1262

HEINEKEN Russia

What is beer? Barley malt, hops, yeast and water. In the world of about 40 thousand types of beer made from the same four ingredients, and everyone has different tastes. How is it all mix and cook to get a tasty beer? Understand this, I was invited to the Siberian Heineken Brewery.

Will be 45 photos and some text via dedmaxopka.livejournal.com/62681.html

Branch "Siberian Heineken Brewery" is part of HEINEKEN company in Russia since 2004. The plant was built in 2003 and is equipped with ultra-modern German equipment. The level of automation "Siberian Heineken Brewery" is considered one of the best in Russia.

The plant produces 8 brands: «Zlaty Bazant», «Bochkarev," "Three Bears", "Zhiguli", "Freestyle Siberia", "Hunting", "PIT" in 2012 - «Ostmark Helles Beer». In 2011, put into production the new beers "Three Bears Crystal", "Three Bears Alpine", "Dark Hunting».

Oddly enough, but the "Siberian Heineken Brewery" does not let himself «Heineken». To create a Heineken beer need horizontal tanks and "Siberian Heineken Brewery" is equipped with a vertical. But more on that below.

Production capacity is 1, 7 million hectoliters of beer per year.

The history of Heineken beer started at a time when the company's founder was able to fundamentally improve the formula for the beverage, brewery applied, which by that time had already existed for 251 years. Designed while the recipe and still persists in the strictest secrecy, but the requirements to ensure that the excellent properties of beer, remain valid until now: high-quality ingredients and a strict control at all stages of production.

Company HEINEKEN beer recipe involves the use of only natural ingredients. Ingredients are 4 main components: barley, hops, yeast and water. At the same time, each type of beer has its own flavor, color and aroma. This is the magic of brewing.

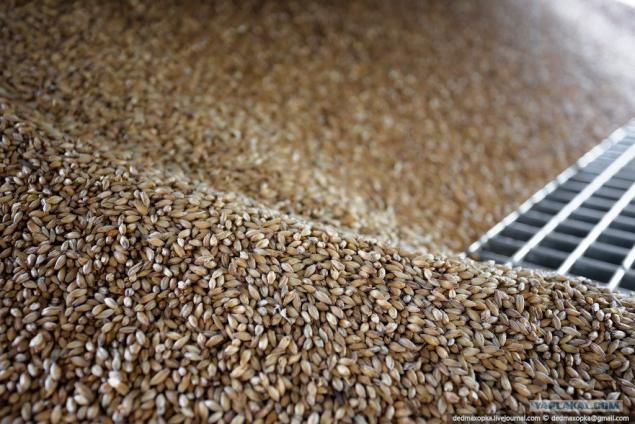

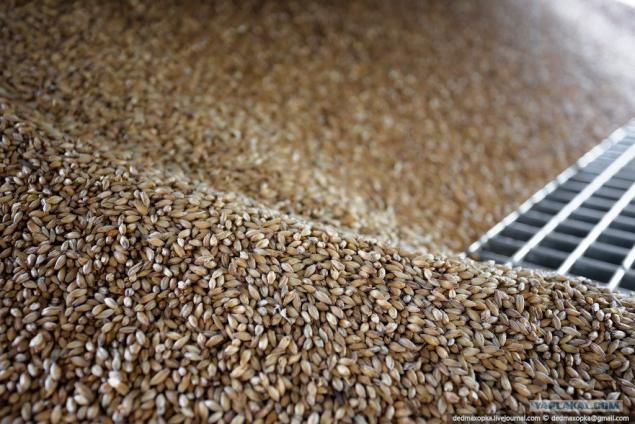

2. It begins with malt

The brewing process:

Stage №1. Malting.

3. Malting - a process of soaking and germinating barley malt drying sprouted and remove germs. Malting is necessary that the substance of barley could go into the water and turned the wort - the basis of fermentation.

The photo is ready to use the malt delivered to the "Siberian Heineken Brewery" by rail from various Russian suppliers.

4. The next stage of the malting - crushing malt. Grain slept in solododrobilku to grind, to result in a husk, grits and flour. There are several ways of crushing: dry, dry grinding and crushing with conditioning with addition of water.

The photo silos that store malt and barley

5. silos with malt

6. On the "Siberian Heineken Brewery" used the latest style - grain after this treatment becomes soft, loose and easy. In addition, this method is safer than others.

In the photo department podrabotochnoe brewery, where the crushing of malt

Step №2. Preparation of the wort.

It consists of 4 phases - mashing, filtration, boiling and bleaching with cooling.

7. Wipe - This process is kept secret brewers. In fact, the beer was invented at this point. The essence is that the mashing occurs by heating with a certain temperature range. The secret to the temperature and heating time.

The photo mash pot, in which the process of mashing.

8. Thereafter, the wort is filtered in a special pan

9. The process of filtration of the wort - the release of the shell and corn grains.

In the photo taken by the filtering process "window" vat.

10. At this stage it is important to achieve the transparency of filtered wort. The more transparent a must have, the better beer. After purification, the wort is boiled from 60 to 120 minutes and added to it and hops. In the same production step the wort is brought to a certain density which the label is expressed as a percentage and is called "extractive density Wort».

11. The taste varies depending on when hops are added at the beginning or at the end of boiling. After boiling, the wort is cooled and clarified.

In the photo: the resulting wort is pumped to the hydrocyclone to lighten the saturation by precipitation of small particles of hops and protein

12. This occurs wort boiler.

13.

Stage №3. Fermentation.

The resulting beverage is injected sterile compressed air, and then add the beer yeast. The air needed to ensure that the yeast can rapidly multiply the first 12-24 hours of fermentation wort.

14. Yeast department. In growing yeast tanks that are used in the preparation of beer.

15.

16. CCT (cylindro-conical tanks) - the main fermentation unit. The fermentation lasts from 6 to 8 days (for different grades) at a temperature of 9-18 degrees Celsius. After fermentation the "young beer" was cooled to a temperature of 3 degrees Celsius, settled yeast is removed from the bottom of CCT

17. The total time of preparation of beer - not less than 14 days! The CCT beer must is at least 2 days (depending on the type of beer).

18. Technological corridors. Since the brewing process is fully automated, technological corridors are necessary in order to minimize the involvement of people in the preparation of beer.

Step №4. Filtering.

This final filtration of particles causing the turbidity of the beverage. After filtration, the beer is saturated with carbon dioxide, and sent to storage.

19. The beer is filtered using kizulgura - sediment with a porous surface through which liquid and fine particles remain.

20. Through the glass you can see the still unfiltered beer

21.

22. And this is a filtered beer

23. The filtration compartment

Step №5. Filling.

The most spectacular stage. Beer goes to the bottling line in different types of packaging to "Siberian Heineken Brewery" has three lines: the line of glass, PET line and the line of the keg.

Filling - is the preparation of containers (washing and sterilization), filling into containers, pasteurization of beer, pasting labels and packaging.

24. First, wash bottles

25. Bottle washing machine

26.

27.

28. Filling beer bottles

29. Many, many bottles of beer are going to get their label with the name of the brand and grade.

30.

31. Even with labels. After that, the beer is packaged and sent to the warehouse.

32. beer Zlatý Bažant

33. Beer Three Bears

34. The line of PET. That such blanks blown bottles.

35.

36.

37. Already filled with beer

38. Automated bottle inspector checks the quality of the content. If the filling is not up to standard, then discarded bottles and beer - drained.

39. Line keg. On the "Siberian Heineken Brewery" beer is poured into kegs capacity of 30 and 50 liters. It turns out that beer - the most popular in our region!

40. This warehouse - a place where beer is awaiting its shipment to stores.

41. Laboratory. They conduct various analyzes of samples from different stages of beer making - from the malt, and the last beer, already bottled.

42. Work microbiologist

43. Beer is analyzed not only by the physical and chemical, and microbiological indicators

44. Unit - here produce heat and steam for brewing beer.

45. Boiler room - one of the most energy efficient and environmentally friendly in Russia

Posted in [mergetime] 1346310265 [/ mergetime]

Source:

Will be 45 photos and some text via dedmaxopka.livejournal.com/62681.html

Branch "Siberian Heineken Brewery" is part of HEINEKEN company in Russia since 2004. The plant was built in 2003 and is equipped with ultra-modern German equipment. The level of automation "Siberian Heineken Brewery" is considered one of the best in Russia.

The plant produces 8 brands: «Zlaty Bazant», «Bochkarev," "Three Bears", "Zhiguli", "Freestyle Siberia", "Hunting", "PIT" in 2012 - «Ostmark Helles Beer». In 2011, put into production the new beers "Three Bears Crystal", "Three Bears Alpine", "Dark Hunting».

Oddly enough, but the "Siberian Heineken Brewery" does not let himself «Heineken». To create a Heineken beer need horizontal tanks and "Siberian Heineken Brewery" is equipped with a vertical. But more on that below.

Production capacity is 1, 7 million hectoliters of beer per year.

The history of Heineken beer started at a time when the company's founder was able to fundamentally improve the formula for the beverage, brewery applied, which by that time had already existed for 251 years. Designed while the recipe and still persists in the strictest secrecy, but the requirements to ensure that the excellent properties of beer, remain valid until now: high-quality ingredients and a strict control at all stages of production.

Company HEINEKEN beer recipe involves the use of only natural ingredients. Ingredients are 4 main components: barley, hops, yeast and water. At the same time, each type of beer has its own flavor, color and aroma. This is the magic of brewing.

2. It begins with malt

The brewing process:

Stage №1. Malting.

3. Malting - a process of soaking and germinating barley malt drying sprouted and remove germs. Malting is necessary that the substance of barley could go into the water and turned the wort - the basis of fermentation.

The photo is ready to use the malt delivered to the "Siberian Heineken Brewery" by rail from various Russian suppliers.

4. The next stage of the malting - crushing malt. Grain slept in solododrobilku to grind, to result in a husk, grits and flour. There are several ways of crushing: dry, dry grinding and crushing with conditioning with addition of water.

The photo silos that store malt and barley

5. silos with malt

6. On the "Siberian Heineken Brewery" used the latest style - grain after this treatment becomes soft, loose and easy. In addition, this method is safer than others.

In the photo department podrabotochnoe brewery, where the crushing of malt

Step №2. Preparation of the wort.

It consists of 4 phases - mashing, filtration, boiling and bleaching with cooling.

7. Wipe - This process is kept secret brewers. In fact, the beer was invented at this point. The essence is that the mashing occurs by heating with a certain temperature range. The secret to the temperature and heating time.

The photo mash pot, in which the process of mashing.

8. Thereafter, the wort is filtered in a special pan

9. The process of filtration of the wort - the release of the shell and corn grains.

In the photo taken by the filtering process "window" vat.

10. At this stage it is important to achieve the transparency of filtered wort. The more transparent a must have, the better beer. After purification, the wort is boiled from 60 to 120 minutes and added to it and hops. In the same production step the wort is brought to a certain density which the label is expressed as a percentage and is called "extractive density Wort».

11. The taste varies depending on when hops are added at the beginning or at the end of boiling. After boiling, the wort is cooled and clarified.

In the photo: the resulting wort is pumped to the hydrocyclone to lighten the saturation by precipitation of small particles of hops and protein

12. This occurs wort boiler.

13.

Stage №3. Fermentation.

The resulting beverage is injected sterile compressed air, and then add the beer yeast. The air needed to ensure that the yeast can rapidly multiply the first 12-24 hours of fermentation wort.

14. Yeast department. In growing yeast tanks that are used in the preparation of beer.

15.

16. CCT (cylindro-conical tanks) - the main fermentation unit. The fermentation lasts from 6 to 8 days (for different grades) at a temperature of 9-18 degrees Celsius. After fermentation the "young beer" was cooled to a temperature of 3 degrees Celsius, settled yeast is removed from the bottom of CCT

17. The total time of preparation of beer - not less than 14 days! The CCT beer must is at least 2 days (depending on the type of beer).

18. Technological corridors. Since the brewing process is fully automated, technological corridors are necessary in order to minimize the involvement of people in the preparation of beer.

Step №4. Filtering.

This final filtration of particles causing the turbidity of the beverage. After filtration, the beer is saturated with carbon dioxide, and sent to storage.

19. The beer is filtered using kizulgura - sediment with a porous surface through which liquid and fine particles remain.

20. Through the glass you can see the still unfiltered beer

21.

22. And this is a filtered beer

23. The filtration compartment

Step №5. Filling.

The most spectacular stage. Beer goes to the bottling line in different types of packaging to "Siberian Heineken Brewery" has three lines: the line of glass, PET line and the line of the keg.

Filling - is the preparation of containers (washing and sterilization), filling into containers, pasteurization of beer, pasting labels and packaging.

24. First, wash bottles

25. Bottle washing machine

26.

27.

28. Filling beer bottles

29. Many, many bottles of beer are going to get their label with the name of the brand and grade.

30.

31. Even with labels. After that, the beer is packaged and sent to the warehouse.

32. beer Zlatý Bažant

33. Beer Three Bears

34. The line of PET. That such blanks blown bottles.

35.

36.

37. Already filled with beer

38. Automated bottle inspector checks the quality of the content. If the filling is not up to standard, then discarded bottles and beer - drained.

39. Line keg. On the "Siberian Heineken Brewery" beer is poured into kegs capacity of 30 and 50 liters. It turns out that beer - the most popular in our region!

40. This warehouse - a place where beer is awaiting its shipment to stores.

41. Laboratory. They conduct various analyzes of samples from different stages of beer making - from the malt, and the last beer, already bottled.

42. Work microbiologist

43. Beer is analyzed not only by the physical and chemical, and microbiological indicators

44. Unit - here produce heat and steam for brewing beer.

45. Boiler room - one of the most energy efficient and environmentally friendly in Russia

Posted in [mergetime] 1346310265 [/ mergetime]

Source: