847

Hiking Shef

In the area of 30 photos

Good all, dear.

I will share with you the first experience of creating a kitchen knife, aka shef knife.

I'm tired of constantly undermine their knives from the Brazilian stainless steel in the cooking process, and I'm fired up for the new year, to organize yourself a gift in the form of a good knife. Climbed tyrnete look for, where would I buy this, I found a couple of offers less, but still not quite right. That shape, the size is not quite consistent with my wishes. Even the price does not play a special role in the region to 10 can spend, a favorite gift is. And my wife said, you want, and look for order, I do not mind at all. There was an option to order, with their size and shape. But at work, and two of his colleagues began to develop as a craft, though they are willing to buy blades, and there are already conjure with handles, and the blades have very small for me. But they advised me to become one, h12mf, said of her look, strong, tough. And away.

After studying the properties of the steel and re-read many articles and reviews, it was decided to search the knife from her. And when came across the video so all a pain in the ass began to play. And then my colleagues brought a piece of steel. Rolling true. But she. Having estimated the state of their arsenal of tools, parts starting price, and the curvature of his hands, he decided that I will make myself a knife, one that is necessary to me. It does not always get all the steps take a picture, but mostly all of the processes are displayed. For pictures of the identity is not particularly kick. All in different places with different lighting and different weather.

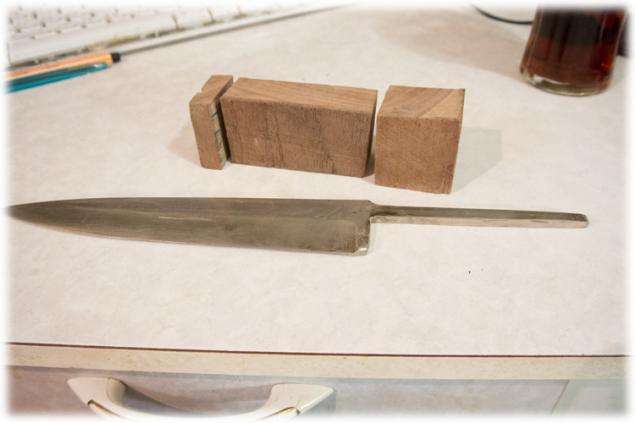

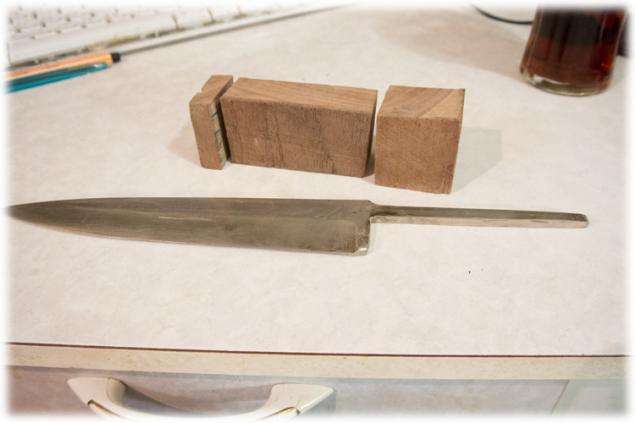

The piece has been declared as 4mm, width of 40, well and took the length of 35 cm, somewhere 20-22 cm on the blade, and 12-13 on the hilt, but the width of the jamb turned out, only 35 mm, but oh well. A knife with a wide blade then do so, in the summer when you can unchain steel)))

Draw either by hand or on a computer, the contours of our future and the knife cut paper Tipo curve. Is applied to the web of steel and paint in black marker all that is necessary to remove from the canvas. We go to the machine and huyarim. That cutting is ready. Here I have some raschertil border runs, and began to withdraw slowly.

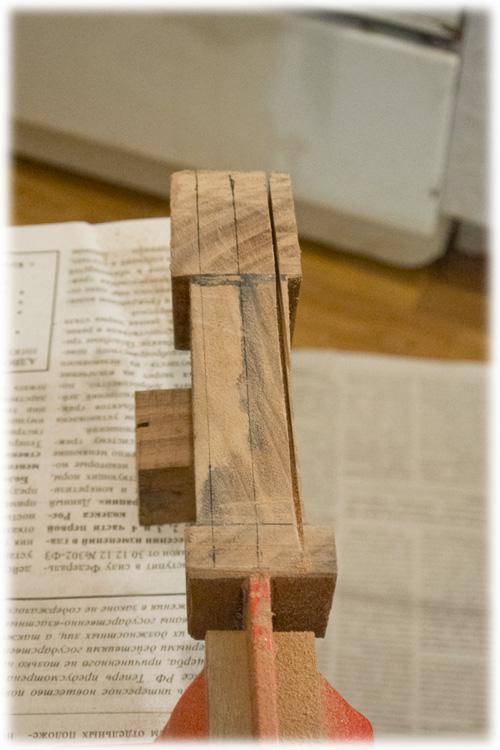

With here is no such contraptions, I did descents. This is the most complicated and long. Melt 2 buckets of snow))) it is necessary to cool the metal, otherwise overtempered.

After agonizing manufacturing runs, rascherchivaem upper limits of the knife, ie butt.

And we get is something like a knife.

And with the help of the bar, very rough, bring descents and derive the cutting edge in the rough. Well shkurochkoy walked a bit, see how it turns out.

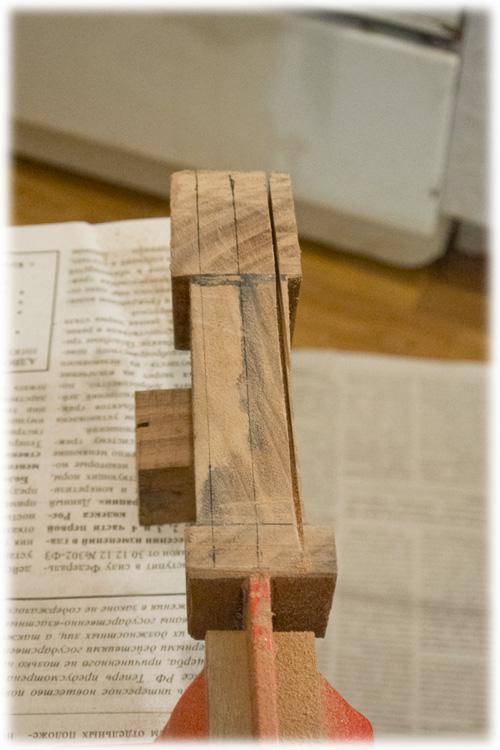

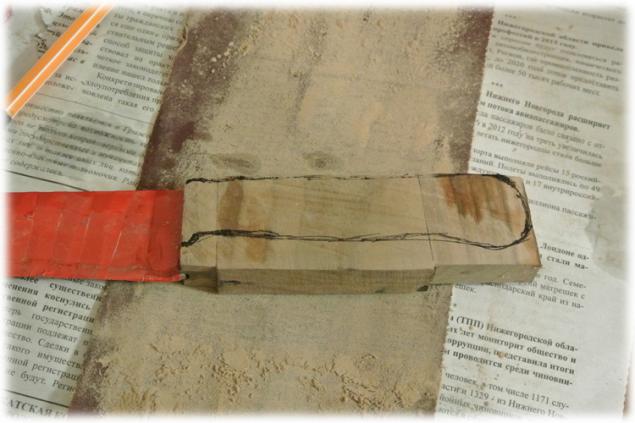

The next step was PREPARATION handle. The guys asked for a slice of red bourgeois nut, not for free of course. Here he was sawn in 3 parts. Long thought to do some pen, like nickel silver tip, but a solid piece of nickel silver is not found, only the thin casting, but for my purposes, it somehow did not really asking her. I decided to clean the wood, but of the 3 pieces, allegedly guard and wooden handle. And the holes easier to do in small pieces. And from harvesting knife remove all unnecessary grinder and sandpaper. In parallel, even the skins of the blade slightly. I got crumpled, made the evenings and nights. At that time enough, and did so.

We mark up a piece of wood, and drill the holes and we clean to put on the shank. From halves not do, I do not like rivets, bridges extra slack handles. Even in cold weather, frost will burn on the hand.

Photos device does not, I will describe so on a flat board is glued to the skin of 2-sided tape, and using it to customize our pieces of wood together, so there are no gaps between them. So dressing and taking off every time on the shank. and remove the gap here.

After all the dancing with a tambourine zamatyvaem blade tape all the way to the glue did not get, a divorce epoxy according to the instructions and proceed.

We are putting our future together with a knife handle. I've pulled together a rope tightening using improvised means, no pictures ((But if you find a large clamp, then it will be easier.

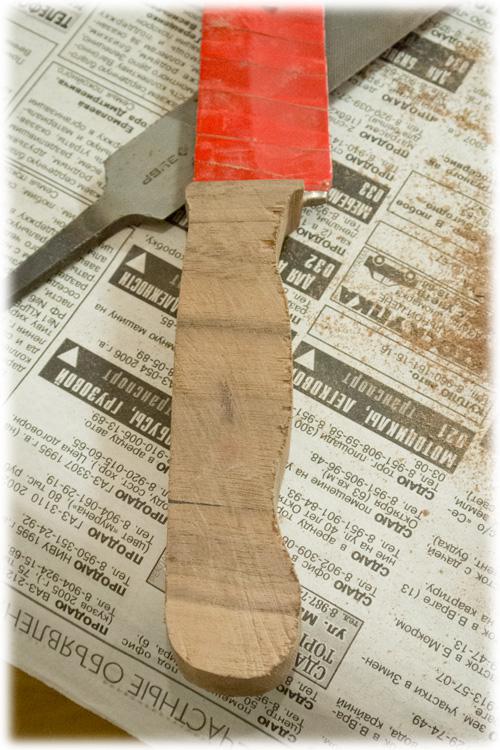

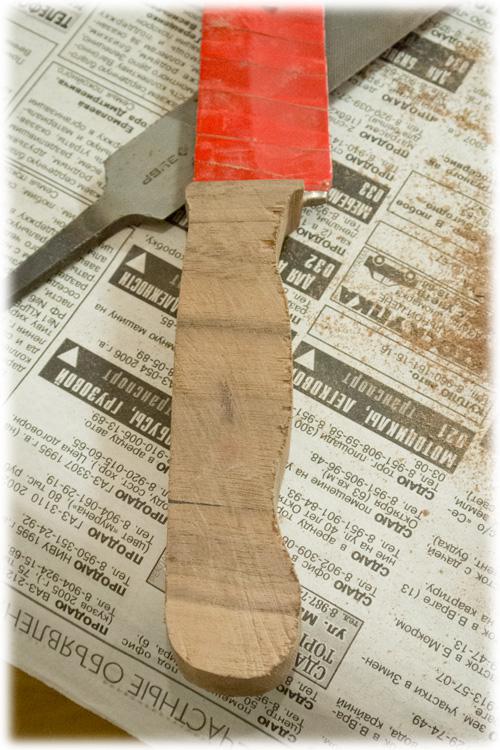

A day later, intended for curing the adhesive, the host for processing handles. SPIL all the excess from the top of the handle with a small margin for further processing. It marks the symmetry axis and away from the edge of the future already handle. And he began to saw off all unnecessary.

Wood dense, hacksaw to saw long, but the main sawn)) and quite smoothly.

Sawed off on the sides of all superfluous, mark the contours of the future of the handle. And all saw off from the bottom.

leaving little for further processing in this case is not finished better than to saw.

Thanks to my teacher for works that do not booze and taught us and learn how to communicate with a file different))) are machined on all Files rude and not very much.

Round off the edge handles, has a small file and coarse sandpaper. Okay, that his wife was asleep and did not see a layer of sawdust))) but I lined a newspaper. and then wiping the floor with a wet cloth)) purity guarantee of success.

Well, after the skins, hides and skins of once, as bequeathed great. Gradually reducing grain sandpaper. This is an intermediate step next to the last love of my kitchen, Brazilian stainless steel.

Hides and handle and blade, leveling all the surfaces. The skins at any free time, both at work and at home.

Well, then take a piece of old felt boots manufacture such a device here: bolt, washer large wheels, felt, large washer, nut. Can one more Lock the nut. By the way round taking the skins and put on the outer side of the felt, you can perform polishing products)))

After all the grindings, the CD felt inflict GOI paste and grind the blade, to the mirror I have been too lazy to communicate, and there is nothing special to me a mirror. And the drill was not at hand, just a screwdriver, and it does not give such great revolutions required for better elimination.

And after the blade, take another blank disc, and they we clean all dust and wood chips. On the right course, in the beginning it was necessary to completely withdraw the blade to shine. And then the handle to do, but again, the time was limited to different conditions, and do it all at once.

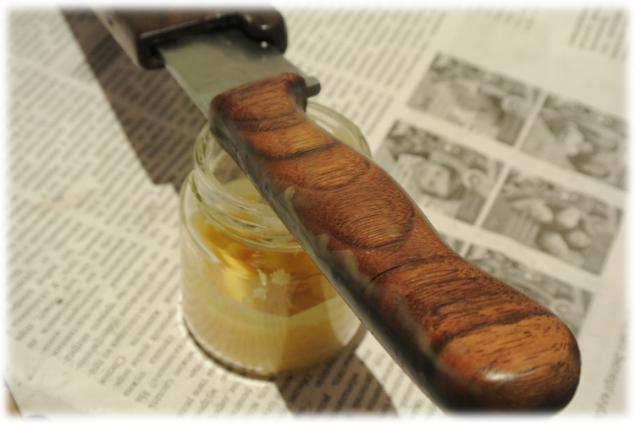

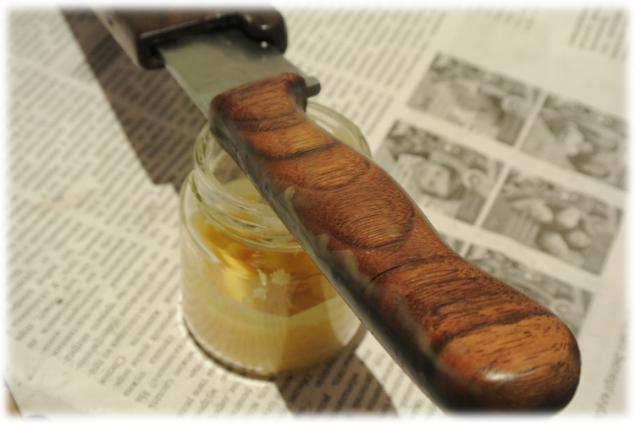

After reviewing a bunch of impregnation, I decided to infiltrate the ancient way, though long, but reliable. I bought a couple of vials of linseed oil artistic. Since the pen is quite big and long, I had to buy a jar of some nasty things. Take a small pan on the bottom of gauze or cloth rag on the exposed bank. The jar pour oil into the pan water do not mix.

Heat the oil to 60-70 degrees, no more, epoxy does not like high temperatures, again zamatyvaem little blade with tape to avoid soiling it, and omit it our handle. And watched as the small wooden stand out air bubbles. As the bubbles stop, remove and wipe with a napkin. I have this procedure took about an hour, with several oil heating.

Lay off the knife on the sill under the rays of the sun, we need a UV polymerization oil. But I have a couple of times a cloth, wipe it with oil until the oil no longer be absorbed at all. Do not forget to turn it every day on the windowsill to all sides polymerized oil. In the evenings we do grind. Here I will not detail all the paint, another on the same topic will be enough theories sharpening knives. Yes, and I have not quite mastered it yet)) study yet.

In the meantime, the oil dries and tochitsya blade made of our shefa, marching variant, will make a sheath for it. I often go on nature, and cook there, and we have to take their knives from the Brazilian stainless steel, izvorachivayas wrap them and put neatly in a backpack, and so that the hand does not hurt if you get what is necessary, and not to pierce the edge of the pack. In general, the more Hemorrhoids. And I decided, once the width of the blade is not perfect for me, and made it a marching variant, Housing'll do another one. The truth probably shoot my wife)) Well, that's another question.

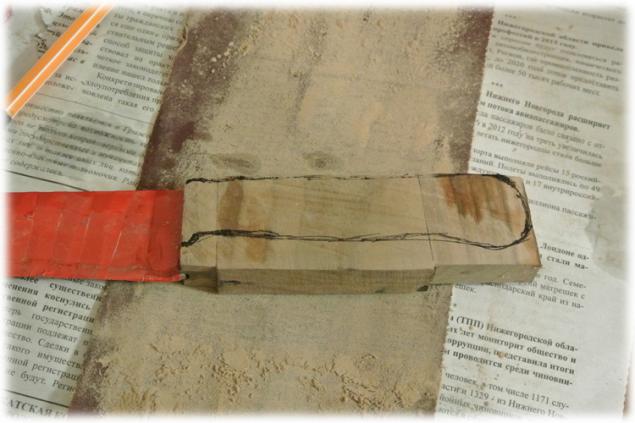

Again, we turn to our colleagues, and we take them another little piece of derevyahi. I decided from one tree to do everything. and handle and scabbard. Again pretends on a piece of paper, it will look like, and some of the pieces composed. Brusochek Mark up and cut into pieces. By this time, I took the lease grinder, which grinds cloth. And this miracle devaysom present door at the joints according to plan in a more or less decent condition. That is to exactly docked. Without major gaps.

That is the next stage, and my patience is exhausted. Drill a hole in each piece under the knife for a long time, I fussed with it, and the desire to quickly finish everything has been great, and because of this the night hastily pokleit these pieces are not fitted to a good joints. As a result, in one place and then swam jamb. But certainly not critical. Yes, and I pasted on Friday night already, and there was a desire for the rest of the process completely vyhi. And the night is still necessary to wait. and I did not postpone and pokleit.

Glued to the reinforcement by the way, that when the lateral load in places of gluing are not collapsed. He reinforced thin metal pins. Each junction of 2 studs.

Well, after the glue has dried, go to the garage, take a miracle grinding, and remove all superfluous with it.

And returns to the felt-device, take different skins to reduce and were ground to the smoothness of the limit, and then we clean pure felt.

The impregnation of the sheath decided to make cold process. True inside pour hot inside were particles of wax, and had them melted and infiltrated the outer part of the week, every day dealing with a thin layer. In the first hour of impregnation of course I inflicted layers until it is no longer absorbed. Well, the knife them. On the window sill. Turning constantly.

Once dried out a knife with a sheath, and polymerized oil, though not completely, then come again. Cooking composition for finishing. Take our beeswax and linseed oil in the proportions somewhere 2 parts oil to 1 part of wax, but I have to face, and perhaps could not stand straight, but after reading this before the recipes, I realized that there are no exact proportions like 1 1/3 want / 4, and you want to clean the wax processing. There was still the possibility of carnauba wax process, but decided to do so of our own, bee. In a water bath to melt the wax oil to homogeneity.

I strain through cheesecloth to get rid of parts of dead bees. Wax is natural, with all parts of the cells, and the smell of honey)).

Clean out all the blank disc derevyahi dust.

When the wax cools down would be a soft paste, take a piece and rub the wood cleared of dust outside of the them. Hairdryer we warm up to all the pores filled

and polish already felt all around the finish.

My task was a knife that can cut and meat, butcher, and that he kept sharpening afterwards. I love tomatoes with meat dishes, and their blunt knife to cut bad. I can say that the task is carried out with a bang. Brazilians because they can not. Knife course turned out not perfect, there are a couple of stocks on the slopes, a pair of stocks on the sheath, but these schools for more - aesthetic quibbles, and practical application have no effect. And I think for the first time forgivable))

Well, a little remark: the budget.

a piece of steel - 300 rubles.

tree on the handle and sheath - 500 rubles (of course, the board of the tree is a 5 rubles, but it is 2 meters, and I used the 15-20 cm from the boards of all)

skin - about 500 rubles.

linseed oil - 200 rubles.

1500

then go for the purchase of a knife, which remained in my possession for a lifetime, so it is difficult to count the cost price of a knife.

Files, Needle, and all sorts of stuff about 1k ruble

bars for sharpening conventional - 150 rubles

Diamond bar 1 to 5.

tisochki small 300 rubles

a total of about 4.5 rubles. It is certainly possible to find a ready knife in such a cost, but left without nishtyakov such as a diamond bar. which then would have to buy anyway.

All you can kick.

Source:

Good all, dear.

I will share with you the first experience of creating a kitchen knife, aka shef knife.

I'm tired of constantly undermine their knives from the Brazilian stainless steel in the cooking process, and I'm fired up for the new year, to organize yourself a gift in the form of a good knife. Climbed tyrnete look for, where would I buy this, I found a couple of offers less, but still not quite right. That shape, the size is not quite consistent with my wishes. Even the price does not play a special role in the region to 10 can spend, a favorite gift is. And my wife said, you want, and look for order, I do not mind at all. There was an option to order, with their size and shape. But at work, and two of his colleagues began to develop as a craft, though they are willing to buy blades, and there are already conjure with handles, and the blades have very small for me. But they advised me to become one, h12mf, said of her look, strong, tough. And away.

After studying the properties of the steel and re-read many articles and reviews, it was decided to search the knife from her. And when came across the video so all a pain in the ass began to play. And then my colleagues brought a piece of steel. Rolling true. But she. Having estimated the state of their arsenal of tools, parts starting price, and the curvature of his hands, he decided that I will make myself a knife, one that is necessary to me. It does not always get all the steps take a picture, but mostly all of the processes are displayed. For pictures of the identity is not particularly kick. All in different places with different lighting and different weather.

The piece has been declared as 4mm, width of 40, well and took the length of 35 cm, somewhere 20-22 cm on the blade, and 12-13 on the hilt, but the width of the jamb turned out, only 35 mm, but oh well. A knife with a wide blade then do so, in the summer when you can unchain steel)))

Draw either by hand or on a computer, the contours of our future and the knife cut paper Tipo curve. Is applied to the web of steel and paint in black marker all that is necessary to remove from the canvas. We go to the machine and huyarim. That cutting is ready. Here I have some raschertil border runs, and began to withdraw slowly.

With here is no such contraptions, I did descents. This is the most complicated and long. Melt 2 buckets of snow))) it is necessary to cool the metal, otherwise overtempered.

After agonizing manufacturing runs, rascherchivaem upper limits of the knife, ie butt.

And we get is something like a knife.

And with the help of the bar, very rough, bring descents and derive the cutting edge in the rough. Well shkurochkoy walked a bit, see how it turns out.

The next step was PREPARATION handle. The guys asked for a slice of red bourgeois nut, not for free of course. Here he was sawn in 3 parts. Long thought to do some pen, like nickel silver tip, but a solid piece of nickel silver is not found, only the thin casting, but for my purposes, it somehow did not really asking her. I decided to clean the wood, but of the 3 pieces, allegedly guard and wooden handle. And the holes easier to do in small pieces. And from harvesting knife remove all unnecessary grinder and sandpaper. In parallel, even the skins of the blade slightly. I got crumpled, made the evenings and nights. At that time enough, and did so.

We mark up a piece of wood, and drill the holes and we clean to put on the shank. From halves not do, I do not like rivets, bridges extra slack handles. Even in cold weather, frost will burn on the hand.

Photos device does not, I will describe so on a flat board is glued to the skin of 2-sided tape, and using it to customize our pieces of wood together, so there are no gaps between them. So dressing and taking off every time on the shank. and remove the gap here.

After all the dancing with a tambourine zamatyvaem blade tape all the way to the glue did not get, a divorce epoxy according to the instructions and proceed.

We are putting our future together with a knife handle. I've pulled together a rope tightening using improvised means, no pictures ((But if you find a large clamp, then it will be easier.

A day later, intended for curing the adhesive, the host for processing handles. SPIL all the excess from the top of the handle with a small margin for further processing. It marks the symmetry axis and away from the edge of the future already handle. And he began to saw off all unnecessary.

Wood dense, hacksaw to saw long, but the main sawn)) and quite smoothly.

Sawed off on the sides of all superfluous, mark the contours of the future of the handle. And all saw off from the bottom.

leaving little for further processing in this case is not finished better than to saw.

Thanks to my teacher for works that do not booze and taught us and learn how to communicate with a file different))) are machined on all Files rude and not very much.

Round off the edge handles, has a small file and coarse sandpaper. Okay, that his wife was asleep and did not see a layer of sawdust))) but I lined a newspaper. and then wiping the floor with a wet cloth)) purity guarantee of success.

Well, after the skins, hides and skins of once, as bequeathed great. Gradually reducing grain sandpaper. This is an intermediate step next to the last love of my kitchen, Brazilian stainless steel.

Hides and handle and blade, leveling all the surfaces. The skins at any free time, both at work and at home.

Well, then take a piece of old felt boots manufacture such a device here: bolt, washer large wheels, felt, large washer, nut. Can one more Lock the nut. By the way round taking the skins and put on the outer side of the felt, you can perform polishing products)))

After all the grindings, the CD felt inflict GOI paste and grind the blade, to the mirror I have been too lazy to communicate, and there is nothing special to me a mirror. And the drill was not at hand, just a screwdriver, and it does not give such great revolutions required for better elimination.

And after the blade, take another blank disc, and they we clean all dust and wood chips. On the right course, in the beginning it was necessary to completely withdraw the blade to shine. And then the handle to do, but again, the time was limited to different conditions, and do it all at once.

After reviewing a bunch of impregnation, I decided to infiltrate the ancient way, though long, but reliable. I bought a couple of vials of linseed oil artistic. Since the pen is quite big and long, I had to buy a jar of some nasty things. Take a small pan on the bottom of gauze or cloth rag on the exposed bank. The jar pour oil into the pan water do not mix.

Heat the oil to 60-70 degrees, no more, epoxy does not like high temperatures, again zamatyvaem little blade with tape to avoid soiling it, and omit it our handle. And watched as the small wooden stand out air bubbles. As the bubbles stop, remove and wipe with a napkin. I have this procedure took about an hour, with several oil heating.

Lay off the knife on the sill under the rays of the sun, we need a UV polymerization oil. But I have a couple of times a cloth, wipe it with oil until the oil no longer be absorbed at all. Do not forget to turn it every day on the windowsill to all sides polymerized oil. In the evenings we do grind. Here I will not detail all the paint, another on the same topic will be enough theories sharpening knives. Yes, and I have not quite mastered it yet)) study yet.

In the meantime, the oil dries and tochitsya blade made of our shefa, marching variant, will make a sheath for it. I often go on nature, and cook there, and we have to take their knives from the Brazilian stainless steel, izvorachivayas wrap them and put neatly in a backpack, and so that the hand does not hurt if you get what is necessary, and not to pierce the edge of the pack. In general, the more Hemorrhoids. And I decided, once the width of the blade is not perfect for me, and made it a marching variant, Housing'll do another one. The truth probably shoot my wife)) Well, that's another question.

Again, we turn to our colleagues, and we take them another little piece of derevyahi. I decided from one tree to do everything. and handle and scabbard. Again pretends on a piece of paper, it will look like, and some of the pieces composed. Brusochek Mark up and cut into pieces. By this time, I took the lease grinder, which grinds cloth. And this miracle devaysom present door at the joints according to plan in a more or less decent condition. That is to exactly docked. Without major gaps.

That is the next stage, and my patience is exhausted. Drill a hole in each piece under the knife for a long time, I fussed with it, and the desire to quickly finish everything has been great, and because of this the night hastily pokleit these pieces are not fitted to a good joints. As a result, in one place and then swam jamb. But certainly not critical. Yes, and I pasted on Friday night already, and there was a desire for the rest of the process completely vyhi. And the night is still necessary to wait. and I did not postpone and pokleit.

Glued to the reinforcement by the way, that when the lateral load in places of gluing are not collapsed. He reinforced thin metal pins. Each junction of 2 studs.

Well, after the glue has dried, go to the garage, take a miracle grinding, and remove all superfluous with it.

And returns to the felt-device, take different skins to reduce and were ground to the smoothness of the limit, and then we clean pure felt.

The impregnation of the sheath decided to make cold process. True inside pour hot inside were particles of wax, and had them melted and infiltrated the outer part of the week, every day dealing with a thin layer. In the first hour of impregnation of course I inflicted layers until it is no longer absorbed. Well, the knife them. On the window sill. Turning constantly.

Once dried out a knife with a sheath, and polymerized oil, though not completely, then come again. Cooking composition for finishing. Take our beeswax and linseed oil in the proportions somewhere 2 parts oil to 1 part of wax, but I have to face, and perhaps could not stand straight, but after reading this before the recipes, I realized that there are no exact proportions like 1 1/3 want / 4, and you want to clean the wax processing. There was still the possibility of carnauba wax process, but decided to do so of our own, bee. In a water bath to melt the wax oil to homogeneity.

I strain through cheesecloth to get rid of parts of dead bees. Wax is natural, with all parts of the cells, and the smell of honey)).

Clean out all the blank disc derevyahi dust.

When the wax cools down would be a soft paste, take a piece and rub the wood cleared of dust outside of the them. Hairdryer we warm up to all the pores filled

and polish already felt all around the finish.

My task was a knife that can cut and meat, butcher, and that he kept sharpening afterwards. I love tomatoes with meat dishes, and their blunt knife to cut bad. I can say that the task is carried out with a bang. Brazilians because they can not. Knife course turned out not perfect, there are a couple of stocks on the slopes, a pair of stocks on the sheath, but these schools for more - aesthetic quibbles, and practical application have no effect. And I think for the first time forgivable))

Well, a little remark: the budget.

a piece of steel - 300 rubles.

tree on the handle and sheath - 500 rubles (of course, the board of the tree is a 5 rubles, but it is 2 meters, and I used the 15-20 cm from the boards of all)

skin - about 500 rubles.

linseed oil - 200 rubles.

1500

then go for the purchase of a knife, which remained in my possession for a lifetime, so it is difficult to count the cost price of a knife.

Files, Needle, and all sorts of stuff about 1k ruble

bars for sharpening conventional - 150 rubles

Diamond bar 1 to 5.

tisochki small 300 rubles

a total of about 4.5 rubles. It is certainly possible to find a ready knife in such a cost, but left without nishtyakov such as a diamond bar. which then would have to buy anyway.

All you can kick.

Source: