901

Shipping containers

In 1937, the co-owner of the family shipping company Malcolm McLean sat in his truck and watched as the dockworkers loaded with cotton bales on the ship served in Turkey and overfilled the universal longing. "Yes, I have made two trips, while those lazy plunge! That would throw the entire truck harbor cranes on board. Wait, this idea! "Malcom invested in the development and in 1956 presented his brainchild - a universal shipping container. Unloading took half a day, which previously required four. Dockers' unions scraped out from under the pile of bricks themselves, but progress has been unstoppable. In today's world turn millions of containers of various applications.

23 photos

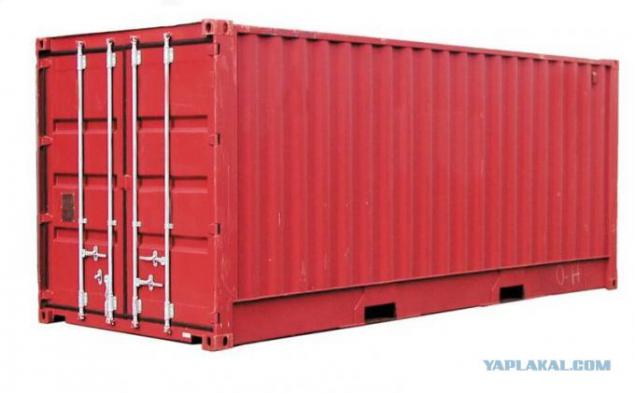

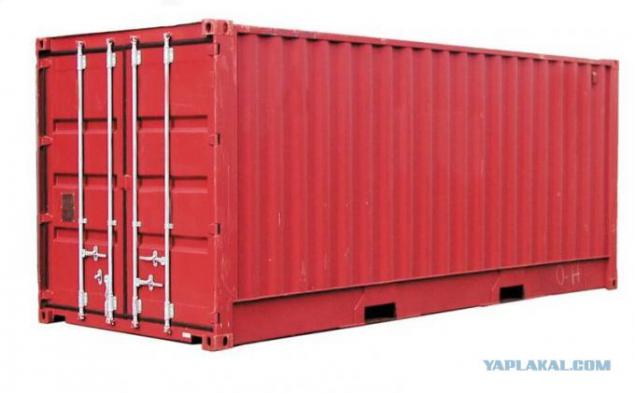

The containers are made of corrugated steel. In the corners there is a special attachment, plus a flat bottom grooves for forklift. The whole idea is of standard sizes - it allows to use the same cranes and vehicles worldwide. The most popular 20 and 40-foot form factor (whether wrong English system of measures!).

Often, instead of "container" say TEU - «twenty-foot equivalent". Modern container postpanamaks luck of a few thousand. Accordingly, the 40-foot container equals two TEU.

The world's very few things that enough. Normally just a little. Especially places. There were containers higher - HightCube. And wider - PalletWight, to two standard pallets vlazit width. And then - 43, 45, 53 feet. Such dlinnomery spetsplatform demand for transportation, but the standard valves are suitable as fastening are not located at the edges.

Typically, the container has a door with one hand, but to speed up the unloading of modified - blinds, sliding side walls, support for self discharge trailers.

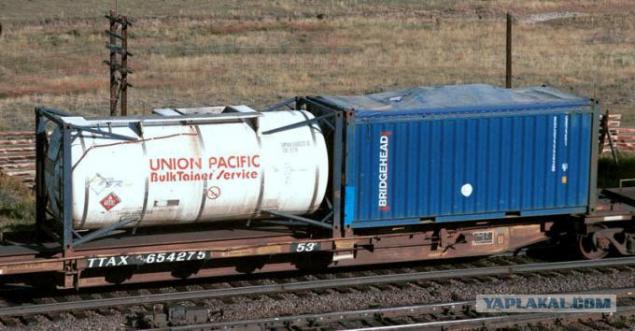

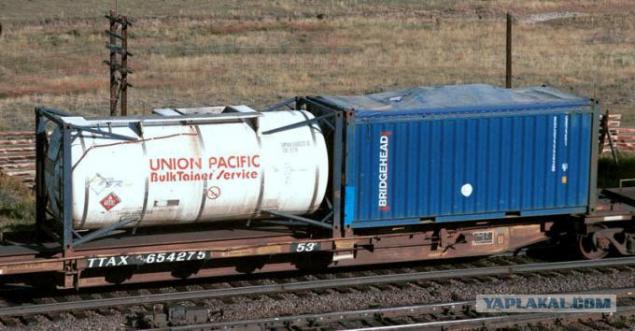

Containers adapted for liquid and bulk cargo - in fact turned into the tank overall frame.

Near the tank other derivative option - container with a canvas roof. The entire burden of the corners, which would not save weight? Yes, and shipping easier monocargo crane from above. And if so, then we can save on the side walls.

Yes, and do folding to stack empty stacks. Is it possible at all to do with the size freely.

Popular varieties - refrigerated container

They are connected to the power system of the vehicle for particularly sensitive goods have a model with an emergency diesel generator.

Handle container was so comfortable that some goods have become integrated in them - packaging steel body. As such, the available generators, all kinds of construction and drilling equipment. It's convenient - lifted by crane, plugged in, drove! We move to a new object - ship back.

Anti complex "Club-K» (Club-K), the ideological heir disguised missile trains:

Popularity gaining container data centers. You can assemble a supercomputer from any canopy - all equipment is already assembled, including the air conditioning system. Supply power to the container, fiber and liquid cooling:

Need a change house, blockhouse, bathroom? Please:

And it is possible and in several floors, containers are strong enough:

And this decision is not only for construction and military base - there are always crazy, located in a stylish and utilitarian containers are used for private homes.

Special angle attachment can move and dock container. Openings in them are oval, special lock (Twistlock) included in them, and rotates 90 degrees, securely fixing cargo:

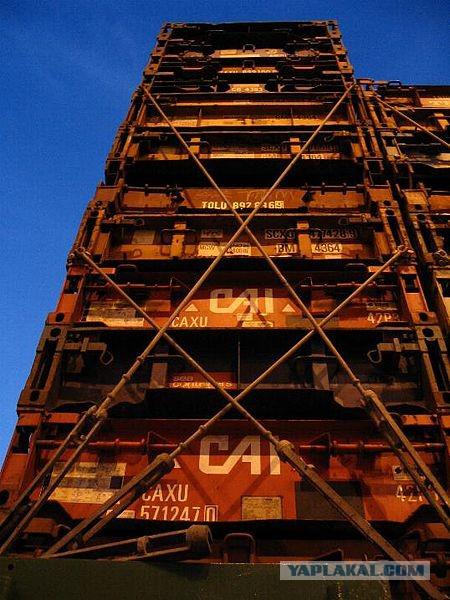

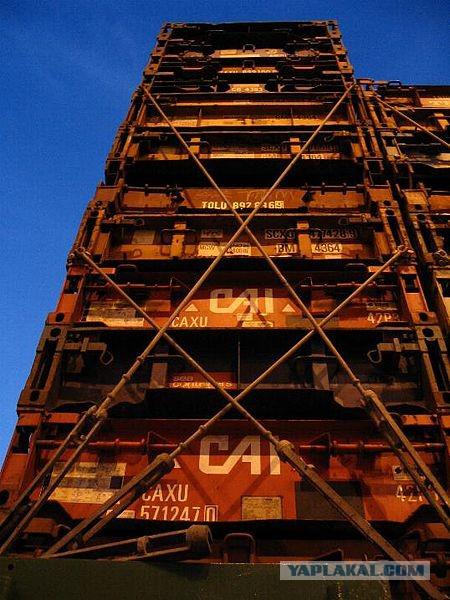

If it is necessary to fix the containers one upon the other placed between four such lock in each corner. If tiers more - use additional ties:

The container can be picked up in the classical way - rigging to the corner mount. But it's not very cool - there are specialized highly productive solution. It called spreader:

This is a special frame with locks automatically catchy container from the top or from the sides. Usually the spreader can be moved apart under different sizes. There are models, catchy just two 20-futovika. Many container ships did not have any mechanism for opening the hold hatches - they have a spreader attachment, the hatch lifted by crane

During ship unloading crane looks at the computer - you need to load evenly on the left and right side, harder to put down containers, refrigerators - outlets.

Modern container ships can accommodate up to 16,000 TEU.

On land containers transported gantry cranes:

Or special spredernymi Handler - Reach Stacker:

...

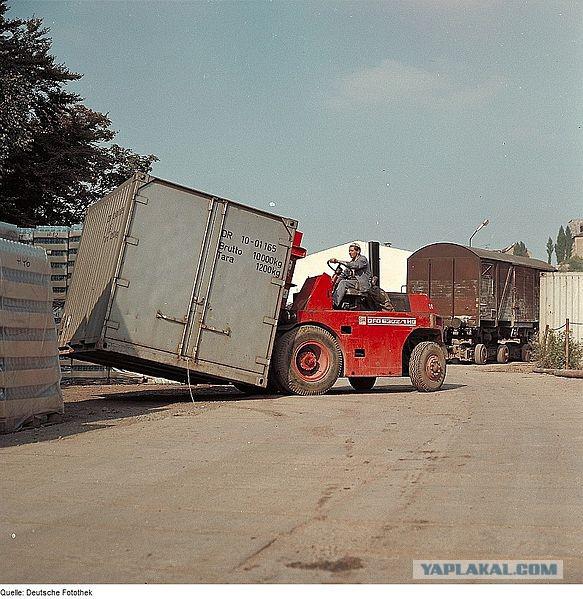

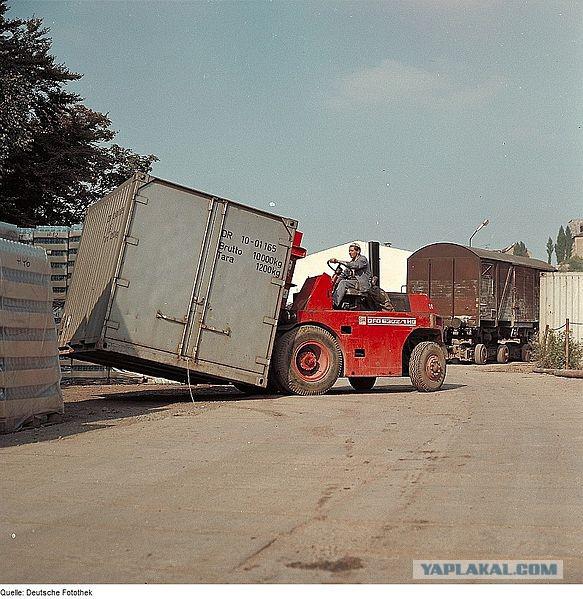

Empty container can be picked up by an electromagnet for a side wall or bottom of the forklift:

In road transport TEU did not become a de facto standard. All the same size car roomier. On vehicles carrying containers are often installed special hydraulic loaders. They can move the container with soil or other truck without the help of a crane:

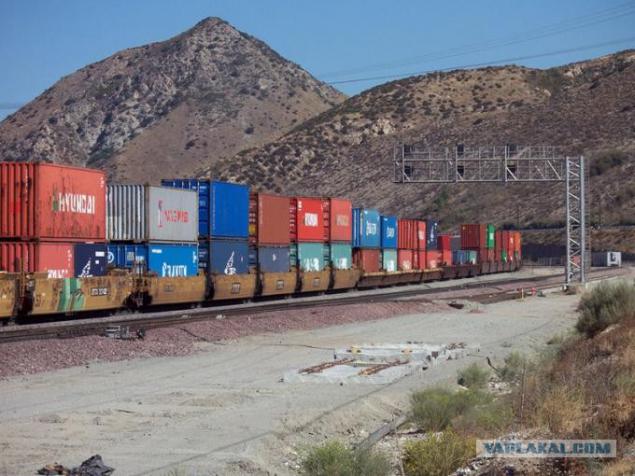

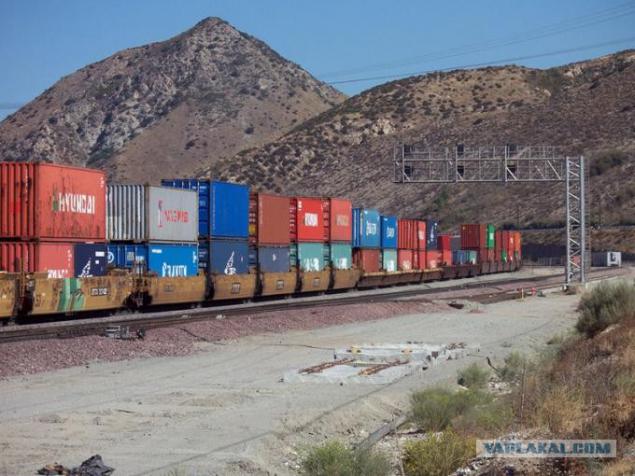

But they came to the containers on the railway. Containers are relatively light, so the platform makes a long - just two 40-feet. In fact, for each container accounted for one truck. But the Americans have gone further. Left in the 19th century in terms of passenger traffic, America gives heat the freight! Containers loaded on articulated platforms "trough" in two tiers. According to one wheel pair in the container. This is facilitated by heavy rails and almost complete disregard for the achievements of electrification. To lower the center of gravity low-floor platform is made. The two-storey accommodation allows you to make the most of the permissible length of the train:

And all this beauty more and accelerates to 160 km / h!

Usually two tiers require diesel traction. But this option is not the Indians approached. At the port, they decided to keep the branch not only locomotives, but also the standard platform. For the safety of a contact network had to raise. Well, to develop monstrous pantographs. That's the story of iron boxes, which had developed into something more.

In 2001, during the funeral of 87-year-old Malcolm McLean thousands of container ships in all the seas of the planet gave horn. End ...

Source:

23 photos

The containers are made of corrugated steel. In the corners there is a special attachment, plus a flat bottom grooves for forklift. The whole idea is of standard sizes - it allows to use the same cranes and vehicles worldwide. The most popular 20 and 40-foot form factor (whether wrong English system of measures!).

Often, instead of "container" say TEU - «twenty-foot equivalent". Modern container postpanamaks luck of a few thousand. Accordingly, the 40-foot container equals two TEU.

The world's very few things that enough. Normally just a little. Especially places. There were containers higher - HightCube. And wider - PalletWight, to two standard pallets vlazit width. And then - 43, 45, 53 feet. Such dlinnomery spetsplatform demand for transportation, but the standard valves are suitable as fastening are not located at the edges.

Typically, the container has a door with one hand, but to speed up the unloading of modified - blinds, sliding side walls, support for self discharge trailers.

Containers adapted for liquid and bulk cargo - in fact turned into the tank overall frame.

Near the tank other derivative option - container with a canvas roof. The entire burden of the corners, which would not save weight? Yes, and shipping easier monocargo crane from above. And if so, then we can save on the side walls.

Yes, and do folding to stack empty stacks. Is it possible at all to do with the size freely.

Popular varieties - refrigerated container

They are connected to the power system of the vehicle for particularly sensitive goods have a model with an emergency diesel generator.

Handle container was so comfortable that some goods have become integrated in them - packaging steel body. As such, the available generators, all kinds of construction and drilling equipment. It's convenient - lifted by crane, plugged in, drove! We move to a new object - ship back.

Anti complex "Club-K» (Club-K), the ideological heir disguised missile trains:

Popularity gaining container data centers. You can assemble a supercomputer from any canopy - all equipment is already assembled, including the air conditioning system. Supply power to the container, fiber and liquid cooling:

Need a change house, blockhouse, bathroom? Please:

And it is possible and in several floors, containers are strong enough:

And this decision is not only for construction and military base - there are always crazy, located in a stylish and utilitarian containers are used for private homes.

Special angle attachment can move and dock container. Openings in them are oval, special lock (Twistlock) included in them, and rotates 90 degrees, securely fixing cargo:

If it is necessary to fix the containers one upon the other placed between four such lock in each corner. If tiers more - use additional ties:

The container can be picked up in the classical way - rigging to the corner mount. But it's not very cool - there are specialized highly productive solution. It called spreader:

This is a special frame with locks automatically catchy container from the top or from the sides. Usually the spreader can be moved apart under different sizes. There are models, catchy just two 20-futovika. Many container ships did not have any mechanism for opening the hold hatches - they have a spreader attachment, the hatch lifted by crane

During ship unloading crane looks at the computer - you need to load evenly on the left and right side, harder to put down containers, refrigerators - outlets.

Modern container ships can accommodate up to 16,000 TEU.

On land containers transported gantry cranes:

Or special spredernymi Handler - Reach Stacker:

...

Empty container can be picked up by an electromagnet for a side wall or bottom of the forklift:

In road transport TEU did not become a de facto standard. All the same size car roomier. On vehicles carrying containers are often installed special hydraulic loaders. They can move the container with soil or other truck without the help of a crane:

But they came to the containers on the railway. Containers are relatively light, so the platform makes a long - just two 40-feet. In fact, for each container accounted for one truck. But the Americans have gone further. Left in the 19th century in terms of passenger traffic, America gives heat the freight! Containers loaded on articulated platforms "trough" in two tiers. According to one wheel pair in the container. This is facilitated by heavy rails and almost complete disregard for the achievements of electrification. To lower the center of gravity low-floor platform is made. The two-storey accommodation allows you to make the most of the permissible length of the train:

And all this beauty more and accelerates to 160 km / h!

Usually two tiers require diesel traction. But this option is not the Indians approached. At the port, they decided to keep the branch not only locomotives, but also the standard platform. For the safety of a contact network had to raise. Well, to develop monstrous pantographs. That's the story of iron boxes, which had developed into something more.

In 2001, during the funeral of 87-year-old Malcolm McLean thousands of container ships in all the seas of the planet gave horn. End ...

Source: