576

How to make a carport at the dacha with his hands

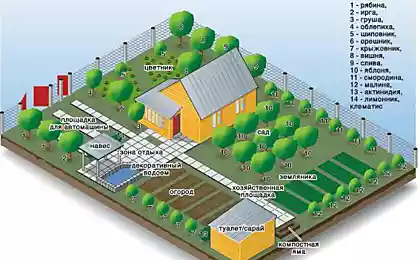

Once you find a place, sketch on paper the layout with exact dimensions, make the calculation and prepare the tool.

An essential toolFor the construction of the canopy a good host will find almost all the necessary tools. Something missing from you can always rent or ask a neighbor. The need for highly specialized tools, no, but depending on the used racks materials may need different set of tools:

Gardening tools: a shovel, a sledgehammer, a pickaxe and a crowbar is required for ground works: leveling of the site and digging pits under stand canopy. Carpentry tools: hammer, handsaw, chisel or chisel — used for the installation of wooden pillars, joists and sheathing of the roof overhang. Measuring tools: tape measure, spirit level or construction level, plumb Bob, carpenter's square is required in any case for proper Assembly and installation of the canopy. Power tools: drill, turbochieftain machine, drill and bits, a jigsaw. And if you install a concrete or metal support posts of the canopy for cars will need a welder.

The expenditure of mounting materials include nails, screws, bolts, metal corners, etc. Their number and sizes are determined depending on the materials and construction shed

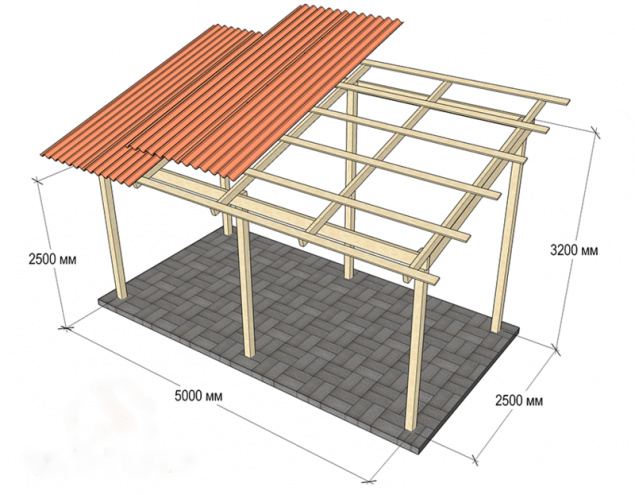

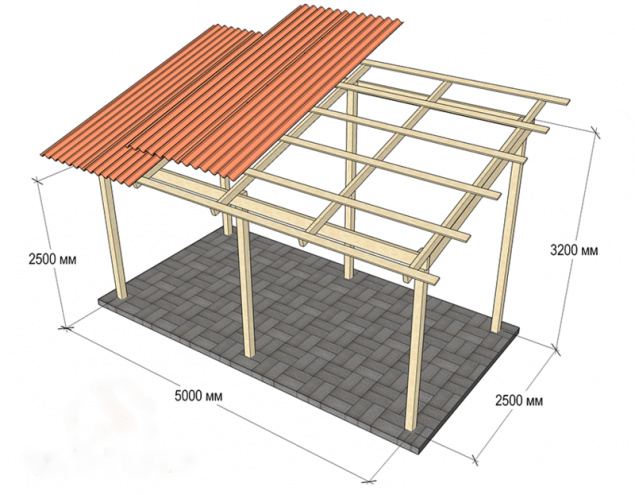

The materials and their costCalculation materials in accordance with the drawing of the carport. Taking conditional the length of the machine is 4 meter canopy is planned 5x2,5 m. If the car exceed the usual dimensions, jeep or minivan, the canopy is constructed are slightly larger, about 6,5x3,5 m. when Designing the shed, pushes away from the dimensions of the roofing sheets. The height of the canopy should allow you to freely open the trunk. It is about 2.5 meters.

The number of pillars depending on the material, the area of the canopy and the weight of the roof varies from 4 to 10 PC In case, if one of the parties adjacent to the building, stands less need. Materials for support posts and frame of the canopy made of metal:

Frame of timber will be cheaper. For support posts timber of softwood 100x100 is worth about 60 rubles per meter. The timber for the frame 50x50 is about 17 rubles Pogue. M. price also depends On grade of wood, humidity and type of wood.

To cover the canopy will fit any materials used for roofing:

1. Corrugated sheets with polymeric coating with a thickness of 0.4 mm is from 155 to 175 RUB/m2, similar to galvanized in the range of 130-150 rubles/m2. Galvanized steel sheet size 1000х2000х0,4 mm is approximately 2660 roubles apiece. Skate galvanized size mm 2000х100 will cost 95-100 rubles apiece, and polymer coated — 120 RUB./PCs. For the arrangement of the roof from metal will require additional and gutter elements.

2. Slate gray type SV-40 has 7 or 8 waves at a thickness of 5.8 mm and standard sizes 1750х1130 mm, is 220-230 rubles per sheet. Weigh a sheet of slate from 19 to 25 kg depending on the thickness and density of the material. Several expensive cost of colour slate — to 300 rubles a sheet. The disadvantages of slate can be attributed to the fragility of the material and weight.

3. Metal thickness 0.4 mm costs from 180 USD/m2. Metal working width 1100 mm, 1180 mm. It is reliable and lightweight material for the roof canopy. It is easy to transport and install.

4. Plastic roofing is suitable for canopies and awnings. Usually made from polycarbonate or polyvinyl chloride. The standard sheet size mm 2000х900 or is issued in rolls 10-20 metres with a width from 1.5 to 3 m. the average price of the sheet in the region of 300 rubles.

The installation of the support struts of the canopyFor support posts of the canopy for marking drill or dig wells with a depth of 0.7 meters. The bottom is filled with gravel and compacted. The end of the concreted support post treated with an antiseptic and bitumen mastic. The exposed vertical support columns are filled with concrete. The principle of installation of the supports is the same for wooden and metal racks.

After drying of the concrete strut is mounted on the truss design for roofs. Wooden support pillar on the perimeter of the tie Board 50х150 mm, formed on the upper crown canopy set rafter skeleton. Suits timber 50x100 mm with a mounting pitch of about a meter. Accurate step size of the rafters dictates the width of the roofing material. Rafter beams shall be placed in areas of overlap of the roofing sheets.

For metal struts of the truss system welded on the ground. Out of the corner of 50x50 mm in size uprights welded rectangular frame. For the corner of the gable roof of the canopy from the same area welded to the rafters. For arched roof used strip of metal. In the rafter system nastelivaetsya attachment holes of the roof. Typically, the hole pitch of any roof is about 10-15 cm Truss system is installed on the support pillar and is attached by welding.

The flooring of the roof of the carportTo the rafters perpendicular to them sewn crate. This is used as edged and unedged mm. 20х100 the First line of crates stuffed on the edge of a slope, the top line in place of fastening of the skate. The distance between the lines is 50-70 cm Line must be located at fixing points and overlap of the roof.

Roofing sheets begin to stack from the lower corner to the ridge with an overlap of 10-15 cm the Slate is attached using special galvanized nails with large nail heads. Nailed it light rhythmic strokes with a hammer on roofing nail, set on the highest point of the wave.

Plastic slate, corrugated sheet, metal roofing used galvanized screws with special plastic pads or prescribe. Usually one roofing sheet requires 10-12 screws. Often roofing sheets comes with a set of fasteners of the corresponding color.

On the frame of the canopy made of metal roofing sheets are fixed with screws with metal and sealing washers, or screws on the metal, under which are installed the gasket.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.rmnt.ru/story/outbuilding/1114736.htm

An essential toolFor the construction of the canopy a good host will find almost all the necessary tools. Something missing from you can always rent or ask a neighbor. The need for highly specialized tools, no, but depending on the used racks materials may need different set of tools:

Gardening tools: a shovel, a sledgehammer, a pickaxe and a crowbar is required for ground works: leveling of the site and digging pits under stand canopy. Carpentry tools: hammer, handsaw, chisel or chisel — used for the installation of wooden pillars, joists and sheathing of the roof overhang. Measuring tools: tape measure, spirit level or construction level, plumb Bob, carpenter's square is required in any case for proper Assembly and installation of the canopy. Power tools: drill, turbochieftain machine, drill and bits, a jigsaw. And if you install a concrete or metal support posts of the canopy for cars will need a welder.

The expenditure of mounting materials include nails, screws, bolts, metal corners, etc. Their number and sizes are determined depending on the materials and construction shed

The materials and their costCalculation materials in accordance with the drawing of the carport. Taking conditional the length of the machine is 4 meter canopy is planned 5x2,5 m. If the car exceed the usual dimensions, jeep or minivan, the canopy is constructed are slightly larger, about 6,5x3,5 m. when Designing the shed, pushes away from the dimensions of the roofing sheets. The height of the canopy should allow you to freely open the trunk. It is about 2.5 meters.

The number of pillars depending on the material, the area of the canopy and the weight of the roof varies from 4 to 10 PC In case, if one of the parties adjacent to the building, stands less need. Materials for support posts and frame of the canopy made of metal:

- the round tube with a diameter of not less than 1 inch or similar shaped (square or rectangular);

- metal corner with a shelf not less than 50 mm or the channel, t or I-beam with a metal thickness of 3 mm.

Frame of timber will be cheaper. For support posts timber of softwood 100x100 is worth about 60 rubles per meter. The timber for the frame 50x50 is about 17 rubles Pogue. M. price also depends On grade of wood, humidity and type of wood.

To cover the canopy will fit any materials used for roofing:

1. Corrugated sheets with polymeric coating with a thickness of 0.4 mm is from 155 to 175 RUB/m2, similar to galvanized in the range of 130-150 rubles/m2. Galvanized steel sheet size 1000х2000х0,4 mm is approximately 2660 roubles apiece. Skate galvanized size mm 2000х100 will cost 95-100 rubles apiece, and polymer coated — 120 RUB./PCs. For the arrangement of the roof from metal will require additional and gutter elements.

2. Slate gray type SV-40 has 7 or 8 waves at a thickness of 5.8 mm and standard sizes 1750х1130 mm, is 220-230 rubles per sheet. Weigh a sheet of slate from 19 to 25 kg depending on the thickness and density of the material. Several expensive cost of colour slate — to 300 rubles a sheet. The disadvantages of slate can be attributed to the fragility of the material and weight.

3. Metal thickness 0.4 mm costs from 180 USD/m2. Metal working width 1100 mm, 1180 mm. It is reliable and lightweight material for the roof canopy. It is easy to transport and install.

4. Plastic roofing is suitable for canopies and awnings. Usually made from polycarbonate or polyvinyl chloride. The standard sheet size mm 2000х900 or is issued in rolls 10-20 metres with a width from 1.5 to 3 m. the average price of the sheet in the region of 300 rubles.

The installation of the support struts of the canopyFor support posts of the canopy for marking drill or dig wells with a depth of 0.7 meters. The bottom is filled with gravel and compacted. The end of the concreted support post treated with an antiseptic and bitumen mastic. The exposed vertical support columns are filled with concrete. The principle of installation of the supports is the same for wooden and metal racks.

After drying of the concrete strut is mounted on the truss design for roofs. Wooden support pillar on the perimeter of the tie Board 50х150 mm, formed on the upper crown canopy set rafter skeleton. Suits timber 50x100 mm with a mounting pitch of about a meter. Accurate step size of the rafters dictates the width of the roofing material. Rafter beams shall be placed in areas of overlap of the roofing sheets.

For metal struts of the truss system welded on the ground. Out of the corner of 50x50 mm in size uprights welded rectangular frame. For the corner of the gable roof of the canopy from the same area welded to the rafters. For arched roof used strip of metal. In the rafter system nastelivaetsya attachment holes of the roof. Typically, the hole pitch of any roof is about 10-15 cm Truss system is installed on the support pillar and is attached by welding.

The flooring of the roof of the carportTo the rafters perpendicular to them sewn crate. This is used as edged and unedged mm. 20х100 the First line of crates stuffed on the edge of a slope, the top line in place of fastening of the skate. The distance between the lines is 50-70 cm Line must be located at fixing points and overlap of the roof.

Roofing sheets begin to stack from the lower corner to the ridge with an overlap of 10-15 cm the Slate is attached using special galvanized nails with large nail heads. Nailed it light rhythmic strokes with a hammer on roofing nail, set on the highest point of the wave.

Plastic slate, corrugated sheet, metal roofing used galvanized screws with special plastic pads or prescribe. Usually one roofing sheet requires 10-12 screws. Often roofing sheets comes with a set of fasteners of the corresponding color.

On the frame of the canopy made of metal roofing sheets are fixed with screws with metal and sealing washers, or screws on the metal, under which are installed the gasket.

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.rmnt.ru/story/outbuilding/1114736.htm

Psychological time: You live in the past or the future?

Jorge Bucay: the Main thing is to give yourself the freedom to be who you are