1530

Knives World 2

66 photos.

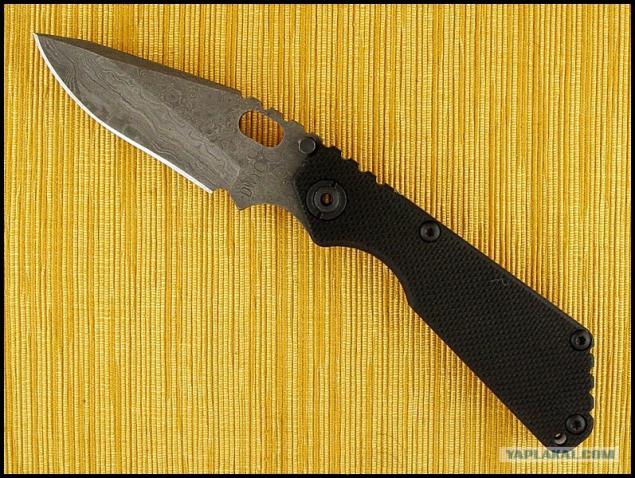

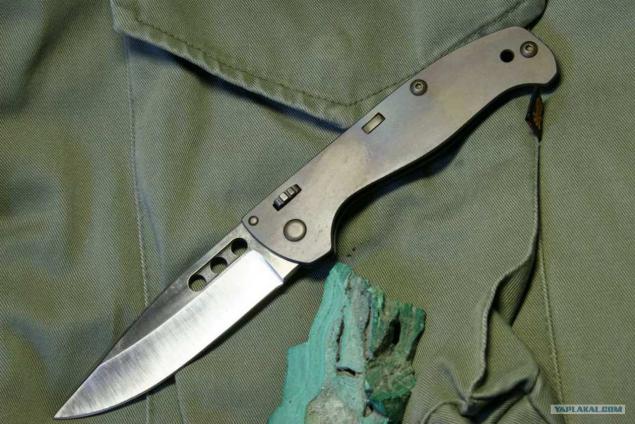

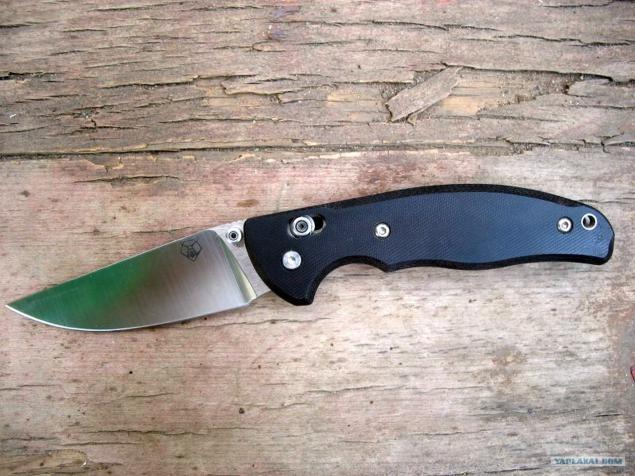

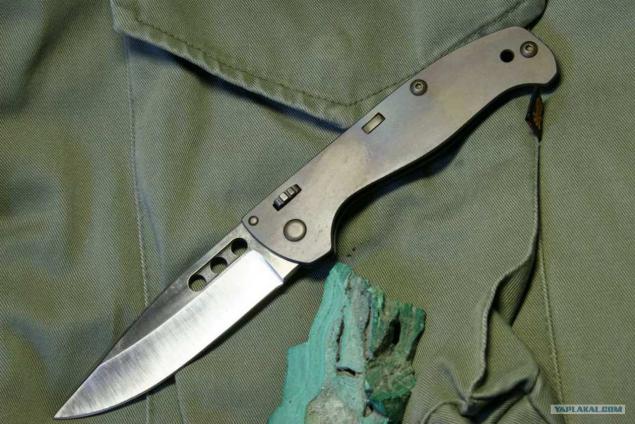

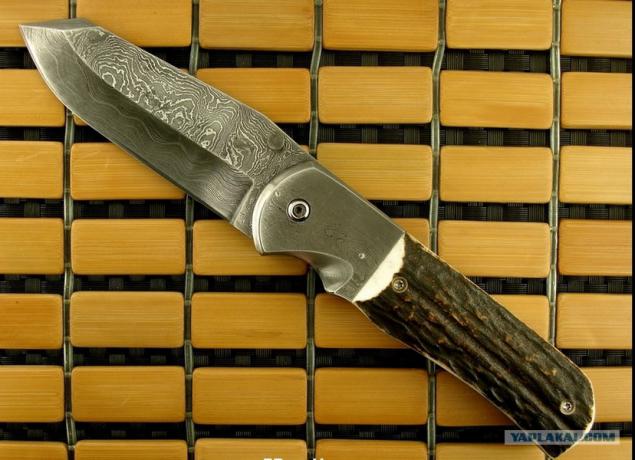

Duane Dwyer

Duane Dwyer - American master nayfmeyker. He made a career in the military, he served in the US Army special units. Since 1994, together with a friend and brother-soldier Mick Strider Dwayne developed tactical knives to arm the US Army and Navy.

Releasing several successful models, Mick Doohan and decided to make nayfmeking their profession. Discharged from the army in 1997 in San Marcos, California, they founded the company Strider Knives.

However, in addition to working in Strider Knives Duane Dwyer actively cooperates with the leading manufacturers of knives and manufactures products under its own name.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

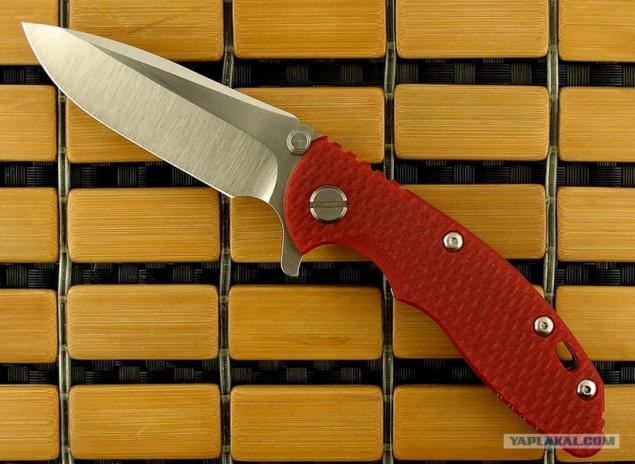

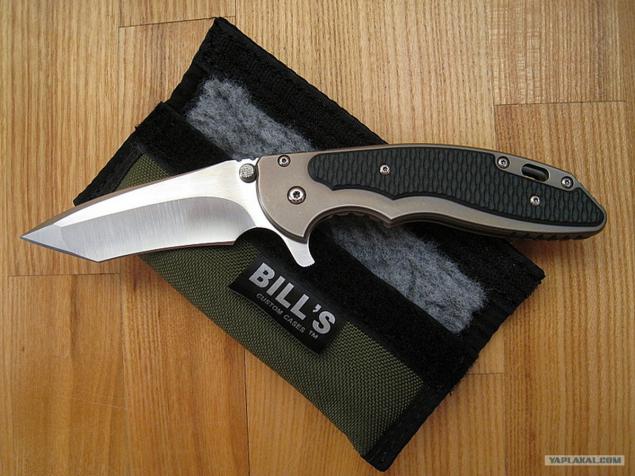

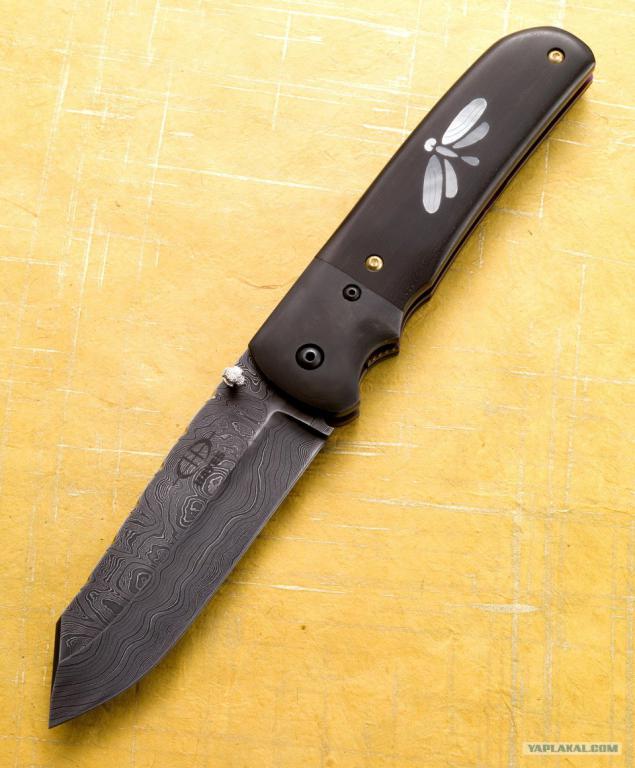

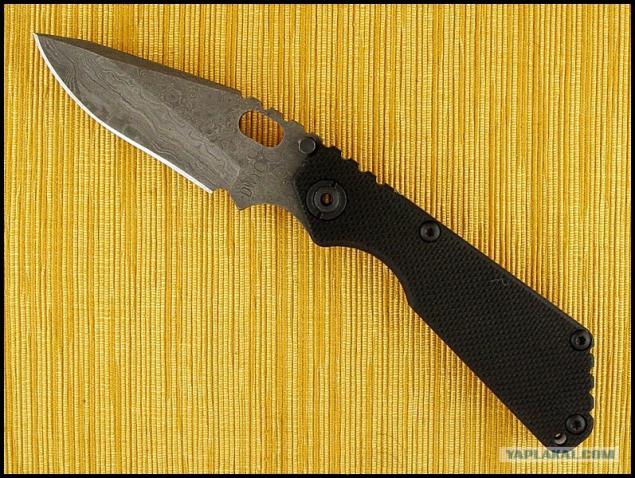

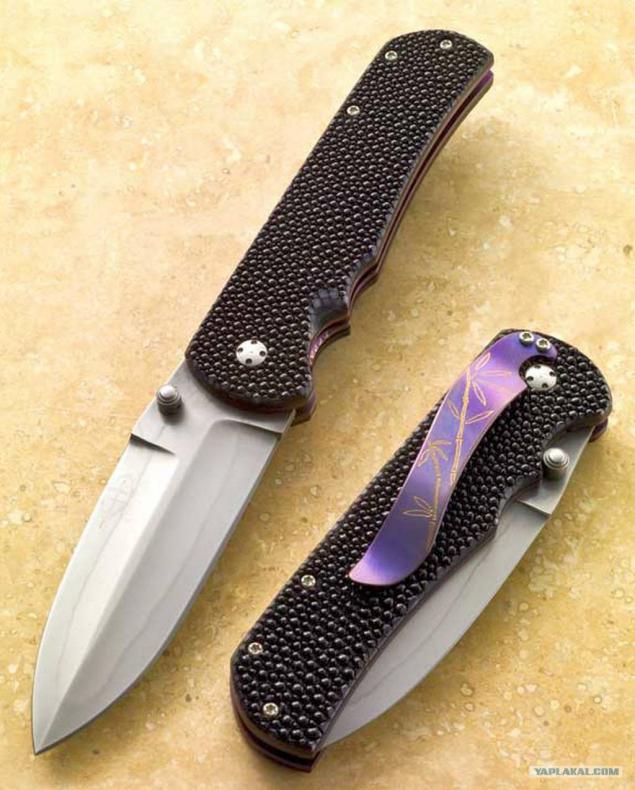

Rick Hinderer

For more than 20 years, Rick Hinderer is engaged in manufacturing of products for personal safety. He owns the brand Rick Hinderer Knives, specializing in the production of exclusive knives and tactical pens.

Early in his career nayfmeykera when Rick was just looking for his style and took the first steps in business, it is made the traditional hunting and tourist knives, and sold them in the vicinity of arms fairs.

Master tried to restore the forgotten art of old blacksmiths and gunsmiths. During this period, his mentor was Hugh Bartug, interested young author Damascus blade manufacturing technology. On a perfect mastery of this technique Rick Hinderer ushlo13 years.

Of particular importance for the master Hinderer always had communication with customers. It occupied and delighted stories about how acquired Rick knife helps them in life, and how they are satisfied with the purchase.

To do really flawless functionality products, Rick stopped playing "artistic" knives. He narrowed his field of activity, choose to specialize their brand manufacturer of knives for hunters and travelers.

In the same period, Rick Hinderer began collaborating with many renowned companies. For Gerber, he developed the famous hunting model Gamepro, for Benchmade - line High Country Hunter. But the master did not forget about working on innovation. Hinderer authored Lockbar Stabilizer for folding knives. With the permission of his Rica design using the best cutlery firms worldwide.

On his achievements author says modestly: "I'm just beginning ....".

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

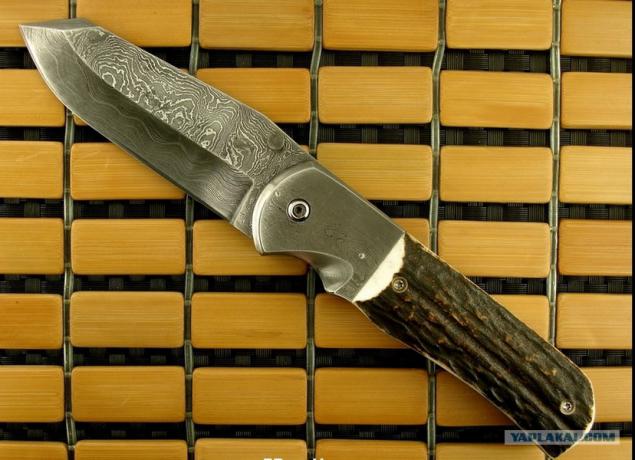

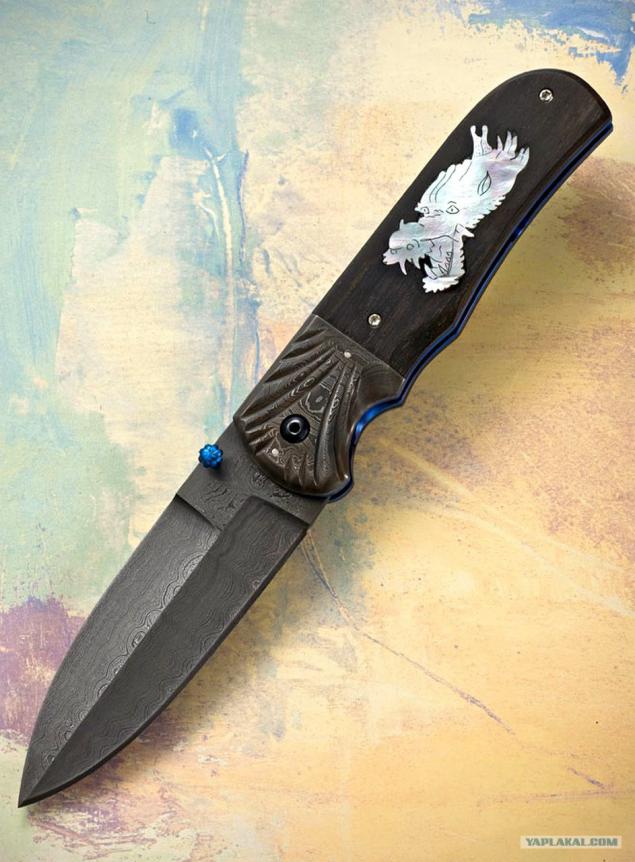

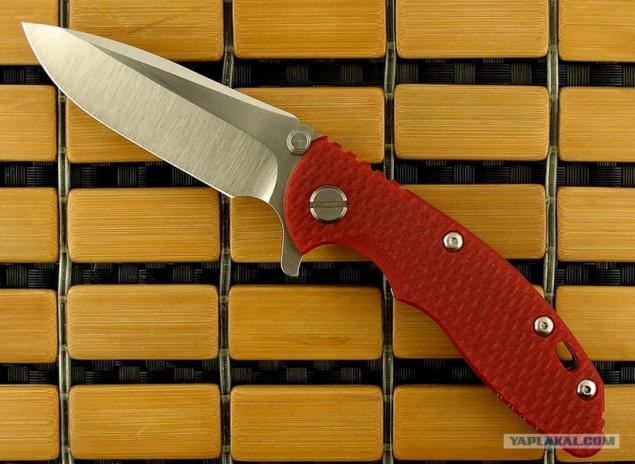

The company «SHOKUROFF» was founded in 1997 gunsmith Alexei Shokurov.

The company produces small batches and custom high-quality folding, awkward, author handmade knives of Damascus, stainless steel and wave.

Lineup includes 25 certified samples. You can see the works of the knives in the catalog, which shows the model description and photo. There you can buy ready-made knife or order the production of the knife for yourself or as a gift through our online system.

In the production of knives used materials:

Stainless steel 95X18 and 110h18;

Damascus steel layers 420-480;

Wave steel;

"Three-layer" steel.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

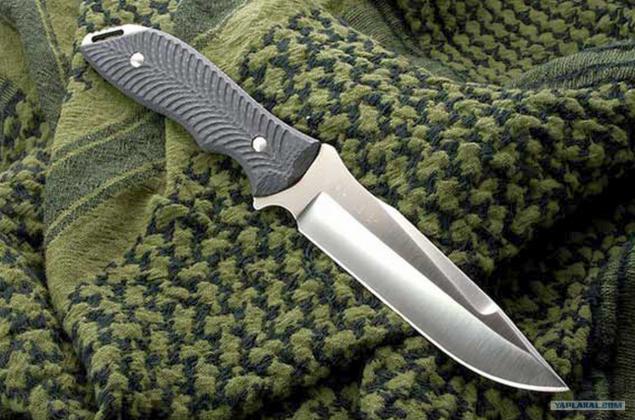

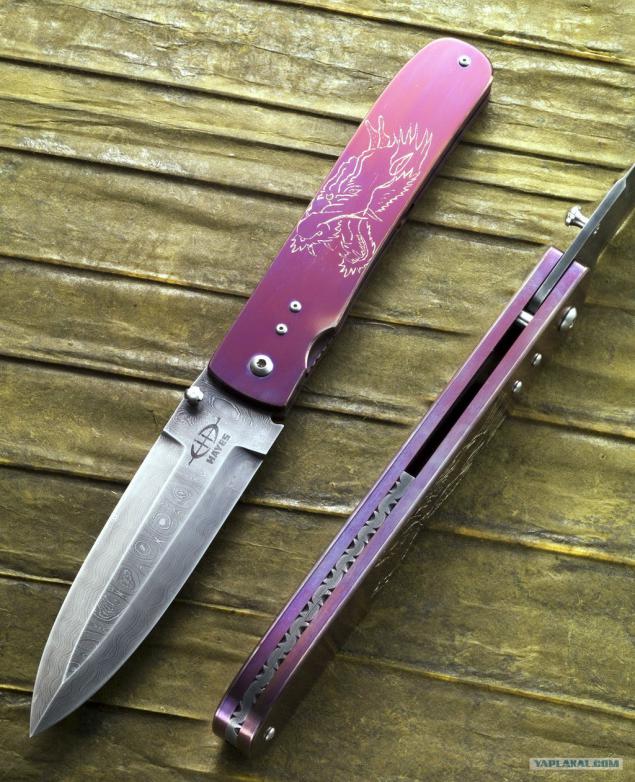

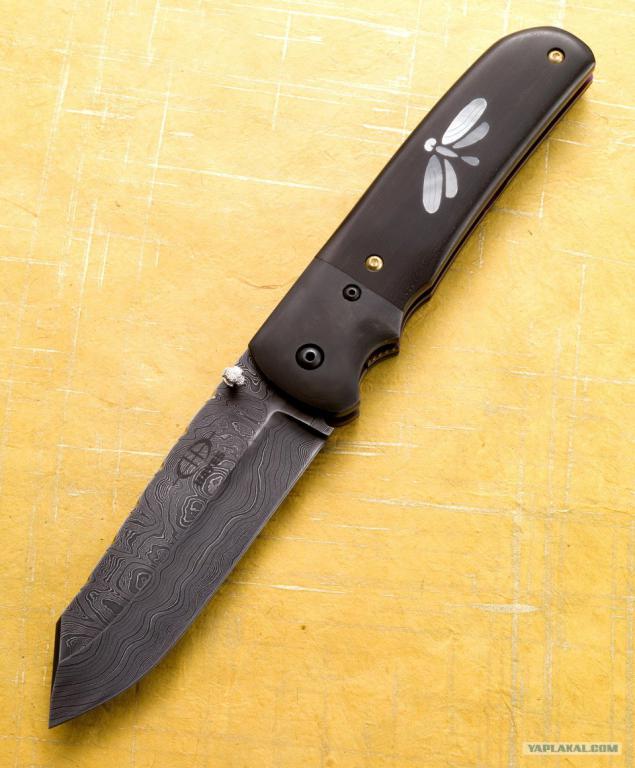

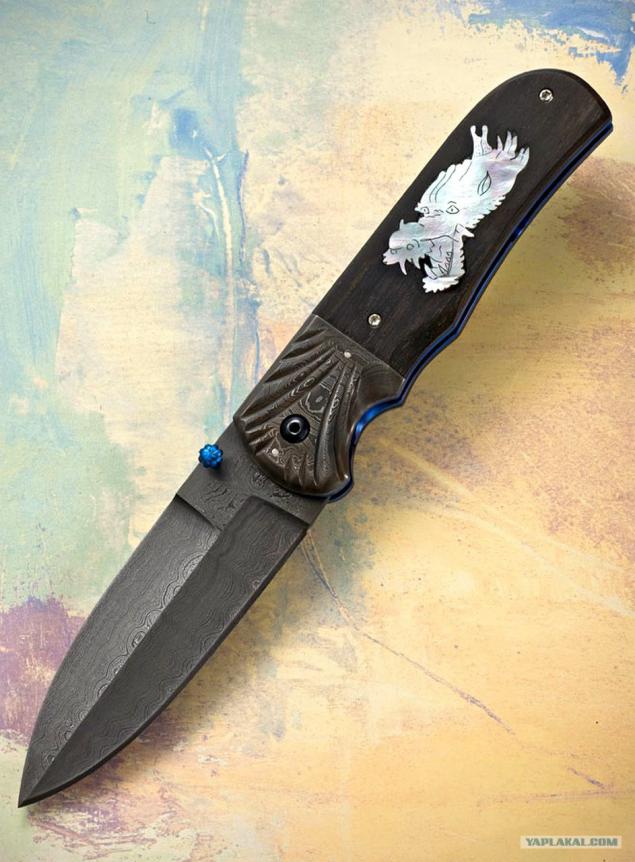

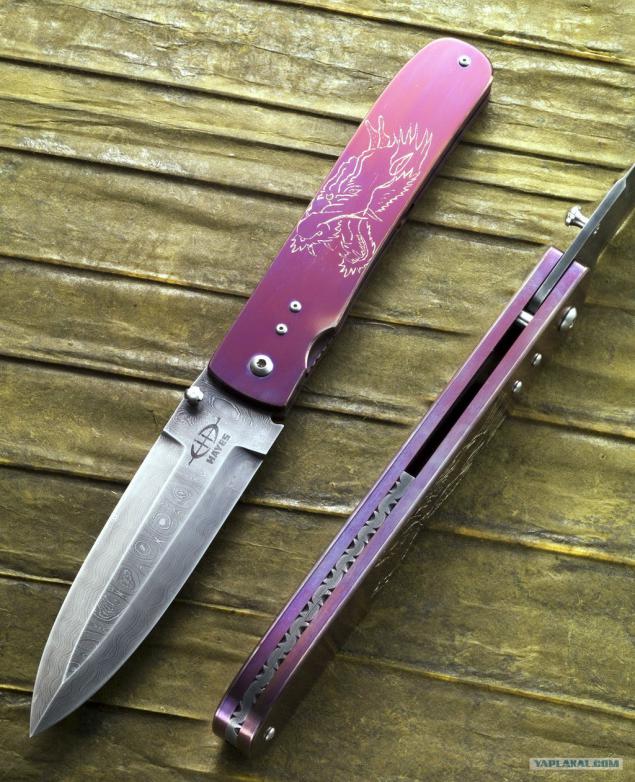

Wally Hayes

Wally Hayes (Wally Hayes) wonderful, talented nayfmeyker. His works capture the imagination of even the most experienced nozhevikov.

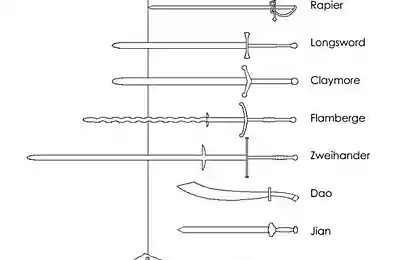

Wally was born in 1963. From early childhood he was seriously impressed with knives and swords.

The general experience of his work as nayfmeykera is more than twenty years. During this time, his best work has repeatedly been featured in various television programs, as well as published in magazines for fans of knives.

To date, Wally Hayes produces not only tactical but also highly knives. The author also indifferent and cutlery Japanese-style and a lot of them in his collection. By the way, all the knives, which makes Wally Hayes - unique in its kind, as the author makes them unique. At some orders, in particular, for the manufacture of swords, the master may take several years!

In the master plans for the future - to expand their skills in jewelry, as well as carving and engraving.

At the moment, Wally Hayes lives and works in his homeland - in Canada.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

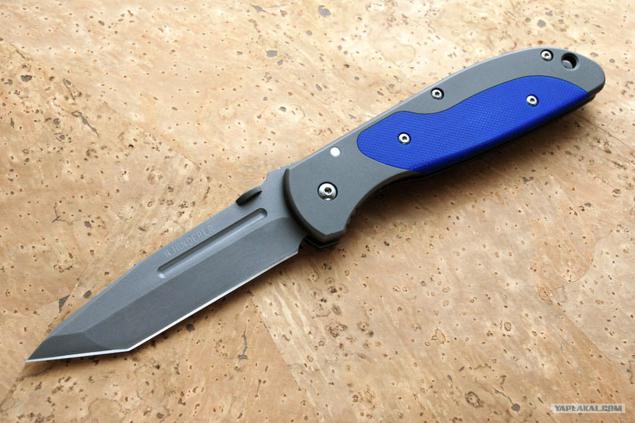

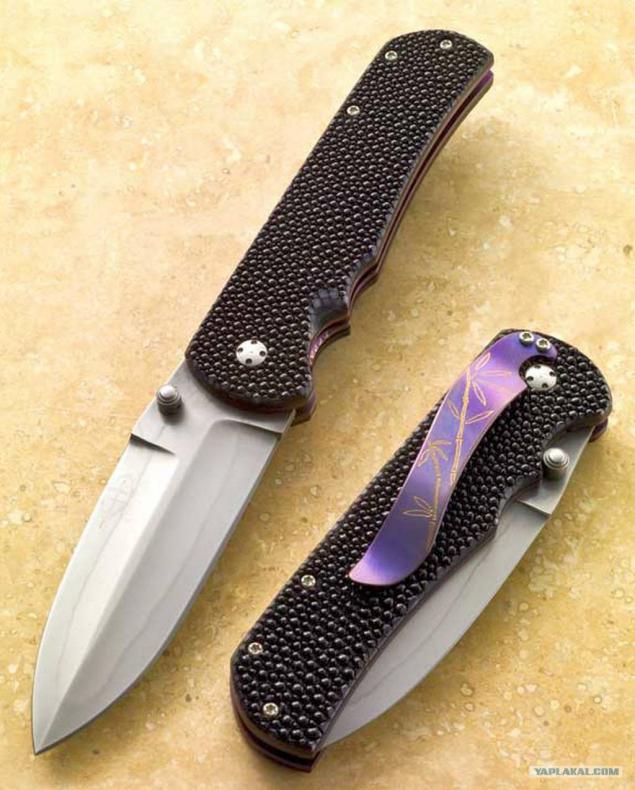

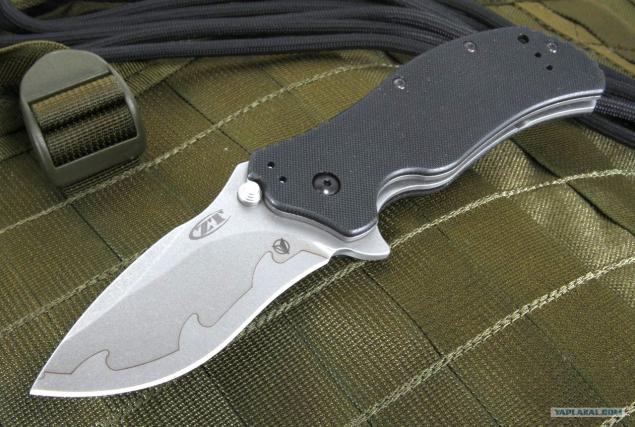

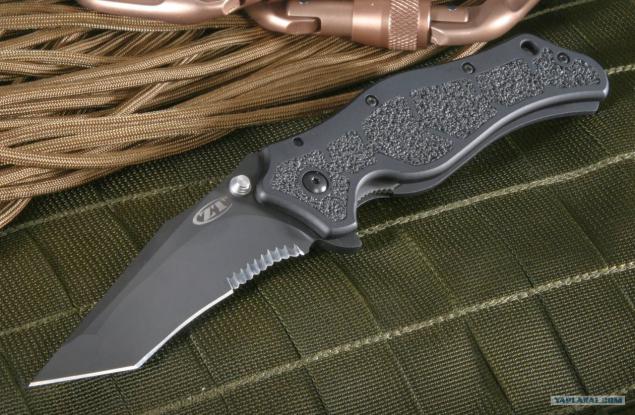

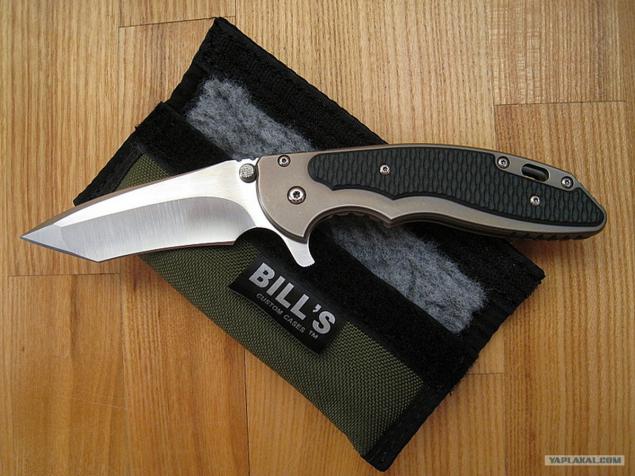

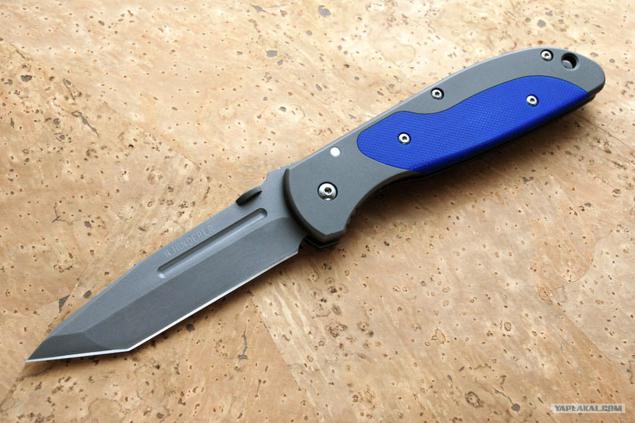

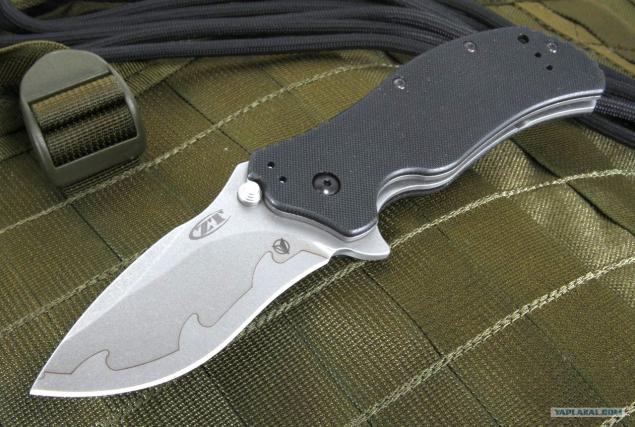

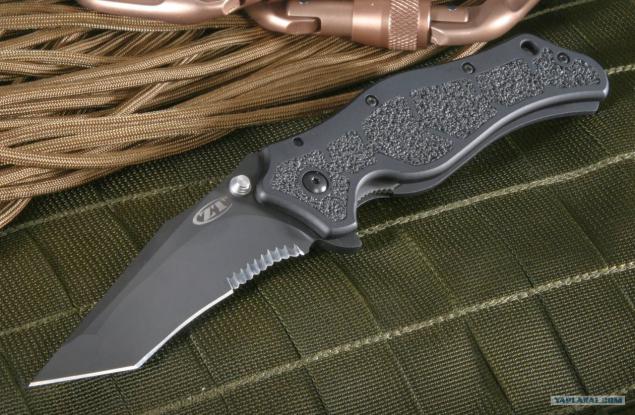

Zero Tolerance

Knives badged ZT (Zero Tolerance) were born in 2006. This trademark belongs to the famous American company Kai USA Ltd., produces knives Kershaw.

Division Zero Tolerance («zero tolerance") is engaged in the development of knives designed for military and law enforcement structures. This specialization provides for a powerful design and use of modern materials.

The blades of most knives Zero Tolerance made of stainless steel powder CPM S30V or 154SM. Locks knives tend to have a system of locking liner lock or frame lock.

Ergonomic handles are made of titanium or anodized aluminum dice, using as a lining of fibrous carbon fiber G10.

That aggressive design Zero Tolerance in conjunction with the "tactical" (black, olive, camouflage) color is a distinctive feature of these powerful knives, regardless of whether they have a folding design or not.

Zero Tolerance products can be safely attributed to the category of strong modern tactical knives.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

1. Where and how to start Shirogorovyh knives.

Northern latitude .: The first knife - sharpening pencils and hacksaw blades, very small, I did in high school. Then I got a simple sandpaper - familiar turner helped. Made several zhabokolov style 'Rambo, Die with envy!' and settled down for a while. Then we had the first Swiss Army knives. They cost, in my opinion, extremely expensive, so buy myself I could not. But I got the old Soviet multi-disciplinary knife, in a terrible state. The main blade it has seen a lot and was heavily made more precise, the remaining items only opened pliers. I replaced his sword then spring, then a screwdriver, then saw made: As a result of the original knife were only center distance so form a handle. All it took quite a long time - about two years, I guess. But it was very interesting, and then I was only skladnikami. Chose to work, do not burden me with respect to time, and began experimenting. Then he decided to issue IP and began to participate in exhibitions. The first knives were made exclusively at home, in time for the studio as it was given an entire room.

2. When the "Workshop Shirogorovyh brothers'?

Northern latitude .: workshop organized immediately. Igor joined in 2005 and took over all the turning part and assembly, parallel work for a large computer company Yaroslavl. Gradually we 'accrete' equipment, and neighbors began to complain about the noise. I had to think seriously about what you need a new room with a constant electricity and without annoying the neighbors. In this room turned out to be a two-story garage area of 50 m2. On the ground floor there 'grinder' and termichka, the second - we spent machining (milling and turning operations) and assembly.

After participating in the show, get a lot of orders for its products and realizing that our knives demand, we have decided to do only the production of knives. And the very same 'Workshop' was organized in 2009, when the garage has become closer and it was decided to remove the larger premises, organize Ltd. and start to hire employees because with the volume of orders we have not cope alone. Many of these employees work with us to this day.

3. What are the goals you set themselves the first place? Why did you decide to do only skladniki?

As such, the specific objectives we did not, try to make high quality and reliable knives that in terms of functionality is not inferior to foreign analogues. Initially folding knives for us were more interesting, and that is to produce them purchased proper equipment and manufacture of conventional blades would lead to his downtime, ie deal with them was inappropriate.

4. The stages of your development.

Much is due to production capabilities, for example, the first knives were made entirely by hand using simple desktop machines. To some extent this is determined the design and specifications. Then some details began to cut using laser and waterjet cutting. At this time, have been developed 'jerboa' and 'Dertnik' with blades 90 mm. Lining made mostly of expensive woods and materials from the customer. Use domestic steel suitable for the manufacture of knives such as 95X18, H12MF, and custom-made knives of Damascus steel famous smiths.

One of the first changes was the acquisition of the concept of the production machine with numerical control (CNC). Now we can do all the parts on their own, with sufficient accuracy, exactly as we wanted, but not how to receive from third parties. Now you can perform more complex elements, there were knives with complex hilts.

The next step can be regarded as placing on the market of imported steel and plastic in sufficient quantity. Were designed knives with titanium bolster, distance sleeve as the axle assembly on pads were uglepalstik and G10. From the tree by the time we have not given up and continue to actively use it.

The next step was the transition to three-dimensional modeling. As a result, there were knives with bulky sticks mainly from G10 and carbon fiber. Tree by the time we began to use less. Then we moved to a larger premises and acquired their first wire EDM machine, we have the opportunity to cut liners and frames. At the same time, we have implemented the first joint project with Dmitry Sinkevich. As a result, there were knives 'dark' and 'Nur'. This was our first knifes with a liner and frame. After that we started experimenting with so-called 'flippers' - knives 'fin', which opens for the blade. As a result, in 2010 there was a knife model 'Flipper', and in 2011 - a model of '111'.

5. Equipment.

The equipment was bought gradually. First, small desktop sleigh, then 'grinder', then in 2007 in the garage was acquired CNC milling machine. After moving to new premises there was an opportunity to get more serious class machines 'machining centers' elektoroerozionnye machines etc.

Currently involved in the production of machining centers, erosion machines - wire and batting, turning universal milling and grinding machines, and good old 'grinder'. After working on CNC machines, each piece is finished by hand, descents blades also still made by hand on a 'grinder' with the help of special tools.

Very long mastered the first CNC machine, with the rest of it was easier. Machines purchased from authorized dealers with training and warranty.

The equipment is very effective. Use of this product in the manufacture of knives that complexity that we are doing is necessary. We are not going to stop there and planning the purchase of a more powerful and modern equipment.

6. Materials.

Damascus we still use, but much smaller, mostly under the order. Domestic steel, unfortunately, can not compete with imports. Moreover, many modern powder steel domestic counterparts simply do not. Therefore, it is our choice, and an objective requirement of the market.

7. What do you mean - 'you refuse to accept individual orders due to the increased volume of production'?

Correct this news to read as follows: to further increase production we had to refuse to accept individual orders. Because production capacity increasing every year, and perform a specific custom knife was simply impossible, orders began to accumulate, and the production time to grow. In this connection, the decision was made. Unfortunately, not all the orders we were able to perform at this time.

8. What media platform you want to use to promote your brand, products, ideas?

Now we have suspended all advertising activities.

9. How do you see your place in the market - the Russian market and the knife world?

Of course, we aim to take a leading position not only in Russia but also in the global market. This year, the first time we participated in the exhibition 'Vlade Show', which was held in Atlanta (USA). We further plan to participate in major international exhibitions in America and Europe. On 'Vlade Show' we presented 'flippers' in different versions, including 'Hati' and '111', too, are different. They also shipped abroad. Also demonstrated the knives of our joint project with Dmitry Sinkevich - 'Dark', 'tetra' and 'Koordinal'.

10. What would like to achieve 'ideally', and then - in the near future?

If we evaluate the prospects, we would like to increase production volumes, further improve quality, expand product range, make our knives are more accessible. This could help us to attract serious investors, obtaining government orders. And in the near future we want to start producing knives with fixed blades.

11. Mission.

We never thought about it. We just do what we like, it brings us pleasure, and we are very pleased that what we are doing, like someone else.

12. The perfect knife - what is it?

The ideal knife does not exist - even the best knife after a while may get bored, stop being interesting and not happy. This is what leads to the birth of new design projects, construction of new blades. Therefore correct to say that the ideal knife - this is the knife that has not yet been made.

13. What kind of artistic style in painting comparable design your knives?

Most likely, we are talking about the schedule, and if you choose the artistic direction, we, I think, towards constructivism, that is obvious. Important 'visual strength' integrity, concise manner knife, providing both functionality and external harmony of lines. Much attention is paid to the elaboration of small parts - chamfer, transitions, etc. There can be minor details, every detail is important.

corr. Elena Arapova

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

Posted in [mergetime] 1413187139 [/ mergetime]

That's all for ... smotrite.pinayte ... if that is not so ...

Duane Dwyer

Duane Dwyer - American master nayfmeyker. He made a career in the military, he served in the US Army special units. Since 1994, together with a friend and brother-soldier Mick Strider Dwayne developed tactical knives to arm the US Army and Navy.

Releasing several successful models, Mick Doohan and decided to make nayfmeking their profession. Discharged from the army in 1997 in San Marcos, California, they founded the company Strider Knives.

However, in addition to working in Strider Knives Duane Dwyer actively cooperates with the leading manufacturers of knives and manufactures products under its own name.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

Rick Hinderer

For more than 20 years, Rick Hinderer is engaged in manufacturing of products for personal safety. He owns the brand Rick Hinderer Knives, specializing in the production of exclusive knives and tactical pens.

Early in his career nayfmeykera when Rick was just looking for his style and took the first steps in business, it is made the traditional hunting and tourist knives, and sold them in the vicinity of arms fairs.

Master tried to restore the forgotten art of old blacksmiths and gunsmiths. During this period, his mentor was Hugh Bartug, interested young author Damascus blade manufacturing technology. On a perfect mastery of this technique Rick Hinderer ushlo13 years.

Of particular importance for the master Hinderer always had communication with customers. It occupied and delighted stories about how acquired Rick knife helps them in life, and how they are satisfied with the purchase.

To do really flawless functionality products, Rick stopped playing "artistic" knives. He narrowed his field of activity, choose to specialize their brand manufacturer of knives for hunters and travelers.

In the same period, Rick Hinderer began collaborating with many renowned companies. For Gerber, he developed the famous hunting model Gamepro, for Benchmade - line High Country Hunter. But the master did not forget about working on innovation. Hinderer authored Lockbar Stabilizer for folding knives. With the permission of his Rica design using the best cutlery firms worldwide.

On his achievements author says modestly: "I'm just beginning ....".

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

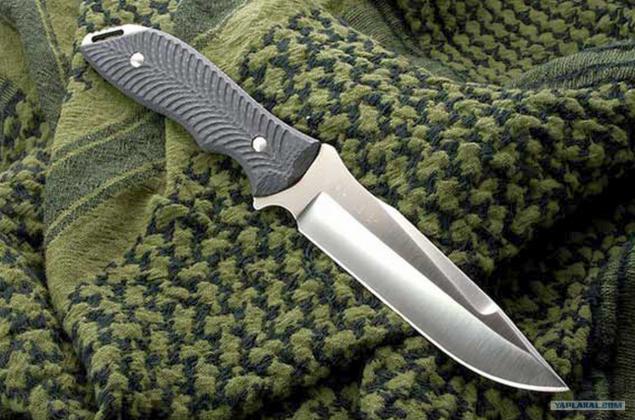

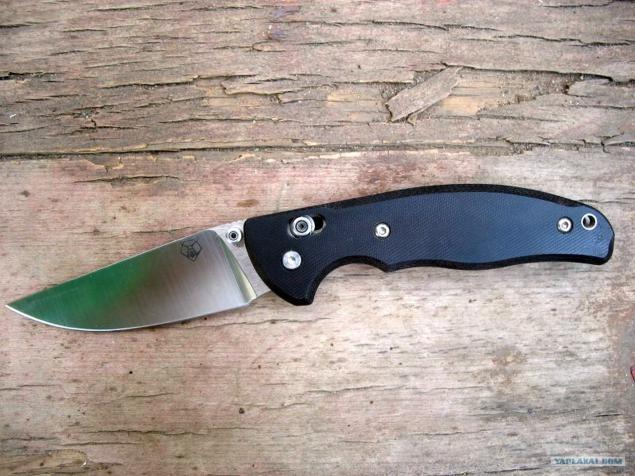

The company «SHOKUROFF» was founded in 1997 gunsmith Alexei Shokurov.

The company produces small batches and custom high-quality folding, awkward, author handmade knives of Damascus, stainless steel and wave.

Lineup includes 25 certified samples. You can see the works of the knives in the catalog, which shows the model description and photo. There you can buy ready-made knife or order the production of the knife for yourself or as a gift through our online system.

In the production of knives used materials:

Stainless steel 95X18 and 110h18;

Damascus steel layers 420-480;

Wave steel;

"Three-layer" steel.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

Wally Hayes

Wally Hayes (Wally Hayes) wonderful, talented nayfmeyker. His works capture the imagination of even the most experienced nozhevikov.

Wally was born in 1963. From early childhood he was seriously impressed with knives and swords.

The general experience of his work as nayfmeykera is more than twenty years. During this time, his best work has repeatedly been featured in various television programs, as well as published in magazines for fans of knives.

To date, Wally Hayes produces not only tactical but also highly knives. The author also indifferent and cutlery Japanese-style and a lot of them in his collection. By the way, all the knives, which makes Wally Hayes - unique in its kind, as the author makes them unique. At some orders, in particular, for the manufacture of swords, the master may take several years!

In the master plans for the future - to expand their skills in jewelry, as well as carving and engraving.

At the moment, Wally Hayes lives and works in his homeland - in Canada.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

Zero Tolerance

Knives badged ZT (Zero Tolerance) were born in 2006. This trademark belongs to the famous American company Kai USA Ltd., produces knives Kershaw.

Division Zero Tolerance («zero tolerance") is engaged in the development of knives designed for military and law enforcement structures. This specialization provides for a powerful design and use of modern materials.

The blades of most knives Zero Tolerance made of stainless steel powder CPM S30V or 154SM. Locks knives tend to have a system of locking liner lock or frame lock.

Ergonomic handles are made of titanium or anodized aluminum dice, using as a lining of fibrous carbon fiber G10.

That aggressive design Zero Tolerance in conjunction with the "tactical" (black, olive, camouflage) color is a distinctive feature of these powerful knives, regardless of whether they have a folding design or not.

Zero Tolerance products can be safely attributed to the category of strong modern tactical knives.

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

1. Where and how to start Shirogorovyh knives.

Northern latitude .: The first knife - sharpening pencils and hacksaw blades, very small, I did in high school. Then I got a simple sandpaper - familiar turner helped. Made several zhabokolov style 'Rambo, Die with envy!' and settled down for a while. Then we had the first Swiss Army knives. They cost, in my opinion, extremely expensive, so buy myself I could not. But I got the old Soviet multi-disciplinary knife, in a terrible state. The main blade it has seen a lot and was heavily made more precise, the remaining items only opened pliers. I replaced his sword then spring, then a screwdriver, then saw made: As a result of the original knife were only center distance so form a handle. All it took quite a long time - about two years, I guess. But it was very interesting, and then I was only skladnikami. Chose to work, do not burden me with respect to time, and began experimenting. Then he decided to issue IP and began to participate in exhibitions. The first knives were made exclusively at home, in time for the studio as it was given an entire room.

2. When the "Workshop Shirogorovyh brothers'?

Northern latitude .: workshop organized immediately. Igor joined in 2005 and took over all the turning part and assembly, parallel work for a large computer company Yaroslavl. Gradually we 'accrete' equipment, and neighbors began to complain about the noise. I had to think seriously about what you need a new room with a constant electricity and without annoying the neighbors. In this room turned out to be a two-story garage area of 50 m2. On the ground floor there 'grinder' and termichka, the second - we spent machining (milling and turning operations) and assembly.

After participating in the show, get a lot of orders for its products and realizing that our knives demand, we have decided to do only the production of knives. And the very same 'Workshop' was organized in 2009, when the garage has become closer and it was decided to remove the larger premises, organize Ltd. and start to hire employees because with the volume of orders we have not cope alone. Many of these employees work with us to this day.

3. What are the goals you set themselves the first place? Why did you decide to do only skladniki?

As such, the specific objectives we did not, try to make high quality and reliable knives that in terms of functionality is not inferior to foreign analogues. Initially folding knives for us were more interesting, and that is to produce them purchased proper equipment and manufacture of conventional blades would lead to his downtime, ie deal with them was inappropriate.

4. The stages of your development.

Much is due to production capabilities, for example, the first knives were made entirely by hand using simple desktop machines. To some extent this is determined the design and specifications. Then some details began to cut using laser and waterjet cutting. At this time, have been developed 'jerboa' and 'Dertnik' with blades 90 mm. Lining made mostly of expensive woods and materials from the customer. Use domestic steel suitable for the manufacture of knives such as 95X18, H12MF, and custom-made knives of Damascus steel famous smiths.

One of the first changes was the acquisition of the concept of the production machine with numerical control (CNC). Now we can do all the parts on their own, with sufficient accuracy, exactly as we wanted, but not how to receive from third parties. Now you can perform more complex elements, there were knives with complex hilts.

The next step can be regarded as placing on the market of imported steel and plastic in sufficient quantity. Were designed knives with titanium bolster, distance sleeve as the axle assembly on pads were uglepalstik and G10. From the tree by the time we have not given up and continue to actively use it.

The next step was the transition to three-dimensional modeling. As a result, there were knives with bulky sticks mainly from G10 and carbon fiber. Tree by the time we began to use less. Then we moved to a larger premises and acquired their first wire EDM machine, we have the opportunity to cut liners and frames. At the same time, we have implemented the first joint project with Dmitry Sinkevich. As a result, there were knives 'dark' and 'Nur'. This was our first knifes with a liner and frame. After that we started experimenting with so-called 'flippers' - knives 'fin', which opens for the blade. As a result, in 2010 there was a knife model 'Flipper', and in 2011 - a model of '111'.

5. Equipment.

The equipment was bought gradually. First, small desktop sleigh, then 'grinder', then in 2007 in the garage was acquired CNC milling machine. After moving to new premises there was an opportunity to get more serious class machines 'machining centers' elektoroerozionnye machines etc.

Currently involved in the production of machining centers, erosion machines - wire and batting, turning universal milling and grinding machines, and good old 'grinder'. After working on CNC machines, each piece is finished by hand, descents blades also still made by hand on a 'grinder' with the help of special tools.

Very long mastered the first CNC machine, with the rest of it was easier. Machines purchased from authorized dealers with training and warranty.

The equipment is very effective. Use of this product in the manufacture of knives that complexity that we are doing is necessary. We are not going to stop there and planning the purchase of a more powerful and modern equipment.

6. Materials.

Damascus we still use, but much smaller, mostly under the order. Domestic steel, unfortunately, can not compete with imports. Moreover, many modern powder steel domestic counterparts simply do not. Therefore, it is our choice, and an objective requirement of the market.

7. What do you mean - 'you refuse to accept individual orders due to the increased volume of production'?

Correct this news to read as follows: to further increase production we had to refuse to accept individual orders. Because production capacity increasing every year, and perform a specific custom knife was simply impossible, orders began to accumulate, and the production time to grow. In this connection, the decision was made. Unfortunately, not all the orders we were able to perform at this time.

8. What media platform you want to use to promote your brand, products, ideas?

Now we have suspended all advertising activities.

9. How do you see your place in the market - the Russian market and the knife world?

Of course, we aim to take a leading position not only in Russia but also in the global market. This year, the first time we participated in the exhibition 'Vlade Show', which was held in Atlanta (USA). We further plan to participate in major international exhibitions in America and Europe. On 'Vlade Show' we presented 'flippers' in different versions, including 'Hati' and '111', too, are different. They also shipped abroad. Also demonstrated the knives of our joint project with Dmitry Sinkevich - 'Dark', 'tetra' and 'Koordinal'.

10. What would like to achieve 'ideally', and then - in the near future?

If we evaluate the prospects, we would like to increase production volumes, further improve quality, expand product range, make our knives are more accessible. This could help us to attract serious investors, obtaining government orders. And in the near future we want to start producing knives with fixed blades.

11. Mission.

We never thought about it. We just do what we like, it brings us pleasure, and we are very pleased that what we are doing, like someone else.

12. The perfect knife - what is it?

The ideal knife does not exist - even the best knife after a while may get bored, stop being interesting and not happy. This is what leads to the birth of new design projects, construction of new blades. Therefore correct to say that the ideal knife - this is the knife that has not yet been made.

13. What kind of artistic style in painting comparable design your knives?

Most likely, we are talking about the schedule, and if you choose the artistic direction, we, I think, towards constructivism, that is obvious. Important 'visual strength' integrity, concise manner knife, providing both functionality and external harmony of lines. Much attention is paid to the elaboration of small parts - chamfer, transitions, etc. There can be minor details, every detail is important.

corr. Elena Arapova

2 ...

3 ...

4 ...

5 ...

6 ...

7 ...

8 ...

9 ...

10 ...

11 ...

Posted in [mergetime] 1413187139 [/ mergetime]

That's all for ... smotrite.pinayte ... if that is not so ...