745

As I did sundeck

Good day.

I offer you a small photo report on the construction of an open veranda and finishing Fasano in the country. Everything was done by 95% alone. Clean all time took about 10 days.

It will be 18 pictures with comments.

So there you go ...

For the device of the foundation under the porch digging a trench wide shovel. Further, it is gravel bed, which are stacked in one row splitternye blocks. Through holes in the blocks in the earth hammering reinforcement and welded to the horizontal reinforcement them along the whole length of blocks. After all this, we fill the holes in the concrete splitter and output have the foundation on which the tape is put outside veranda bearing beam.

The second supporting beam is fixed with anchor bolts to the foundation blocks of the house. Subsequently, it will be replaced by concrete slabs for greater strength support.

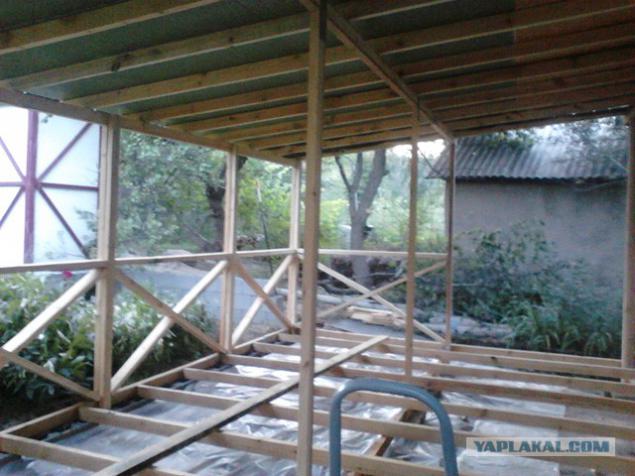

Logs are stacked on top of the beam to the inside to the outside and back to back beam (lie on the splitter) in increments of 60 cm. Fixing lag to the beams is carried out with the use of perforated steel-reinforced corners and screws. All use pine lumber 80h40.

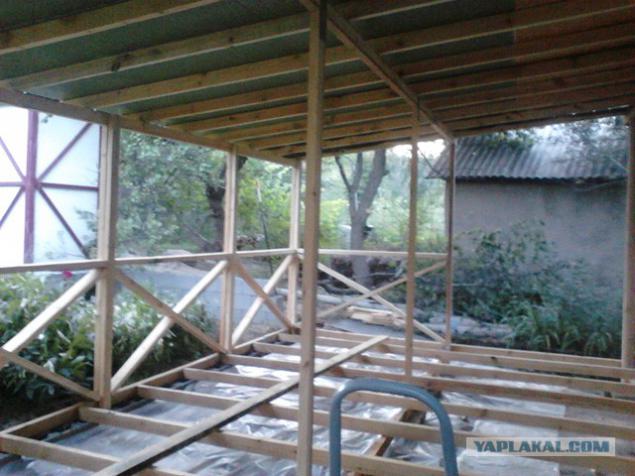

Further, the outer and inner beam set rack device for a roof. Fixed by means of perforated plates with screws. Laid at the front and two girders for the roof - external and internal, secured well plates.

On the girders laid rafters in increments of 50 cm. Is attached to the beams again reinforced corners and screws.

more ...

To strengthen the design add to the uprights another timber and fastening them together by pins with washers oversized, so as not to push the tree.

Adding intermediate beam and pillar to support the roof, put the rack less. Under lags well as adding a beam which supports the additional racks. Under the beams and concrete slabs set Splitters support.

Varganov beautiful railing and move on to the roofing works ...

As the base, under the roofing using existing grinbord OSB and 8 mm thick. Fasten the whole thing to the rafters with screws and using a cord mark the location of the rafters. Markings on the roof need to be seen where it was coming, because the body weight of quintal risks fall ...

more ...

Next, go to the installation of a soft roof - shingles. Fasten it to the base of special roofing galvanized nails. Long and tedious ... Adding drain.

more ...

Go to laying the floor. To use OSB flooring 20 mm. Subsequently, it put a thick bespodkladny commercial linoleum.

more ...

To protect from rain and other precipitation, rails sheets sewn inside LSU (steklomagnezit) 4 mm thick, thicker because it makes no sense. Prishurupivat they should be carefully, the material is quite fragile and may break if the twist. By the way the screws need to be a head or with Zenko pressshayboy (ugly but it sticks out). Self-tapping screws Drywall burst LSU once or twice, if they screwed close to the edge.

Posted in [mergetime] 1381993023 [/ mergetime]

All the wood is painted impregnated 3in1 color stained oak. Sheets LSU usual facade paint. Their great advantage is that being painted, they spit on all types of deposits, well, plus the low cost and ease of installation. The photo shows the way showers, made of the same sheet LSU true thickness of 6 mm. It should be 3 years, and watered on the outside and inside, and nothing he did not do it.

We are doing the wiring and light.

And finally stones facade of the second floor on the crate LSU sheets of plasterboard profiles. What a terrible, he was seen in the previous photo. Paint facade paint.

All is ready. Thank you for attention.

Source:

I offer you a small photo report on the construction of an open veranda and finishing Fasano in the country. Everything was done by 95% alone. Clean all time took about 10 days.

It will be 18 pictures with comments.

So there you go ...

For the device of the foundation under the porch digging a trench wide shovel. Further, it is gravel bed, which are stacked in one row splitternye blocks. Through holes in the blocks in the earth hammering reinforcement and welded to the horizontal reinforcement them along the whole length of blocks. After all this, we fill the holes in the concrete splitter and output have the foundation on which the tape is put outside veranda bearing beam.

The second supporting beam is fixed with anchor bolts to the foundation blocks of the house. Subsequently, it will be replaced by concrete slabs for greater strength support.

Logs are stacked on top of the beam to the inside to the outside and back to back beam (lie on the splitter) in increments of 60 cm. Fixing lag to the beams is carried out with the use of perforated steel-reinforced corners and screws. All use pine lumber 80h40.

Further, the outer and inner beam set rack device for a roof. Fixed by means of perforated plates with screws. Laid at the front and two girders for the roof - external and internal, secured well plates.

On the girders laid rafters in increments of 50 cm. Is attached to the beams again reinforced corners and screws.

more ...

To strengthen the design add to the uprights another timber and fastening them together by pins with washers oversized, so as not to push the tree.

Adding intermediate beam and pillar to support the roof, put the rack less. Under lags well as adding a beam which supports the additional racks. Under the beams and concrete slabs set Splitters support.

Varganov beautiful railing and move on to the roofing works ...

As the base, under the roofing using existing grinbord OSB and 8 mm thick. Fasten the whole thing to the rafters with screws and using a cord mark the location of the rafters. Markings on the roof need to be seen where it was coming, because the body weight of quintal risks fall ...

more ...

Next, go to the installation of a soft roof - shingles. Fasten it to the base of special roofing galvanized nails. Long and tedious ... Adding drain.

more ...

Go to laying the floor. To use OSB flooring 20 mm. Subsequently, it put a thick bespodkladny commercial linoleum.

more ...

To protect from rain and other precipitation, rails sheets sewn inside LSU (steklomagnezit) 4 mm thick, thicker because it makes no sense. Prishurupivat they should be carefully, the material is quite fragile and may break if the twist. By the way the screws need to be a head or with Zenko pressshayboy (ugly but it sticks out). Self-tapping screws Drywall burst LSU once or twice, if they screwed close to the edge.

Posted in [mergetime] 1381993023 [/ mergetime]

All the wood is painted impregnated 3in1 color stained oak. Sheets LSU usual facade paint. Their great advantage is that being painted, they spit on all types of deposits, well, plus the low cost and ease of installation. The photo shows the way showers, made of the same sheet LSU true thickness of 6 mm. It should be 3 years, and watered on the outside and inside, and nothing he did not do it.

We are doing the wiring and light.

And finally stones facade of the second floor on the crate LSU sheets of plasterboard profiles. What a terrible, he was seen in the previous photo. Paint facade paint.

All is ready. Thank you for attention.

Source: