636

How to make the attachment on the trimmer with your hands

For many gardeners trimmer has long been a familiar technique and almost irreplaceable. But it is not always possible to buy a model that allows to satisfy all needs. It happens that with fresh young vegetation trimmer easily, but there is a desire to clear the space behind the fence or along the access road, and the tall ripe grass is the technique of "not too tough".

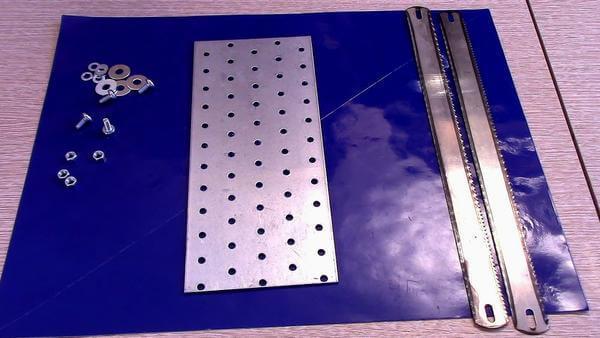

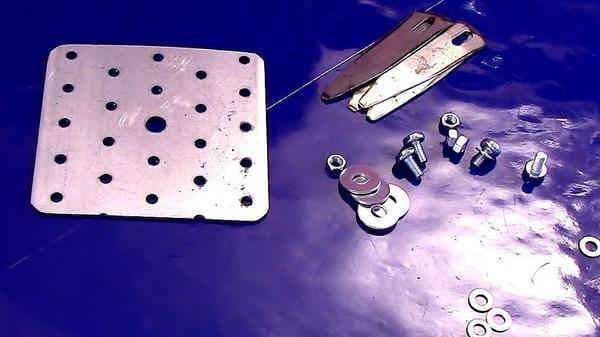

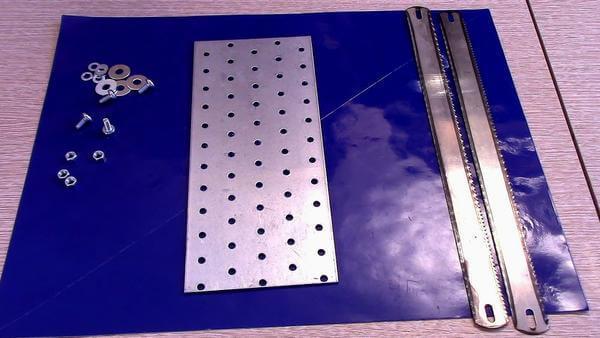

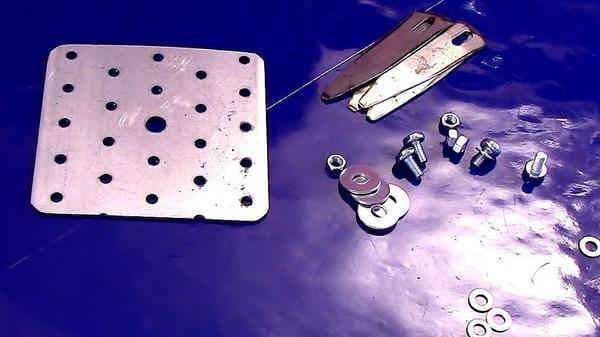

We offer the option of self-production tips for trimmer of simple, almost improvised means. You will need a metal perforated plate (100mm x 240mm), two blades for metal, 4 screws and 4 nuts M5, 4 washers and 4 fender washers. From the point of view of safety, the saw blade should not be completely hardened.

All that is required for manufacturing the nozzle

The hardest part of the manufacture of the nozzle symmetrically to mark and carry out the holes for the knives and the shaft of the trimmer. That's why select is ready perforated plate.

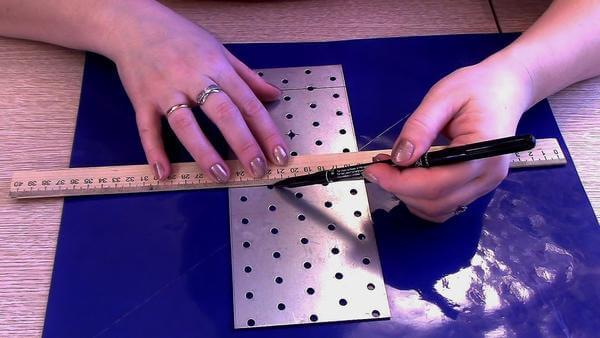

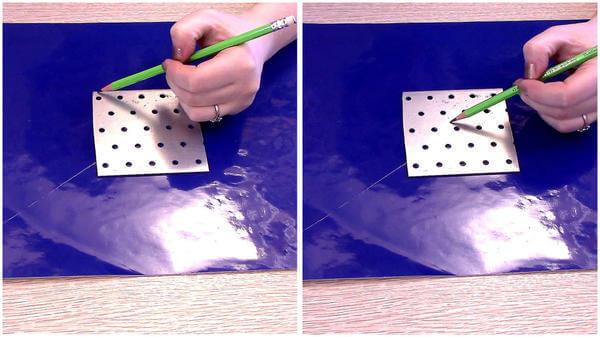

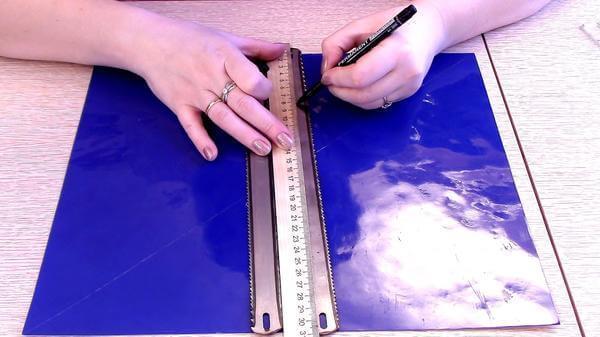

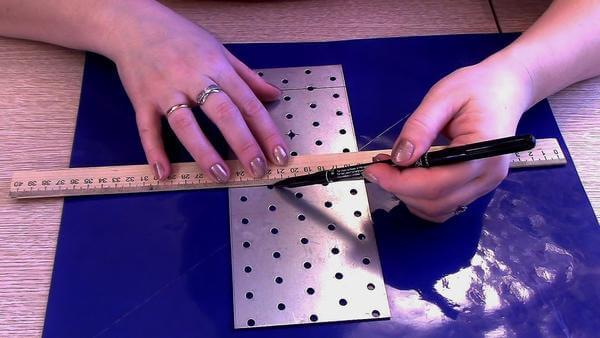

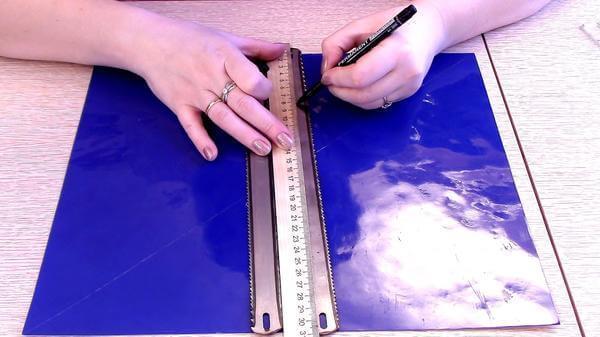

First, you need to make the base of the nozzle. This metal sheet grinder cut a square of side 100 mm. Mark it is necessary so that the exact center (at the intersection of the diagonals) there was a hole. To do this, from the center of the hole perpendicular to the short side of the plate measured distance 50 mm of the planned cut lines.

Mark the base of the nozzle

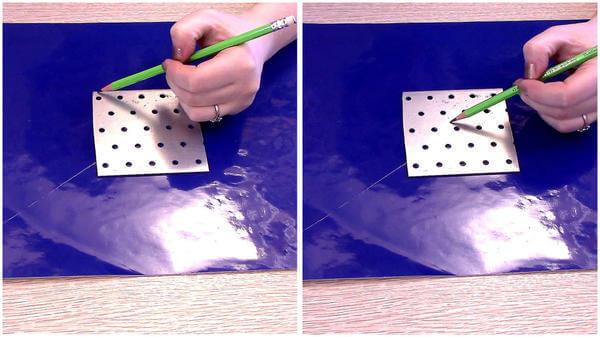

Cut the excess and get a square of 100 mm × 100 mm. Now you need to slightly round the corners and drilled the Central hole for the shaft of the trimmer.

Make the corners rounded and drilled the Central hole for the shaft of the trimmer

Blades for the metal to be cut, measuring from each end of the 8 see Receive the four blanks with finished bores.

Cut the fabric at the metal

These blanks must be given in the form of knives. For this proposed line of cut on the eye (special accuracy is not needed), fasten all four blanks together and grind the excess.

From blanks cut knives

The result is the same weight and size blades, they can be a bit sharpened on one side. Now all the parts are homemade tips for trimmer prepared, you can begin Assembly.

All ready for Assembly

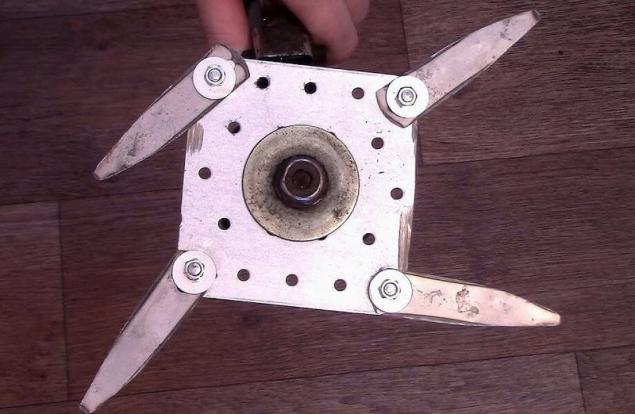

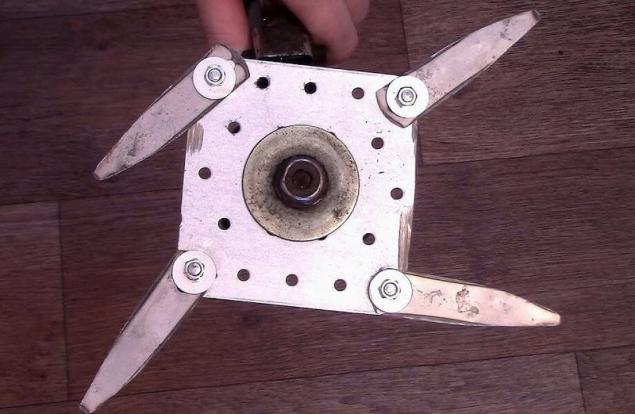

On the screw put a small washer and put it in the corner hole. On top put the knife, having sharpened side during the rotation of the shaft of the trimmer. Followed by a large washer and nut that is not tightened to the knife rotated freely. In the same way fasten the other three knives.

Fixed knives

The end of the screw needs to rasclaat that nut will not come loose.

The end of the screw needs to rasclaat

Nozzle ready. It is nuts to the ground and secured in the same manner as three-bladed knife supplied with the trimmer. When confronted with the stone knives fold up and go inside a bit.

This idea was suggested to us by our regular contributor video Tatiana (Tula oblast). Learn more to see the whole process of manufacture of such attachments for the trimmer and learn some of the nuances you can, watch the video, which she prepared.

When working with the trimmer, it is important not to forget about safety, using any tips, and especially homemade. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.7dach.ru/Eleko/nasadka-na-trimmer-svoimi-rukami-106078.html

We offer the option of self-production tips for trimmer of simple, almost improvised means. You will need a metal perforated plate (100mm x 240mm), two blades for metal, 4 screws and 4 nuts M5, 4 washers and 4 fender washers. From the point of view of safety, the saw blade should not be completely hardened.

All that is required for manufacturing the nozzle

The hardest part of the manufacture of the nozzle symmetrically to mark and carry out the holes for the knives and the shaft of the trimmer. That's why select is ready perforated plate.

First, you need to make the base of the nozzle. This metal sheet grinder cut a square of side 100 mm. Mark it is necessary so that the exact center (at the intersection of the diagonals) there was a hole. To do this, from the center of the hole perpendicular to the short side of the plate measured distance 50 mm of the planned cut lines.

Mark the base of the nozzle

Cut the excess and get a square of 100 mm × 100 mm. Now you need to slightly round the corners and drilled the Central hole for the shaft of the trimmer.

Make the corners rounded and drilled the Central hole for the shaft of the trimmer

Blades for the metal to be cut, measuring from each end of the 8 see Receive the four blanks with finished bores.

Cut the fabric at the metal

These blanks must be given in the form of knives. For this proposed line of cut on the eye (special accuracy is not needed), fasten all four blanks together and grind the excess.

From blanks cut knives

The result is the same weight and size blades, they can be a bit sharpened on one side. Now all the parts are homemade tips for trimmer prepared, you can begin Assembly.

All ready for Assembly

On the screw put a small washer and put it in the corner hole. On top put the knife, having sharpened side during the rotation of the shaft of the trimmer. Followed by a large washer and nut that is not tightened to the knife rotated freely. In the same way fasten the other three knives.

Fixed knives

The end of the screw needs to rasclaat that nut will not come loose.

The end of the screw needs to rasclaat

Nozzle ready. It is nuts to the ground and secured in the same manner as three-bladed knife supplied with the trimmer. When confronted with the stone knives fold up and go inside a bit.

This idea was suggested to us by our regular contributor video Tatiana (Tula oblast). Learn more to see the whole process of manufacture of such attachments for the trimmer and learn some of the nuances you can, watch the video, which she prepared.

When working with the trimmer, it is important not to forget about safety, using any tips, and especially homemade. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.7dach.ru/Eleko/nasadka-na-trimmer-svoimi-rukami-106078.html

Sewed curtains for the kitchen, and now can't stop me. Simple detail transforms the entire house!

Why there are surges and how to protect themselves from them