1862

Design and manufacture of wooden clock

It is always interesting to read about the people who make all sorts of unusual things. Sometimes these stories are an incentive to collect something like that, and sometimes they just voskhischaeshsya because you know - is very unlikely to get done. It was about this diy I want to tell more precisely about one of his classes - designing and manufacturing of wooden clock. In the photo he is. Call him Andrew, the name Kuznetsov.

Everything you need is in the garage.

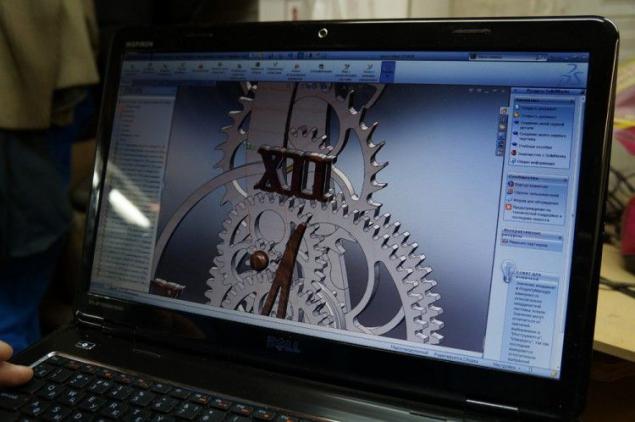

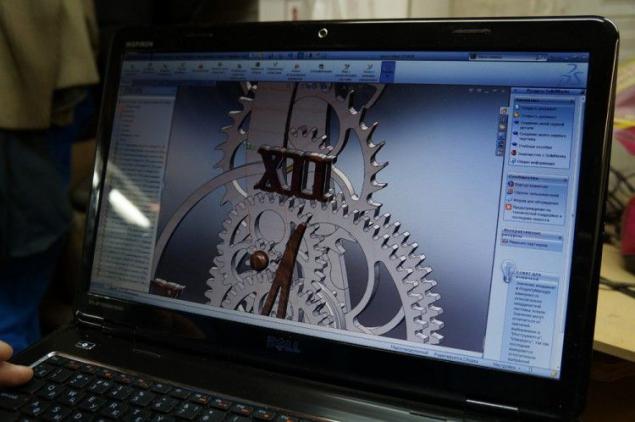

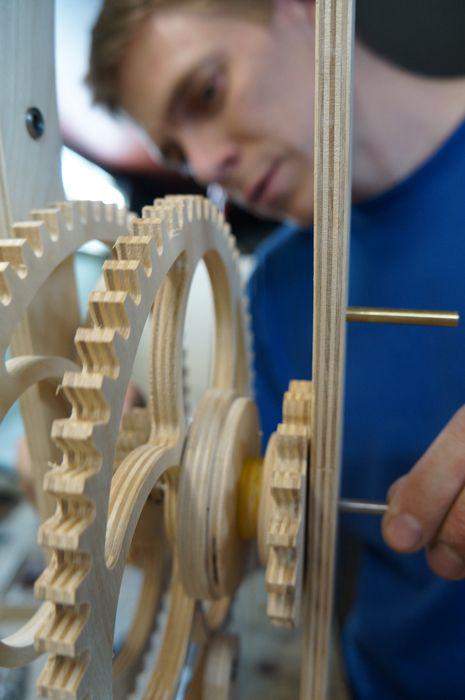

It begins with design hours - calculation of the trigger mechanism, gearbox and all other components whose names I do not know.

Bit closer, suddenly someone wants to enjoy the interface or read the name of the program. For those who failed to report, everything is done in SolidWorks.

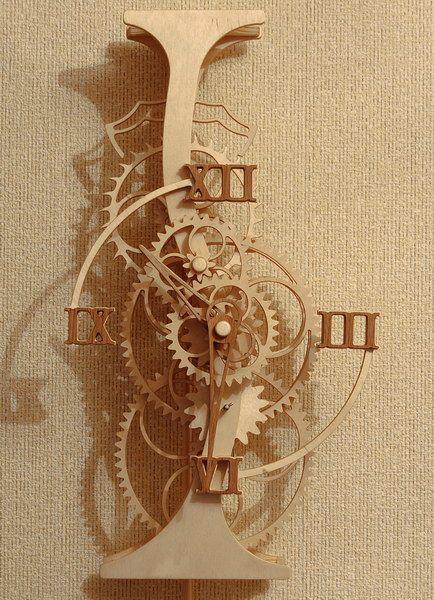

This is one of the designs of hours, and they are all different, for example such.

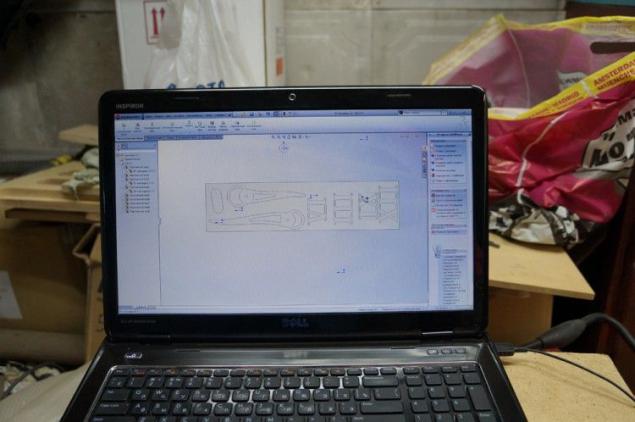

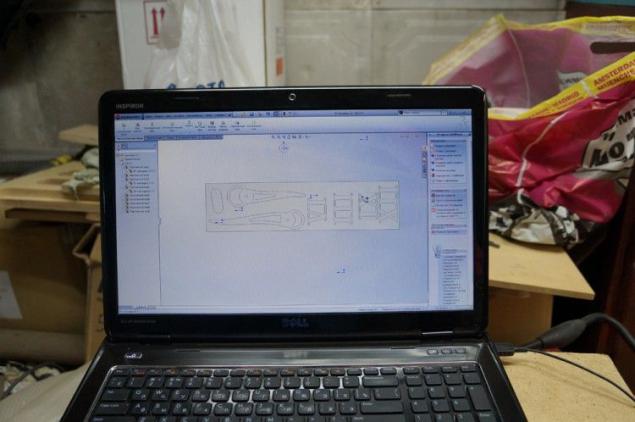

The watch is designed, it is time to cut the part. This will cut milling machine controlled by a computer that emulates the CNC (hopefully nothing is messed up).

To do this, the details on the company's list.

And transferred to a computer connected to the other computer that emulates the CNC.

Here is a file movement cutter and sent to the PC-NC.

Secured fanerka.

Exhibiting the starting point.

And forward. Headphones are not here for the beauty - the noise from the machine as during takeoff.

It helps him in this vacuum cleaner, incidentally, also homemade. In the photo he left, if anything.

First, the internal circuits are cut, then the outside and ready Circuits.

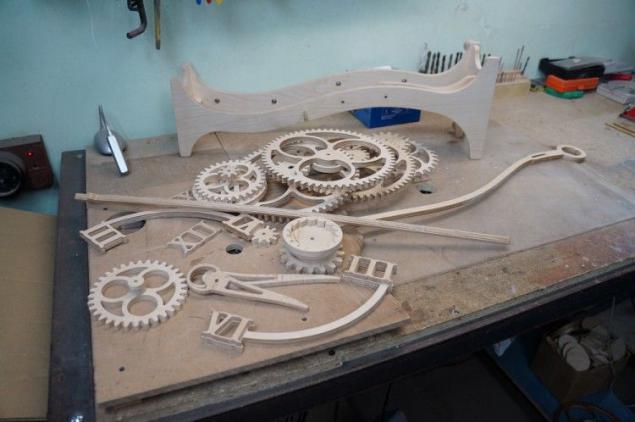

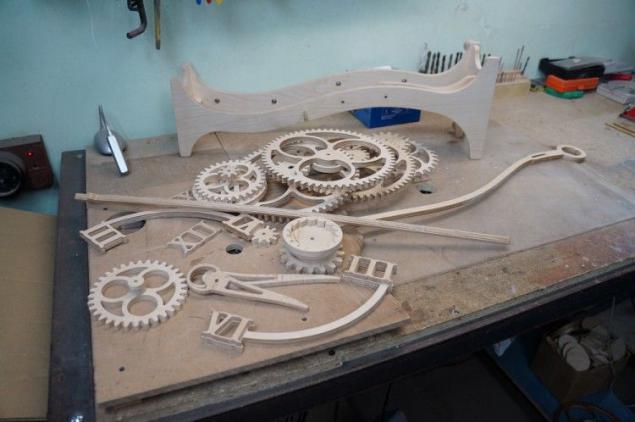

All sawed and turned around a set of: frame, all sorts of gear, folding pendulum arrows and decorative objects.

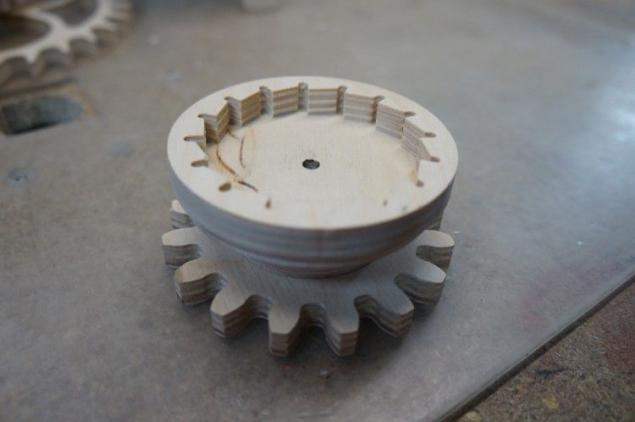

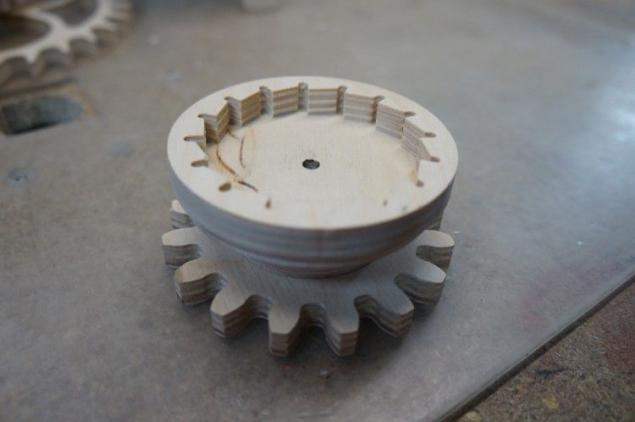

And this is the main wheel (do not know how on the scientific name). It screwed thread with the load, causing it revolves. It, in turn, vraschet shaft on which is mounted a minute hand. Clock gear rotates through slowing. Something like this.

All is ready for assembly.

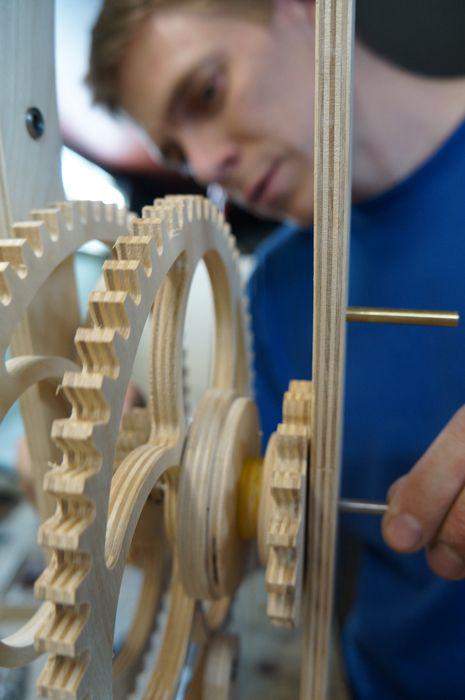

Please hang up the gear wheel motor reducer.

All shafts bearings. By reducing the friction of all the parts, it requires less load weights for the operation of the entire mechanism.

Then mounted gear trigger. Together with the anchor they convert a rotary motion of the main wheel in a "step", counting seconds.

Check. All the twists and turns.

Put the anchor. Now spin the wheel will not turn.

The mechanism assembly. In the long pin is the minute hand. Below - the plant, there is inserted the key and lifts the weight. At the top of the shaft for mounting decelerating gear clockwise.

Check progress. Kettlebell lowered anchor walks, spinning gears. Beauty.

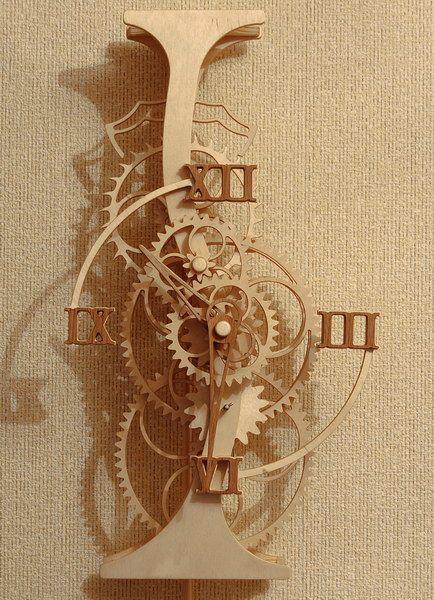

You're all varnished, hang arrows, numbers, and you get a weight like this.

Source: ibigdan.livejournal.com

Everything you need is in the garage.

It begins with design hours - calculation of the trigger mechanism, gearbox and all other components whose names I do not know.

Bit closer, suddenly someone wants to enjoy the interface or read the name of the program. For those who failed to report, everything is done in SolidWorks.

This is one of the designs of hours, and they are all different, for example such.

The watch is designed, it is time to cut the part. This will cut milling machine controlled by a computer that emulates the CNC (hopefully nothing is messed up).

To do this, the details on the company's list.

And transferred to a computer connected to the other computer that emulates the CNC.

Here is a file movement cutter and sent to the PC-NC.

Secured fanerka.

Exhibiting the starting point.

And forward. Headphones are not here for the beauty - the noise from the machine as during takeoff.

It helps him in this vacuum cleaner, incidentally, also homemade. In the photo he left, if anything.

First, the internal circuits are cut, then the outside and ready Circuits.

All sawed and turned around a set of: frame, all sorts of gear, folding pendulum arrows and decorative objects.

And this is the main wheel (do not know how on the scientific name). It screwed thread with the load, causing it revolves. It, in turn, vraschet shaft on which is mounted a minute hand. Clock gear rotates through slowing. Something like this.

All is ready for assembly.

Please hang up the gear wheel motor reducer.

All shafts bearings. By reducing the friction of all the parts, it requires less load weights for the operation of the entire mechanism.

Then mounted gear trigger. Together with the anchor they convert a rotary motion of the main wheel in a "step", counting seconds.

Check. All the twists and turns.

Put the anchor. Now spin the wheel will not turn.

The mechanism assembly. In the long pin is the minute hand. Below - the plant, there is inserted the key and lifts the weight. At the top of the shaft for mounting decelerating gear clockwise.

Check progress. Kettlebell lowered anchor walks, spinning gears. Beauty.

You're all varnished, hang arrows, numbers, and you get a weight like this.

Source: ibigdan.livejournal.com