge vats. Once it reaches the desired consistency, it is loaded into the machine, which are cut white mass into billets of appropriate size.

4.

In the first decades of his work, "Baker" is not a high level of technology: the bread in the oven planted by hand shovel with a long handle, and in the shops was wet heat as in the jungle. The bread was mainly rye. Now everything is different: the work carried out in the spacious ventilated rooms, and a large part of the machines operate.

5.

Still, not all the machines are able to. Paradox: the production of bread lends itself to mechanization worse than, for example, the production of electronics. Computer motherboard immeasurably harder bagel, but it makes automatic, but may take the form of a bagel only human hands.

6.

When the plant operates a laboratory, where specialists are engaged in improving the composition of bread, and his invention of new varieties. But the new is often a well-forgotten old: those favorite childhood products like black "Borodino", white bread, Easter cakes, made according to traditional recipes, which are more than 50 years.

7.

Future loaves are ready to attend the stove. The daily output of the plant is 109 tons. A baked bread for a month will be enough to feed the inhabitants of the whole week rather big French city of Toulouse.

8.

In addition to the bread factory and produce packaging for bakery products: set the line outputs of 45 plastic bags per minute. The size varies depending on the particular product.

9.

In 2011, "baker" was launched nearly 20 new products. Some of them, the company has positioned as indispensable attributes of celebrations: the employees of the plant argue that the wedding in a rare complete without "Russian Karavai." However, walking around the factory, I have not found where it is made.

10.

Bakers have done everything that depended on them. The case for logistics. The company has its own convoy of 50 new machines, which delivers bread every day on 80 routes. In all, "Baker '900 customers - mostly in the Smolensk region.

Source: