922

Cook beer at home.

Brew beer at home - it's not particularly tricky, but in every sense of charity. Firstly, it is very tasty. Second, domestic beer from natural raw materials gives far less hangover and cumulative damage to health is also smaller. Third, when you regale friends and acquaintances, proudly stating - "at I cooked myself," then seeing their round eyes, your ego swells to such an extent that interferes with walking. For some reason, people believe that brewing - it's somewhere between the harsh alchemy and necromancy.

This opus, I'll break into two parts. The first - about the equipment and materials that will be needed for a more or less comfortable working and the second - actually about brewing beer, named by the recipe "Black Rhino".

Equipment.

The first thing you need - a pan or pot 40 liters can enamel, they can be stainless steel. Stainless steel is better, but more expensive. Enameled capacity personal identity, but three times cheaper. I bought here is a miracle for 2000 rubles. Barely I found, by the way. Home pan during cooking can be dispensed liters to 50. Then you have to buy more than a serious technique as carry 50 liters of boiling water hands is difficult and dangerous.

Will be 23 photos.

By the degree of hardcore, home brewing can be divided into two types: the concentrate and all-grain (grain).

In the first case, we have finished wort, in the form of evaporated concentrate. This is not chemistry. It's that neither is natyurprodukt. Now the choice is very large concentrates, it is possible for every taste for something to pick up. They cost in the region of 800 rubles for a jar of 20 liters of finished beer.

In the second, we buy malt, and sneered at him already own. There are, however, absolutely perfectionists, they themselves make malt from barley and water is prepared, achieving the desired salinity. Well, for example, if one beer is brewed in the English village Fuckthishole, it turns out there the mineral composition of the water and do the same. It's over 80 levels house. brewing. For those who like quite a good buy in the store or collect water from nearby wells / spring / crane.

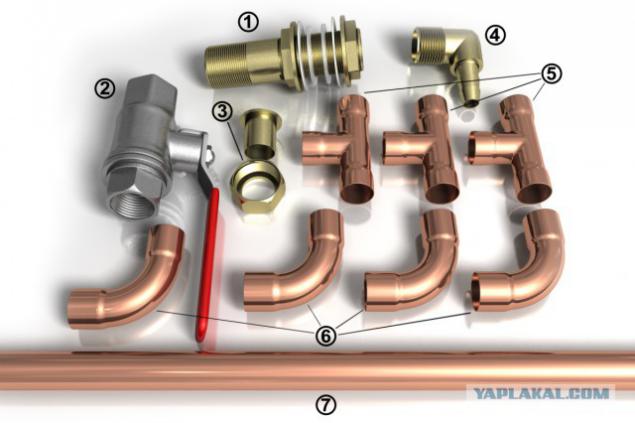

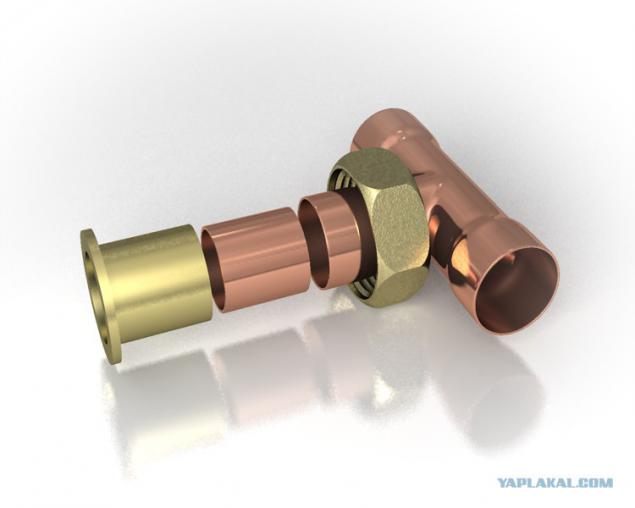

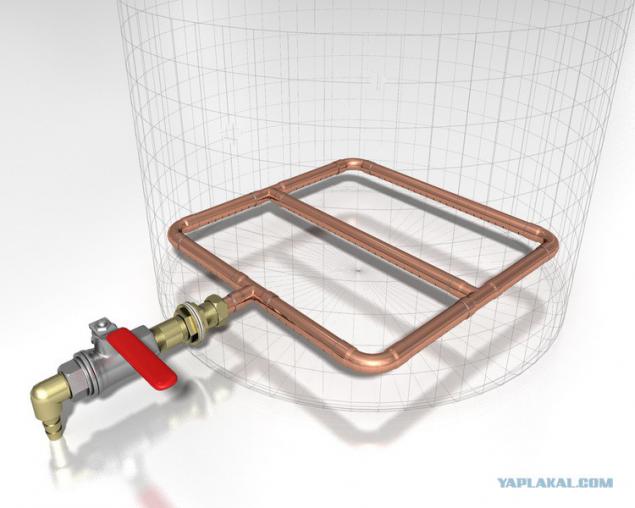

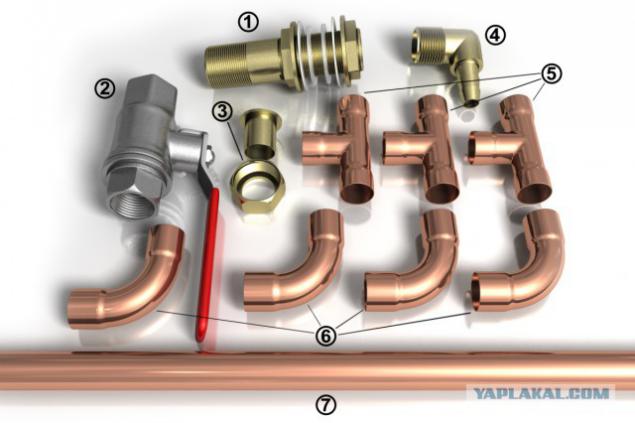

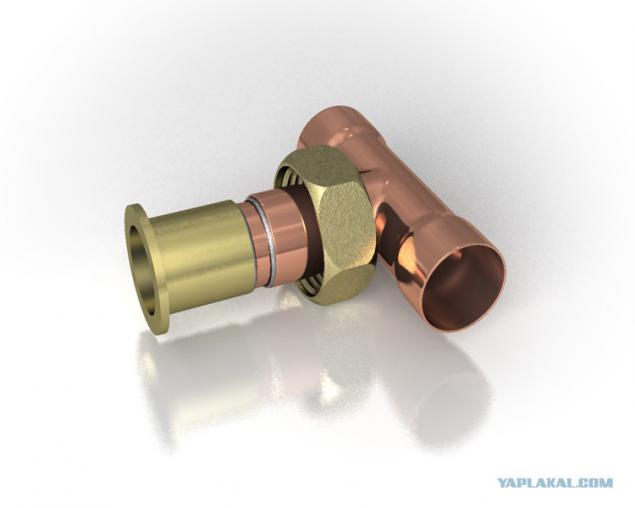

Further, it is necessary to turn the banal into a pan-zatornik suslovarnik. You can use two tanks, one for the mash, the other for cooking, but in terms of apartments, the smaller the volume of trash - the lower the wife swears. What is important for the brewer. Go to the nearest market system and buy the parts you need:

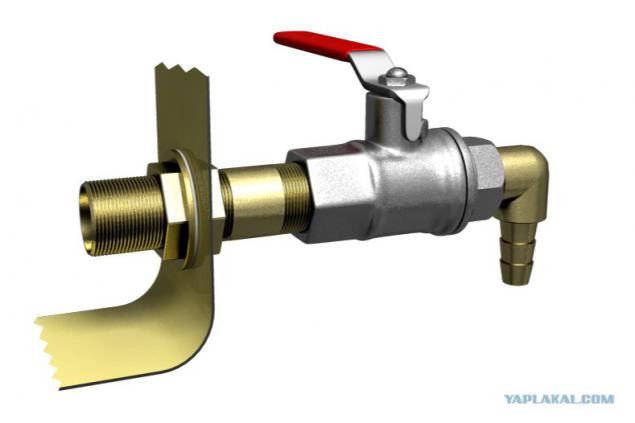

1. Brass eviction on half-inch lock nut plus two plus two silicone gaskets, plus two PTFE gaskets.

2. Ball valve with internal thread identity ½ inch.

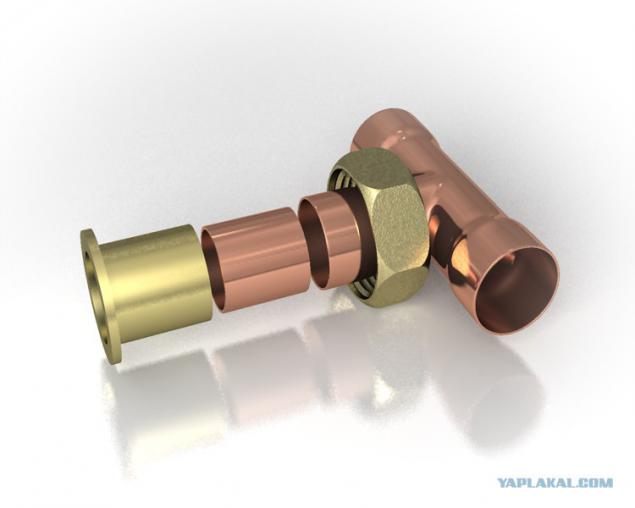

3. The American solder copper pipe.

4. Corner fitting.

5. Three 15mm diameter copper tee.

6. Four Corner 15 mm.

7. Two meters unannealed copper tube.

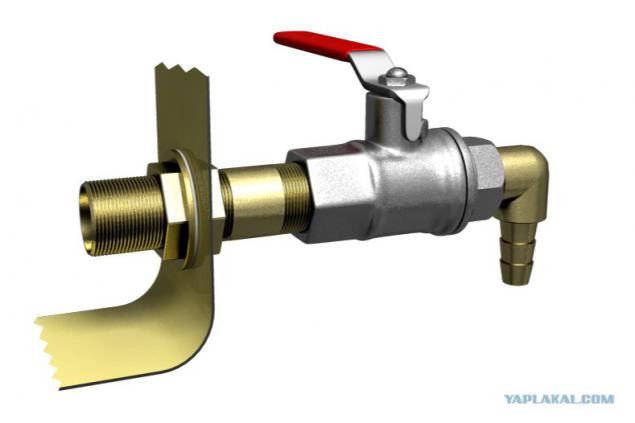

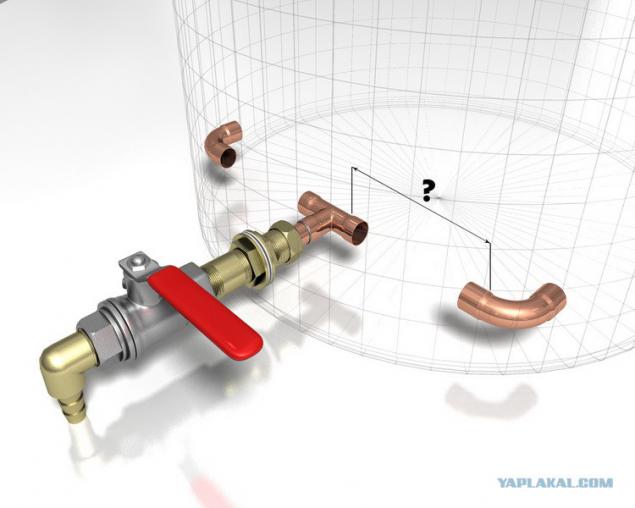

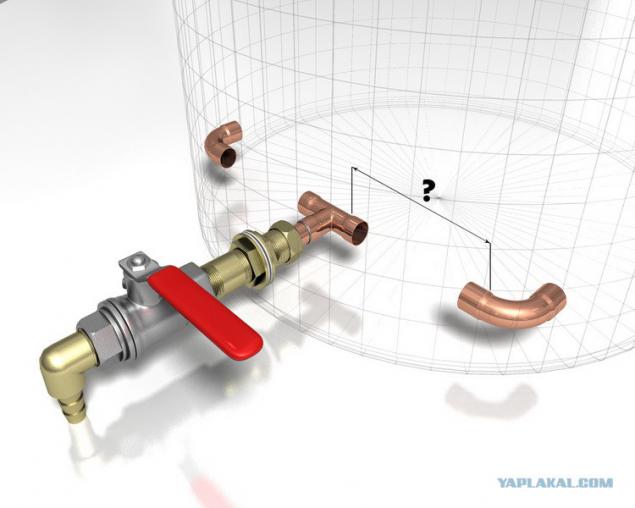

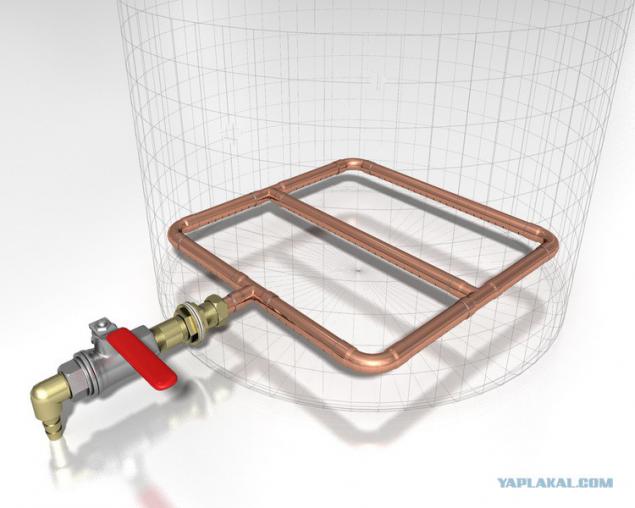

In a saucepan drill hole as low as possible (there's one some tools and skills rukozhopiya), trying to minimally damage the enamel and collect just such a structure:

By the wall of the pot, first put silicone gasket and Teflon on it. Otherwise, nuts silicone zaderut.

Well, here is ready suslovarnik. Now, upgrades it to zatornika. Here it is necessary to delve a bit into the theory.

Wipe - is a process of keeping congestion (water + malt) at a certain temperature. This is called maintaining the temperature pause. During this time, enzymes contained in malt, digested starch, which has a polysaccharide, into simpler sugars, edible yeast. The enzymes involved in this process is the so-called alpha and beta-amylase. In figurative expression of one of our colleagues, if present starch tree, beta-amylase biting twigs (fermentable sugars) reach a fork in the branches and freeze, and the alpha cuts at random by arbitrary pieces (non-fermentable sugar). The thing is that these enzymes are most active at various temperatures. Beta-amylase at 60-65 degrees, alpha - at 70-75. Accordingly, if allowed to work longer beta - we must get the maximum fermentability, high amounts of alcohol, but pustovat tastes, for all the sugar will turn into alcohol yeast and water. Conversely, if the steer will be alpha-amylase, the beer will be dense, rich but very easy, because the yeast there would be almost nothing. Combining thermal break and reach the right balance between the body of beer and alcohol. Here, the theory of rough.

To turn our tank in zatornik to assemble the filter element. Here, unfortunately, it takes some rukozhopstvo.

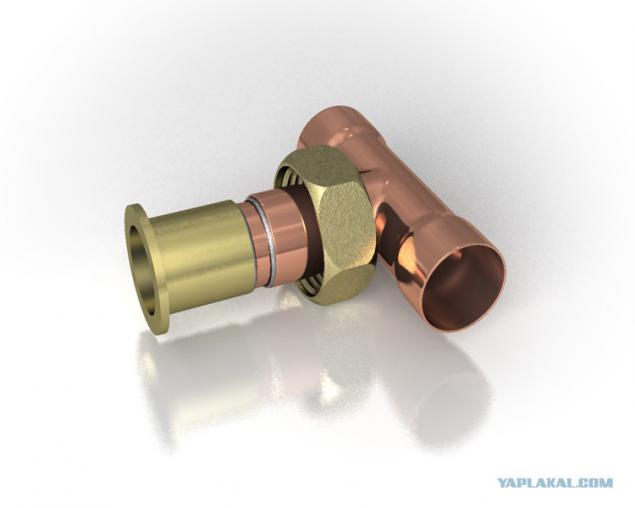

To begin, take an American, a tee, a piece of copper pipe and solder one to the other.

Payaem.

Posted in [mergetime] 1394715292 [/ mergetime]

Soldering copper pipes easy. Need solder necessarily lead-free and flux. All this is freely available on the market or in shops plumbing. Solder look Sn97-Cu3. No soldering flux does not work, the solder will flow down to the dull copper. If there is a gas torch for soldering - well, if not, come down and a gas cooker. We clean the surface, causes a thin layer of flux, we gather together and heated. When plastered submerged parts appear small droplets of tin - tray wire solder to the joint, and tin capillary action itself to be lured. Let cool and voila. Only we must remember, copper has excellent thermal conductivity, work only tool, or severe burns guaranteed. Copper can not, as a piece of coal, to transfer from hand to hand, even a short touch - burn.

Resulting damn screwed to the ebbs and determine the length of tubing to the walls of the pan. The filter must be in thrust.

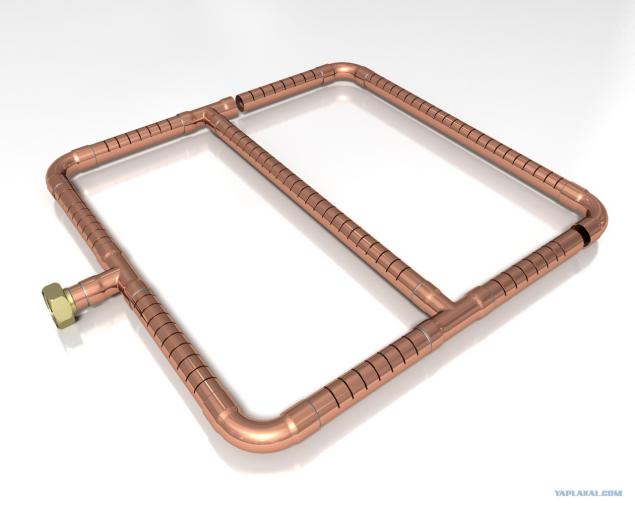

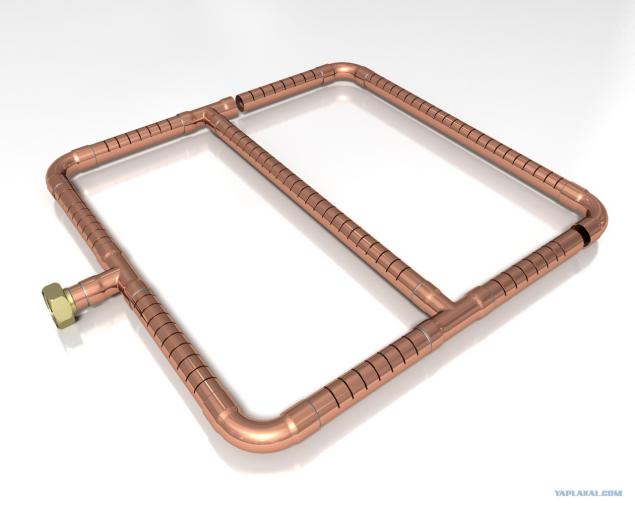

So gradually we collect just such a design.

The tubes do hacksaw cuts a third diameter and somewhere millimeter wide. The two places are not soldered pipes, leaving collapsible, so you can wash the filter.

All together:

Here's a devil-instrument.

The latter, which will need rukozhopie - it is cooler, or as it is called, the chiller. Again we go to the market, and buy 10-12 meters annealed copper tube diameter of 10-12 mm and several meters (depending on how far from the brewing will be the connection point to the cold water) of any hose, plus a pair of buckles. Annealed tube, unlike easily bent by hand. That Gnehm, reeling something suitable diameter. Then, carefully, a large radius, not to the hall, we deduce end up. For stiffness coils can be soldered to the vertical tubes, I just strapped copper wire (in rukozhopii there must be "zhopie»).

We now turn to what to do problematic.

1. hydrometer the AC-3. This garbage is necessary to measure the density of the wort. Without it, you can, but it's better with him. Many use refractometers for the same, but I have not used them, did not speak.

2. The capacity to ferment. Now, many online stores offer here are 32-liter drums directly with the hydraulic lock (4) and the tap (5). Even with the scale and pasted liquid crystal thermometer. You can buy, you can individually. But if brewing stores this tank is 300 - 350 rubles, in the offices, trading of plastic packaging, it is worth 160 rubles. A matter of taste and laziness.

3. malt mill. Specifically, here, this is called Comfort-500, made in the name of the farm 47 years of Mao looks scary, metal processing at the level of the Stone Age, but it is worth fifteen hundred and performs its function. The same, but made in Belgium is already 3,500. Advanced two-three-roll mills are already between 5 and 9000. No grinder, mincer and blenders will not fit. A little later I explain why. Suitable rolling pin, but it will not grind, and the punishment of God and the seven plagues ebiptskih.

4 - 5 - 6. The precise digital thermometer with remote probe. Accuracy least within a degree. One thing is absolutely necessary that in the picture, I foolishly bought for 1500 rubles. Then it turned out that it was possible to buy good Chinese thermometer for 300 rubles. On Avito.

7. Libra. It must also be more or less accurate. If within the program - the ideal. The picture Energy-403, weigh up to 5 kg, has a tare function. Accuracy - grams. Well, it is written ...

Posted in [mergetime] 1394715496 [/ mergetime]

The last thing we need - two and a half meters under the silicone hose fitting on the pan. I draw it did not, the hose and bight, clear this. It is necessary to drain the hot wort. PVC does not go, it stinks when heated and releases itself from all sorts of nastiness. Need medical silicone hose is suitable for sterilization. Where can I get it - it depends on your imagination.

Actually all. Micro-brewery for home, for the family is ready. There are all sorts of little things to make things easier, but initially you can do. The budget of all this ugliness ranges from 10 to 15 thousand. Depending upon.

BOILING.

Now, we move on to the actual brewing. Just once I want to clarify that in addition to equipment and ingredients that you will need more patience and the sea. The process of digestion takes 6-8 hours, the fermentation of 7 to 14 days, an excerpt from a couple of weeks to a year. That is, even in the simplest case, your first beer you try not earlier than one month after cooking. But, believe me, it's worth it.

And another important point. The room in which the whole devilry must be clean. No mold in the corners, no fermented milk products nearby. No animals. Wort - a sverhpitatelnaya medium for fungi and bacteria. Therefore, the cleaner in the room, the smaller the chance of contamination of beer. Pro disinfection equipment then write below.

So, we will cook Chorny Rhino. This recipe, while clearly in a state of enlightenment, came up with a friend of the club house. Brewers with the nickname Rhino. Beer dark. Therefore Chorny.

We need, at the rate of 28 liters of finished beer (we are limited to a 32-liter fermentation):

Malt Munich, Munich, with color EBC 25 (in stores is "Munich-25") - 5.77 kg.

Malt melanoidin, Melano, EBC 80 - 0.87 kg.

Caramel malt, Cara, EBC 50 (Cara-150 can be darker and richer) - 0.35 kg.

Hops are a traditional, also known as Traditional - 20 grams.

Žatec Hops or Saaz - 40 grams.

Yeast Fermentis Safale S-04 - one sachet of 11 grams.

First and foremost, it is necessary to grind the malt. We get our hellish mill and forth. You can twist the arms can prisobachit screwdriver, I enrolled smarter and pripahali his flock. Six kilos of malt require half an hour to smoke breaks.

Trick grinding malt that should not receive the flour and fragmented in several parts and thus grain intact membranes. That's why no coffee grinders are not suitable. These membranes, settling on the bottom zatornika form a filtering layer, through which the wort is actually filtered. And flows through our filter system of copper pipes. Propylene is small enough to peel slipped through them, but large enough to filtration took a reasonable time. Without the husk pellet quickly score the slot and must be filtered before the onset of democracy in North Korea. Here is the-ground malt:

This recipe uses odnopauznoe mashing at 72 degrees. Above I mentioned how temperature affects the mash. That is the beer must get "full-bodied" with a small amount of alcohol. Put in tank filter, take four times more water (24 liters) relative to the amount of malt and is heated to 78 degrees, malt filling temperature to fall to 72. By the way we need, there degree, degree here - is not lethal. But when more than 75, the enzyme activity decreases sharply. Overheating ninada.

Heated - fall asleep malt mix. (Photographed on the Comfort-500, comparable quality). To measure the temperature.

It must be 72 degrees.

Close the lid and zamatyvaem tank in a blanket / jacket as tightly as possible.

We are waiting for a half hour. 1 hour, 30 minutes. Patience ... Patience ...

While the malt is overwritten, prepare the yeast. Dry yeast - they need to rehydrate.

Take the jar, flask or something like that, sterilize in boiling water and pour it somewhere 250 ml of water. Water temperature - 20-24 degrees. Fall asleep to the dregs of the bag and plug neck fleece. The composition of dry yeast nutrients added to them for the first time, so you can do just water. They will have to wander there in half an hour.

It took half an hour. Now we have to carry out so-called "iodine sample". Take a spoon and a little wort to drip iodine. If the color has not changed - so the starch in the mash is gone, all split into sugar. And it is gud. If turns blue - this is not gud. You can still try to hold under a blanket is a must, but most likely it will not help. Although I have not seen the quality imported malt gave after rubbing on the blue iodine sample.

Now is the time for a mystical process called intelligent mesh-out (mash-out). Put the pot on the stove and stirring constantly - for prigorit, bring the temperature of the mash to 78 degrees. Turn off the heat and kept so again under a blanket for 15 minutes. It is necessary to stop the activity of enzymes. Starch stop.

During these 15 minutes preparing the water for washing. It's such a special water usually differs only by the fact that heated to 80 degrees. When we merge the primary wort, a lot of sugar remains in the spent grains. Worthless throw away a good thing, so try to wash them out.

It's time to filter the traffic jam. We put on fitting silicone hose, plastic drags our fermentation and open the valve.

Why do you need a hose. The trick is that the hot wort is actively oxidized on contact with air. This gives off-flavor in beer. To minimize contact with air, and the hose is necessary.

At first, it must go much murky - husks have not really settled on the bottom, so the first fused liters return. There is a subtlety - it is important to form a filter layer, but pouring back into the tank must we stirred up sediment again. What would it was not, put on top of a large plate, she let them sink, but will now flow to it and not disturb pellet.

Merge slowly. Once gone clean wort, stop his return to zatornik and start typing it in the fermentation.

At the same time, keep grains is not exposed. As soon as it seems, made up wash water. So, gradually, drain and refilling we need to collect 30-32 liters of wort. At the end of the wash water pouring stop and just merge all there. The first part of the ballet marlezonskogo completed. Throw away the spent grains, unscrew the filter, rinse the tank and pour into a clean filtered wort. And put to boil. 30 liters will be heated for a long time, you can speed up, covered with a lid. But remember, if you miss the boiling point - must run away and wash of burnt sugar on a plate - is hell, and Israel. Also heard from his wife a lot about myself, about beer and about the universe as a whole.

Once the boil, weigh 20 grams of traditional hops and throw it in there. It bittering hops. Pinpoint 50 minutes, let boil. Total cooking we need 90 minutes or half an hour. During this time, boil about 3-4 liters, any unnecessary evaporate with the steam of the sugars caramelize and the walls are covered with beads of condensation.

Carefully my fermentation, fill it with water and pour it into the vial 5% pharmaceutical iodine. There also throw water seal with stopper and pushes the lid fermentation. This disinfection. Iodine is rapidly degraded, so foreign odors and tastes leaves. Instead of iodine can use special disinfectants, specialized stores sell them in disastrous numbers. We reserve so stand.

After 50 minutes, weigh 20 grams of Žatec and entered into the wort. It hops flavor.

15 minutes before end of cooking, connect the unit to cool water and omit it in the wort. This is to ensure that he could be sterilized with boiling water.

Five minutes before the end of cooking are making the remaining 20 grams of Žatec. It hops aroma. In total, we received about 20 IBU (bitterness units). It's a not strong, pleasant bitterness.

Part of the wort is drained into the beaker 100 ml, about which I forgot to write in the equipment, and strictly separate cooling to 20 degrees to measure the density. We thrust to the hydrometer to float and watch the value of the initial density (NP). In this recipe, we need to get 13.5% of the NP. If there is more - just need to add boiled water. If less - even simmer. Although less - is unlikely. In general, the output should be 28 liters.

Posted in [mergetime] 1394715946 [/ mergetime]

(Here, unfortunately, the picture from another cooking hydrometer shows 14.5%)

At the end of cooking, turn the water in the chiller, turn off the heat. The meaning of the unit that must be cooled as quickly as possible should be from 100 to appropriate yeast 20-24 degrees. This copper spiral handle it about 15 minutes If you take a tank into the bathroom and put in cold water - it will take 40-50 minutes. And the longer a must and is in contact with the air, the more likely to infect his "wild" yeast or bacteria, koi plentiful fly around.

Over the remaining five minutes to run the fermentation, pour out the solution of iodine. Who wants to - can rinse with boiled water, but in principle, and so will descend.

All.

Source:

This opus, I'll break into two parts. The first - about the equipment and materials that will be needed for a more or less comfortable working and the second - actually about brewing beer, named by the recipe "Black Rhino".

Equipment.

The first thing you need - a pan or pot 40 liters can enamel, they can be stainless steel. Stainless steel is better, but more expensive. Enameled capacity personal identity, but three times cheaper. I bought here is a miracle for 2000 rubles. Barely I found, by the way. Home pan during cooking can be dispensed liters to 50. Then you have to buy more than a serious technique as carry 50 liters of boiling water hands is difficult and dangerous.

Will be 23 photos.

By the degree of hardcore, home brewing can be divided into two types: the concentrate and all-grain (grain).

In the first case, we have finished wort, in the form of evaporated concentrate. This is not chemistry. It's that neither is natyurprodukt. Now the choice is very large concentrates, it is possible for every taste for something to pick up. They cost in the region of 800 rubles for a jar of 20 liters of finished beer.

In the second, we buy malt, and sneered at him already own. There are, however, absolutely perfectionists, they themselves make malt from barley and water is prepared, achieving the desired salinity. Well, for example, if one beer is brewed in the English village Fuckthishole, it turns out there the mineral composition of the water and do the same. It's over 80 levels house. brewing. For those who like quite a good buy in the store or collect water from nearby wells / spring / crane.

Further, it is necessary to turn the banal into a pan-zatornik suslovarnik. You can use two tanks, one for the mash, the other for cooking, but in terms of apartments, the smaller the volume of trash - the lower the wife swears. What is important for the brewer. Go to the nearest market system and buy the parts you need:

1. Brass eviction on half-inch lock nut plus two plus two silicone gaskets, plus two PTFE gaskets.

2. Ball valve with internal thread identity ½ inch.

3. The American solder copper pipe.

4. Corner fitting.

5. Three 15mm diameter copper tee.

6. Four Corner 15 mm.

7. Two meters unannealed copper tube.

In a saucepan drill hole as low as possible (there's one some tools and skills rukozhopiya), trying to minimally damage the enamel and collect just such a structure:

By the wall of the pot, first put silicone gasket and Teflon on it. Otherwise, nuts silicone zaderut.

Well, here is ready suslovarnik. Now, upgrades it to zatornika. Here it is necessary to delve a bit into the theory.

Wipe - is a process of keeping congestion (water + malt) at a certain temperature. This is called maintaining the temperature pause. During this time, enzymes contained in malt, digested starch, which has a polysaccharide, into simpler sugars, edible yeast. The enzymes involved in this process is the so-called alpha and beta-amylase. In figurative expression of one of our colleagues, if present starch tree, beta-amylase biting twigs (fermentable sugars) reach a fork in the branches and freeze, and the alpha cuts at random by arbitrary pieces (non-fermentable sugar). The thing is that these enzymes are most active at various temperatures. Beta-amylase at 60-65 degrees, alpha - at 70-75. Accordingly, if allowed to work longer beta - we must get the maximum fermentability, high amounts of alcohol, but pustovat tastes, for all the sugar will turn into alcohol yeast and water. Conversely, if the steer will be alpha-amylase, the beer will be dense, rich but very easy, because the yeast there would be almost nothing. Combining thermal break and reach the right balance between the body of beer and alcohol. Here, the theory of rough.

To turn our tank in zatornik to assemble the filter element. Here, unfortunately, it takes some rukozhopstvo.

To begin, take an American, a tee, a piece of copper pipe and solder one to the other.

Payaem.

Posted in [mergetime] 1394715292 [/ mergetime]

Soldering copper pipes easy. Need solder necessarily lead-free and flux. All this is freely available on the market or in shops plumbing. Solder look Sn97-Cu3. No soldering flux does not work, the solder will flow down to the dull copper. If there is a gas torch for soldering - well, if not, come down and a gas cooker. We clean the surface, causes a thin layer of flux, we gather together and heated. When plastered submerged parts appear small droplets of tin - tray wire solder to the joint, and tin capillary action itself to be lured. Let cool and voila. Only we must remember, copper has excellent thermal conductivity, work only tool, or severe burns guaranteed. Copper can not, as a piece of coal, to transfer from hand to hand, even a short touch - burn.

Resulting damn screwed to the ebbs and determine the length of tubing to the walls of the pan. The filter must be in thrust.

So gradually we collect just such a design.

The tubes do hacksaw cuts a third diameter and somewhere millimeter wide. The two places are not soldered pipes, leaving collapsible, so you can wash the filter.

All together:

Here's a devil-instrument.

The latter, which will need rukozhopie - it is cooler, or as it is called, the chiller. Again we go to the market, and buy 10-12 meters annealed copper tube diameter of 10-12 mm and several meters (depending on how far from the brewing will be the connection point to the cold water) of any hose, plus a pair of buckles. Annealed tube, unlike easily bent by hand. That Gnehm, reeling something suitable diameter. Then, carefully, a large radius, not to the hall, we deduce end up. For stiffness coils can be soldered to the vertical tubes, I just strapped copper wire (in rukozhopii there must be "zhopie»).

We now turn to what to do problematic.

1. hydrometer the AC-3. This garbage is necessary to measure the density of the wort. Without it, you can, but it's better with him. Many use refractometers for the same, but I have not used them, did not speak.

2. The capacity to ferment. Now, many online stores offer here are 32-liter drums directly with the hydraulic lock (4) and the tap (5). Even with the scale and pasted liquid crystal thermometer. You can buy, you can individually. But if brewing stores this tank is 300 - 350 rubles, in the offices, trading of plastic packaging, it is worth 160 rubles. A matter of taste and laziness.

3. malt mill. Specifically, here, this is called Comfort-500, made in the name of the farm 47 years of Mao looks scary, metal processing at the level of the Stone Age, but it is worth fifteen hundred and performs its function. The same, but made in Belgium is already 3,500. Advanced two-three-roll mills are already between 5 and 9000. No grinder, mincer and blenders will not fit. A little later I explain why. Suitable rolling pin, but it will not grind, and the punishment of God and the seven plagues ebiptskih.

4 - 5 - 6. The precise digital thermometer with remote probe. Accuracy least within a degree. One thing is absolutely necessary that in the picture, I foolishly bought for 1500 rubles. Then it turned out that it was possible to buy good Chinese thermometer for 300 rubles. On Avito.

7. Libra. It must also be more or less accurate. If within the program - the ideal. The picture Energy-403, weigh up to 5 kg, has a tare function. Accuracy - grams. Well, it is written ...

Posted in [mergetime] 1394715496 [/ mergetime]

The last thing we need - two and a half meters under the silicone hose fitting on the pan. I draw it did not, the hose and bight, clear this. It is necessary to drain the hot wort. PVC does not go, it stinks when heated and releases itself from all sorts of nastiness. Need medical silicone hose is suitable for sterilization. Where can I get it - it depends on your imagination.

Actually all. Micro-brewery for home, for the family is ready. There are all sorts of little things to make things easier, but initially you can do. The budget of all this ugliness ranges from 10 to 15 thousand. Depending upon.

BOILING.

Now, we move on to the actual brewing. Just once I want to clarify that in addition to equipment and ingredients that you will need more patience and the sea. The process of digestion takes 6-8 hours, the fermentation of 7 to 14 days, an excerpt from a couple of weeks to a year. That is, even in the simplest case, your first beer you try not earlier than one month after cooking. But, believe me, it's worth it.

And another important point. The room in which the whole devilry must be clean. No mold in the corners, no fermented milk products nearby. No animals. Wort - a sverhpitatelnaya medium for fungi and bacteria. Therefore, the cleaner in the room, the smaller the chance of contamination of beer. Pro disinfection equipment then write below.

So, we will cook Chorny Rhino. This recipe, while clearly in a state of enlightenment, came up with a friend of the club house. Brewers with the nickname Rhino. Beer dark. Therefore Chorny.

We need, at the rate of 28 liters of finished beer (we are limited to a 32-liter fermentation):

Malt Munich, Munich, with color EBC 25 (in stores is "Munich-25") - 5.77 kg.

Malt melanoidin, Melano, EBC 80 - 0.87 kg.

Caramel malt, Cara, EBC 50 (Cara-150 can be darker and richer) - 0.35 kg.

Hops are a traditional, also known as Traditional - 20 grams.

Žatec Hops or Saaz - 40 grams.

Yeast Fermentis Safale S-04 - one sachet of 11 grams.

First and foremost, it is necessary to grind the malt. We get our hellish mill and forth. You can twist the arms can prisobachit screwdriver, I enrolled smarter and pripahali his flock. Six kilos of malt require half an hour to smoke breaks.

Trick grinding malt that should not receive the flour and fragmented in several parts and thus grain intact membranes. That's why no coffee grinders are not suitable. These membranes, settling on the bottom zatornika form a filtering layer, through which the wort is actually filtered. And flows through our filter system of copper pipes. Propylene is small enough to peel slipped through them, but large enough to filtration took a reasonable time. Without the husk pellet quickly score the slot and must be filtered before the onset of democracy in North Korea. Here is the-ground malt:

This recipe uses odnopauznoe mashing at 72 degrees. Above I mentioned how temperature affects the mash. That is the beer must get "full-bodied" with a small amount of alcohol. Put in tank filter, take four times more water (24 liters) relative to the amount of malt and is heated to 78 degrees, malt filling temperature to fall to 72. By the way we need, there degree, degree here - is not lethal. But when more than 75, the enzyme activity decreases sharply. Overheating ninada.

Heated - fall asleep malt mix. (Photographed on the Comfort-500, comparable quality). To measure the temperature.

It must be 72 degrees.

Close the lid and zamatyvaem tank in a blanket / jacket as tightly as possible.

We are waiting for a half hour. 1 hour, 30 minutes. Patience ... Patience ...

While the malt is overwritten, prepare the yeast. Dry yeast - they need to rehydrate.

Take the jar, flask or something like that, sterilize in boiling water and pour it somewhere 250 ml of water. Water temperature - 20-24 degrees. Fall asleep to the dregs of the bag and plug neck fleece. The composition of dry yeast nutrients added to them for the first time, so you can do just water. They will have to wander there in half an hour.

It took half an hour. Now we have to carry out so-called "iodine sample". Take a spoon and a little wort to drip iodine. If the color has not changed - so the starch in the mash is gone, all split into sugar. And it is gud. If turns blue - this is not gud. You can still try to hold under a blanket is a must, but most likely it will not help. Although I have not seen the quality imported malt gave after rubbing on the blue iodine sample.

Now is the time for a mystical process called intelligent mesh-out (mash-out). Put the pot on the stove and stirring constantly - for prigorit, bring the temperature of the mash to 78 degrees. Turn off the heat and kept so again under a blanket for 15 minutes. It is necessary to stop the activity of enzymes. Starch stop.

During these 15 minutes preparing the water for washing. It's such a special water usually differs only by the fact that heated to 80 degrees. When we merge the primary wort, a lot of sugar remains in the spent grains. Worthless throw away a good thing, so try to wash them out.

It's time to filter the traffic jam. We put on fitting silicone hose, plastic drags our fermentation and open the valve.

Why do you need a hose. The trick is that the hot wort is actively oxidized on contact with air. This gives off-flavor in beer. To minimize contact with air, and the hose is necessary.

At first, it must go much murky - husks have not really settled on the bottom, so the first fused liters return. There is a subtlety - it is important to form a filter layer, but pouring back into the tank must we stirred up sediment again. What would it was not, put on top of a large plate, she let them sink, but will now flow to it and not disturb pellet.

Merge slowly. Once gone clean wort, stop his return to zatornik and start typing it in the fermentation.

At the same time, keep grains is not exposed. As soon as it seems, made up wash water. So, gradually, drain and refilling we need to collect 30-32 liters of wort. At the end of the wash water pouring stop and just merge all there. The first part of the ballet marlezonskogo completed. Throw away the spent grains, unscrew the filter, rinse the tank and pour into a clean filtered wort. And put to boil. 30 liters will be heated for a long time, you can speed up, covered with a lid. But remember, if you miss the boiling point - must run away and wash of burnt sugar on a plate - is hell, and Israel. Also heard from his wife a lot about myself, about beer and about the universe as a whole.

Once the boil, weigh 20 grams of traditional hops and throw it in there. It bittering hops. Pinpoint 50 minutes, let boil. Total cooking we need 90 minutes or half an hour. During this time, boil about 3-4 liters, any unnecessary evaporate with the steam of the sugars caramelize and the walls are covered with beads of condensation.

Carefully my fermentation, fill it with water and pour it into the vial 5% pharmaceutical iodine. There also throw water seal with stopper and pushes the lid fermentation. This disinfection. Iodine is rapidly degraded, so foreign odors and tastes leaves. Instead of iodine can use special disinfectants, specialized stores sell them in disastrous numbers. We reserve so stand.

After 50 minutes, weigh 20 grams of Žatec and entered into the wort. It hops flavor.

15 minutes before end of cooking, connect the unit to cool water and omit it in the wort. This is to ensure that he could be sterilized with boiling water.

Five minutes before the end of cooking are making the remaining 20 grams of Žatec. It hops aroma. In total, we received about 20 IBU (bitterness units). It's a not strong, pleasant bitterness.

Part of the wort is drained into the beaker 100 ml, about which I forgot to write in the equipment, and strictly separate cooling to 20 degrees to measure the density. We thrust to the hydrometer to float and watch the value of the initial density (NP). In this recipe, we need to get 13.5% of the NP. If there is more - just need to add boiled water. If less - even simmer. Although less - is unlikely. In general, the output should be 28 liters.

Posted in [mergetime] 1394715946 [/ mergetime]

(Here, unfortunately, the picture from another cooking hydrometer shows 14.5%)

At the end of cooking, turn the water in the chiller, turn off the heat. The meaning of the unit that must be cooled as quickly as possible should be from 100 to appropriate yeast 20-24 degrees. This copper spiral handle it about 15 minutes If you take a tank into the bathroom and put in cold water - it will take 40-50 minutes. And the longer a must and is in contact with the air, the more likely to infect his "wild" yeast or bacteria, koi plentiful fly around.

Over the remaining five minutes to run the fermentation, pour out the solution of iodine. Who wants to - can rinse with boiled water, but in principle, and so will descend.

All.

Source: