742

Simple solution to the problem of the home country: house container

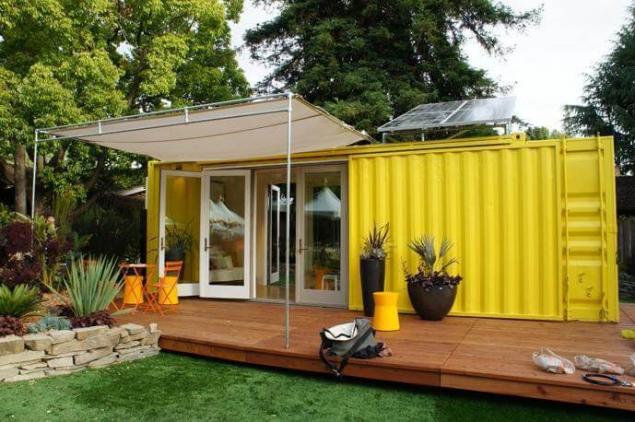

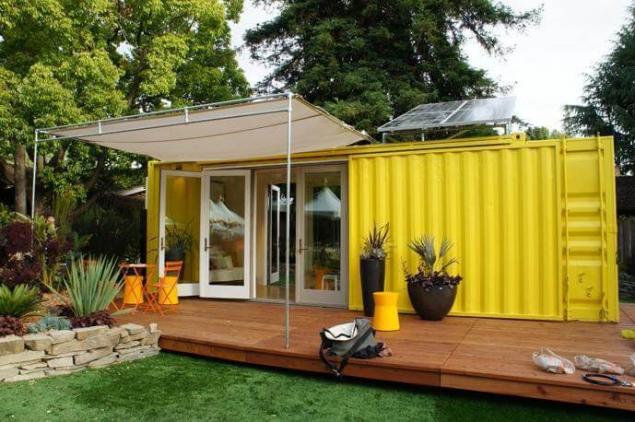

Construction of a small summerhouse from the container, used and bought on the cheap, attracted many owners of country houses. After all, to find "shelter" in a few days. Purchased container it is only necessary to bring to the country and to set on reserved for the house location, using material handling equipment. A little more time it will take, if the vacationers wish to have insulation and finish building-container. In this case, will not just a temporary shelter, and a full country house with all amenities.

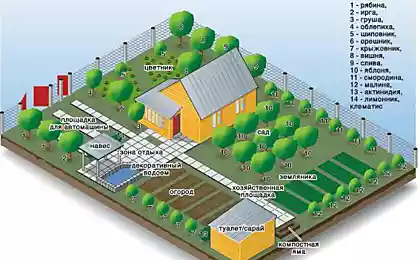

There are many options for partitioning the total area of the container into functional zones, of which select the most suitable layout given the number of guests, seasonality of use, country house, design preferences and other considerations, known only to you.

Using modern materials, you can change the appearance of a conventional cargo container to recognition. No one would think that cozy country house was obtained from a decommissioned 40-Tanganika. To significantly increase the useful area of the object by construction of the country house of several containers, placed close alongside each other or at an angle and on two floors. In the latter case, even manage to do a carport and an outdoor terrace for relaxation due to the displacement of the upper container a few meters to the side relative to the lower block.

Standard sizes of cargo containers

For the construction of country houses from all existing types of container vessels typically use a universal large-tonnage containers:

It should be noted that the width of all containers is the same and is 2350 mm, Length 20-foot module shall be calculated 5898 mm, and 40-foot – 12032 mm. the Height of both the container is 2393 mm high container High Cube this parameter is greater than 300 mm. dimensions 45-Potok a few millimeters larger than 40-foot module.

Design features of large containers

Country house built from a container, will not be available for fans of another's property, constantly come into the territory of horticultural societies. Because the container design is not only simplicity but also reliability.

A rigid frame

It is based on a solid frame, welded steel beams. The lower base frame serve the longitudinal and transverse beams, to which the corners of the welded side edges. The upper plane, forming the roof of the container, also specified transverse and longitudinal load-bearing beams.

Steel cladding

Trim, cargo modules made of steel sheets with anti-corrosion corrugated profile, made of high quality alloy steel grade CORTEN steel.

The thickness of the galvanized walls of the container varies from 1.5 to 2.0 mm, so the design is very durable and quite hard. Quality paint applied on the walls of the container around the perimeter, protect the metal from the negative impact of the environment and corrosion processes.

Finish floor plywood

As the floor in the large containers used most often molded plywood with a thickness up to 40 mm. This material is further impregnated with a special compound that prevents the development of fungi and mold.

The use of plywood and other lumber for the floor device provides:

Door swing type

Standard containers are equipped with swing type doors that are hung on durable hinges. Open doors with special handles to actuate the locking mechanisms. For sealing the door opening around the perimeter with a sealing gum.

Requirements for design of Foundation

Despite the large dimensions, the containers weigh quite a bit. Weight of 20-foot module is 2,200 kg, and 45-foot – 4590 kg. Therefore, under such a light construction necessary to erect powerful perimeter Foundation with strapping.

Enough to put a container house on piles, the length of which depends on the type of soil, depth of groundwater, the complexity of the terrain, the probability of flooding of the area in the spring flood period and other factors, typical for this region. As a Foundation there may be:

Country house from a standard santimetrovy

Budget option of building a house of one standard 20-foot (six-metre) container implies:

Even more will have to spend, if to design two Windows in the container, replace the finishing of PVC panels, laminated chipboard panels any color, to organize the heating of an electric heater equipped with thermostat, hold hidden wiring using earthing-pin and euromilitary. The floor is tiled, and order special furniture that fit into a long and narrow space of the container.

The more exclusive the design assumes the presence of panoramic Windows, sliding doors that expand the interior space at the expense of the adjoining terraces, exterior finishes, construction of the roof.

Insulation: inside or outside?

Insulate the metal container from the outside is possible only in the case if you intend to operate the year round. In this case, the container will not freeze and, therefore, will not fall out of the condensate on the inner walls of the house. If the house you want to use mainly in the summer, and in winter to pay a visit on the occasion, it is necessary to perform heat insulation on the inside.

In what sequence to do it? Here's how:

1. First, cut out all window and door openings in accordance with the project of modernization of the container and holes for ventilation and chimneys.

2. Weld to the casing point on both sides of each cutout opening of square tubing that will go from floor to ceiling. To him weld a continuous weld horizontal pipe, fired over the opening and under him. So you will restore the structural strength of the wall of the container weakened by disturbances of continuity of the ribs.

3. Brew a hinged door of a container, and clean the surface from rust, if any.

4. Of wooden bars with thickness of 5-10 cm make vertical sheathing, which will serve as a beacon during the deposition of polystyrene or polyurethane foam, well-filling profiles in the walls of the container.

5. Spend the deposition of the insulation and cut off the excess exposed bars, beacons.

6. Similarly, perform insulation of the ceiling.

7. Then tighten the walls and ceiling of the container vapor barrier membrane, targeting it to the bars of the furring construction stapler.

8. Finishing swipe with a lining, plasterboard, chipboard, PVC panels and other materials.

9. Insulate the floor using the same spraying or polystyrene plates. It is not forbidden and screed lightweight concrete. Undesirable as the insulation of the floor to use mineral wool, which in contact with water for a long time retains moisture that can cause rusting of the bottom of the container, as well as the formation of mold and mildew.

It should also be noted that with the installation of fireplaces, stoves, chimneys need to use 5-10 cm of basalt cotton wool to isolate places of possible contact with hot surfaces.

Spraying insulation on the walls and ceiling of the container is in a protective mask and disposable overalls

Construction of country houses of multiple containers

Much more interesting and turns a country house built from multiple containers. To position the modules relative to each other in different ways, getting open terraces, small courtyards, carports, recreation areas and privacy of the guest room. As a Foundation, and in this case are piles that you can buy prepared or cast using a disposable cardboard cylindrical formwork. Installation of piles at the site with difficult terrain is conducted with due regard to their alignment in a single level. Step of installation of piles is 3 meters.

Directly under the bathroom is constructed of insulated concrete basement, which houses a pumping station with accumulator, filters for purification of water from wells and other important elements of an Autonomous water supply system a country house.

Over all containers built low gable roof, which allows you to take free-standing modules as a single ensemble. In addition to the decorative effect of this roof leads to the additional warmth and waterproofing of roof space of the house.

Natural light inside a country house is ensured not only through the panoramic Windows installed in the walls of the container, but also anti-aircraft Windows mounted on the ceiling with an exit to the roof through light wells. These Windows allow to organize the ventilation of the internal space of the country house.

As heating of the country house from multiple containers it is better to use the system "Warm floor". The heating cable is laid a spiral around the house, and filled with screed. Under cable it is advisable to put foil polyethylene foam, protected by Mylar. This will reduce the amount of heat loss through the floor of the metal container. When pouring the screed it is necessary to provide expansion joints, not allowing the surface to crack under temperature variations. Received a concrete floor can then be sanded, painted and varnish.

To create a common space, the walls of adjacent containers cut openings of different widths, using posts and beams from the I-beam to strengthen the structure. The walls of the containers are metal runners for spray insulation-polyurethane foam. Before the deposition of the heater wiring is laid in the selective circuit with the RCD. Necessarily provided between all metal parts of the house with a common bus and ground.

Partitions inside the house-container set made of metal profile is screwed to the MDM gypsum plasterboard or drywall. The joints between the plasterboard sheets are glued and tape - junctions, which holds the applied putty non-shrinking mortar. The walls of the containers sheathe with sheets of drywall, which will then be plastered and painted in bright colors, which visually expand the living space.

On the ceiling of the containers have to hem the rails, and then placed the wiring for the organization of artificial lighting of suburban homes. For finishing the ceiling space using natural wood tones contrasting well with the bright walls of the house and visually increasing the ceiling height.

The outer walls of the containers to be painted in one or several matching colors, it does not skimp on the paint, and then have three years to enjoy that ill-fitting facade of a country house. It is better to use for this purpose high-quality marine paint - enamel. Here's how easy it is to build a house of multiple containers with their hands.

A large country house several containers, painted in different contrasting colors is a part of the site, forming a cozy patio To the door of such a house usually leads to the stairs or the track ramp, which is easy to clean in the winter from snow. From a small container you can make a storeroom, in which to store all garden equipment.

Street lighting solar: effectively and economicallyHow to make a wooden countertop for the kitchen with their hands: step by step instructions

The photos posted in the article, you see that country house from containers, it turns out beautiful and functional. If the outside a house to sheathe a siding or a tree, to distinguish it from other country structures is unlikely. Thus the construction of the house it will take much less time and money.published

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: diz-cafe.com/postroiki/achnyj-dom-iz-kontejnera.html

There are many options for partitioning the total area of the container into functional zones, of which select the most suitable layout given the number of guests, seasonality of use, country house, design preferences and other considerations, known only to you.

Using modern materials, you can change the appearance of a conventional cargo container to recognition. No one would think that cozy country house was obtained from a decommissioned 40-Tanganika. To significantly increase the useful area of the object by construction of the country house of several containers, placed close alongside each other or at an angle and on two floors. In the latter case, even manage to do a carport and an outdoor terrace for relaxation due to the displacement of the upper container a few meters to the side relative to the lower block.

Standard sizes of cargo containers

For the construction of country houses from all existing types of container vessels typically use a universal large-tonnage containers:

- 20-ft (dry freight);

- 40ft (dry freight or high-high cube);

- 45 ' (dry freight or high-high cube).

It should be noted that the width of all containers is the same and is 2350 mm, Length 20-foot module shall be calculated 5898 mm, and 40-foot – 12032 mm. the Height of both the container is 2393 mm high container High Cube this parameter is greater than 300 mm. dimensions 45-Potok a few millimeters larger than 40-foot module.

Design features of large containers

Country house built from a container, will not be available for fans of another's property, constantly come into the territory of horticultural societies. Because the container design is not only simplicity but also reliability.

A rigid frame

It is based on a solid frame, welded steel beams. The lower base frame serve the longitudinal and transverse beams, to which the corners of the welded side edges. The upper plane, forming the roof of the container, also specified transverse and longitudinal load-bearing beams.

Steel cladding

Trim, cargo modules made of steel sheets with anti-corrosion corrugated profile, made of high quality alloy steel grade CORTEN steel.

The thickness of the galvanized walls of the container varies from 1.5 to 2.0 mm, so the design is very durable and quite hard. Quality paint applied on the walls of the container around the perimeter, protect the metal from the negative impact of the environment and corrosion processes.

Finish floor plywood

As the floor in the large containers used most often molded plywood with a thickness up to 40 mm. This material is further impregnated with a special compound that prevents the development of fungi and mold.

The use of plywood and other lumber for the floor device provides:

- the wooden base resistance to mechanical damage;

- good elasticity of the material;

- maintainability and easy replacement of flooring;

- a high coefficient of friction during transportation of goods.

Door swing type

Standard containers are equipped with swing type doors that are hung on durable hinges. Open doors with special handles to actuate the locking mechanisms. For sealing the door opening around the perimeter with a sealing gum.

Requirements for design of Foundation

Despite the large dimensions, the containers weigh quite a bit. Weight of 20-foot module is 2,200 kg, and 45-foot – 4590 kg. Therefore, under such a light construction necessary to erect powerful perimeter Foundation with strapping.

Enough to put a container house on piles, the length of which depends on the type of soil, depth of groundwater, the complexity of the terrain, the probability of flooding of the area in the spring flood period and other factors, typical for this region. As a Foundation there may be:

- normal blocks;

- concrete supports;

- screw piles;

- piles of TISE with the extension down in the form of a sole;

- rubble concrete pillars poured into the formwork;

- large diameter pipes etc.

Country house from a standard santimetrovy

Budget option of building a house of one standard 20-foot (six-metre) container implies:

- one swing of the single-chamber Windows of PVC with double glazing;

- external doors;

- individual heating;

- insulation;

- the inner liner made of PVC-panels (ceiling) and MDF-boards (walls);

- household linoleum used as floor covering.

- Artificial lighting is available with two fluorescent lamps.

- There is one outlet and one switch.

Even more will have to spend, if to design two Windows in the container, replace the finishing of PVC panels, laminated chipboard panels any color, to organize the heating of an electric heater equipped with thermostat, hold hidden wiring using earthing-pin and euromilitary. The floor is tiled, and order special furniture that fit into a long and narrow space of the container.

The more exclusive the design assumes the presence of panoramic Windows, sliding doors that expand the interior space at the expense of the adjoining terraces, exterior finishes, construction of the roof.

Insulation: inside or outside?

Insulate the metal container from the outside is possible only in the case if you intend to operate the year round. In this case, the container will not freeze and, therefore, will not fall out of the condensate on the inner walls of the house. If the house you want to use mainly in the summer, and in winter to pay a visit on the occasion, it is necessary to perform heat insulation on the inside.

In what sequence to do it? Here's how:

1. First, cut out all window and door openings in accordance with the project of modernization of the container and holes for ventilation and chimneys.

2. Weld to the casing point on both sides of each cutout opening of square tubing that will go from floor to ceiling. To him weld a continuous weld horizontal pipe, fired over the opening and under him. So you will restore the structural strength of the wall of the container weakened by disturbances of continuity of the ribs.

3. Brew a hinged door of a container, and clean the surface from rust, if any.

4. Of wooden bars with thickness of 5-10 cm make vertical sheathing, which will serve as a beacon during the deposition of polystyrene or polyurethane foam, well-filling profiles in the walls of the container.

5. Spend the deposition of the insulation and cut off the excess exposed bars, beacons.

6. Similarly, perform insulation of the ceiling.

7. Then tighten the walls and ceiling of the container vapor barrier membrane, targeting it to the bars of the furring construction stapler.

8. Finishing swipe with a lining, plasterboard, chipboard, PVC panels and other materials.

9. Insulate the floor using the same spraying or polystyrene plates. It is not forbidden and screed lightweight concrete. Undesirable as the insulation of the floor to use mineral wool, which in contact with water for a long time retains moisture that can cause rusting of the bottom of the container, as well as the formation of mold and mildew.

It should also be noted that with the installation of fireplaces, stoves, chimneys need to use 5-10 cm of basalt cotton wool to isolate places of possible contact with hot surfaces.

Spraying insulation on the walls and ceiling of the container is in a protective mask and disposable overalls

Construction of country houses of multiple containers

Much more interesting and turns a country house built from multiple containers. To position the modules relative to each other in different ways, getting open terraces, small courtyards, carports, recreation areas and privacy of the guest room. As a Foundation, and in this case are piles that you can buy prepared or cast using a disposable cardboard cylindrical formwork. Installation of piles at the site with difficult terrain is conducted with due regard to their alignment in a single level. Step of installation of piles is 3 meters.

Directly under the bathroom is constructed of insulated concrete basement, which houses a pumping station with accumulator, filters for purification of water from wells and other important elements of an Autonomous water supply system a country house.

Over all containers built low gable roof, which allows you to take free-standing modules as a single ensemble. In addition to the decorative effect of this roof leads to the additional warmth and waterproofing of roof space of the house.

Natural light inside a country house is ensured not only through the panoramic Windows installed in the walls of the container, but also anti-aircraft Windows mounted on the ceiling with an exit to the roof through light wells. These Windows allow to organize the ventilation of the internal space of the country house.

As heating of the country house from multiple containers it is better to use the system "Warm floor". The heating cable is laid a spiral around the house, and filled with screed. Under cable it is advisable to put foil polyethylene foam, protected by Mylar. This will reduce the amount of heat loss through the floor of the metal container. When pouring the screed it is necessary to provide expansion joints, not allowing the surface to crack under temperature variations. Received a concrete floor can then be sanded, painted and varnish.

To create a common space, the walls of adjacent containers cut openings of different widths, using posts and beams from the I-beam to strengthen the structure. The walls of the containers are metal runners for spray insulation-polyurethane foam. Before the deposition of the heater wiring is laid in the selective circuit with the RCD. Necessarily provided between all metal parts of the house with a common bus and ground.

Partitions inside the house-container set made of metal profile is screwed to the MDM gypsum plasterboard or drywall. The joints between the plasterboard sheets are glued and tape - junctions, which holds the applied putty non-shrinking mortar. The walls of the containers sheathe with sheets of drywall, which will then be plastered and painted in bright colors, which visually expand the living space.

On the ceiling of the containers have to hem the rails, and then placed the wiring for the organization of artificial lighting of suburban homes. For finishing the ceiling space using natural wood tones contrasting well with the bright walls of the house and visually increasing the ceiling height.

The outer walls of the containers to be painted in one or several matching colors, it does not skimp on the paint, and then have three years to enjoy that ill-fitting facade of a country house. It is better to use for this purpose high-quality marine paint - enamel. Here's how easy it is to build a house of multiple containers with their hands.

A large country house several containers, painted in different contrasting colors is a part of the site, forming a cozy patio To the door of such a house usually leads to the stairs or the track ramp, which is easy to clean in the winter from snow. From a small container you can make a storeroom, in which to store all garden equipment.

Street lighting solar: effectively and economicallyHow to make a wooden countertop for the kitchen with their hands: step by step instructions

The photos posted in the article, you see that country house from containers, it turns out beautiful and functional. If the outside a house to sheathe a siding or a tree, to distinguish it from other country structures is unlikely. Thus the construction of the house it will take much less time and money.published

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: diz-cafe.com/postroiki/achnyj-dom-iz-kontejnera.html