540

How to make monolithic stairs with their hands

The charging device of monolithic stairs — simple and reliable solution for massive porch or a separate entrance to the building. It can be done, not possessing special knowledge or skills in their hands. You need only desire and a minimal set of tools.

Fifty four million eight hundred thirty six thousand one hundred forty six

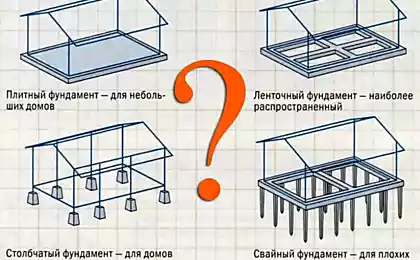

DesignMonolithic stairs sediment consists of a rigid box made of bricks or cinder blocks, platforms and stairs. The space under future stages pre-filled with sand, slag, or just an extra ground.

This ladder does not require additional formwork and support structures under the March. Has exceptional strength and reliability due to the fact that it fully relies on the prepared base.

Under the walls of the box arranged in the tape reinforced concrete Foundation (300-400 mm thick). The optimum size in terms of length of the March 3 m (10 rungs at 300 mm), width from 1 to 1.5 m. the Size of stage 300х150 mm.

Where to startFor work will need the usual set of tools: cement mixer, hammer drill, angle grinder, angle 90°, thread, rule 2 m, hydrolevel any.

Materials (per 10 steps and 1 m platforms, 1 m wide, two side walls):

Support wallsPour a Foundation under the whole area of the stairs is not necessary! Masonry supporting walls on strip Foundation on waterproofing is the thickness of one brick (one of the walls will always be a wall of a building).

Must be anchored rebar (wire) to a static wall and lay the reinforcing mesh or wire every 4-5 rows, especially in the corners (the walls have to withstand the load from the backfill and tamping). It is desirable to apply liquid waterproofing on the inside.

The finished wall must not be less future stages, their continuation can be element of the architecture of the porch (columns, railings, etc.).

Eighty three million five hundred seventeen thousand eight hundred thirty four

MarkingThe calculation of the size of the ladder is top-down from the doorway. Markup will need a mold of 90°. You can make it, securing a small level on the long side standard steel flat square (with dimensions of not less than 300х150 mm):

Determine the floor level (surface finishing material) the top of the stairs. The designated level platform "for concrete" — subtract the thickness of the finishing layer. It will be the horizon site. Define the location of the site relative to the door opening (alignment, offset, depending on the purpose of the porch). Find the extreme points. If the ladder is along the wall, from the extreme point straight down delay level down 150 mm. the riser Is the last part of the site. If the ladder is forward of the opening, the extreme points applied to support walls, pre-marking them on the horizon site.

Further, by using patterns, delayed and outlined steps down, focusing on the evidence level. Then the join line along the bottom corners of the March. From this line lay off a perpendicular down 100 mm and hold a parallel line. The interval between these Parallels is called the "body." The bottom one is a border of filling.

BackfillBackfill sinuses of the stairs is strictly not earlier than 3 days after the masonry supporting walls! Filling of the sinus is carried out in layers (300-400 mm) with compaction of each layer. A hand tamper can be made, securing the door handle at the end of the stump with a diameter of 20-30 cm Ramming machine to work no closer than 300 mm from the wall.

When using sand as the filler of the sinus allowed water spilling (after soaking 24 hours). On top of the backfill is laid waterproofing (usually polyethylene, or geotextile parasol), so the concrete did not mix with the soil and does not lose its qualities.

A prefabricated reinforcement cageFor tying with binding wire of reinforcement when the reinforcement will need a hook that can be manufactured, sharpened and arched in a convenient form wire 6 or 8 mm.

Reinforcement of Foundation under the supporting walls is in the form of the frame beams 4 working rod, distributed in space with clamps or short vertical bars.

The armature frame consists of a ladder grid in the base (rebar 12) and mesh by the steps (welded wire mesh 50x50, 3 mm).

For the device the main working grid in the middle of the body ladders and platforms anteroom rebar mirrored with a step of 200 mm. the editions we tied rods with a length equal to the width of the stairs. Then vyberaem length pad + marsh and flexible one-piece rods at the corner of March and set them in increments of 200 (for 1 meter width of stairs will get 6 pieces).

For reinforcement of the steps vygeboom welded mesh in shape of letter G and fixed with binding wire to the main grid.

Attention! Consider protective concrete layer 30 to 40 mm (from the rebar to the concrete surface)!

For the top layer of the reinforcement pad anteroom rebar (2-3 rod on each side) below the horizon to 40 mm and imposed on them a sheet of welded mesh.

Flanging stepsFor flanging steps produce risers, usually a strip of plywood with a width equal to the height of the degree sewed on the Board of 40-50 mm. the edges are fastened to either the corners or bars. Risers are attached on the markup to support the walls of the stair anchors the "quick installation" or other available means. It is desirable to lubricate the plywood used motor oil (it will ease disassembly). Then, along the March, on top of all flanged, solid sewn Board of 25-40 mm, with a focus at the bottom (to hold size). When the width of the stairs greater than 1.2 m is set to 2 boards.

CastingFor best results (quality dry concrete) and ease of installation of mixture recommended to use a vibrator (vibroblade with a diameter of 40 mm). Concrete placement in the ladder is from the bottom up. The concrete needs to be "cool" (dry) to flow through the tread.

Forty three million four hundred forty two thousand four hundred thirty five

When vibrating the concrete "sets", filling the void, so it's best to put him in the stage "hill" from the whole March. Vibration should start from the top down. This will allow us to expel from the steps of the extra concrete. Playground fit and vybiraetsya last. The concrete surface is smoothed with trowels and semigraters. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.rmnt.ru/story/stairs/677407.htm

Fifty four million eight hundred thirty six thousand one hundred forty six

DesignMonolithic stairs sediment consists of a rigid box made of bricks or cinder blocks, platforms and stairs. The space under future stages pre-filled with sand, slag, or just an extra ground.

This ladder does not require additional formwork and support structures under the March. Has exceptional strength and reliability due to the fact that it fully relies on the prepared base.

Under the walls of the box arranged in the tape reinforced concrete Foundation (300-400 mm thick). The optimum size in terms of length of the March 3 m (10 rungs at 300 mm), width from 1 to 1.5 m. the Size of stage 300х150 mm.

Where to startFor work will need the usual set of tools: cement mixer, hammer drill, angle grinder, angle 90°, thread, rule 2 m, hydrolevel any.

Materials (per 10 steps and 1 m platforms, 1 m wide, two side walls):

- brick — 2 m3 (1.8 m3 cinder block)

- soil or sand filling — 3.6 m3

- concrete — 4 m3

- armature (12V) — 100 linear m

- welded masonry mesh 50x50, 3 mm — 10 m2

Support wallsPour a Foundation under the whole area of the stairs is not necessary! Masonry supporting walls on strip Foundation on waterproofing is the thickness of one brick (one of the walls will always be a wall of a building).

Must be anchored rebar (wire) to a static wall and lay the reinforcing mesh or wire every 4-5 rows, especially in the corners (the walls have to withstand the load from the backfill and tamping). It is desirable to apply liquid waterproofing on the inside.

The finished wall must not be less future stages, their continuation can be element of the architecture of the porch (columns, railings, etc.).

Eighty three million five hundred seventeen thousand eight hundred thirty four

MarkingThe calculation of the size of the ladder is top-down from the doorway. Markup will need a mold of 90°. You can make it, securing a small level on the long side standard steel flat square (with dimensions of not less than 300х150 mm):

Determine the floor level (surface finishing material) the top of the stairs. The designated level platform "for concrete" — subtract the thickness of the finishing layer. It will be the horizon site. Define the location of the site relative to the door opening (alignment, offset, depending on the purpose of the porch). Find the extreme points. If the ladder is along the wall, from the extreme point straight down delay level down 150 mm. the riser Is the last part of the site. If the ladder is forward of the opening, the extreme points applied to support walls, pre-marking them on the horizon site.

Further, by using patterns, delayed and outlined steps down, focusing on the evidence level. Then the join line along the bottom corners of the March. From this line lay off a perpendicular down 100 mm and hold a parallel line. The interval between these Parallels is called the "body." The bottom one is a border of filling.

BackfillBackfill sinuses of the stairs is strictly not earlier than 3 days after the masonry supporting walls! Filling of the sinus is carried out in layers (300-400 mm) with compaction of each layer. A hand tamper can be made, securing the door handle at the end of the stump with a diameter of 20-30 cm Ramming machine to work no closer than 300 mm from the wall.

When using sand as the filler of the sinus allowed water spilling (after soaking 24 hours). On top of the backfill is laid waterproofing (usually polyethylene, or geotextile parasol), so the concrete did not mix with the soil and does not lose its qualities.

A prefabricated reinforcement cageFor tying with binding wire of reinforcement when the reinforcement will need a hook that can be manufactured, sharpened and arched in a convenient form wire 6 or 8 mm.

Reinforcement of Foundation under the supporting walls is in the form of the frame beams 4 working rod, distributed in space with clamps or short vertical bars.

The armature frame consists of a ladder grid in the base (rebar 12) and mesh by the steps (welded wire mesh 50x50, 3 mm).

For the device the main working grid in the middle of the body ladders and platforms anteroom rebar mirrored with a step of 200 mm. the editions we tied rods with a length equal to the width of the stairs. Then vyberaem length pad + marsh and flexible one-piece rods at the corner of March and set them in increments of 200 (for 1 meter width of stairs will get 6 pieces).

For reinforcement of the steps vygeboom welded mesh in shape of letter G and fixed with binding wire to the main grid.

Attention! Consider protective concrete layer 30 to 40 mm (from the rebar to the concrete surface)!

For the top layer of the reinforcement pad anteroom rebar (2-3 rod on each side) below the horizon to 40 mm and imposed on them a sheet of welded mesh.

Flanging stepsFor flanging steps produce risers, usually a strip of plywood with a width equal to the height of the degree sewed on the Board of 40-50 mm. the edges are fastened to either the corners or bars. Risers are attached on the markup to support the walls of the stair anchors the "quick installation" or other available means. It is desirable to lubricate the plywood used motor oil (it will ease disassembly). Then, along the March, on top of all flanged, solid sewn Board of 25-40 mm, with a focus at the bottom (to hold size). When the width of the stairs greater than 1.2 m is set to 2 boards.

CastingFor best results (quality dry concrete) and ease of installation of mixture recommended to use a vibrator (vibroblade with a diameter of 40 mm). Concrete placement in the ladder is from the bottom up. The concrete needs to be "cool" (dry) to flow through the tread.

Forty three million four hundred forty two thousand four hundred thirty five

When vibrating the concrete "sets", filling the void, so it's best to put him in the stage "hill" from the whole March. Vibration should start from the top down. This will allow us to expel from the steps of the extra concrete. Playground fit and vybiraetsya last. The concrete surface is smoothed with trowels and semigraters. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.rmnt.ru/story/stairs/677407.htm