452

Residential house for 2 days

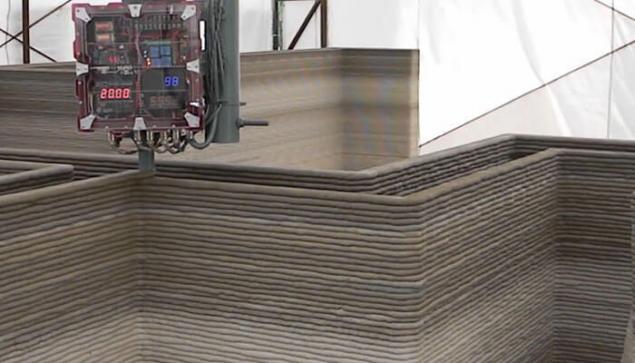

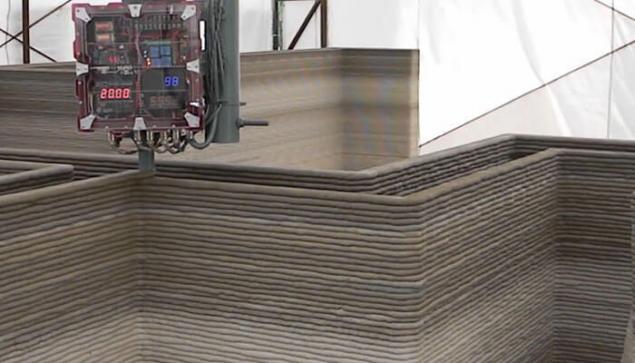

A couple of years ago, "native American") Andrey Rudenko began to build concrete models of medieval castles in Minnesota, USA. It was a fairly large model, with area of base is 3*5 metres. To create such a castle was not used a concrete mixer and a shovel, and a specially designed 3D printer. The locks themselves are also designed not for the game, and to practice the construction process. Andrew had planned the same way to build homes.

And now these plans become a reality. The other day on YouTube was posted a video that shows the construction process of a house. It is about creating a basic frame, which after finishing, add power lines, water, etc. turning into a residential house. And for comparison shows the normal process of building a house. By the way, the frame with 3D printer was built in just 48 hours.

The Creator of house printing process is an engineering and architectural education, it helps in the process of development. In addition, homes are created with safety and other requirements of the relevant authorities. The building that builds Rudenko, resistant to hurricanes and even tornadoes. SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man.

That's what he tells himself Andrey Rudenko in the comments on the composition of the mixture and the printer is on YouTube: "the mix is pretty simple but requires very careful selection of the proportions depending on the type of sand, climate. A different proportion and all... so working on a fully automatic mixing system with different sensors for humidity, temperature, weight, etc... Installation (printing system) is expensive because it includes many components (automatic mixing unit, pumps, and so forth). Does not make sense to talk about the cost of individual parts, all will work well only in the kit, it is useless to try to use for example an ordinary concrete mixer (we tried)".

And here's an old video about the construction of castles (looks like the video recorded from the TV screen, so the quality is not great):

After the castles, Andrew has already tested its technology in commercial construction in the Philippines.

He created the extension to the hotel, with columns and a Jacuzzi (in General, the previous version was very similar to the current one).

In addition, when building a house You must plan and heating system. http://teplovoy-nasos.baltcomfort.ru/ — this is an opportunity to get environmentally friendly and economical way of heating at the same time.

Source: geektimes.ru/post/271774/

And now these plans become a reality. The other day on YouTube was posted a video that shows the construction process of a house. It is about creating a basic frame, which after finishing, add power lines, water, etc. turning into a residential house. And for comparison shows the normal process of building a house. By the way, the frame with 3D printer was built in just 48 hours.

The Creator of house printing process is an engineering and architectural education, it helps in the process of development. In addition, homes are created with safety and other requirements of the relevant authorities. The building that builds Rudenko, resistant to hurricanes and even tornadoes. SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man.

That's what he tells himself Andrey Rudenko in the comments on the composition of the mixture and the printer is on YouTube: "the mix is pretty simple but requires very careful selection of the proportions depending on the type of sand, climate. A different proportion and all... so working on a fully automatic mixing system with different sensors for humidity, temperature, weight, etc... Installation (printing system) is expensive because it includes many components (automatic mixing unit, pumps, and so forth). Does not make sense to talk about the cost of individual parts, all will work well only in the kit, it is useless to try to use for example an ordinary concrete mixer (we tried)".

And here's an old video about the construction of castles (looks like the video recorded from the TV screen, so the quality is not great):

After the castles, Andrew has already tested its technology in commercial construction in the Philippines.

He created the extension to the hotel, with columns and a Jacuzzi (in General, the previous version was very similar to the current one).

In addition, when building a house You must plan and heating system. http://teplovoy-nasos.baltcomfort.ru/ — this is an opportunity to get environmentally friendly and economical way of heating at the same time.

Source: geektimes.ru/post/271774/