530

Samarkand silk paper — making secrets

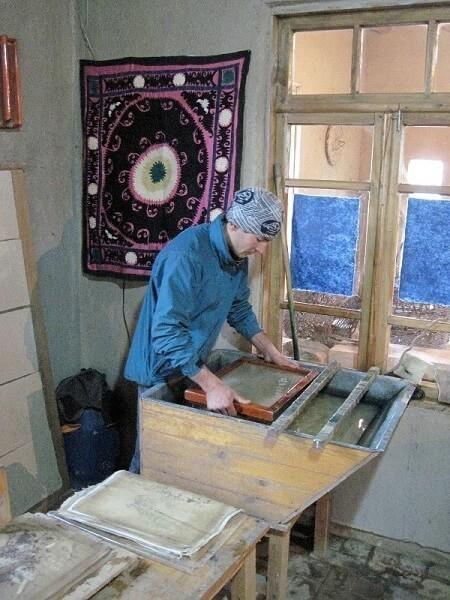

Near Samarkand is the village of Konig. There is one local pretzel organized the production of paper. Old. On old technology. Himself, so to speak, to live. And a tourist attraction. This paper is called Samarkand silk paper. Recipe restored in accordance with the instructions. And they, in turn, repeat the technology, invented by the Chinese.

But, anyway, all very interesting and clearly.

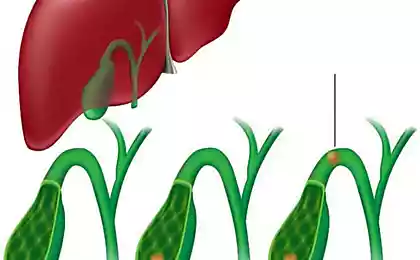

This is a mulberry tree. Growing there — on the corner of each village. First things first cut the branches. And in under pressure in the water. Soak. Then they stripped the bark. After this mouth-watering action — svejesobranna bark boiled in a cauldron. After that, the most spectacular (for them, Uzbek standards) part of the process. The mill intricate designs boiled the bark by rough musilova, make quite a shapeless pulp..

Slurry as the slurry should be sent in a tub with water. Cold. Then abruptly scrambled mess, dropped in the mixing frame with the sieve, let the water drain out...

... actually, that's almost it. If you reject the nuances of a sheet of paper ready.

The fibers of the mulberry tree were intertwined together like felt. So, all that is now required is to remove the water. A sheet of paper already formed. Under the press, and then manually every leaf on the Board! To dry! Brush — flatten. To bubbles no. (Who pasted a protective film on anything — knows this hemorrhoids. And in a couple of days to Polish! Polished (probably also on the advice of these old manuskriptov) two items. Stone. And shell...

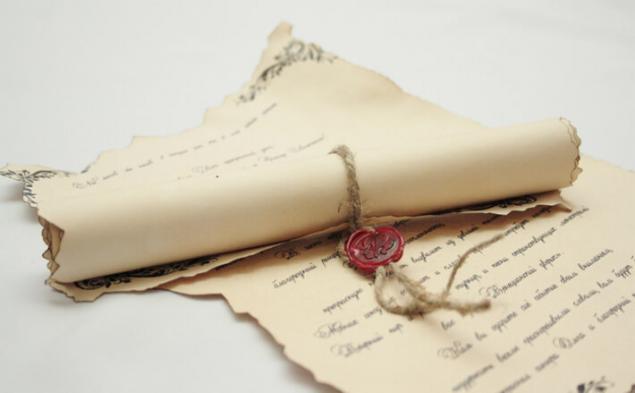

Even in our age of computers and yet the hypothetical rejection of the "writing" paper is difficult to imagine life without it: printing, wrapping, Wallpaper, cash, cigarette, finally, the toilet... it is believed that it was invented in 1910 years ago, in March of 106 years, and the inventor was a Chinese official, the eunuch Cai LUN. Mix powdered fiber mulberry, ash wood, cloth and hemp, for the first time he received something without which we now can not live.

