1381

Jackknife. Instructions for manufacturing

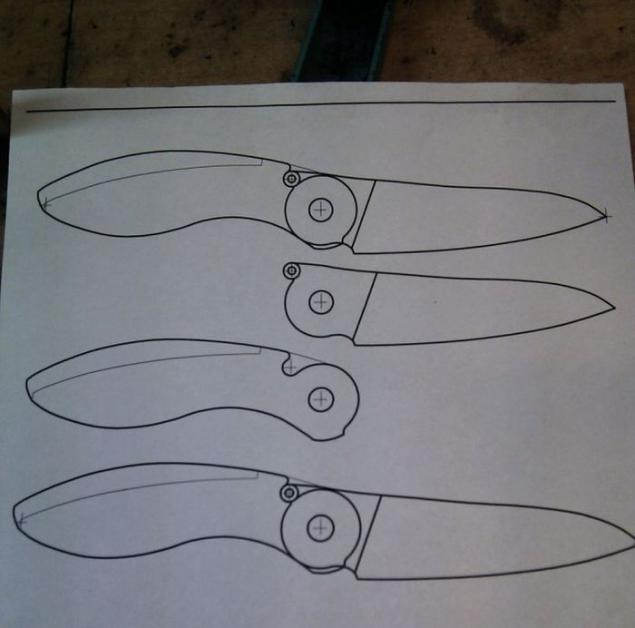

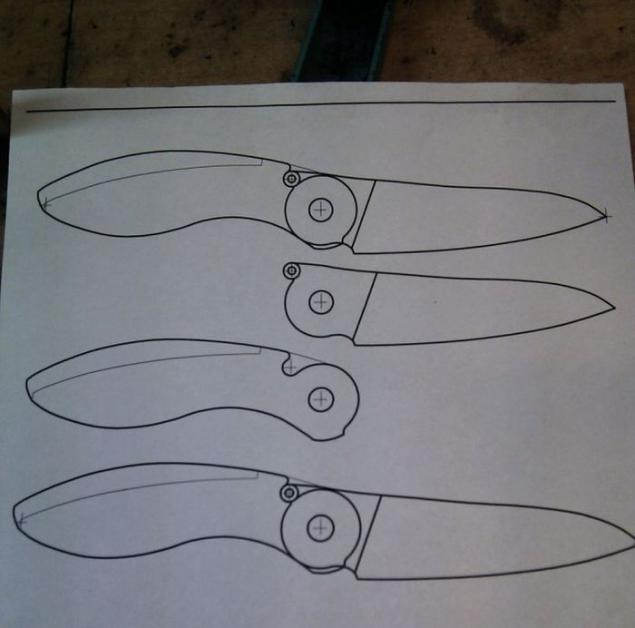

For the production of the knife need material: damask production blacksmith Chelyabinsk Andrei Cherepanov, titanium plates on, German carbon, stainless steel. hardware. Feature of the project on the computer, working through the main sites - the castle, the holes and sampling.

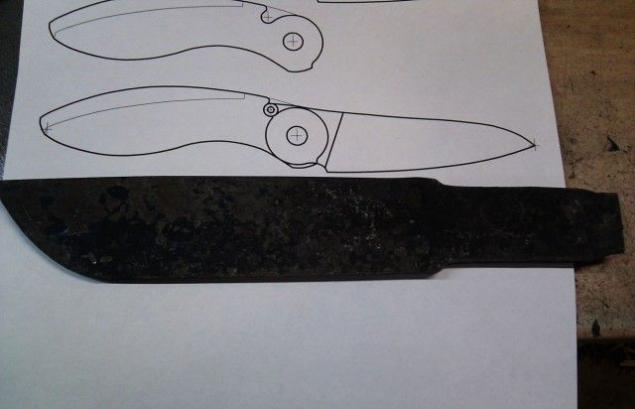

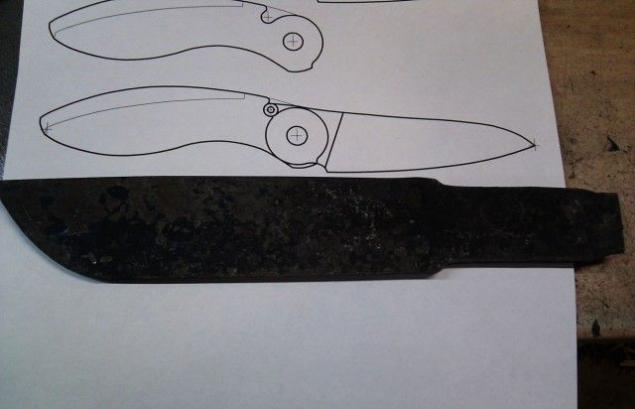

We are looking in the bins for zagotovochku blade - damask

Grinder was equal to the workpiece. The tape is the rough, ceramic grain.

Approximately vchernovuyu cut blade

Dub, picking up the loop and being careful not to burn the

Mark up the knife slips. Titanium plate

We cut titanium. Fun iskriiiitsyayayaya under Bulgarian titaaaan! (song helps to not swearing)

All the rage and cut ...

Roughly cut at last ...

About stripped at Grinder. In the process again cheerful sparks from titanium ...

Drill Hole Wizard

All drilling and drill ...

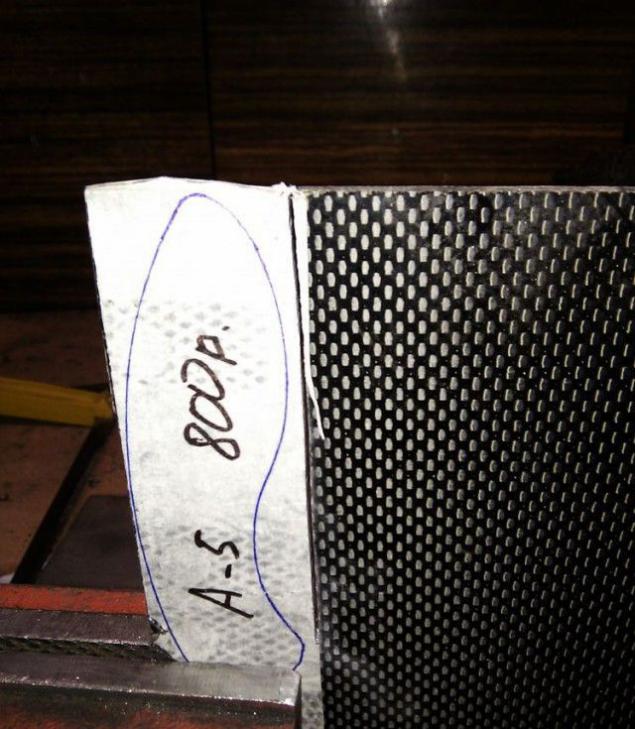

Take the carbon out of the bins and ruthlessly his sawing. Do not forget about TB and PPE, and it will itch like mangy pig. And breathe this dust - all nifiga useful ...

Doom, cut ...

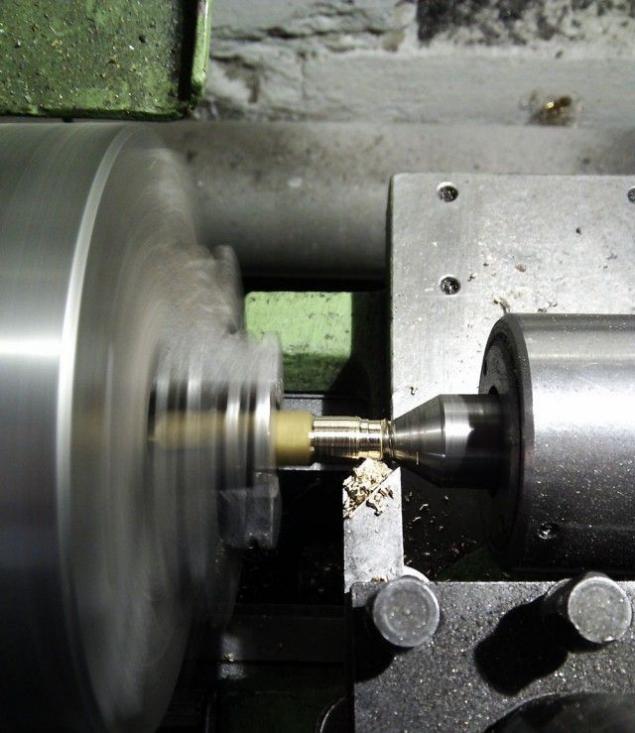

Let us locking peg.

Make the pin locking

Make a hole where the pin comes and fixes the blade in the open sosotoyanii.

The strip of carbon is necessary to choose a niche for the pin.

Almost ready Circuits

Output

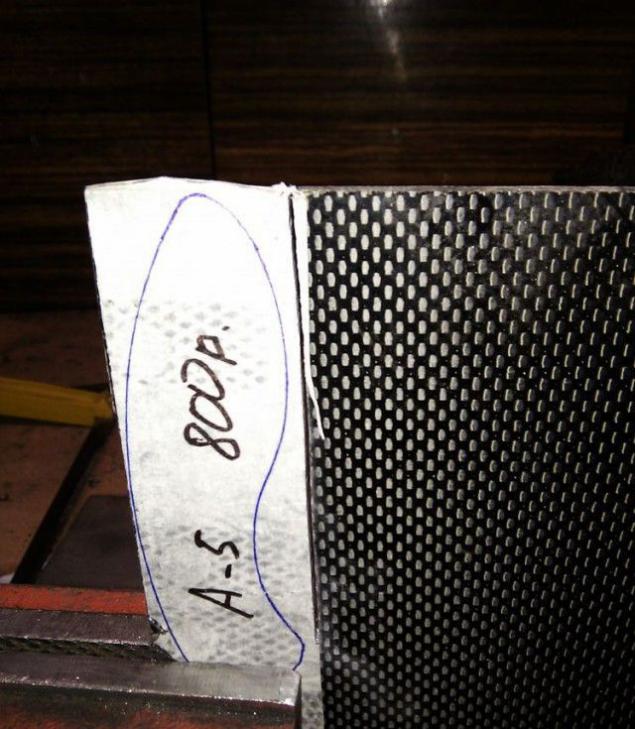

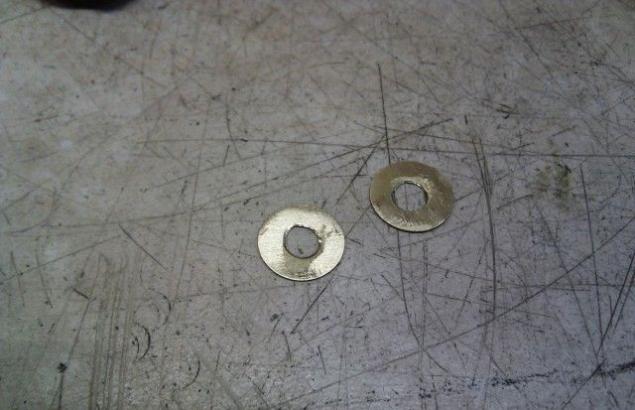

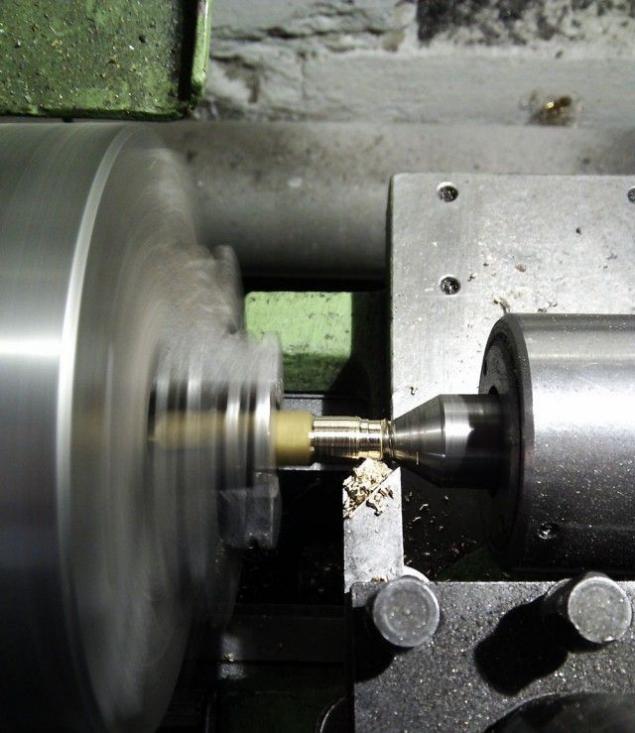

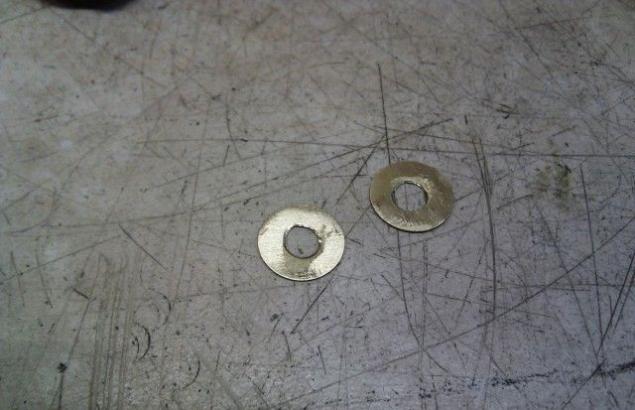

Cooking rough washers for assembly of the knife. Then I do the normal.

Drills, give shape to ...

Mark up the outline of the spacer on a thick titanium.

Roughly case if you get a spacer. Very rude ...

They collected a spacer

Stripped spacer with the handle assembly

The spacer plates and drill the holes where necessary, threaded M3

Cut through the liner. No laser - only Dremel with a cutting circle. Only hardcore!

Fuuu, cut ...

Make a weakening groove to easily folded liner.

Mark pyatochku blade under lock and key. Already normal washers made ...

The intermediate assembly

It works because, the infection !!!

Extracted from the tiny bearing balls.

Press-fit ball in the liner

Press-fit ball in the liner. Do not forget to enclose a piece of the ball bystroreza and zapressuem in the jaws, rather than titanium ...

Begins to form a wedge. Making descents (Hussars, be silent !!!) Nozhedely understand. We use adjust.

Slowly remove the meat.

And sensitive. So, slowly, with ohladzheniem.

Capsized, and a second side exposed flog.

Then flog ...

The assembly, fitting

Damascus stsuko, beautiful, but to see it, you need to poison.

Take the blade, degrease it thoroughly, cover with nail polish places that do not have a mordant (where the puck)

Prepare the sauce - a solution of ferric chloride.

Degreasing spirtikom

Dipped in sauce, used, pulled out, washed with a little sandpaper 2000 walked

Repeat several times to deeper travanut

All etched ... put aside and go to Latro - hello labrantam from my school - fishschiki office. With them, I steal this wonderful machine for more than 15 years ago.

Plus we clean to connect it to the workpiece, and a minus - a cotton swab to push it through the wire to the wool. Vata moisten the electrolyte. Caution Acid !!!

Latro exhibited at 25 volts and gently mazyukaem. The process is called - anodizing. Googling, who are interested.

That's what happens.

Reduces up to 15 volts and taught a beautiful golden hue. Anodizing spacer.

Grease build-

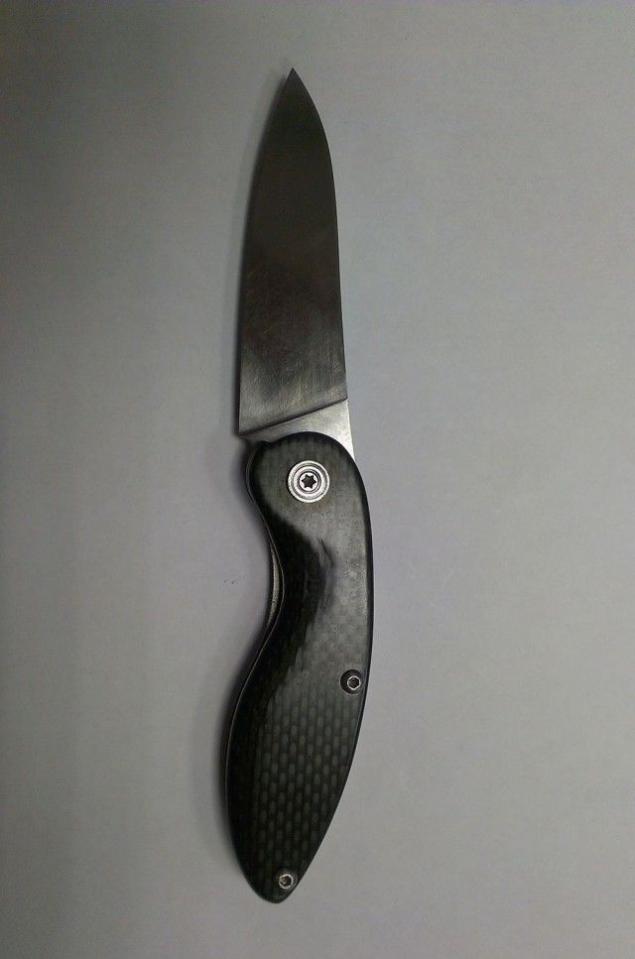

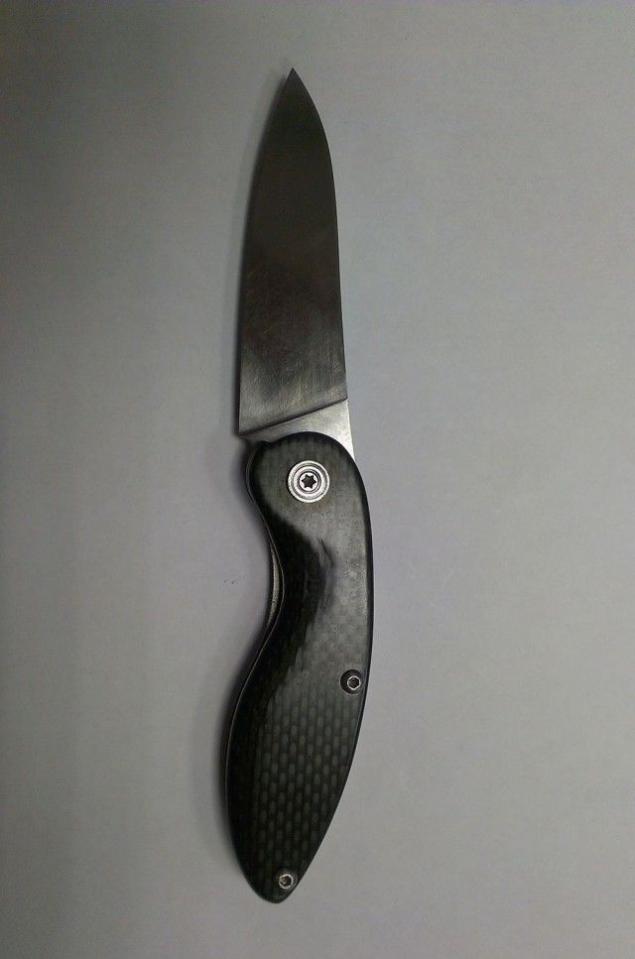

Well, not handsome ?!

Cool, vert, admire. Photos do not convey the true colors. They are juicier. Believe me. Beauty carbon also in the pictures not the same. It is deep.

Admiring

Ready

All sharpen to adapt and to his pocket.

Author: nikifor66

--img76--

Source:

We are looking in the bins for zagotovochku blade - damask

Grinder was equal to the workpiece. The tape is the rough, ceramic grain.

Approximately vchernovuyu cut blade

Dub, picking up the loop and being careful not to burn the

Mark up the knife slips. Titanium plate

We cut titanium. Fun iskriiiitsyayayaya under Bulgarian titaaaan! (song helps to not swearing)

All the rage and cut ...

Roughly cut at last ...

About stripped at Grinder. In the process again cheerful sparks from titanium ...

Drill Hole Wizard

All drilling and drill ...

Take the carbon out of the bins and ruthlessly his sawing. Do not forget about TB and PPE, and it will itch like mangy pig. And breathe this dust - all nifiga useful ...

Doom, cut ...

Let us locking peg.

Make the pin locking

Make a hole where the pin comes and fixes the blade in the open sosotoyanii.

The strip of carbon is necessary to choose a niche for the pin.

Almost ready Circuits

Output

Cooking rough washers for assembly of the knife. Then I do the normal.

Drills, give shape to ...

Mark up the outline of the spacer on a thick titanium.

Roughly case if you get a spacer. Very rude ...

They collected a spacer

Stripped spacer with the handle assembly

The spacer plates and drill the holes where necessary, threaded M3

Cut through the liner. No laser - only Dremel with a cutting circle. Only hardcore!

Fuuu, cut ...

Make a weakening groove to easily folded liner.

Mark pyatochku blade under lock and key. Already normal washers made ...

The intermediate assembly

It works because, the infection !!!

Extracted from the tiny bearing balls.

Press-fit ball in the liner

Press-fit ball in the liner. Do not forget to enclose a piece of the ball bystroreza and zapressuem in the jaws, rather than titanium ...

Begins to form a wedge. Making descents (Hussars, be silent !!!) Nozhedely understand. We use adjust.

Slowly remove the meat.

And sensitive. So, slowly, with ohladzheniem.

Capsized, and a second side exposed flog.

Then flog ...

The assembly, fitting

Damascus stsuko, beautiful, but to see it, you need to poison.

Take the blade, degrease it thoroughly, cover with nail polish places that do not have a mordant (where the puck)

Prepare the sauce - a solution of ferric chloride.

Degreasing spirtikom

Dipped in sauce, used, pulled out, washed with a little sandpaper 2000 walked

Repeat several times to deeper travanut

All etched ... put aside and go to Latro - hello labrantam from my school - fishschiki office. With them, I steal this wonderful machine for more than 15 years ago.

Plus we clean to connect it to the workpiece, and a minus - a cotton swab to push it through the wire to the wool. Vata moisten the electrolyte. Caution Acid !!!

Latro exhibited at 25 volts and gently mazyukaem. The process is called - anodizing. Googling, who are interested.

That's what happens.

Reduces up to 15 volts and taught a beautiful golden hue. Anodizing spacer.

Grease build-

Well, not handsome ?!

Cool, vert, admire. Photos do not convey the true colors. They are juicier. Believe me. Beauty carbon also in the pictures not the same. It is deep.

Admiring

Ready

All sharpen to adapt and to his pocket.

Author: nikifor66

--img76--

Source: