435

Audi will present spring polymer reinforced with fibre glass

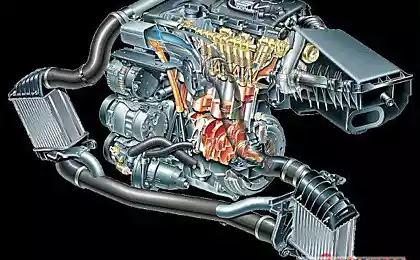

The task of optimization of fuel consumption is forcing car manufacturers to work on reducing the weight of machines. The use of aluminum, carbon fiber and fiberglass helps to meet stringent emission standards. Inspired by an original idea, Audi has announced that by the end of the year it will represent polymer springs for cars, reinforced with fiberglass.

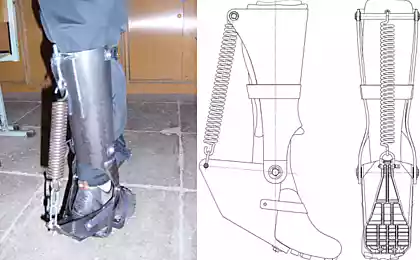

The basis of the spring consists of glass fibers twisted together and containing epoxy resin. The company expects to use the equipment for cheating additional glass fiber strands on the base and heat-treating articles in a furnace. Strands wound around each other at an angle of 45 degrees, which allows to distribute the load across the spring.

What are the advantages of these springs compared to steel springs? They do not corrode, even in case of damage, and not exposed to chemicals used for washing of the wheels of the car. On snowy roads treated with salt, their advantages become even more tangible.

Another advantage of these springs, compared to the traditional tools is their weight. For machines of medium size, according to representatives of Audi, the weight of the spring is 2.7 kg, while the weight of the polymeric spring only 1.6 kg. the Difference is approximately 40 %. The total difference of 4.4 kg seems insignificant, but every gram reduces emissions, and improves vehicle control.

Regarding the last point, the company notes that the polymer of the spring can be "exactly matched" to the current task, from regular driving to sport events, allowing you to experience the benefits of the springs regardless of the type of car. To top it off, compared to the traditional means for the production of plastic springs require less energy.

The company plans to release the first batch of springs for the "machines of medium size" (presumably the models A6 and A7) by the end of 2014.

Source: nauka21vek.ru

The basis of the spring consists of glass fibers twisted together and containing epoxy resin. The company expects to use the equipment for cheating additional glass fiber strands on the base and heat-treating articles in a furnace. Strands wound around each other at an angle of 45 degrees, which allows to distribute the load across the spring.

What are the advantages of these springs compared to steel springs? They do not corrode, even in case of damage, and not exposed to chemicals used for washing of the wheels of the car. On snowy roads treated with salt, their advantages become even more tangible.

Another advantage of these springs, compared to the traditional tools is their weight. For machines of medium size, according to representatives of Audi, the weight of the spring is 2.7 kg, while the weight of the polymeric spring only 1.6 kg. the Difference is approximately 40 %. The total difference of 4.4 kg seems insignificant, but every gram reduces emissions, and improves vehicle control.

Regarding the last point, the company notes that the polymer of the spring can be "exactly matched" to the current task, from regular driving to sport events, allowing you to experience the benefits of the springs regardless of the type of car. To top it off, compared to the traditional means for the production of plastic springs require less energy.

The company plans to release the first batch of springs for the "machines of medium size" (presumably the models A6 and A7) by the end of 2014.

Source: nauka21vek.ru

Resonant method of extracting energy from a physical vacuum

Popigai meteorite led to the mass extinction of species