A brief history of paper

The Chinese kept the secret of papermaking for nearly 500 years, but in the beginning of the VII century it became known in Korea, Japan, and even 150 years later taken prisoner by the masters of Central Asians and Arabs. In XI–XII centuries, the paper appeared in Europe, where he quickly replaced the expensive animal parchment. But until the XVII century it was manufactured in the same ancient way: by pounding the pulp in a mortar and bailing on a grid with mesh bottom.In the XVII century, the process has improved the invented grinding machine — roll, and at the end of the XVIII century appeared the paper machine.

Toilet paper

Toilet paper industrial way began to produce only 160 years ago. The first factory was located in new York and produced a thin paper soaked in healing aloe Vera juice, in 1884, she was smart enough to fold into a roll. In China, the use of paper in "hygienic" purposes known already in VI century. Custom "do not wash with water but only wipe themselves with paper" surprised Arab travelers who visited medieval China, but with time the Arabs are partially adopted Chinese habits..

Generally, the process of making paper is very interesting. It begins with the pulp. It is a product of processing wood chips. By cooking wood chips in various herstomach it is removed from the resinous substances, and lignin, which binds wood fibers and gives strength to the stems and trunks.

The pulping process is a piece of technology, and his conduct at individual factories, the product of which is cellulose. She arrives at the factory for the production of paper.

The paper mill, the pulp is subjected to grinding. After grinding the cellulose pulp is obtained, which is cast in paper on the paper machine.

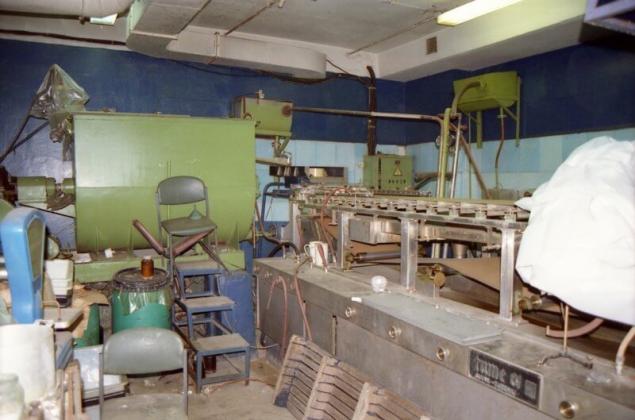

I have to say — the cars mass and each is unique in their own way, but fundamentally industrial machine can be divided into two categories — krugovorote and canteens (or ploskostopie). Here ploskostopie low tide we were interested in.

Looked after my colleagues and little ploskorelefnuju machine in one once the Union Institute in the capital city and decided to try it. Agreed with the owners. The ready pulp, pressed it and drove to Moscow.

Machine made in Finland — the Finns are a notable wallets. For those associated with industrial machinery, this machine is simple and just a little bit, but the principle is the same.

I want to say that the production of paper with the rather simple process. But! there's a huge amount of details and nuances that affect the quality and even then, you get paper or not. Once when he was studying in graduate school (which I never finished writing the dissertation) read the papers of the symposia on the paper and came across an article about the production of paper. So there was written a phrase which I remembered — despite the degree of automation and computerization of the modern paper-making industries, paper manufacturing remains an art. Confirm 10 years of experience — pure shamanism.

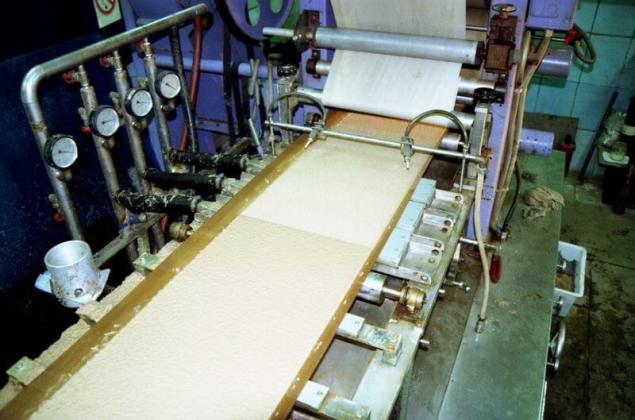

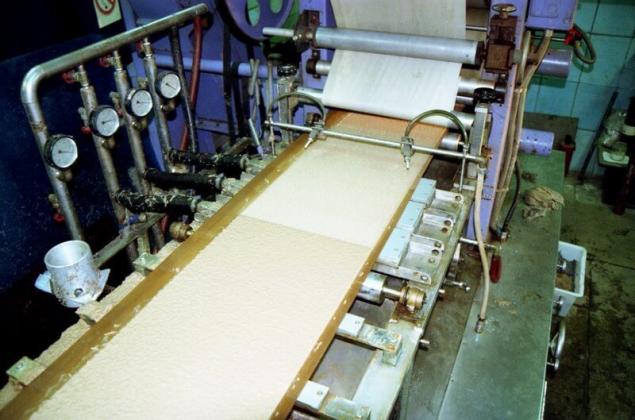

In the photo — the wet end of the machine, namely the table, where goes the tide of paper. Big green tank — consumable pool, where the suspension is loaded. Right from her little tank — it is tank constant head of water for dilution in the stream.

Looking in the other direction and see the rest of the car. There are many interesting, but yet pay attention to the blue cap. Under that cap is dried paper and vapor is removed by ventilation from the premises.

Both tanks have plum in a trough with partitions — there is a dilution of the suspension to a working concentration and the averaged concentration.

Our gutter is also not simple. It is equipped with a vibrator, the vibration helps the homogenization of the pulp and prevents the formation of clots. I must say that prepared to tint cellulose (in suspension she was not alone, there's a whole bunch of components, but it forms a cellulose paper) has a surprisingly high tendency to knot... thus to form strong paper. This property it acquires in the process of preparation for grinding (it would be better to say grinding, but that profiling) equipment (i.e. what we did at home).

Roughly speaking — cellulose is a long, thin and very fluffy fibers, and strive to get complicated and form tangles. But, until the formation of the paper sheet we don't need. We need to minimize this behavior, because otherwise it will give non-uniformities in the paper.

So, our suspension was diluted and srednjaci, drip from the chute in a calm, wide jet and got in the car. The chute with a small device, where the suspension is the headbox, i.e. a device for release of suspension on the grid machines.

Box it box, but it's almost the key, and, by the way, is a very complex structure in the industrial machine. The boxes are calculated, but their finishing is always a delicate process. What is shown in the photo, nothing in common with the industrial device doesn't have only functional similarity.

First machines the suspension meets the perforated roller, which rotates counterclockwise. Mix more aligned to the concentrate and dispersed in the direction from the beginning of the machine to the end, flowing on the mesh "wet end" of the machine. Cushion also unravels was already starting to form globules of the cellulose. Tangles still relatively easy to unravel, because water is still a lot. As soon as the water goes from the suspension to unravel the tangles will be impossible.

So, the suspension got on the net. The mesh moves from the beginning of the machine to the end along the so-called Desk and it's time to see how the table of the machine. Moreover, on the upper photo you can see that the mixture has already started to give water — see frozen water droplets. The grid on this machine not moving very fast, industrial machines, especially in the production of thin papers, mesh with a soft rustle of flying, it's flying speed is very large, even impossible to make out on the grid... Obezvozhivani on the grid suspension naslano forms — cellulose and other components are firmly retained twisted cellulose fibers. Water in the tincture. And then the grid is three rows (it's only on this machine, each machine has its number depending on the grades issued securities) vacuum suction boxes. Removing water held by surface tension in the tangle of cellulose fibers.

Please note that in the process of forced dehydration nastoyka much thinner. Clean "vodacce". Further nastoyka carefully pressed down the shaft of the press, to too completely to give water.

The next photo shows how to construct a press. The lower shaft rubber. Top roller presses on the lower. The pressure should be optimal, because naslano can be crushed and then get the paper tears and creases.

Please note that the top shaft in a white shirt. This shirt is called "Manson". The shirt need to, in the first place, gently push, and secondly, to nasluka stuck to it and removed from the grid. Mesh rubber surrounds the lower shaft and moves down the car, previously having washed the bottom of the machine in the jet shower.

"Manson" the wet paper is easily removed and fueled on the drying cylinder called a Yankee cylinder.

Around the cylinder the paper is dried and removed from it. In the beginning of the process to contrive to remove the paper. because it is very thin. Then she would go thicker. And is wound on the receiving shaft when everything is set up... published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: livejournal.com/magazine/1387588.html