331

View from the inside: are Filament lamps so good?

Today we will talk about one burning and extremely popular recently topic, namely filament (or, in Russian, filament) LED lamps. We conducted a detailed analysis of lamps from different manufacturers, including measuring the temperature of LED filaments. And under the rink, we will try to answer the question: are filament lamps as good as marketers present them to us?

BackgroundWhen it comes to new technology, one of the most important questions immediately arises: how does this technology merge into the overall technological “eco-environment”? Usually, revolutionary technologies simply do not fit into the usual course of things, and you have to make a huge effort to introduce revolutionary products. For example, this was the case with renewable energy sources installed on private homes, when the cost of the “set” fell by orders of magnitude, and in some places of our planet people are also paid for electricity generation, which required a review of the relationship between producers and consumers of electricity. A very similar story happened with electric cars, when the industry split and went two ways: hybrids and full-fledged electric cars with separate “refueling” stations.

About 5 years ago, LED lighting began to actively win over its henchmen and adherents. Engineers have long tried to adapt two-dimensional by nature light sources for three-dimensional illumination (what only are lamps in the form of corn cobs).

And here on the market were released filament lamps. It would seem that found, albeit not perfect, but the optimal solution to the problem, when "sheep are fed and wolves are whole": the light bulb is practically no different from the Ilyich bulb both in shape and content, only the tungsten thread is replaced by an LED filament. Even the old glass mills and workshops found work. It is now proposed to use a ceramic translucent substrate to improve the radial distribution of the light flux of lamps (for example, Crystal Ceramic MCOB).

What is this mysterious filament? Briefly on filament design

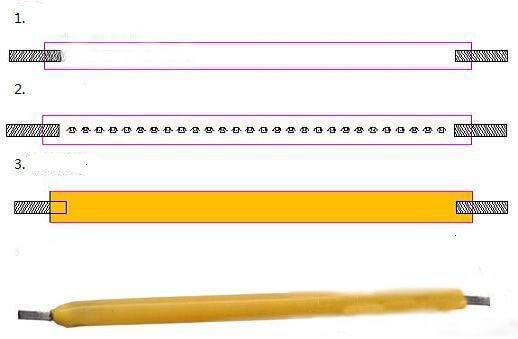

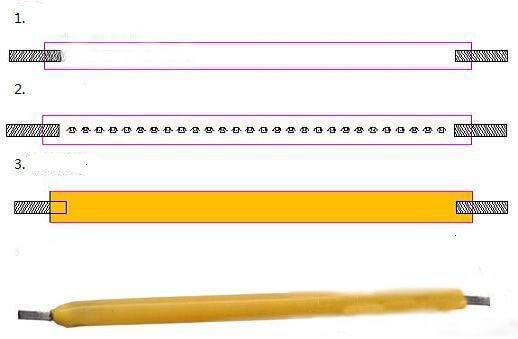

A filament is a cake consisting of several components. A thin glass (not as good at conducting heat) or sapphire/ceramic (good conducting heat) substrate – depends on the greed of the manufacturer – with two contacts at the edges. LED chips are installed on this substrate, which are connected successively with the thinnest gold thread. Then the entire structure is filled with a phosphor and, voila, filament is ready.

Diagram of the LED filament

The idea behind this type of LED is simple: trying to squeeze a little bit more lm/W, because in such a design it does not matter where the LED emits, unlike the SMD. The light will still reach the phosphor and give the warm component (green and red).

However, despite the undeniable advantages over SMD LEDs, filament lamps have a number of problems that for some reason do not want to notice. For example, in the “standard” layout with SMD diodes, a fairly massive aluminum substrate and body effectively remove heat, whereas in threads the only way to remove heat is actually only convection and dissipation through the walls of the glass bulb. That is, banal overheating gradually kills both the diodes themselves (the drop in brightness with temperature) and the phosphor (the color reproduction index CRI or R a and the color temperature CCT suffer). Yes, this method of “overheating” works for a tungsten lamp, because the gas in it partially contributes to the regeneration of the filament during use, but no more. As follows from the presented article, temperatures of the order of 60-70 degrees can be considered relatively harmless.

In a nutshell, for the average consumer, overheating or insufficient heat removal from LEDs means only one thing - a multiple (sometimes orders of magnitude) deterioration in the characteristics of LED lamps.

To confirm or refute this point of view, we need to stock up on lamps, take conventional LED lamps for comparison and experiment... including temperature measurement, which will help us with the Flir 5-series thermal imager with a matrix of 240 by 320 pixels. With this camera, the temperature was measured both on the bulb for half an hour and on the LEDs themselves after the bulb was removed.

Traditionally, conclusions for rushers are presented in two final tables at the very end of the article. And lovers of thorough disassembly, we ask for mercy in the experimental part.

Part experimentalSo, for the experiments, three lamps were taken from different manufacturers: a cheap Chinese light bulb with Ebay from CroLED (actually equivalent to Eglo), another Eglo lamp from the local Leroy Merlin and the well-respected and well-known Phillips. Yes, it is worth noting that perhaps the light bulb with Ebay has nothing to do with the company CroLED.

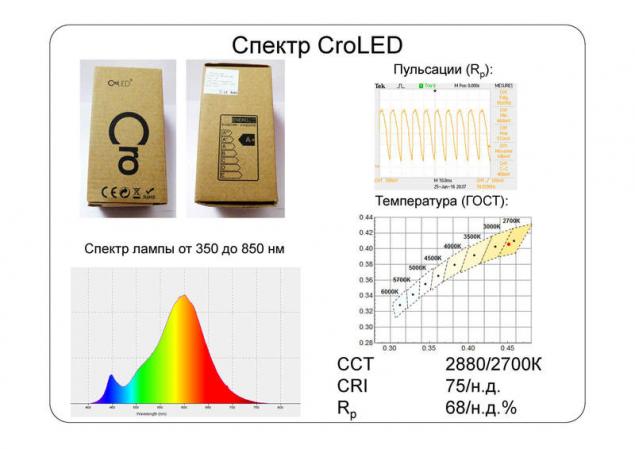

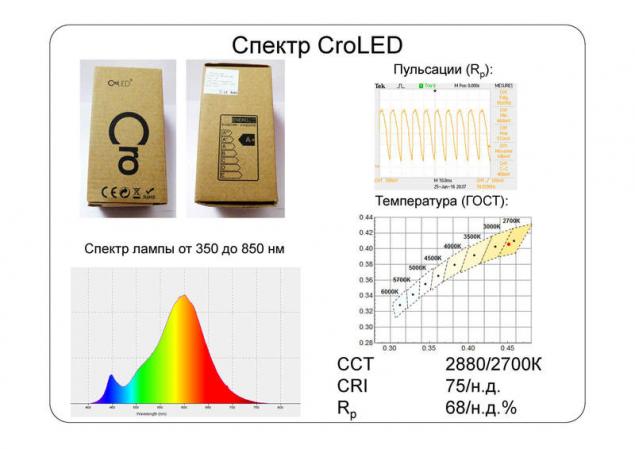

CroLED: Chinese quality EbayLet’s start with a filament lamp from China. The light bulb arrived from China in a simple cardboard box with a minimum of information on it (temperature, power and power voltage). To be honest, expectations were different, but the reality was much harsher. The pulsation coefficient was 67%. Oh, I think it's a record! In fact, the light bulb went out and ignited again with a frequency of 10 ms. The color temperature differed slightly from what was indicated in the seller’s store on eBay.

The analysis of the light bulb revealed one interesting feature of the design - namely the driver. More precisely, its complete absence: the bulb is powered through a banal MB10F diode bridge with a pair of resistors and a huge solid-state capacitor. It's compact!

LEDs are located on a matte substrate in the amount of 18 pieces. Each LED chip is made of a sapphire textured substrate of the “star” type. Chips are very small, smaller than a human hair.

Why is it profitable for the manufacturer to make ultra-small LEDs?

Interesting question. The reason is purely economic. Small LED chips simply do not require additional gold contacts to evenly distribute the electric field and, accordingly, uniform luminosity throughout the diode.

Another reason is the heat sink. It makes no sense to put a powerful large LED on a substrate that conducts heat relatively poorly.

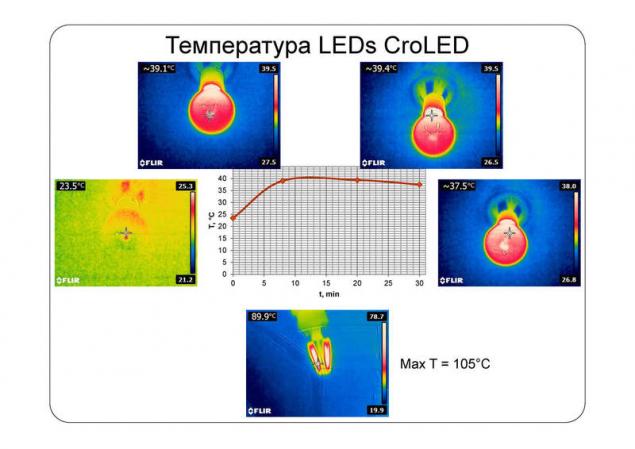

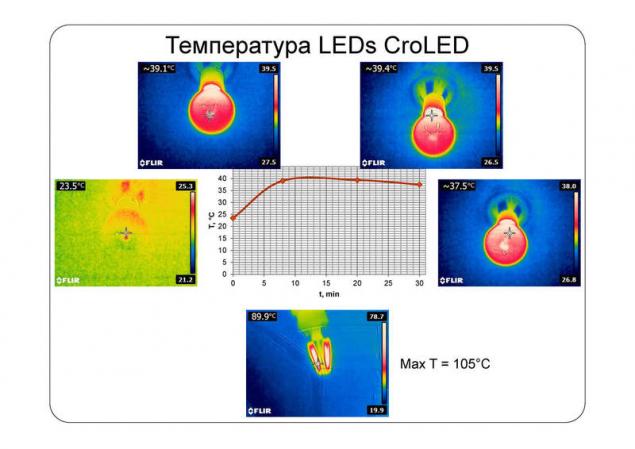

What about the temperature?- the reader will ask. Yes, the temperature on the flask for 5-7 minutes reaches about 40 degrees and remains so for half an hour.

But now let's look under the bulb of our lamp. After removing the glass and measuring the temperature, it turned out that the filaments are very quickly (literally in 1 minute) heated to almost 90 degrees, and in some places, apparently, where the LEDs are located, the temperature reaches more than 100 degrees.

Eglo: ordinary lamps with normal characteristics

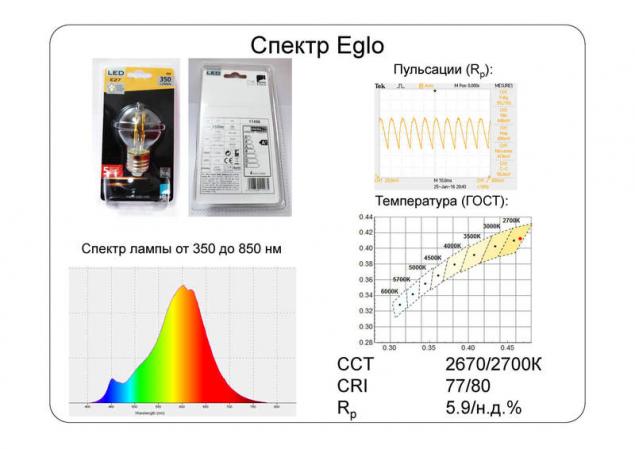

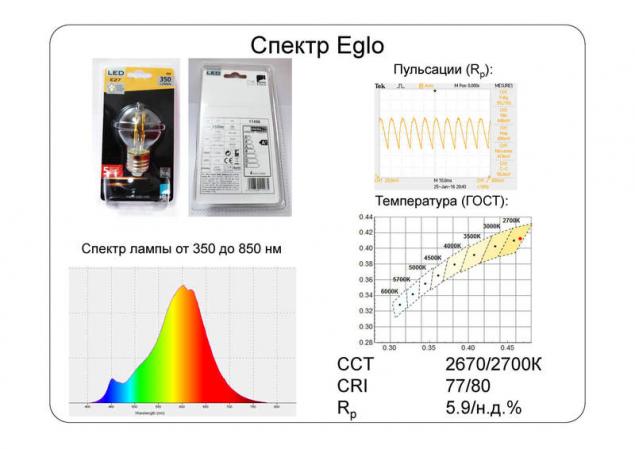

The next lamp from the company Eglo, which, by the way, has a representative office in Russia, in general, pleased with its characteristics. Pulsations at 100 Hz were about 6%, while the color temperature and CRI are quite consistent with the declared characteristics.

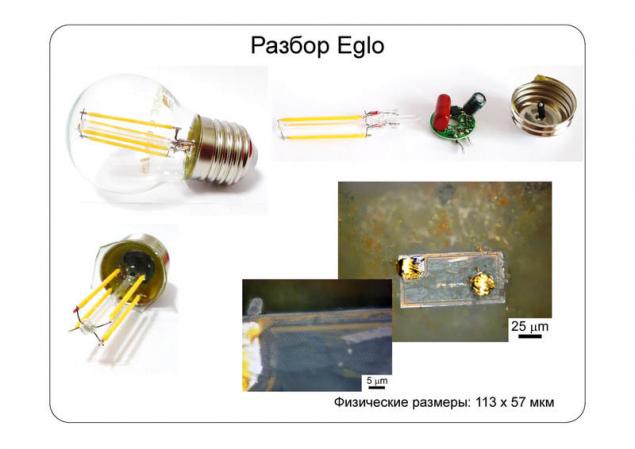

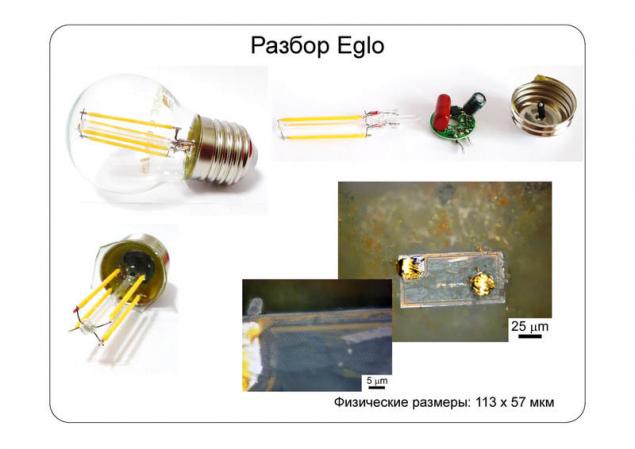

Inside the lamp there are also four filaments of LEDs, as in the Chinese lamp. Inside is a driver based on capacitor ballast. LEDs are slightly larger - 113 by 57 microns than in the previous case. However, they are extremely poorly fixed on the matte substrate again.

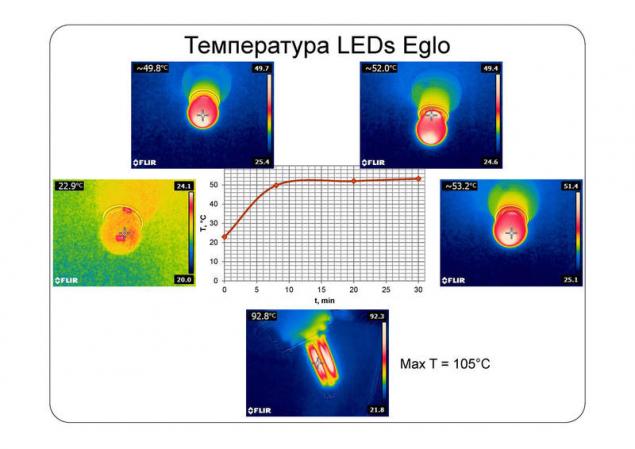

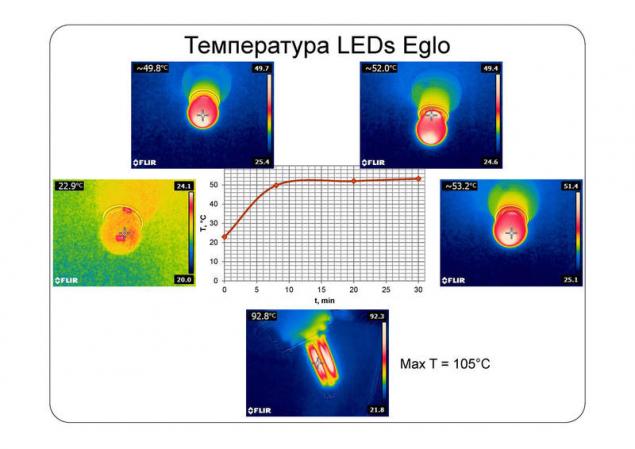

As for the temperature, the light bulb quickly (for the same 5-7 minutes) is heated to a temperature of about 50 degrees. And the threads again show a temperature of ~90 degrees. Just like the curse of the design of the lamp "incandescent" some!

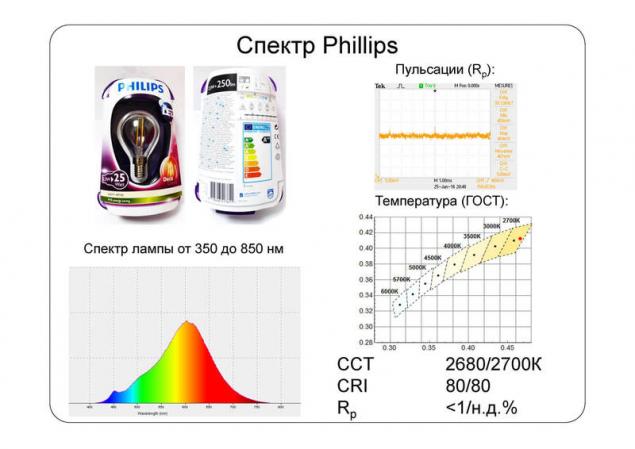

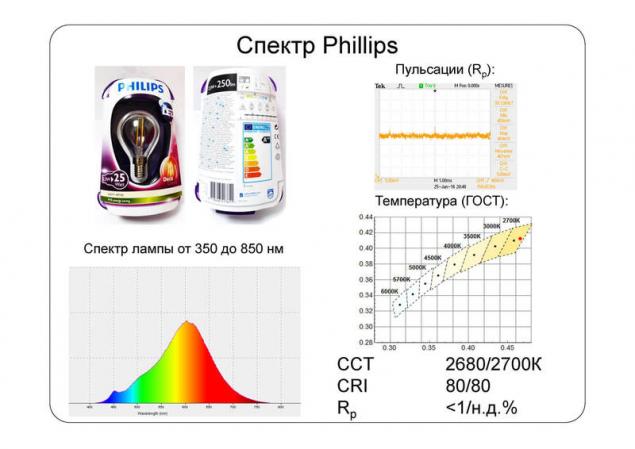

Phillips: Quality comes first

The latest light bulb manufactured by Phillips. Surprisingly, this light bulb in the case of E14 demonstrates excellent compliance with the declared characteristics and extremely low pulsation level.

What is the reason for this, since the E14 cap is much smaller than the E27?- Ask yourself a question. Phillips has good, very good engineers who are able to create an ultra-compact driver (reverse converter) so that it fits into the E14 cartridge, while the driver provides an extremely low pulsation level (<1%).

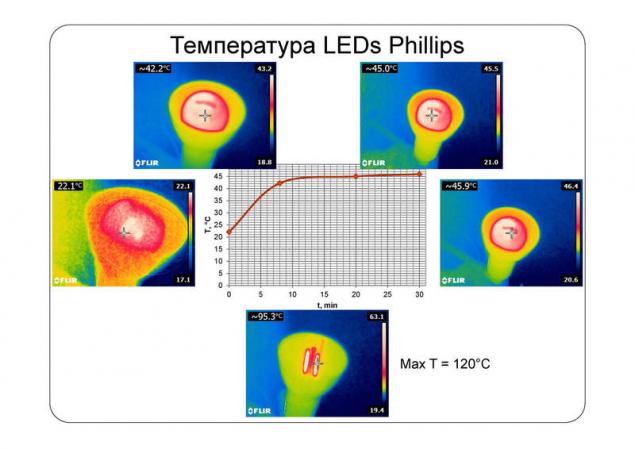

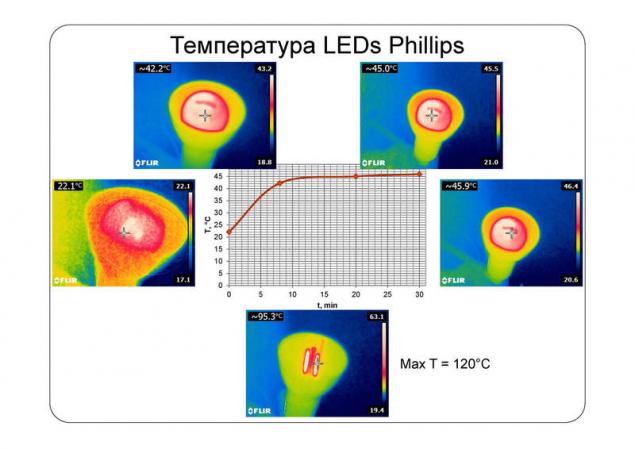

The lamp itself has only two LED filaments, as it consumes only 2.3 watts. LED chips are placed on a transparent substrate and are similar in size to those used in Eglo lamps, but with a different texture of the substrate – “shield”. As mentioned above, you cannot resist the laws of thermal physics.

In about 10 minutes, the bulb of the lamp warms up to ~45 degrees (two threads slower "heat" the entire lamp). However, the temperature of the filaments without a glass bulb was still 95 degrees, in some places – we will repeat, most likely, at the place where LED chips are attached to the substrate – reaching values of 110-120 degrees.

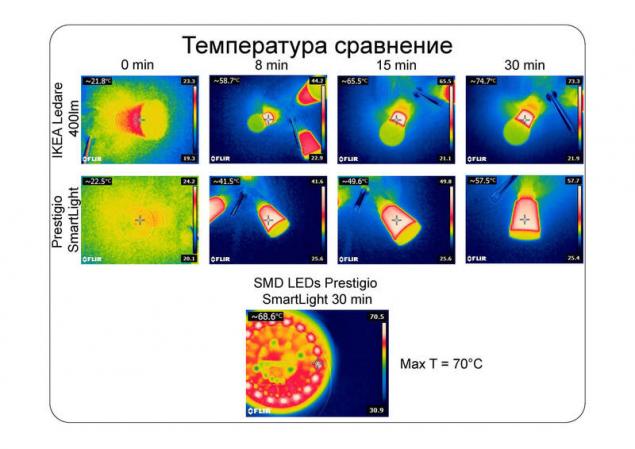

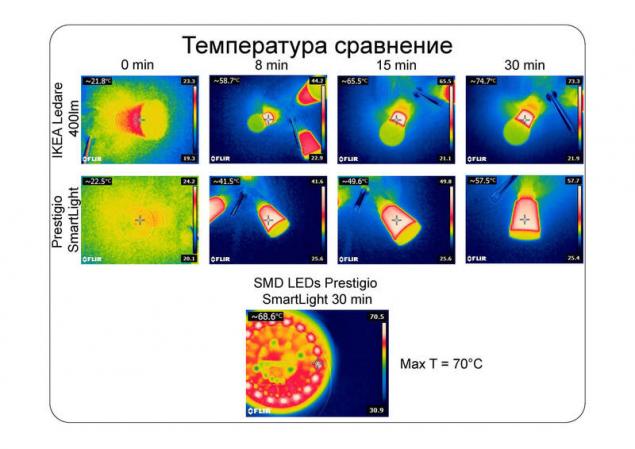

In order not to be unfounded in the verdict regarding filament lamps, we will add a few photos of the already familiar IKEA lamps and powerful smart lamps Prestigio. The body of the IKEA lamp warms up to 75 degrees for half an hour, and the smart lamp Prestigio to 58. At the same time, SMD LEDs of Prestigio lamps, for example, are heated at maximum power only to the “safe” temperature of 60-70 degrees indicated at the very beginning of the article.

Findings

Let’s now sum up some results and try to answer the question: is the game worth filament?

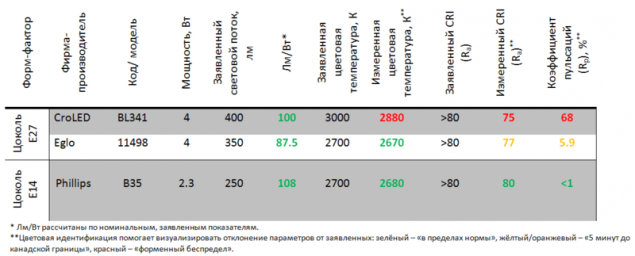

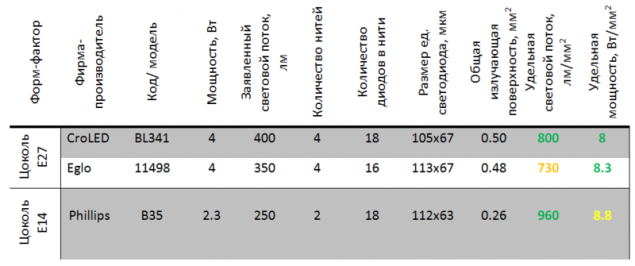

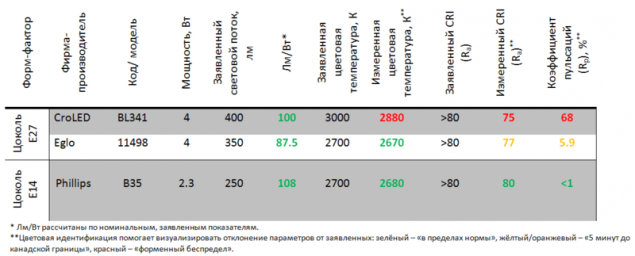

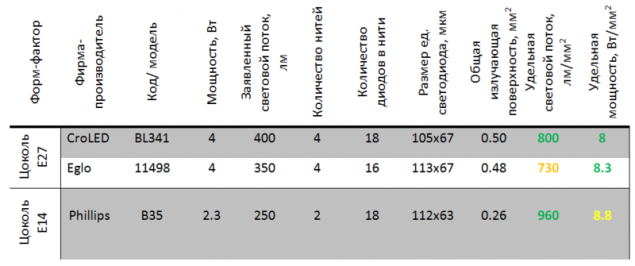

1.Traditionally, the obtained test data are summarized in the table below. But, in my opinion, one should not trust the declared light flux of the Chinese lamp, and other characteristics do not inspire confidence. Manufacturers have a habit of overstating results. Otherwise, the Eglo and Phillips lamps correspond to what is stated on the package, and China – you understand everything perfectly.

Please save your health and time – ask for test results before buying LED lamps on eBay, and in regular stores, too, will soon have to introduce this measure!

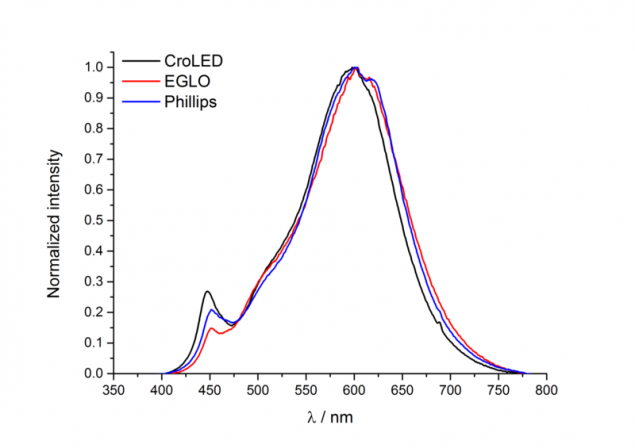

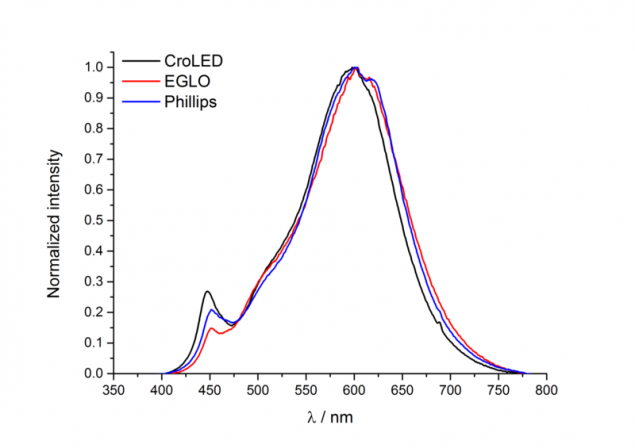

2.The comparison of spectra did not reveal any significant differences: all lamps most likely use the same phosphor, which gives a warm lamp filament-light. There are small variations in the blue components, which can be seen in the color temperature above: Eglo has the warmest, Phillips in the middle, CroLED has the coldest.

3.If we talk about some technology, only Phillips has the right to be called a good and safe lamp with a normal driver, once again confirming the status of a leading player in the market.

All the lamps tested have surprisingly similar values of specific luminous flux and specific power. These values are comparable to the average SMD lamps. Apparently, the heat transfer and heating of LEDs significantly limit these characteristics compared to the usual layout based on SMD LED assemblies.

4.And the most delicious is for dessert. Measurements of the temperature of the filaments themselves with the help of an IR camera (thermal imager) – we hope – convincingly show and prove that filament technology cannot be a full-fledged replacement for conventional SMD lamps with an aluminum radiator and a much more efficient heat sink. Plus, we add a significantly organic space for the driver and as a result we get that bright and powerful lamps with a long service life based on filament will be problematic to create (already 12 W lamps are often equipped with a radiator).

Reporting: Of the installed IKEA, Gauss and Presigio smart bulbs, only IKEA LED bulbs are noticeably buzzing. And everything: that E27, that E14 and different in power. Gauss practically does not make noise, as well as Prestigio (don’t forget, still in modern devices there is an effective noise cancellation).

Source: //geektimes.ru/company/prestigio/blog/271198/

BackgroundWhen it comes to new technology, one of the most important questions immediately arises: how does this technology merge into the overall technological “eco-environment”? Usually, revolutionary technologies simply do not fit into the usual course of things, and you have to make a huge effort to introduce revolutionary products. For example, this was the case with renewable energy sources installed on private homes, when the cost of the “set” fell by orders of magnitude, and in some places of our planet people are also paid for electricity generation, which required a review of the relationship between producers and consumers of electricity. A very similar story happened with electric cars, when the industry split and went two ways: hybrids and full-fledged electric cars with separate “refueling” stations.

About 5 years ago, LED lighting began to actively win over its henchmen and adherents. Engineers have long tried to adapt two-dimensional by nature light sources for three-dimensional illumination (what only are lamps in the form of corn cobs).

And here on the market were released filament lamps. It would seem that found, albeit not perfect, but the optimal solution to the problem, when "sheep are fed and wolves are whole": the light bulb is practically no different from the Ilyich bulb both in shape and content, only the tungsten thread is replaced by an LED filament. Even the old glass mills and workshops found work. It is now proposed to use a ceramic translucent substrate to improve the radial distribution of the light flux of lamps (for example, Crystal Ceramic MCOB).

What is this mysterious filament? Briefly on filament design

A filament is a cake consisting of several components. A thin glass (not as good at conducting heat) or sapphire/ceramic (good conducting heat) substrate – depends on the greed of the manufacturer – with two contacts at the edges. LED chips are installed on this substrate, which are connected successively with the thinnest gold thread. Then the entire structure is filled with a phosphor and, voila, filament is ready.

Diagram of the LED filament

The idea behind this type of LED is simple: trying to squeeze a little bit more lm/W, because in such a design it does not matter where the LED emits, unlike the SMD. The light will still reach the phosphor and give the warm component (green and red).

However, despite the undeniable advantages over SMD LEDs, filament lamps have a number of problems that for some reason do not want to notice. For example, in the “standard” layout with SMD diodes, a fairly massive aluminum substrate and body effectively remove heat, whereas in threads the only way to remove heat is actually only convection and dissipation through the walls of the glass bulb. That is, banal overheating gradually kills both the diodes themselves (the drop in brightness with temperature) and the phosphor (the color reproduction index CRI or R a and the color temperature CCT suffer). Yes, this method of “overheating” works for a tungsten lamp, because the gas in it partially contributes to the regeneration of the filament during use, but no more. As follows from the presented article, temperatures of the order of 60-70 degrees can be considered relatively harmless.

In a nutshell, for the average consumer, overheating or insufficient heat removal from LEDs means only one thing - a multiple (sometimes orders of magnitude) deterioration in the characteristics of LED lamps.

To confirm or refute this point of view, we need to stock up on lamps, take conventional LED lamps for comparison and experiment... including temperature measurement, which will help us with the Flir 5-series thermal imager with a matrix of 240 by 320 pixels. With this camera, the temperature was measured both on the bulb for half an hour and on the LEDs themselves after the bulb was removed.

Traditionally, conclusions for rushers are presented in two final tables at the very end of the article. And lovers of thorough disassembly, we ask for mercy in the experimental part.

Part experimentalSo, for the experiments, three lamps were taken from different manufacturers: a cheap Chinese light bulb with Ebay from CroLED (actually equivalent to Eglo), another Eglo lamp from the local Leroy Merlin and the well-respected and well-known Phillips. Yes, it is worth noting that perhaps the light bulb with Ebay has nothing to do with the company CroLED.

CroLED: Chinese quality EbayLet’s start with a filament lamp from China. The light bulb arrived from China in a simple cardboard box with a minimum of information on it (temperature, power and power voltage). To be honest, expectations were different, but the reality was much harsher. The pulsation coefficient was 67%. Oh, I think it's a record! In fact, the light bulb went out and ignited again with a frequency of 10 ms. The color temperature differed slightly from what was indicated in the seller’s store on eBay.

The analysis of the light bulb revealed one interesting feature of the design - namely the driver. More precisely, its complete absence: the bulb is powered through a banal MB10F diode bridge with a pair of resistors and a huge solid-state capacitor. It's compact!

LEDs are located on a matte substrate in the amount of 18 pieces. Each LED chip is made of a sapphire textured substrate of the “star” type. Chips are very small, smaller than a human hair.

Why is it profitable for the manufacturer to make ultra-small LEDs?

Interesting question. The reason is purely economic. Small LED chips simply do not require additional gold contacts to evenly distribute the electric field and, accordingly, uniform luminosity throughout the diode.

Another reason is the heat sink. It makes no sense to put a powerful large LED on a substrate that conducts heat relatively poorly.

What about the temperature?- the reader will ask. Yes, the temperature on the flask for 5-7 minutes reaches about 40 degrees and remains so for half an hour.

But now let's look under the bulb of our lamp. After removing the glass and measuring the temperature, it turned out that the filaments are very quickly (literally in 1 minute) heated to almost 90 degrees, and in some places, apparently, where the LEDs are located, the temperature reaches more than 100 degrees.

Eglo: ordinary lamps with normal characteristics

The next lamp from the company Eglo, which, by the way, has a representative office in Russia, in general, pleased with its characteristics. Pulsations at 100 Hz were about 6%, while the color temperature and CRI are quite consistent with the declared characteristics.

Inside the lamp there are also four filaments of LEDs, as in the Chinese lamp. Inside is a driver based on capacitor ballast. LEDs are slightly larger - 113 by 57 microns than in the previous case. However, they are extremely poorly fixed on the matte substrate again.

As for the temperature, the light bulb quickly (for the same 5-7 minutes) is heated to a temperature of about 50 degrees. And the threads again show a temperature of ~90 degrees. Just like the curse of the design of the lamp "incandescent" some!

Phillips: Quality comes first

The latest light bulb manufactured by Phillips. Surprisingly, this light bulb in the case of E14 demonstrates excellent compliance with the declared characteristics and extremely low pulsation level.

What is the reason for this, since the E14 cap is much smaller than the E27?- Ask yourself a question. Phillips has good, very good engineers who are able to create an ultra-compact driver (reverse converter) so that it fits into the E14 cartridge, while the driver provides an extremely low pulsation level (<1%).

The lamp itself has only two LED filaments, as it consumes only 2.3 watts. LED chips are placed on a transparent substrate and are similar in size to those used in Eglo lamps, but with a different texture of the substrate – “shield”. As mentioned above, you cannot resist the laws of thermal physics.

In about 10 minutes, the bulb of the lamp warms up to ~45 degrees (two threads slower "heat" the entire lamp). However, the temperature of the filaments without a glass bulb was still 95 degrees, in some places – we will repeat, most likely, at the place where LED chips are attached to the substrate – reaching values of 110-120 degrees.

In order not to be unfounded in the verdict regarding filament lamps, we will add a few photos of the already familiar IKEA lamps and powerful smart lamps Prestigio. The body of the IKEA lamp warms up to 75 degrees for half an hour, and the smart lamp Prestigio to 58. At the same time, SMD LEDs of Prestigio lamps, for example, are heated at maximum power only to the “safe” temperature of 60-70 degrees indicated at the very beginning of the article.

Findings

Let’s now sum up some results and try to answer the question: is the game worth filament?

1.Traditionally, the obtained test data are summarized in the table below. But, in my opinion, one should not trust the declared light flux of the Chinese lamp, and other characteristics do not inspire confidence. Manufacturers have a habit of overstating results. Otherwise, the Eglo and Phillips lamps correspond to what is stated on the package, and China – you understand everything perfectly.

Please save your health and time – ask for test results before buying LED lamps on eBay, and in regular stores, too, will soon have to introduce this measure!

2.The comparison of spectra did not reveal any significant differences: all lamps most likely use the same phosphor, which gives a warm lamp filament-light. There are small variations in the blue components, which can be seen in the color temperature above: Eglo has the warmest, Phillips in the middle, CroLED has the coldest.

3.If we talk about some technology, only Phillips has the right to be called a good and safe lamp with a normal driver, once again confirming the status of a leading player in the market.

All the lamps tested have surprisingly similar values of specific luminous flux and specific power. These values are comparable to the average SMD lamps. Apparently, the heat transfer and heating of LEDs significantly limit these characteristics compared to the usual layout based on SMD LED assemblies.

4.And the most delicious is for dessert. Measurements of the temperature of the filaments themselves with the help of an IR camera (thermal imager) – we hope – convincingly show and prove that filament technology cannot be a full-fledged replacement for conventional SMD lamps with an aluminum radiator and a much more efficient heat sink. Plus, we add a significantly organic space for the driver and as a result we get that bright and powerful lamps with a long service life based on filament will be problematic to create (already 12 W lamps are often equipped with a radiator).

Reporting: Of the installed IKEA, Gauss and Presigio smart bulbs, only IKEA LED bulbs are noticeably buzzing. And everything: that E27, that E14 and different in power. Gauss practically does not make noise, as well as Prestigio (don’t forget, still in modern devices there is an effective noise cancellation).

Source: //geektimes.ru/company/prestigio/blog/271198/