1504

Salt production in Kazakhstan

In Soviet times it was different, mining Aral salt reached 600 thousand tonnes annually, now - 250 thousand tons.

15 republics of the Soviet Union provided mined salt, it is now used only for the domestic market.

It's a new time, private investors have taken matters into their own hands, there are new technologies, cut jobs, and even salt has changed ...

Stocks of salt in the southern basin constitute 11 million. Tons, which is enough for about another 40 -50 years. Restoration of salt reserves of the lake occurs every 35-45 years

Salt formed after evaporation of highly concentrated salt brine

The thickness of the salt layer reaches 1, 5 meters. Now salt extraction from the lake takes place every two years, from May to November. Volume production for the season is 250 thousand tons

Rubber boots six months so corroded by salt, that they have to change. On the seasonal extraction, transportation and unloading of salt attracts more than 100 workers. Furthermore they are constantly at the plant JSC "Araltuz" employs 700 people at its facilities allow to contain only 400. But the leadership of the plant is on it to give us something to take local people. But on the lake protection ensures that thieves do not pilfered abandoned equipment

In the old days people extracted salt manually, the clock is at the concentrated salt water

The deposit is located 10 km from the village Zhaksykylysh, which is home to about 6000 people. All of them tend to work in the factory. The average salary is 30-35 thousand tenge

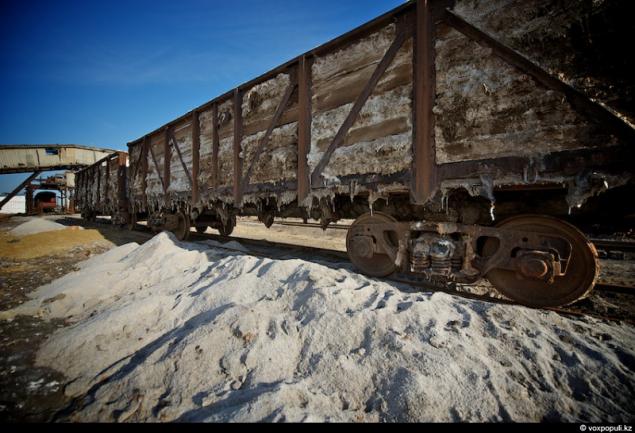

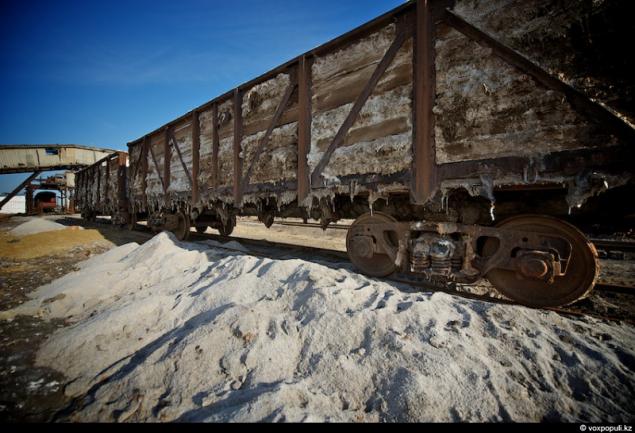

After the salt produced, it is transferred to a gondola. In the night on the hill sent 40 wagons

After the salt is fed to unloader TR-2 (conveyor of high bugrovaniya)

The height of the salt mountain is 25 meters

With the help of a bulldozer made bugrovaniya process and storage of salt on the hill

Stockpiled salt hardens and in order to loosen it, it explodes with the help of ammonites

Salt raw salt from the mound for processing into a hopper is supplied with bulldozers

And there already using conveyor funds goes to grinding and enrichment department

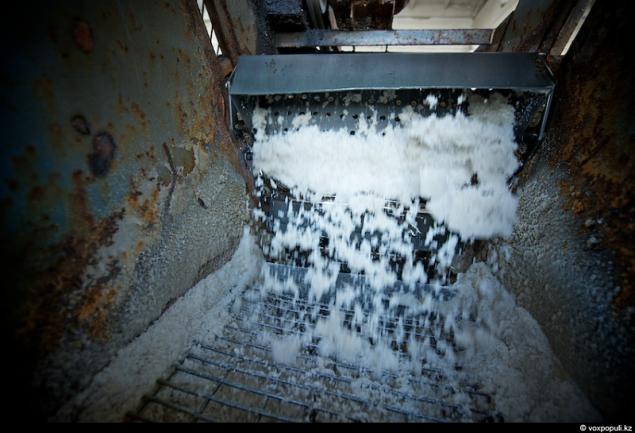

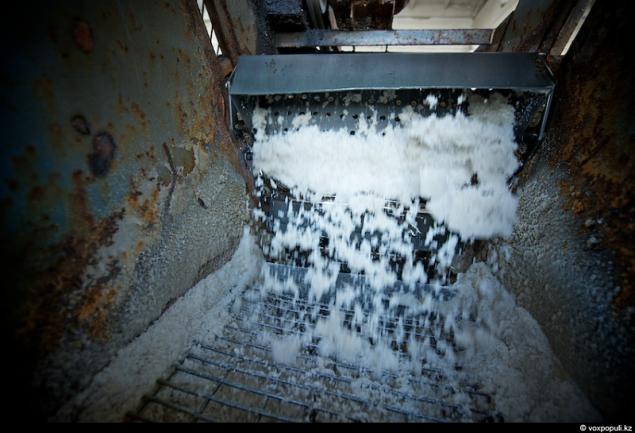

Since the conveyor belt is fed to the crushing salt

The spiral classifier salt passes the primary stage of enrichment

For this purpose, a classifier is fed lake brine - brine

After spiral classifier and a countercurrent separator salt is fed to a dewatering elevator

And only after that enriched salt is fed into the drying compartment where the COP apparatus (fluidized bed) by means of hot air from the drying process occurs elektrokolarifera

Dried salt at a temperature of 100 -140S

And then begins the process of iodization. In the past, when there was no special equipment to enrich salt with minerals and iodine, salt was not purified, so it had a grayish tint. Now she is white

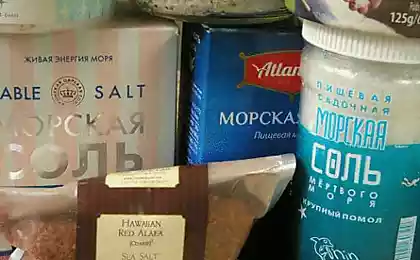

Ready salt laid out in polypropylene bags of 10, 30, 50 kg

Prepacked salt of the feed conveyor is fed to the packaging process

And from there to zheleznorozhnye covered wagons. Every day, the plant sends 4-5 wagon all over Kazakhstan

Warehouse "Araltuz" accommodates 750 tons

Several years ago, enterprising people from the south of Kazakhstan tried to counterfeit products "Araltuz", creating the same package, but fasuya unsupplemented and non-iodized salt from Suzak field. To distinguish a fake, when you buy should pay attention to marking and manufacture date of the salt

Before sending the salt production laboratory checks every two hours finished products for the maintenance of minerals and iodine percentage

Source: www.voxpopuli.kz

15 republics of the Soviet Union provided mined salt, it is now used only for the domestic market.

It's a new time, private investors have taken matters into their own hands, there are new technologies, cut jobs, and even salt has changed ...

Stocks of salt in the southern basin constitute 11 million. Tons, which is enough for about another 40 -50 years. Restoration of salt reserves of the lake occurs every 35-45 years

Salt formed after evaporation of highly concentrated salt brine

The thickness of the salt layer reaches 1, 5 meters. Now salt extraction from the lake takes place every two years, from May to November. Volume production for the season is 250 thousand tons

Rubber boots six months so corroded by salt, that they have to change. On the seasonal extraction, transportation and unloading of salt attracts more than 100 workers. Furthermore they are constantly at the plant JSC "Araltuz" employs 700 people at its facilities allow to contain only 400. But the leadership of the plant is on it to give us something to take local people. But on the lake protection ensures that thieves do not pilfered abandoned equipment

In the old days people extracted salt manually, the clock is at the concentrated salt water

The deposit is located 10 km from the village Zhaksykylysh, which is home to about 6000 people. All of them tend to work in the factory. The average salary is 30-35 thousand tenge

After the salt produced, it is transferred to a gondola. In the night on the hill sent 40 wagons

After the salt is fed to unloader TR-2 (conveyor of high bugrovaniya)

The height of the salt mountain is 25 meters

With the help of a bulldozer made bugrovaniya process and storage of salt on the hill

Stockpiled salt hardens and in order to loosen it, it explodes with the help of ammonites

Salt raw salt from the mound for processing into a hopper is supplied with bulldozers

And there already using conveyor funds goes to grinding and enrichment department

Since the conveyor belt is fed to the crushing salt

The spiral classifier salt passes the primary stage of enrichment

For this purpose, a classifier is fed lake brine - brine

After spiral classifier and a countercurrent separator salt is fed to a dewatering elevator

And only after that enriched salt is fed into the drying compartment where the COP apparatus (fluidized bed) by means of hot air from the drying process occurs elektrokolarifera

Dried salt at a temperature of 100 -140S

And then begins the process of iodization. In the past, when there was no special equipment to enrich salt with minerals and iodine, salt was not purified, so it had a grayish tint. Now she is white

Ready salt laid out in polypropylene bags of 10, 30, 50 kg

Prepacked salt of the feed conveyor is fed to the packaging process

And from there to zheleznorozhnye covered wagons. Every day, the plant sends 4-5 wagon all over Kazakhstan

Warehouse "Araltuz" accommodates 750 tons

Several years ago, enterprising people from the south of Kazakhstan tried to counterfeit products "Araltuz", creating the same package, but fasuya unsupplemented and non-iodized salt from Suzak field. To distinguish a fake, when you buy should pay attention to marking and manufacture date of the salt

Before sending the salt production laboratory checks every two hours finished products for the maintenance of minerals and iodine percentage

Source: www.voxpopuli.kz