771

In the production of the Sukhoi Superjet 100

NAPO. Chkalov ("Chkalovsky plant") - one of the largest enterprises in Russia Aircraft Manufacturing, part of the company "Sukhoi". In addition to the state defense order in 2004, the company, together with Russian and foreign partners, is working on the Sukhoi Superjet 100 (SSj-100) - the new Russian regional aircraft. The plant manufactures the nose and tail sections of fuselages and horizontal and vertical tail.

28 photos

The introduction of the enterprise modern equipment for the machining of parts of civil airliner the Sukhoi Superjet 100 began in 2007

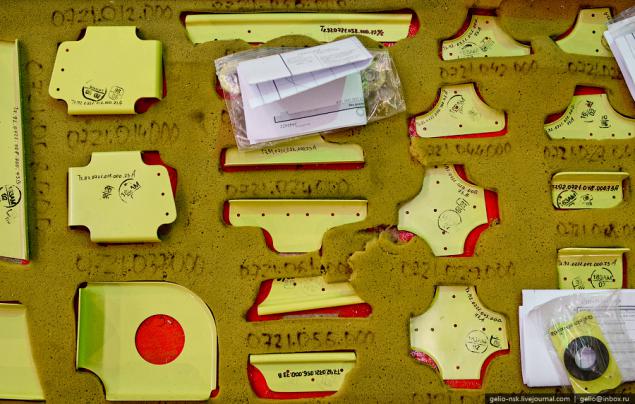

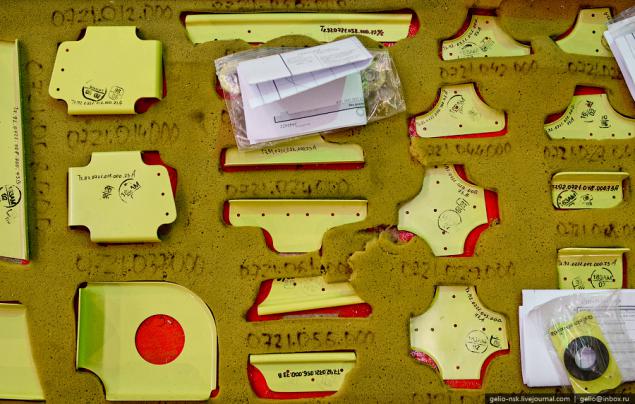

The interim storage plant components are located in designated lodgment. In each component in place.

This method of storage enables warehouse workers to save time in their search for when picking and delivery to the assembly.

Each set has its own "passport»

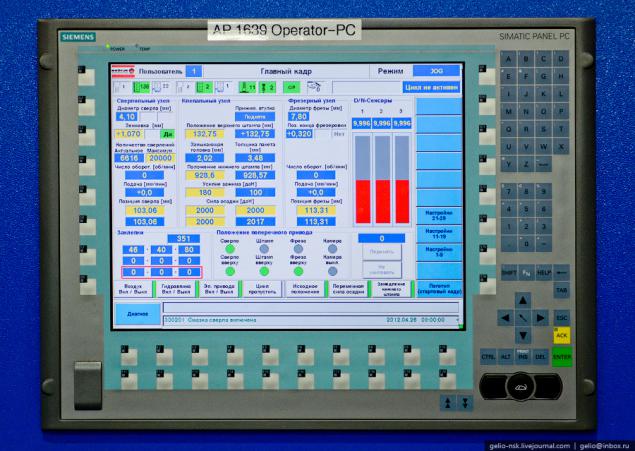

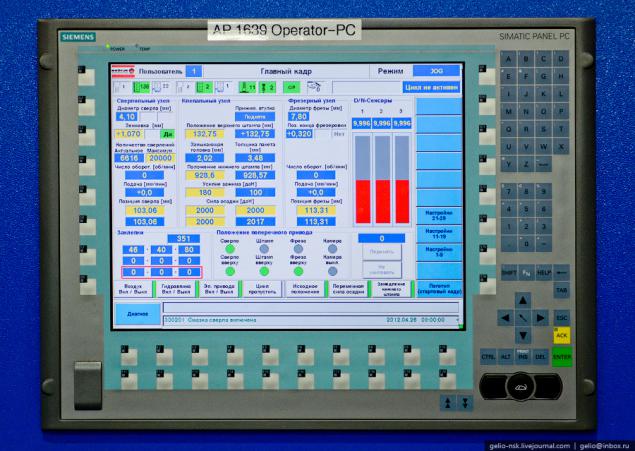

The operator of the machining center is preparing processing.

After processing the sheet metal panel liner turns into

The metal is placed in a machining center Handtmann

Handtmann is a high-speed five-axis machining center, computer controlled with high accuracy to produce large-sized parts and panels.

Ready panel, waiting for their turn to build

Drilling and riveting press «Broetie» dowel for large panels of the liner.

Designed to minimize manual labor fitter-assemblers.

10

Despite the automation of many production processes, profession fitter-assemblers and fitter still remain the most popular in the manufacture of aircraft constructing.

Riveting cabin liner

13

Carcass cockpit

15

16

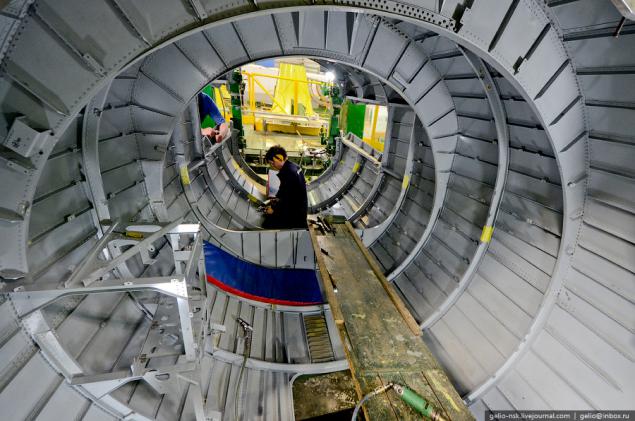

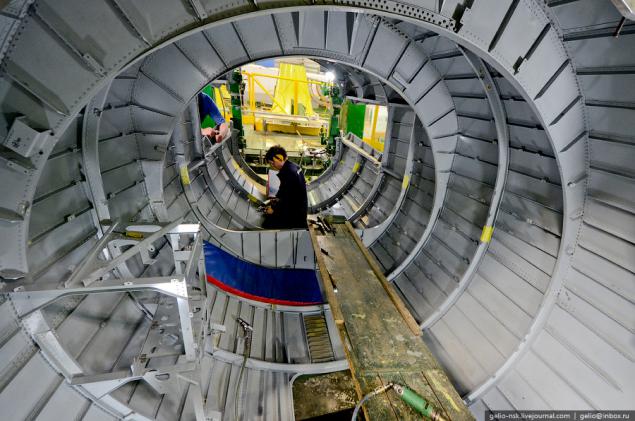

Assembling the rear fuselage

See all reinforcing elements of design: spars, stringers, frames, etc.

18

Fitter

Assembling the horizontal stabilizer - Stabilizer liner.

The forward fuselage airliner on final assembly.

Operators machining center

Frame horizontal tail liner

Paint accessories

At the beginning of 2008, NAPO launched a program of technologies "lean" manufacturing (Lean-technology) designed to significantly reduce the cycle of assembly of the aircraft, by improving the processes by several management decisions and a number of organizational methods. Experience of which was borrowed from industrial giants such as Toyota and Boeing.

The plant is located near "SibNIA" conducted endurance testing of aircraft SSJ-100.

The Sukhoi Superjet 100 - a Russian short-haul passenger aircraft.

Family aircraft Sukhoi SuperJet-100 is designed for range up to 4400 km.

The first flight of the prototype took place on 19 May 2008 and the beginning of operation of 21 April 2011.

Source:

28 photos

The introduction of the enterprise modern equipment for the machining of parts of civil airliner the Sukhoi Superjet 100 began in 2007

The interim storage plant components are located in designated lodgment. In each component in place.

This method of storage enables warehouse workers to save time in their search for when picking and delivery to the assembly.

Each set has its own "passport»

The operator of the machining center is preparing processing.

After processing the sheet metal panel liner turns into

The metal is placed in a machining center Handtmann

Handtmann is a high-speed five-axis machining center, computer controlled with high accuracy to produce large-sized parts and panels.

Ready panel, waiting for their turn to build

Drilling and riveting press «Broetie» dowel for large panels of the liner.

Designed to minimize manual labor fitter-assemblers.

10

Despite the automation of many production processes, profession fitter-assemblers and fitter still remain the most popular in the manufacture of aircraft constructing.

Riveting cabin liner

13

Carcass cockpit

15

16

Assembling the rear fuselage

See all reinforcing elements of design: spars, stringers, frames, etc.

18

Fitter

Assembling the horizontal stabilizer - Stabilizer liner.

The forward fuselage airliner on final assembly.

Operators machining center

Frame horizontal tail liner

Paint accessories

At the beginning of 2008, NAPO launched a program of technologies "lean" manufacturing (Lean-technology) designed to significantly reduce the cycle of assembly of the aircraft, by improving the processes by several management decisions and a number of organizational methods. Experience of which was borrowed from industrial giants such as Toyota and Boeing.

The plant is located near "SibNIA" conducted endurance testing of aircraft SSJ-100.

The Sukhoi Superjet 100 - a Russian short-haul passenger aircraft.

Family aircraft Sukhoi SuperJet-100 is designed for range up to 4400 km.

The first flight of the prototype took place on 19 May 2008 and the beginning of operation of 21 April 2011.

Source: