748

Graphene aerogel - lightest material in the world

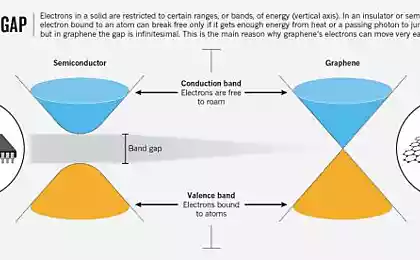

Created last year material called airbrushing couldn't hold the title of the lightest material in the world. The crown had to give the new aerogel made from graphene, the miracle material of the 21st century. Density, ultra-light material below the density of helium, and half hydrogen.

The new material was developed by a group of researchers led by Professor Gao Chao from the laboratory of the Department of science and technology of polymers, Zhejiang University (China).

The aerogels, originally created in 1931 by American scientist and chemical engineer Samuel Stephens Killerom, recently started to pay a lot of attention. In 2011, the aerogel-based multilayer carbon nanotubes (MCNT), also known as "frozen smoke" with a density of 4 mg/cm3 gave place to the easiest material in the world with micro-lattice structure, the density of which is equal to 0.9 mg/cm3. Later it shifted airbrush (0.18 mg/cm3), whose triumph was as short-lived. Today, the palm belongs grafenovoy the aerogel. Its density is 0.16 mg/cm3.

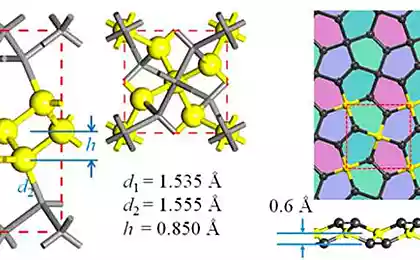

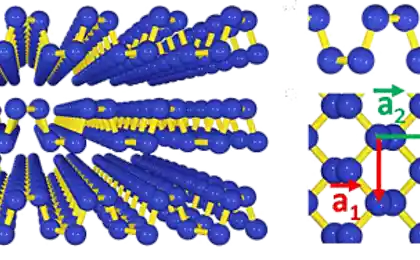

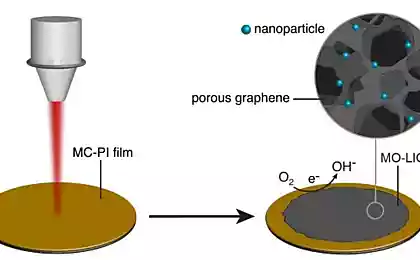

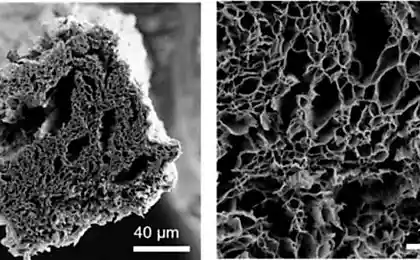

The researchers already have created a macroscopic graphene materials, in particular one-dimensional fibers and two-dimensional films obtained from graphene. To put the record, they only had to add one dimension to obtain three-dimensional porous material.

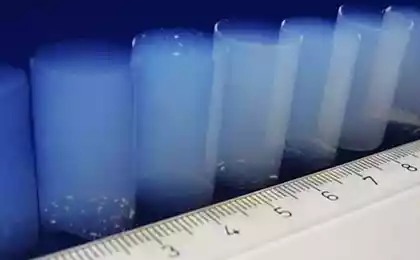

Instead of the Sol-gel technology and other methods used to create aerogels, Gao applied the new method of drying, which helped to create a carbon sponge custom forms.

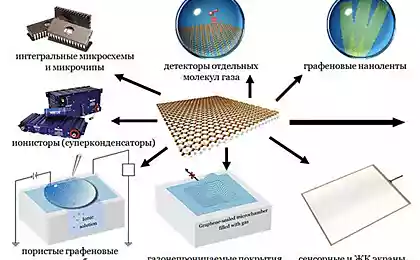

"The need to use templates because the size of the material depends on the size of the container. The larger the container, the more aerogel. We can talk about thousands of cubic centimeters, and this is not the limit". According to scientists, "derived" them the material has extremely high strength and elasticity. He is able to quickly return to shape after compression, to absorb and retain a large amount is not soluble in water substances up to 900 times its own weight. It's hard to believe, but in one second gram of aerogel soaks up to 68.8 grams of organic substances, which makes it attractive for use in areas of oil spill.

"Maybe one day it will help prevent an ecological disaster. Thanks to the elastic properties of the material the collected oil and the aerogel can be recycled," says Gao. Researchers are studying the possibility of applying new material. According to them, graphene aerogel can be used as insulating material, catalyst substrate or high performance composite.

Source: /users/104

The new material was developed by a group of researchers led by Professor Gao Chao from the laboratory of the Department of science and technology of polymers, Zhejiang University (China).

The aerogels, originally created in 1931 by American scientist and chemical engineer Samuel Stephens Killerom, recently started to pay a lot of attention. In 2011, the aerogel-based multilayer carbon nanotubes (MCNT), also known as "frozen smoke" with a density of 4 mg/cm3 gave place to the easiest material in the world with micro-lattice structure, the density of which is equal to 0.9 mg/cm3. Later it shifted airbrush (0.18 mg/cm3), whose triumph was as short-lived. Today, the palm belongs grafenovoy the aerogel. Its density is 0.16 mg/cm3.

The researchers already have created a macroscopic graphene materials, in particular one-dimensional fibers and two-dimensional films obtained from graphene. To put the record, they only had to add one dimension to obtain three-dimensional porous material.

Instead of the Sol-gel technology and other methods used to create aerogels, Gao applied the new method of drying, which helped to create a carbon sponge custom forms.

"The need to use templates because the size of the material depends on the size of the container. The larger the container, the more aerogel. We can talk about thousands of cubic centimeters, and this is not the limit". According to scientists, "derived" them the material has extremely high strength and elasticity. He is able to quickly return to shape after compression, to absorb and retain a large amount is not soluble in water substances up to 900 times its own weight. It's hard to believe, but in one second gram of aerogel soaks up to 68.8 grams of organic substances, which makes it attractive for use in areas of oil spill.

"Maybe one day it will help prevent an ecological disaster. Thanks to the elastic properties of the material the collected oil and the aerogel can be recycled," says Gao. Researchers are studying the possibility of applying new material. According to them, graphene aerogel can be used as insulating material, catalyst substrate or high performance composite.

Source: /users/104