2162

How do Swiss Army Knives

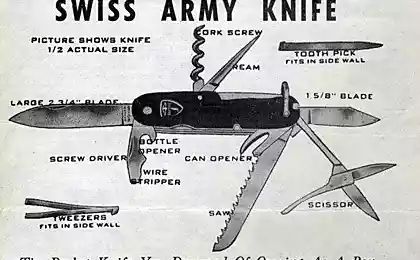

The Swiss Army knife - a multi-function folding knife, which is equipped with a blade and a number of additional tools, such as screwdrivers, bottle opener, corkscrew and so on. In the inoperative position the tools are inside the handle of the knife and removed the internal rotation around the hinge.

What feelings you will experience if you find yourself suddenly in a large room filled with dozens and dozens of containers of different sizes, which contain the individual components that are part of Swiss army knives?

As part of Road Trip 2011, reporter Agency CNET Daniel Terdiman got a unique opportunity to visit the plant, which is located in a small town in central Switzerland, where the company «Victorinox» has been producing world famous knives since 1891 - even before it became known this name.

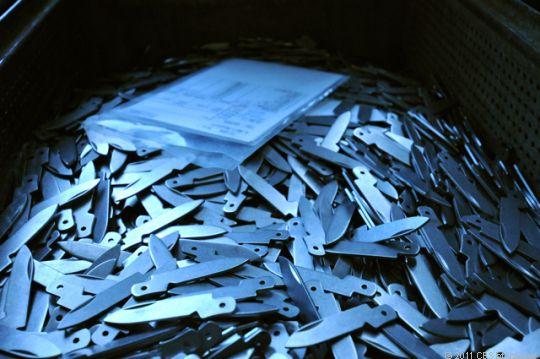

1. Today, the company produces more than a million knives a year, about 350 different models.

The photo - a container with tweezers, which is a mandatory part of almost each of these models.

2. Before you - one of the original models of Swiss Army knife, made back in 1891. It was then that the company owner Carl Elzener decided to equip the Swiss army knives of manufacture. Although he did not have time even now well-known logo and the company Elzenera has not carried the name «Victorinox» (she was a few years later, after the mother Elzenera Victoria, and because the French word «inox», meaning "stainless steel ") - this knife is not the slightest difficulty in recognizing the direct predecessor of that almost every one of us has today. The Swiss government still buys knives for all his soldiers just at this company. Since 1891, there was a total of eight different models for the Swiss military, the last of which came in 2008.

3. At the bottom of the main blade of the Original Swiss Army Knife can see the logo of the company Karl Elzenera - before it was called «Victorinox», it bore the name of its owner.

4. Elzener dreamed to make a special official Swiss Army knife for officers, and even started production of a new product. But the Swiss government decided that officers will still use the ordinary soldier army knife, which they have received, when only joined the army, and decided not to enter into another contract Elzenerom. However, the company has been producing knives officer for many years. So it looks model 1931.

5. In the factory of the company «Victorinox» in the city of Ubach box ready army knives waiting for packing and shipping.

6. workers not to cut yourself, getting out of the container has just descended from the conveyor blade is used for this special grip.

7. This device guides the strip of aluminum stamping machines for the production of delimiters for the various tools that are component parts of the Swiss army knife. These delimiters are made of aluminum, so as not to add to the finished knife overweight. Themselves constituent parts of the knife is usually made of stainless steel.

8. Punching machines used in the manufacture of more than eight hundred pieces, which may be parts of the Swiss army knife of the company «Victorinox».

9. In this photo you can see a gradual evolution of the Swiss army knife, starting with the original model of 1891 in the lower right corner. In the upper right corner is the latest model released in 2008. The previous model, made in 1968, is located in the upper left corner. Officer's Knife 1931 release to be in the bottom left corner. And in the center is one of the latest models with the red handle.

10. In stock are dozens of containers in the details for Swiss army knives. This, for example, key chains.

11. The factories of Swiss army knives «Victorinox» puts the sheets of stainless steel in the stamping machine which manufactures blades.

12. Pictured worker puts the workpiece blade small standard Swiss Army knives on the conveyor so that it has sent them into a furnace in which they are exposed to temperatures of 1050 degrees Celsius to harden the stainless steel, that makes blades suitable for use for decades, not allowing them to break down almost immediately.

13. Once they come out of the stamping machines, special device shakes the container with the blades of knives for the Swiss to have fallen off the extra bits of metal that might accidentally hit the surface of the blades.

14..Poverhnost blades emanating from the stamping machine, is rough and uneven. Therefore, they are placed in these special machines, which with the help of artificial ceramic chips and water polished edge for a long time, five to eight hours. Thereafter, the blade surface becomes perfectly smooth.

15. A container with a corkscrew, are part of Swiss army knife.

16. The container with toothpicks, are part of Swiss army knife.

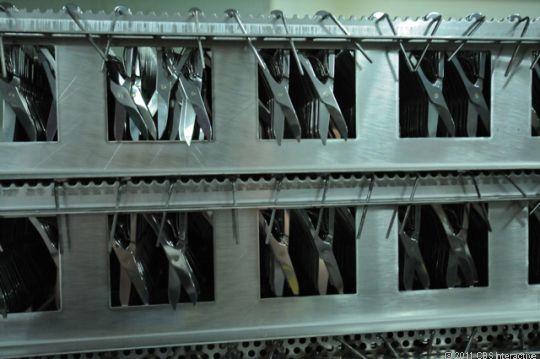

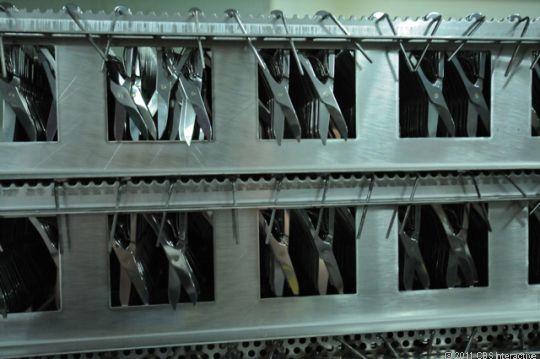

17. The halves of scissors, outside the traditional Swiss army knife.

18. And here's the scissors ready. Soon they will be sent to the assembly plant, where they become part of Swiss army knives.

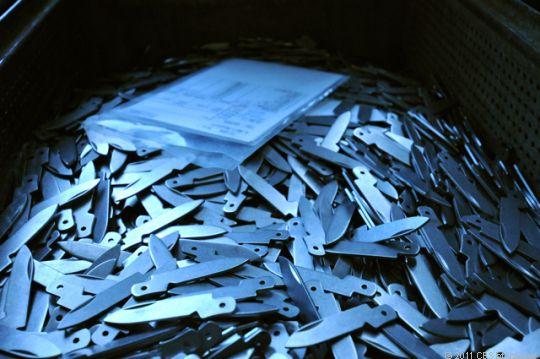

19. Boxes with small blades for the traditional Swiss army knives.

20. And this - with ready-made handles racks for Swiss army knives. They can be in several colors, including the traditional blue and red.

21. Bookcase with red handles Swiss army knives.

22. The box is almost ready with a Swiss Army knife. They lack the currently single - handle.

23. Conveyor handles for Swiss army knives. Workers placed the handle and the blade with a set of tools in a special compression machine. They handle pressure is attached to the main body, and eventually turns the knife almost ready - well, except for a pair of tweezers, toothpick and key ring.

24. In this picture factory worker «Victorinox» in the workplace collects a Swiss Army knife - she takes part in different boxes and quickly joins them together.

25.

26. Working for attaching handles to the Swiss army knives.

27. In this photo we see a container with tweezers and toothpicks facing jobs. Task workers - quickly attached tweezers and toothpick in coming to them on a conveyor belt knives.

28. The Working toothpick to attach a Swiss Army knife.

29. A spokesman for the factory «Victorinox» Urs Wyss shows the blank blade Swiss Army knives.

30. pliers that are part of Swiss army knife.

31. Box with aluminum clamps. They fix the main blade Swiss Army knife when it is open.

32. The container with the main blade of the traditional Swiss army knife.

33. Box with unsharpened blades Swiss army knife.

34. In addition to direct production of Swiss Army knives, the company «Victorinox» for a small fee offers another, truly invaluable service - repair or replacement of any knife, manufactured by the company's history. In the picture: This knife, made in 1931, refused the spring responsible for the action of the main blade.

35. Because of the popularity, which has always enjoyed the Swiss Army knife of the company «Victorinox», the markets comes an incredible number of cheap and low-quality fakes, manufactured mainly in China.

36. Handles small Swiss army knives.

37. In this photo Working check every detail of a Swiss army knife. It uses a special fabric, so as not to injure the hands and the tool that helps you test each knife and all its constituent instruments.

38. One of the details of the Swiss army knife.

What feelings you will experience if you find yourself suddenly in a large room filled with dozens and dozens of containers of different sizes, which contain the individual components that are part of Swiss army knives?

As part of Road Trip 2011, reporter Agency CNET Daniel Terdiman got a unique opportunity to visit the plant, which is located in a small town in central Switzerland, where the company «Victorinox» has been producing world famous knives since 1891 - even before it became known this name.

1. Today, the company produces more than a million knives a year, about 350 different models.

The photo - a container with tweezers, which is a mandatory part of almost each of these models.

2. Before you - one of the original models of Swiss Army knife, made back in 1891. It was then that the company owner Carl Elzener decided to equip the Swiss army knives of manufacture. Although he did not have time even now well-known logo and the company Elzenera has not carried the name «Victorinox» (she was a few years later, after the mother Elzenera Victoria, and because the French word «inox», meaning "stainless steel ") - this knife is not the slightest difficulty in recognizing the direct predecessor of that almost every one of us has today. The Swiss government still buys knives for all his soldiers just at this company. Since 1891, there was a total of eight different models for the Swiss military, the last of which came in 2008.

3. At the bottom of the main blade of the Original Swiss Army Knife can see the logo of the company Karl Elzenera - before it was called «Victorinox», it bore the name of its owner.

4. Elzener dreamed to make a special official Swiss Army knife for officers, and even started production of a new product. But the Swiss government decided that officers will still use the ordinary soldier army knife, which they have received, when only joined the army, and decided not to enter into another contract Elzenerom. However, the company has been producing knives officer for many years. So it looks model 1931.

5. In the factory of the company «Victorinox» in the city of Ubach box ready army knives waiting for packing and shipping.

6. workers not to cut yourself, getting out of the container has just descended from the conveyor blade is used for this special grip.

7. This device guides the strip of aluminum stamping machines for the production of delimiters for the various tools that are component parts of the Swiss army knife. These delimiters are made of aluminum, so as not to add to the finished knife overweight. Themselves constituent parts of the knife is usually made of stainless steel.

8. Punching machines used in the manufacture of more than eight hundred pieces, which may be parts of the Swiss army knife of the company «Victorinox».

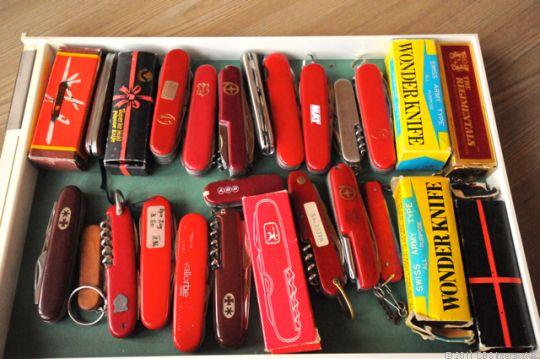

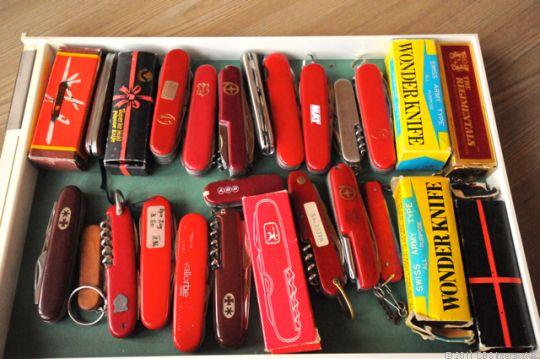

9. In this photo you can see a gradual evolution of the Swiss army knife, starting with the original model of 1891 in the lower right corner. In the upper right corner is the latest model released in 2008. The previous model, made in 1968, is located in the upper left corner. Officer's Knife 1931 release to be in the bottom left corner. And in the center is one of the latest models with the red handle.

10. In stock are dozens of containers in the details for Swiss army knives. This, for example, key chains.

11. The factories of Swiss army knives «Victorinox» puts the sheets of stainless steel in the stamping machine which manufactures blades.

12. Pictured worker puts the workpiece blade small standard Swiss Army knives on the conveyor so that it has sent them into a furnace in which they are exposed to temperatures of 1050 degrees Celsius to harden the stainless steel, that makes blades suitable for use for decades, not allowing them to break down almost immediately.

13. Once they come out of the stamping machines, special device shakes the container with the blades of knives for the Swiss to have fallen off the extra bits of metal that might accidentally hit the surface of the blades.

14..Poverhnost blades emanating from the stamping machine, is rough and uneven. Therefore, they are placed in these special machines, which with the help of artificial ceramic chips and water polished edge for a long time, five to eight hours. Thereafter, the blade surface becomes perfectly smooth.

15. A container with a corkscrew, are part of Swiss army knife.

16. The container with toothpicks, are part of Swiss army knife.

17. The halves of scissors, outside the traditional Swiss army knife.

18. And here's the scissors ready. Soon they will be sent to the assembly plant, where they become part of Swiss army knives.

19. Boxes with small blades for the traditional Swiss army knives.

20. And this - with ready-made handles racks for Swiss army knives. They can be in several colors, including the traditional blue and red.

21. Bookcase with red handles Swiss army knives.

22. The box is almost ready with a Swiss Army knife. They lack the currently single - handle.

23. Conveyor handles for Swiss army knives. Workers placed the handle and the blade with a set of tools in a special compression machine. They handle pressure is attached to the main body, and eventually turns the knife almost ready - well, except for a pair of tweezers, toothpick and key ring.

24. In this picture factory worker «Victorinox» in the workplace collects a Swiss Army knife - she takes part in different boxes and quickly joins them together.

25.

26. Working for attaching handles to the Swiss army knives.

27. In this photo we see a container with tweezers and toothpicks facing jobs. Task workers - quickly attached tweezers and toothpick in coming to them on a conveyor belt knives.

28. The Working toothpick to attach a Swiss Army knife.

29. A spokesman for the factory «Victorinox» Urs Wyss shows the blank blade Swiss Army knives.

30. pliers that are part of Swiss army knife.

31. Box with aluminum clamps. They fix the main blade Swiss Army knife when it is open.

32. The container with the main blade of the traditional Swiss army knife.

33. Box with unsharpened blades Swiss army knife.

34. In addition to direct production of Swiss Army knives, the company «Victorinox» for a small fee offers another, truly invaluable service - repair or replacement of any knife, manufactured by the company's history. In the picture: This knife, made in 1931, refused the spring responsible for the action of the main blade.

35. Because of the popularity, which has always enjoyed the Swiss Army knife of the company «Victorinox», the markets comes an incredible number of cheap and low-quality fakes, manufactured mainly in China.

36. Handles small Swiss army knives.

37. In this photo Working check every detail of a Swiss army knife. It uses a special fabric, so as not to injure the hands and the tool that helps you test each knife and all its constituent instruments.

38. One of the details of the Swiss army knife.