455

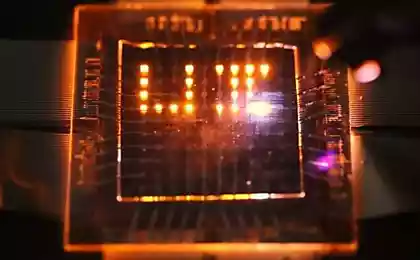

Invented a new method of water purification by means of LEDs

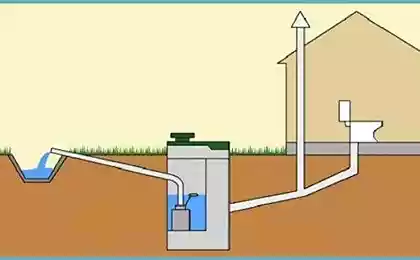

Deep ultraviolet radiation is used for purification of drinking water and thorough sterilization of medical equipment. Unfortunately, the equipment with which such disinfection is made using large mercury lamps, this makes the device inconvenient in the field. Engineers from the Ohio state University decided to change the design of the equipment, creating a small device.

"Right now, if you want to do a clean deep ultraviolet light, you must use a mercury lamp," said Roberto Myers, associate Professor of materials science and engineering at the State University of Ohio: "Mercury is toxic, and lamps are bulky, and is electrically inefficient. LEDs, on the other hand, are really effective, so if we can do the UV LEDs, safe, portable and inexpensive, we could make safe drinking water where we need it."

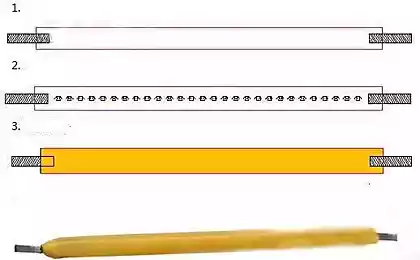

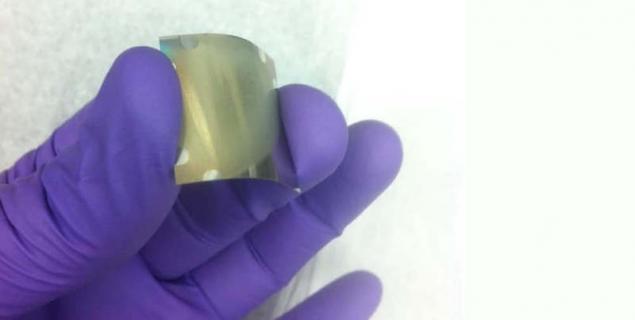

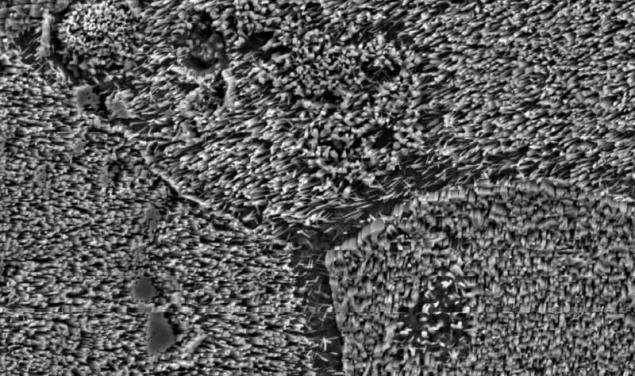

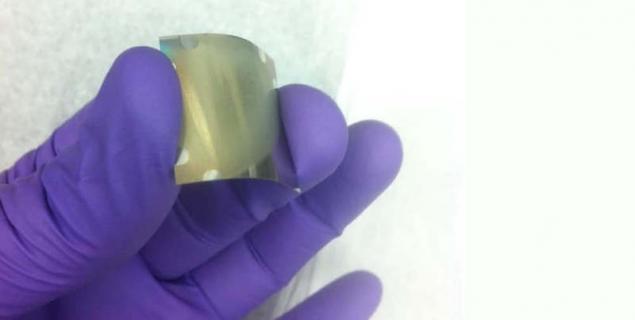

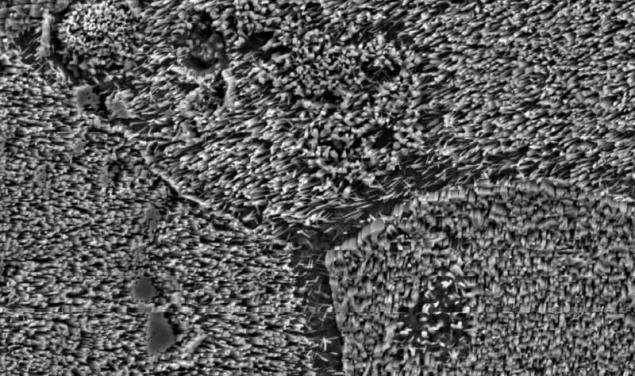

Researchers use new foil based on nanotechnology, which is used as semiconductor structures for molecular beam epitaxy, where the molecular beams are used to vaporize the materials, and then allow them to land on the surface, where they self-assemble into the layers of nanostructures. In this case, the researchers used this method for the distribution of densely Packed aluminum gallium nitride wires (about 200 nanometers in height, and 20-50 nm in diameter) film, titanium and tantalum to create a flexible Mat of conductive fibers. When an electric current is applied to the nanowire, it emits light almost as bright as LEDs.

The researchers say that their technique may one day allow on an industrial scale to produce cheap LEDs for deep UV radiation. published

materials newatlas.com

Source: ecotechnology

"Right now, if you want to do a clean deep ultraviolet light, you must use a mercury lamp," said Roberto Myers, associate Professor of materials science and engineering at the State University of Ohio: "Mercury is toxic, and lamps are bulky, and is electrically inefficient. LEDs, on the other hand, are really effective, so if we can do the UV LEDs, safe, portable and inexpensive, we could make safe drinking water where we need it."

Researchers use new foil based on nanotechnology, which is used as semiconductor structures for molecular beam epitaxy, where the molecular beams are used to vaporize the materials, and then allow them to land on the surface, where they self-assemble into the layers of nanostructures. In this case, the researchers used this method for the distribution of densely Packed aluminum gallium nitride wires (about 200 nanometers in height, and 20-50 nm in diameter) film, titanium and tantalum to create a flexible Mat of conductive fibers. When an electric current is applied to the nanowire, it emits light almost as bright as LEDs.

The researchers say that their technique may one day allow on an industrial scale to produce cheap LEDs for deep UV radiation. published

materials newatlas.com

Source: ecotechnology