866

How do cigars in Russia

Did you know that half a century ago, the Russian Empire was one of the leading powers in Europe cigar? Then produces 150-200 million cigars a year, is the amount of cigar production in Cuba. Cigars are exported to Europe and valued for taste and quality.

Many will be news, but cigars are produced in Russia now. Pogarskaya cigarette-cigar factory will soon celebrate its centenary and is currently the only company in our country, producing cigars.

We have a rare chance to see the inside of a factory.

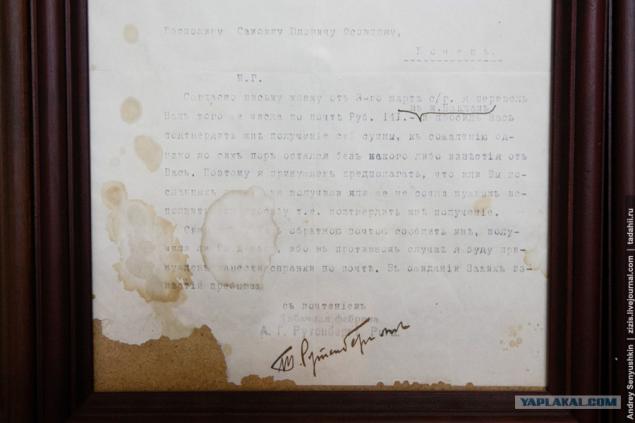

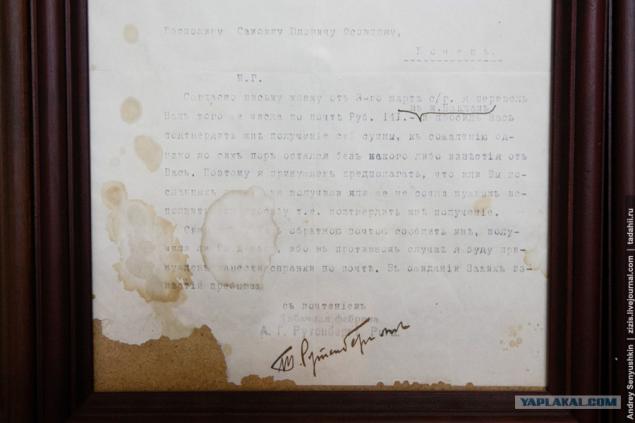

The factory was built early last century as a branch of the Riga «Koffsky & Kunchczynski» Alexander von Rutenberg. The occasion was the opening for not wanting to expand production, but the beginning of the First World War. To hedge the business, part of the production was moved away from the front lines.

Today, looking at the Bryansk region, it is difficult to imagine that a hundred years ago on this earth marquee excellent way to grow tobacco. Dozens, even hundreds of acres of tobacco fields cover the gauze. Under it created a microclimate necessary for the aging first-class tobacco with an elastic sheet and a thin vein.

In the year of going about two million pounds (320 tonnes) of first-class tobacco. Some processed in factories in Pohar and Riga, but the bulk was exported, the famous tobacco fair in Bremen.

Shortly after the opening of the factory there was a great October and the company, along with farmland passed into the control of the labor class. Tobacco is immediately stopped growing, there were shortages of raw materials and factory nearly stood up.

Let's look at the process of production, and the story I will tell later. Let's start with the most simple and inexpensive: with cigarettes and cigarettes. Here the tobacco fed to the conveyor. He rastrushivaetsya (bagged and baled tobacco comes slightly compressed), mixed, chopped and fed into a special drum.

It resembles a horizontal rotary kiln for manufacturing cement, only smaller, and another. There tobacco is dried, cut, moistened, flavored and further stirred.

Modern equipment, but there are a lot of "dinosaurs".

That such a ready stream of tobacco fed to the loading and shipping in the shop. Of course, we can not look inside the drum, although I'm sure there are a lot of interesting things.

The factory produces almost all types of tobacco products. None except that chewing tobacco and snuff. "White Sea" and "Accept" then began to produce after the Great Patriotic War. The demand is there and release them so far, one "impurity" more than a dozen species.

Let's start with something simpler. The structure of cigarettes knows probably everyone. The sleeve of thick paper to approximately 2/3 of the length, the top tissue paper, 1/3 of the tobacco.

The photo is refilling paper liners. In the same car comes rolling paper and tobacco.

The output is finished cigarette. You know how tobacco is inside? I'm sure you know, but I recall. A certain amount of tobacco fed into the machine in a cylinder, the cylinder is inserted into the preform and simultaneously a cigarette with recovery of the cylinder is extruded tobacco. The concept is simple. One minute this way about a hundred stuffed cigarettes.

Next uncomplicated packaging and ready, a pack can be guided in Karelia.

With "Prima" is still easier, there sleeve is not necessary, we'll skip the line. Let's look at the production of filter cigarettes.

And watch something and nothing special. A huge machine for production, and a couple of packaging. By air tube of tobacco is fed into the machine, there is dressed with paper and filters. A ready output cigarettes.

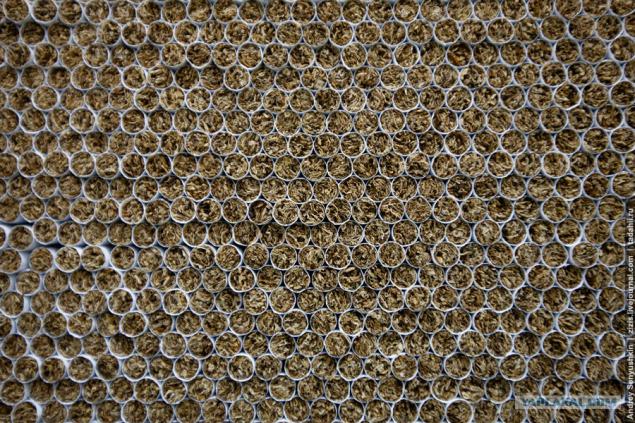

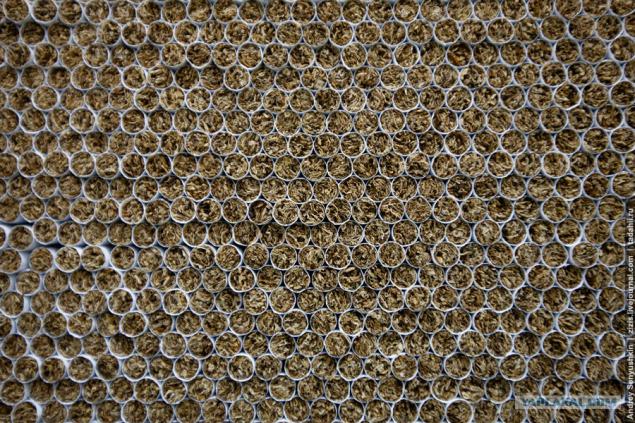

A lot of cigarettes. They are placed in special boxes, trays and transported to the next machine.

On this machine, rejection occurs in packs and packaging.

The second photo

The viewing window for rejection. Workers in the course of determining the defective cigarette and withdraw it from the total flow. When I pulled this one. How to distinguish them in a continuous stream, for me it remains a mystery.

The standard 20-ty cigarettes are wrapped with foil, cardboard or paper packaging and cellophane. Done!

The second photo

I tried to find out the percentage of smokers in the workplace. It turned out that no such statistics are not kept, although it is recognized that the likely percentage above the national average. Maybe the point is that, as in any production you can not make the products, but to use it on the premises is not prohibited. It is clear that this applies only to cigarettes and cigarettes.

Despite this, some prefer the products of competitors. The taste and color ...

And we come to the fun part: to pipe tobacco and cigars. In the photo a different tobacco from Cigarette cut to almost black Cavendish. In fact, tobacco types of course much greater than four.

Now the production is completely tied to imported raw materials, even paper bought overseas. Tobacco shop or from reliable partners, either on the same tobacco fair in Bremen. Tobacco is purchased from, perhaps, of all countries, its manufacturing.

Past large chests for aging pipe tobacco, we go down to the cellars.

In addition to the existing air-raid shelters for the seven seals there is a room for aging cigars. It looks more like a warehouse, so stop on it we will not.

Source:

Many will be news, but cigars are produced in Russia now. Pogarskaya cigarette-cigar factory will soon celebrate its centenary and is currently the only company in our country, producing cigars.

We have a rare chance to see the inside of a factory.

The factory was built early last century as a branch of the Riga «Koffsky & Kunchczynski» Alexander von Rutenberg. The occasion was the opening for not wanting to expand production, but the beginning of the First World War. To hedge the business, part of the production was moved away from the front lines.

Today, looking at the Bryansk region, it is difficult to imagine that a hundred years ago on this earth marquee excellent way to grow tobacco. Dozens, even hundreds of acres of tobacco fields cover the gauze. Under it created a microclimate necessary for the aging first-class tobacco with an elastic sheet and a thin vein.

In the year of going about two million pounds (320 tonnes) of first-class tobacco. Some processed in factories in Pohar and Riga, but the bulk was exported, the famous tobacco fair in Bremen.

Shortly after the opening of the factory there was a great October and the company, along with farmland passed into the control of the labor class. Tobacco is immediately stopped growing, there were shortages of raw materials and factory nearly stood up.

Let's look at the process of production, and the story I will tell later. Let's start with the most simple and inexpensive: with cigarettes and cigarettes. Here the tobacco fed to the conveyor. He rastrushivaetsya (bagged and baled tobacco comes slightly compressed), mixed, chopped and fed into a special drum.

It resembles a horizontal rotary kiln for manufacturing cement, only smaller, and another. There tobacco is dried, cut, moistened, flavored and further stirred.

Modern equipment, but there are a lot of "dinosaurs".

That such a ready stream of tobacco fed to the loading and shipping in the shop. Of course, we can not look inside the drum, although I'm sure there are a lot of interesting things.

The factory produces almost all types of tobacco products. None except that chewing tobacco and snuff. "White Sea" and "Accept" then began to produce after the Great Patriotic War. The demand is there and release them so far, one "impurity" more than a dozen species.

Let's start with something simpler. The structure of cigarettes knows probably everyone. The sleeve of thick paper to approximately 2/3 of the length, the top tissue paper, 1/3 of the tobacco.

The photo is refilling paper liners. In the same car comes rolling paper and tobacco.

The output is finished cigarette. You know how tobacco is inside? I'm sure you know, but I recall. A certain amount of tobacco fed into the machine in a cylinder, the cylinder is inserted into the preform and simultaneously a cigarette with recovery of the cylinder is extruded tobacco. The concept is simple. One minute this way about a hundred stuffed cigarettes.

Next uncomplicated packaging and ready, a pack can be guided in Karelia.

With "Prima" is still easier, there sleeve is not necessary, we'll skip the line. Let's look at the production of filter cigarettes.

And watch something and nothing special. A huge machine for production, and a couple of packaging. By air tube of tobacco is fed into the machine, there is dressed with paper and filters. A ready output cigarettes.

A lot of cigarettes. They are placed in special boxes, trays and transported to the next machine.

On this machine, rejection occurs in packs and packaging.

The second photo

The viewing window for rejection. Workers in the course of determining the defective cigarette and withdraw it from the total flow. When I pulled this one. How to distinguish them in a continuous stream, for me it remains a mystery.

The standard 20-ty cigarettes are wrapped with foil, cardboard or paper packaging and cellophane. Done!

The second photo

I tried to find out the percentage of smokers in the workplace. It turned out that no such statistics are not kept, although it is recognized that the likely percentage above the national average. Maybe the point is that, as in any production you can not make the products, but to use it on the premises is not prohibited. It is clear that this applies only to cigarettes and cigarettes.

Despite this, some prefer the products of competitors. The taste and color ...

And we come to the fun part: to pipe tobacco and cigars. In the photo a different tobacco from Cigarette cut to almost black Cavendish. In fact, tobacco types of course much greater than four.

Now the production is completely tied to imported raw materials, even paper bought overseas. Tobacco shop or from reliable partners, either on the same tobacco fair in Bremen. Tobacco is purchased from, perhaps, of all countries, its manufacturing.

Past large chests for aging pipe tobacco, we go down to the cellars.

In addition to the existing air-raid shelters for the seven seals there is a room for aging cigars. It looks more like a warehouse, so stop on it we will not.

Source: