1580

The Sukhoi Superjet 100

Let's fast forward to the Far East and look at production SSJ100.

Assembling the finished product is divided into nine sections where there are certain assembly operations. Six sites are in the final assembly shop (DSP) of the aircraft, and three more were added by the former "Painting." On this panorama you can see the areas TsOSa from second to sixth. The first is not visible, it is hidden behind the central plane. Final assembly shop - a place where thousands of parts of the aircraft of the future are joined in a single entity, to become a great iron bird, packed with electronics and the most modern systems.

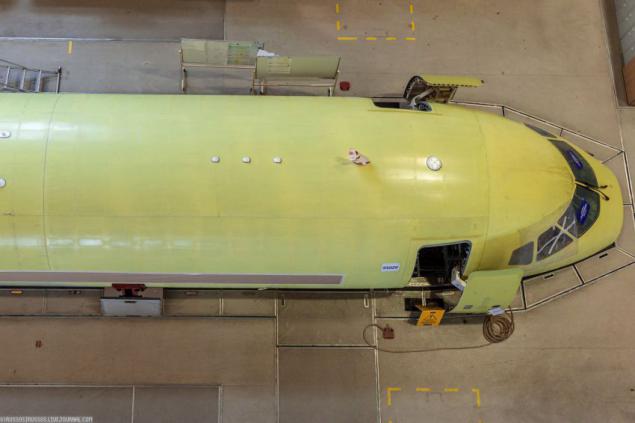

But it all starts here - in the first section. On the fuselage, which was brought already collected from the shop build the fuselage, hung doors, mounted stabilizer and fin.

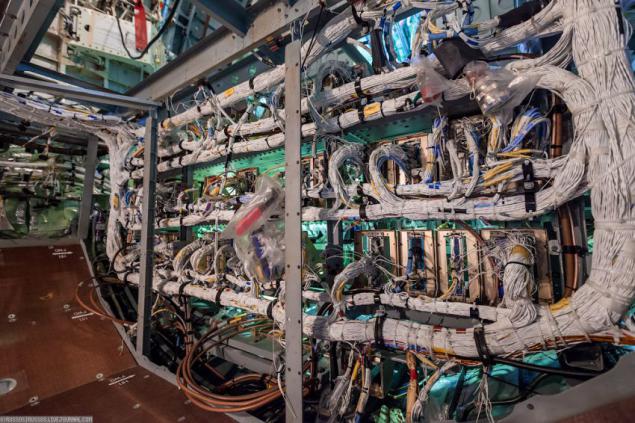

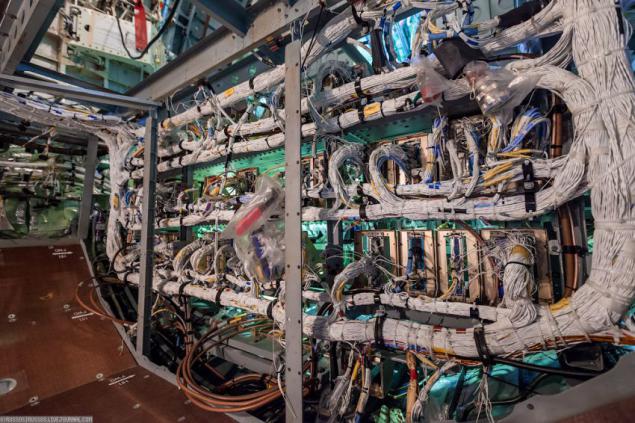

But to collect the aircraft structure - it is not even half the story - it's just very simple. And then begins a very difficult and demanding job of wiring harnesses and installation of the electrical network of the future car.

Wiring harness of the remote control is made in view of triple redundancy, and power cables - single trails of consumers in view of redundancy of the 1st category.

Work carried out in three shifts - around the clock and shift out about 300 major workers.

Center wing aircraft. In the second section it will be docked to the detachable part of the wing (SUNGLASSES). And in the center section is one of the fuel tanks. Two more - in the wing panel. The total stock of fuel for the two versions of the aircraft (B - basic and LR - extended range) - 12 690 kilograms.

By the way, over the past 25 years, was released 74 machines Tu-204 and Il-24, 96, respectively. GSS also from 2008 to 2014 have already released 50 cars, both experienced and serial. Feel the difference.

The bow, and the tail section and a stabilizer manufactured in Novosibirsk. Before they get off of Komsomolsk in the usual way on a trailer. Now one of the main tasks of the assembly of the aircraft - to unload the final assembly shop of the assembly operations that can be performed in other areas.

The main problem of domestic aircraft industry at all times was wiring and motors. There also seems to be able to solve them. Yet despite the restoration of the IL-14, I hit the wiring complexity in this relatively simple aircraft. And on the Superjet, which is essentially a flying computer, wiring harnesses, and a strong order more. The total length of the entire electrical network of a dozen kilometers. And the process of installation is very labor intensive and time consuming, which then requires a thorough and rigorous inspections. Traditionally, before (for example, on the Tu-154), after the wiring harness connectors were sealed manually, prozvanivatsya and labeled them. Work hellish. And, as usual, in such monotonous and demanding job, busy girl.

Therefore, a large force is now thrown to the modernization of the cable network. Harness - a bundle of wires from two to several tens or hundreds of living. Typically one end is placed one or more slots, and then the harness is branched to connect to various devices and systems. And earlier, at best, it was only sealed connectors on one side harness. On Superjet during the development of the production was able to reduce the number embedded in TsOSe connectors from 1,500 to 900. And this is not the limit. Again, for the main task of unloading TsOSa are working on the transfer of the wiring to other sites. Considerable work on the implementation of the new cable system, which will leave a large amount of manipulation by sealing of the connectors on the board. Now in the assembly hall of the fuselage will come with a ready network. And the rest of the wiring is installed using prefabricated wiring

In the second section of the fuselage comes docked with wings - a special system of locks and exposes them to respect each other, providing the necessary sweep and transverse V (the angle between the plane of the wing chord and transverse axis of the aircraft, when looking at the front of the plane).

The car with the number 95,036 is going to the Mexican airline Interjet. It electroplaits installation has been carried out already in the assembly of the fuselage, which will further relieve the DSP and reduce the time spent on the site of each machine.

Key support can have one of two versions: four-wheel or two-wheel truck. Select the type of support defines the main customer. Units of different sample supports unified, and the choice of the size of the landing gear is based on the need to place it any support.

The connection of the wing with the center section. Holes are drilled for connection and are sealed in place after the installation of all the parts of space. Since the joint between the wing and center-console is a very responsible union, drilling and cutting elements of the final design of the wing and center wing at the joint is made in TsOSe. When this compound is bolted. It also carried out a test tank and the center section of the caisson SUNGLASSES for leaks.

Installation of flaps.

The third portion. It completed work on the electrical system.

At that time, the production was nine planes, which were collected for the airline Interjet (Mexico) (one of the sides referred to the LIS, his first flight took place on March 24, 2013), Gazpromavia (version LR), Sky Aviation (Indonesia), Aeroflot, Lao Central (Lao PDR). Three of them were in the former "paint brushes", one of which is when we rolled out for the next test flight, but more on that later. The photo TsOSa the farthest left side - one of the first mass-produced cars, which is now back with the conservation and redesigning the interior to demonstrate the business version of the aircraft - Sukhoi Business Jet (SBJ). This aircraft is the fourth area where pressurized cabin after mounting SLE is being tested for leaks.

Initially cycle (finding the aircraft at the site) is 30 days.

Now 10, and by the end of 2014 it is planned to reduce the cycle to 5 days, which will release this year of about 50 aircraft.

The fifth section. There is almost ready aircraft. Completes installation of avionics and airborne systems. Being tested hydraulic system.

Reducing the stroke is due to the introduction of new technologies, staff motivation, changes in technology and work to optimize it.

Pylon engine is a titanium box. It was very light, compact and with a minimum number of parts.

Complete wiring of the aircraft and its heart - the autopilot units and on-board computer. The aircraft is certified as Protected Aircraft. Similar certificates are A320, A330, A340, A380 and the Dassault Falcon 7X. This means that the control system monitors the actions of the Superjet pilots and gives them to enter the illegal flight mode. And at the moment among the produced models on this aircraft is equipped with the most fancy FBWCS system (wire control system).

For electricity and hydraulic pressure in the event of engine failure, there is provided a wind generator, which automatically discharged into the air stream, and provides the necessary current to the control system.

From machine shop out with such facilities. Further, the board flies in Ulyanovsk, or the Czech Republic to Venice (depending on the wishes of the customer) for the installation and painting the interior of the aircraft in the airline's corporate colors of the customer.

The front part of the cab at the front door. In general, it struck me that absolutely all the connectors are provided with connection plugs and packed in bags. And, perhaps, of all industries, where I've ever been, this is one of the most beautiful.

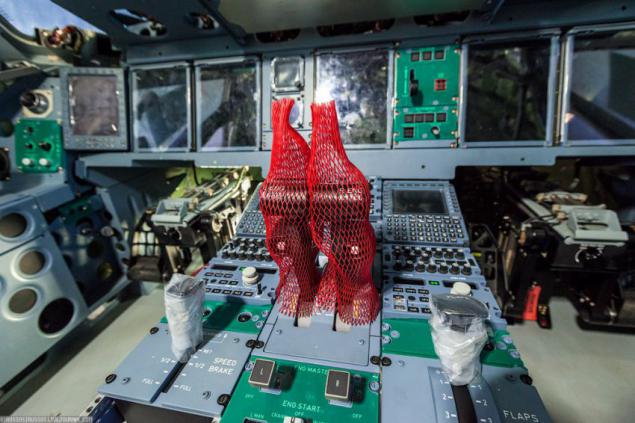

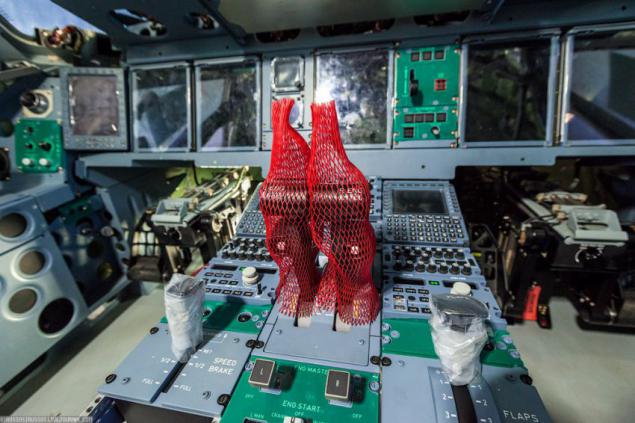

Cab drivers during installation of avionics.

Avionics made by French company Thales, which also makes it for Airbus.

everoyatno beautiful red cheholchiki on ores. A green surface on the dashboard - a protective film.

Technical protection against unauthorized opening of the vents on during final assembly. Cheerful people working on kanafeh - they helped her castle :) Well, you remember Mimino? :)

Main during assembly of the aircraft - to withstand cycles. All operations are strictly rationed, and much depends on component suppliers. Establish work with them, to bring all the parts and put in time to the workplace - that even art!

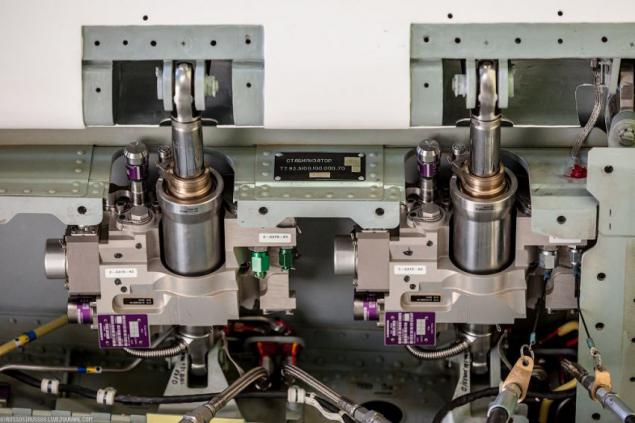

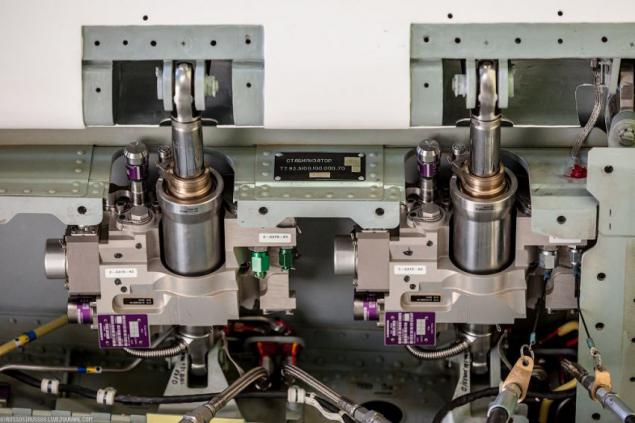

The uniqueness of the Sukhoi Superjet 100 aircraft is the first time in the world for aircraft of this class was created by digital wire control system without heavy mechanical alarm system. Abroad, only one aircraft has the same control system - the A380. The ailerons and elevators are operated by two elektrogidroprivodami (pictured just drive the elevator), where each of them is working on various hydraulic systems. One of the drives is always in active mode and the second passive. Change of roles happens every time you turn on the aircraft under current.

The tail door and a sealed bulkhead. On the right, near the bulkhead, is an emergency recorder. This is the sixth station.

Part of the air conditioning system.

Studying the documentation, I stumbled upon a system of neutral gas. It turns out that it is designed to prevent the formation of flammable vapors in fuel tanks by reducing the content of oxygen and nitrogen pressurization of which with the aid of a membrane separator is released from the outboard air. Such a system is installed on domestic aircraft for the first time and it gives military background aircraft manufacturer: Dry well designed and military vehicles - there are tanks with nitrogen pressurization system has long been used on the fighters.

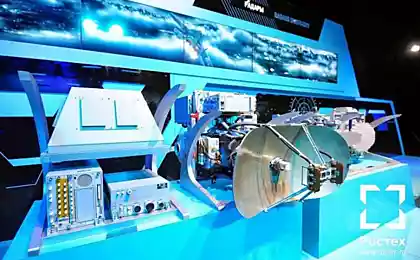

Installation of the radar. Since the machine manufacturer's serial number 95025 (Full version for Aeroflot) locator on the SSJ100 will show wind shear.

The sixth section is mounted engines and put the plane under the current. During the winter this area put the next board only after it refueled with kerosene and checked for purity tanks. Then, the plane weighed after filling and draining of fuel are calculated undrainable residue. If all goes well, the re-activation occurs engines and APU.

As told by test pilots GSS, the SaM146 engine has shown amazing reliability in operation. In April 2012, in the shuttle flight, during landing at Sheremetyevo plane collided with a migrating goose. Gus (not like pigeons and other small birds) was in the left engine. Shot hit the fan stage low-pressure compressor. It is his (goose) unwound and knocked out by the cold loop. At the same time a little bent ends of the blades of the fan a few steps, and the engine continued to work without comment. In another flight one engine caught three seagulls, and the second, almost immediately, two. The power plant has survived and it is.

All assembly work TsOSe almost completed. The sixth section passes the baton to the first, which are just starting to collect the new board. A graduate is sent to the receiving and inspection of all systems.

The road to LIS - where he was waiting for factory testing and the first flight.

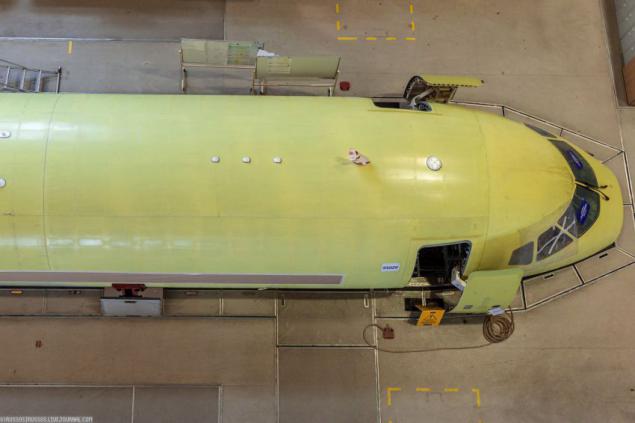

The aircraft with increased range SSJ 100LR. The prototype (95032) made its first flight February 12, 2013

In the hangar another aircraft for the Mexican Interjet. This, with the serial number 95028, first flew on March 24, 2013.

Panorama of the former paint shop, which has recently been converted to the tasks of the DSP. In the center - 95025 machine - full version for Aeroflot. About her rolling out some interesting details in the next post.

Source: russos.livejournal.com

Assembling the finished product is divided into nine sections where there are certain assembly operations. Six sites are in the final assembly shop (DSP) of the aircraft, and three more were added by the former "Painting." On this panorama you can see the areas TsOSa from second to sixth. The first is not visible, it is hidden behind the central plane. Final assembly shop - a place where thousands of parts of the aircraft of the future are joined in a single entity, to become a great iron bird, packed with electronics and the most modern systems.

But it all starts here - in the first section. On the fuselage, which was brought already collected from the shop build the fuselage, hung doors, mounted stabilizer and fin.

But to collect the aircraft structure - it is not even half the story - it's just very simple. And then begins a very difficult and demanding job of wiring harnesses and installation of the electrical network of the future car.

Wiring harness of the remote control is made in view of triple redundancy, and power cables - single trails of consumers in view of redundancy of the 1st category.

Work carried out in three shifts - around the clock and shift out about 300 major workers.

Center wing aircraft. In the second section it will be docked to the detachable part of the wing (SUNGLASSES). And in the center section is one of the fuel tanks. Two more - in the wing panel. The total stock of fuel for the two versions of the aircraft (B - basic and LR - extended range) - 12 690 kilograms.

By the way, over the past 25 years, was released 74 machines Tu-204 and Il-24, 96, respectively. GSS also from 2008 to 2014 have already released 50 cars, both experienced and serial. Feel the difference.

The bow, and the tail section and a stabilizer manufactured in Novosibirsk. Before they get off of Komsomolsk in the usual way on a trailer. Now one of the main tasks of the assembly of the aircraft - to unload the final assembly shop of the assembly operations that can be performed in other areas.

The main problem of domestic aircraft industry at all times was wiring and motors. There also seems to be able to solve them. Yet despite the restoration of the IL-14, I hit the wiring complexity in this relatively simple aircraft. And on the Superjet, which is essentially a flying computer, wiring harnesses, and a strong order more. The total length of the entire electrical network of a dozen kilometers. And the process of installation is very labor intensive and time consuming, which then requires a thorough and rigorous inspections. Traditionally, before (for example, on the Tu-154), after the wiring harness connectors were sealed manually, prozvanivatsya and labeled them. Work hellish. And, as usual, in such monotonous and demanding job, busy girl.

Therefore, a large force is now thrown to the modernization of the cable network. Harness - a bundle of wires from two to several tens or hundreds of living. Typically one end is placed one or more slots, and then the harness is branched to connect to various devices and systems. And earlier, at best, it was only sealed connectors on one side harness. On Superjet during the development of the production was able to reduce the number embedded in TsOSe connectors from 1,500 to 900. And this is not the limit. Again, for the main task of unloading TsOSa are working on the transfer of the wiring to other sites. Considerable work on the implementation of the new cable system, which will leave a large amount of manipulation by sealing of the connectors on the board. Now in the assembly hall of the fuselage will come with a ready network. And the rest of the wiring is installed using prefabricated wiring

In the second section of the fuselage comes docked with wings - a special system of locks and exposes them to respect each other, providing the necessary sweep and transverse V (the angle between the plane of the wing chord and transverse axis of the aircraft, when looking at the front of the plane).

The car with the number 95,036 is going to the Mexican airline Interjet. It electroplaits installation has been carried out already in the assembly of the fuselage, which will further relieve the DSP and reduce the time spent on the site of each machine.

Key support can have one of two versions: four-wheel or two-wheel truck. Select the type of support defines the main customer. Units of different sample supports unified, and the choice of the size of the landing gear is based on the need to place it any support.

The connection of the wing with the center section. Holes are drilled for connection and are sealed in place after the installation of all the parts of space. Since the joint between the wing and center-console is a very responsible union, drilling and cutting elements of the final design of the wing and center wing at the joint is made in TsOSe. When this compound is bolted. It also carried out a test tank and the center section of the caisson SUNGLASSES for leaks.

Installation of flaps.

The third portion. It completed work on the electrical system.

At that time, the production was nine planes, which were collected for the airline Interjet (Mexico) (one of the sides referred to the LIS, his first flight took place on March 24, 2013), Gazpromavia (version LR), Sky Aviation (Indonesia), Aeroflot, Lao Central (Lao PDR). Three of them were in the former "paint brushes", one of which is when we rolled out for the next test flight, but more on that later. The photo TsOSa the farthest left side - one of the first mass-produced cars, which is now back with the conservation and redesigning the interior to demonstrate the business version of the aircraft - Sukhoi Business Jet (SBJ). This aircraft is the fourth area where pressurized cabin after mounting SLE is being tested for leaks.

Initially cycle (finding the aircraft at the site) is 30 days.

Now 10, and by the end of 2014 it is planned to reduce the cycle to 5 days, which will release this year of about 50 aircraft.

The fifth section. There is almost ready aircraft. Completes installation of avionics and airborne systems. Being tested hydraulic system.

Reducing the stroke is due to the introduction of new technologies, staff motivation, changes in technology and work to optimize it.

Pylon engine is a titanium box. It was very light, compact and with a minimum number of parts.

Complete wiring of the aircraft and its heart - the autopilot units and on-board computer. The aircraft is certified as Protected Aircraft. Similar certificates are A320, A330, A340, A380 and the Dassault Falcon 7X. This means that the control system monitors the actions of the Superjet pilots and gives them to enter the illegal flight mode. And at the moment among the produced models on this aircraft is equipped with the most fancy FBWCS system (wire control system).

For electricity and hydraulic pressure in the event of engine failure, there is provided a wind generator, which automatically discharged into the air stream, and provides the necessary current to the control system.

From machine shop out with such facilities. Further, the board flies in Ulyanovsk, or the Czech Republic to Venice (depending on the wishes of the customer) for the installation and painting the interior of the aircraft in the airline's corporate colors of the customer.

The front part of the cab at the front door. In general, it struck me that absolutely all the connectors are provided with connection plugs and packed in bags. And, perhaps, of all industries, where I've ever been, this is one of the most beautiful.

Cab drivers during installation of avionics.

Avionics made by French company Thales, which also makes it for Airbus.

everoyatno beautiful red cheholchiki on ores. A green surface on the dashboard - a protective film.

Technical protection against unauthorized opening of the vents on during final assembly. Cheerful people working on kanafeh - they helped her castle :) Well, you remember Mimino? :)

Main during assembly of the aircraft - to withstand cycles. All operations are strictly rationed, and much depends on component suppliers. Establish work with them, to bring all the parts and put in time to the workplace - that even art!

The uniqueness of the Sukhoi Superjet 100 aircraft is the first time in the world for aircraft of this class was created by digital wire control system without heavy mechanical alarm system. Abroad, only one aircraft has the same control system - the A380. The ailerons and elevators are operated by two elektrogidroprivodami (pictured just drive the elevator), where each of them is working on various hydraulic systems. One of the drives is always in active mode and the second passive. Change of roles happens every time you turn on the aircraft under current.

The tail door and a sealed bulkhead. On the right, near the bulkhead, is an emergency recorder. This is the sixth station.

Part of the air conditioning system.

Studying the documentation, I stumbled upon a system of neutral gas. It turns out that it is designed to prevent the formation of flammable vapors in fuel tanks by reducing the content of oxygen and nitrogen pressurization of which with the aid of a membrane separator is released from the outboard air. Such a system is installed on domestic aircraft for the first time and it gives military background aircraft manufacturer: Dry well designed and military vehicles - there are tanks with nitrogen pressurization system has long been used on the fighters.

Installation of the radar. Since the machine manufacturer's serial number 95025 (Full version for Aeroflot) locator on the SSJ100 will show wind shear.

The sixth section is mounted engines and put the plane under the current. During the winter this area put the next board only after it refueled with kerosene and checked for purity tanks. Then, the plane weighed after filling and draining of fuel are calculated undrainable residue. If all goes well, the re-activation occurs engines and APU.

As told by test pilots GSS, the SaM146 engine has shown amazing reliability in operation. In April 2012, in the shuttle flight, during landing at Sheremetyevo plane collided with a migrating goose. Gus (not like pigeons and other small birds) was in the left engine. Shot hit the fan stage low-pressure compressor. It is his (goose) unwound and knocked out by the cold loop. At the same time a little bent ends of the blades of the fan a few steps, and the engine continued to work without comment. In another flight one engine caught three seagulls, and the second, almost immediately, two. The power plant has survived and it is.

All assembly work TsOSe almost completed. The sixth section passes the baton to the first, which are just starting to collect the new board. A graduate is sent to the receiving and inspection of all systems.

The road to LIS - where he was waiting for factory testing and the first flight.

The aircraft with increased range SSJ 100LR. The prototype (95032) made its first flight February 12, 2013

In the hangar another aircraft for the Mexican Interjet. This, with the serial number 95028, first flew on March 24, 2013.

Panorama of the former paint shop, which has recently been converted to the tasks of the DSP. In the center - 95025 machine - full version for Aeroflot. About her rolling out some interesting details in the next post.

Source: russos.livejournal.com