657

Nonalcoholic beer

Recently there was a tour of the brewery Baltika. It was always interesting to understand how to prepare non-alcoholic beer (beer and if at all), which many myths and conversations. Here it was possible to learn about the brewery itself and my best ...

Will 22 photo + not many letters

Plant entrance. The territory covers 30 hectares, it is almost the size of the Vatican (44 hectares):

1

It should be noted that non-alcoholic beer came here in 2001, "Baltika 0" has become the first domestic non-alcoholic beer. The equipment on which it is made, allows the use of the most advanced to date, a method of producing non-alcoholic beer - dialysis.

How it is made non-alcoholic beer? There are several ways of manufacturing non-alcoholic beer: the suppression of fermentation, evaporation and removal of the fortress of the finished beer. Optimal method - membrane filtration technology, in which the finished beer removed from the alcohol, produced in this way "Baltic 0". This method allows you to get rid of the fortress without sacrificing taste and flavor.

2.

The tour also begins with a long corridor, where there are stands with awards and diplomas. There are more than 600 Russian and international professional and consumer contests. Non-alcoholic beer is no exception, many times "Baltika 0" is recognized as the best non-alcoholic beer in the Russian and international professional competitions, in 2006 - a silver medal World Beer Cup, in 2008 - bronze Australian International Beer Awards.

3.

The brewhouse is preparing the foundation for a beer - a must. First the malt is milled to have access to water soluble substances. Then malt grist is mixed with water and heated to transfer the soluble components in the extract. Next, the wort is filtered, and the pellet remaining after cleaning is dried and fed to livestock:

4.

Then the wort enters the special boilers where hops are added, which gives the beer bitterness and a variety of aromatics after it is cooled, pumped into a special cylindric tanks (CCT) and begins, in fact, the stage of fermentation. I remember the historic copper vats that are not working and are a monument to the first production capacity of the brewery. It is with them all began in 1990. If you look on the floor visible circles left over from other tanks:

5.

I could not pass up and looked in the mini-brewery in the test center. In it are the research and development of new varieties. Power pilot brewery is small, only 500 liters. But industrial production scale here is not required:

All technological processes are controlled in the production laboratory:

6.

7.

8.

All processes are automated brewery. The only process which is closely monitored by the people - a quality control:

9.

All raw materials are imported or Russian, grown under the supervision of the Brewers. This malts that are used in a brewery. The most popular - pale malt (leftmost). It is because it is brewed non-alcoholic beer:

10.

Fermentation room. It is here that non-alcoholic beer and matures on a par with conventional large cylinder-conical tanks with a certain temparature, pressure and duration of the process. As I learned, beer varies according to the method of fermentation, and is divided into only two types - ale and lager:

11.

Elem is considered top-fermented beer as the drink ferments at room temperature, and the yeast rises to the surface of the beer. Lager same roams at low temperatures, and yeast, conversely, fall to the bottom. Non-alcoholic beer - a lager.

Since the non-alcoholic beer, as well as any other - a product of fermentation, it contains a small percentage of alcohol: up to 0, 5 and kefir kvass also contain alcohol: fresh yogurt, for example, contain 0, 2% alcohol, stale, the figure comes to 1%. In kvass may contain from 0 to 6, 1, 2%.

Tanks beautifully illuminated with multicolored illumination:

12.

13.

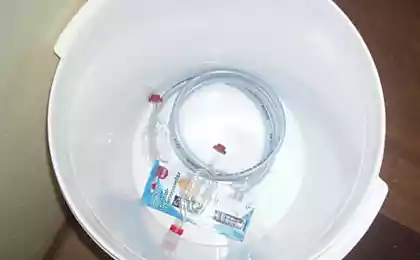

After fermentation, the beer (except non-filtered) is adjudged to filter and non-alcoholic beer just takes a more complicated process. As I mentioned, "Baltika 0" - made dialysis technology, the beer runs a complex and multi-stage filter system in which it is removed from the fortress due to the difference in the size of the molecules of water and alcohol.

Lines of flood finished beverage:

14.

The link to the guidance:

15.

In the end I was taken to the museum of the company which presents various exhibits dedicated not only to the Baltic Sea, but also all the beer. This, for example, beer wagon, which went to St Petersburg:

16.

Such was the home brewery in Russia:

17.

And it is - a legacy of the Soviet Union. Previously, the city grew so quickly that food infrastructure (shops, restaurants) did not have time for them. Then the solution was found - mobile cans of beer:

18.

European Area:

19.

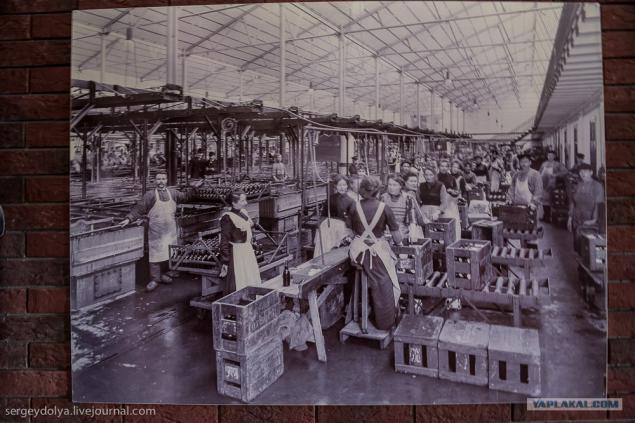

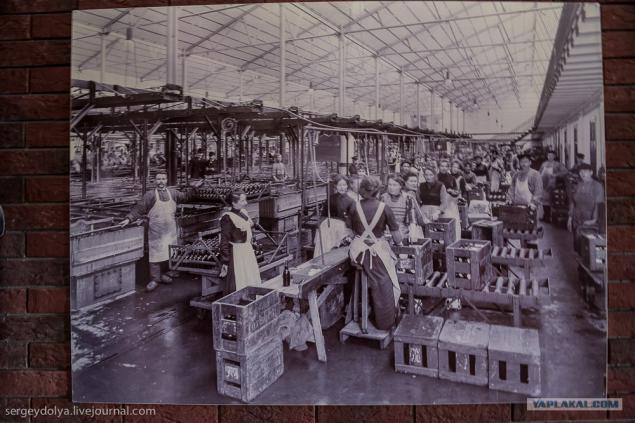

Photo Carlsberg factory - formerly used manual labor (women, usually) and the brewing of beer was quite time-consuming process:

20.

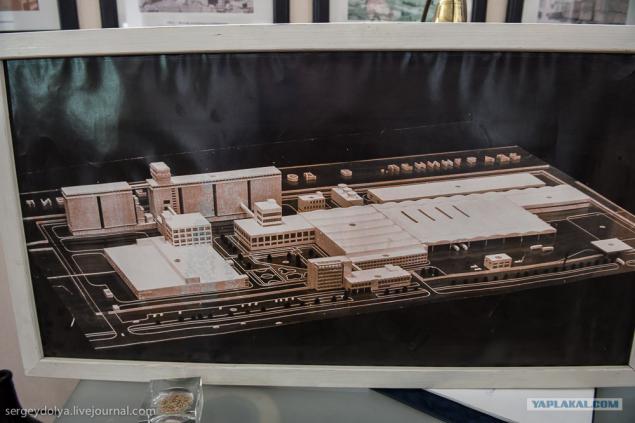

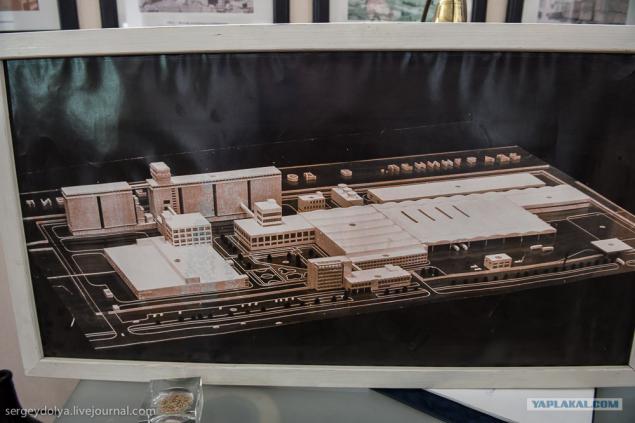

The layout of the plant "Baltika" in St. Petersburg:

21.

We ended our tour in the tasting room. I had the opportunity to compare the non-alcoholic beer and the usual taste:

Thanks to the staff for a tour of the Baltic Sea and the detailed story.

sergeydolya.livejournal.com

22.

Source:

Will 22 photo + not many letters

Plant entrance. The territory covers 30 hectares, it is almost the size of the Vatican (44 hectares):

1

It should be noted that non-alcoholic beer came here in 2001, "Baltika 0" has become the first domestic non-alcoholic beer. The equipment on which it is made, allows the use of the most advanced to date, a method of producing non-alcoholic beer - dialysis.

How it is made non-alcoholic beer? There are several ways of manufacturing non-alcoholic beer: the suppression of fermentation, evaporation and removal of the fortress of the finished beer. Optimal method - membrane filtration technology, in which the finished beer removed from the alcohol, produced in this way "Baltic 0". This method allows you to get rid of the fortress without sacrificing taste and flavor.

2.

The tour also begins with a long corridor, where there are stands with awards and diplomas. There are more than 600 Russian and international professional and consumer contests. Non-alcoholic beer is no exception, many times "Baltika 0" is recognized as the best non-alcoholic beer in the Russian and international professional competitions, in 2006 - a silver medal World Beer Cup, in 2008 - bronze Australian International Beer Awards.

3.

The brewhouse is preparing the foundation for a beer - a must. First the malt is milled to have access to water soluble substances. Then malt grist is mixed with water and heated to transfer the soluble components in the extract. Next, the wort is filtered, and the pellet remaining after cleaning is dried and fed to livestock:

4.

Then the wort enters the special boilers where hops are added, which gives the beer bitterness and a variety of aromatics after it is cooled, pumped into a special cylindric tanks (CCT) and begins, in fact, the stage of fermentation. I remember the historic copper vats that are not working and are a monument to the first production capacity of the brewery. It is with them all began in 1990. If you look on the floor visible circles left over from other tanks:

5.

I could not pass up and looked in the mini-brewery in the test center. In it are the research and development of new varieties. Power pilot brewery is small, only 500 liters. But industrial production scale here is not required:

All technological processes are controlled in the production laboratory:

6.

7.

8.

All processes are automated brewery. The only process which is closely monitored by the people - a quality control:

9.

All raw materials are imported or Russian, grown under the supervision of the Brewers. This malts that are used in a brewery. The most popular - pale malt (leftmost). It is because it is brewed non-alcoholic beer:

10.

Fermentation room. It is here that non-alcoholic beer and matures on a par with conventional large cylinder-conical tanks with a certain temparature, pressure and duration of the process. As I learned, beer varies according to the method of fermentation, and is divided into only two types - ale and lager:

11.

Elem is considered top-fermented beer as the drink ferments at room temperature, and the yeast rises to the surface of the beer. Lager same roams at low temperatures, and yeast, conversely, fall to the bottom. Non-alcoholic beer - a lager.

Since the non-alcoholic beer, as well as any other - a product of fermentation, it contains a small percentage of alcohol: up to 0, 5 and kefir kvass also contain alcohol: fresh yogurt, for example, contain 0, 2% alcohol, stale, the figure comes to 1%. In kvass may contain from 0 to 6, 1, 2%.

Tanks beautifully illuminated with multicolored illumination:

12.

13.

After fermentation, the beer (except non-filtered) is adjudged to filter and non-alcoholic beer just takes a more complicated process. As I mentioned, "Baltika 0" - made dialysis technology, the beer runs a complex and multi-stage filter system in which it is removed from the fortress due to the difference in the size of the molecules of water and alcohol.

Lines of flood finished beverage:

14.

The link to the guidance:

15.

In the end I was taken to the museum of the company which presents various exhibits dedicated not only to the Baltic Sea, but also all the beer. This, for example, beer wagon, which went to St Petersburg:

16.

Such was the home brewery in Russia:

17.

And it is - a legacy of the Soviet Union. Previously, the city grew so quickly that food infrastructure (shops, restaurants) did not have time for them. Then the solution was found - mobile cans of beer:

18.

European Area:

19.

Photo Carlsberg factory - formerly used manual labor (women, usually) and the brewing of beer was quite time-consuming process:

20.

The layout of the plant "Baltika" in St. Petersburg:

21.

We ended our tour in the tasting room. I had the opportunity to compare the non-alcoholic beer and the usual taste:

Thanks to the staff for a tour of the Baltic Sea and the detailed story.

sergeydolya.livejournal.com

22.

Source: