1260

3D Printed Homes and Modern Green Building Trends at FabCity

3D-printed houses made of waterproof cardboard are one of the most interesting ideas on display at a special exhibition in Amsterdam.

At the FabCity campus on the island of Java in the Dutch capital, visitors can explore new technologies designed to create a green future. In total, there are 50 installations and prototypes developed by students and professional designers.

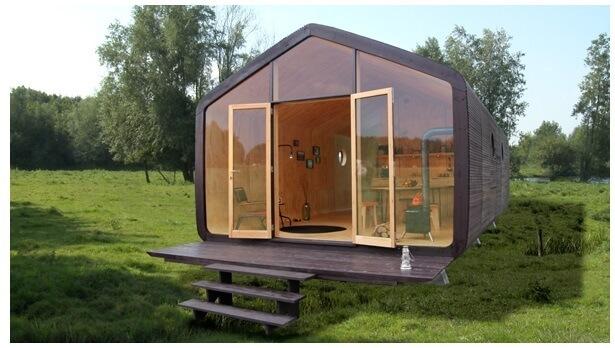

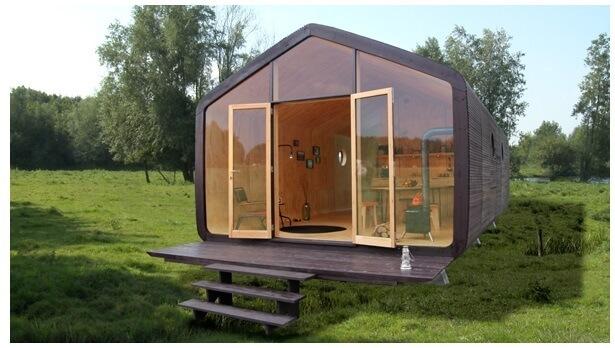

For example, this tiny mobile house called Woonpioners is built with environmentally friendly materials. House half-timbered (framework) under a steel roof and on wheels.

The 18-meter interior includes a small living room, kitchen, toilet and shower room, it also has a double bed, which can only be reached by “overcoming” a coffee table.

The cost of a prototype mini-house on wheels is 35 thousand euros.

“People are very surprised that such a small house is so spacious. In addition, we used a lot of glass, so it looks amazingly open and harmoniously interacts with the environment, says project manager Gelte Glas.

A module called Wikkelhouse is a concept home built entirely of cardboard. Its plaster-covered "walls" are made of 24 layers of compressed cardboard, each glued to the previous one.

The structure is covered with wooden frames to protect against external influences, in particular, ultraviolet radiation.

“I could already live in this little house, but now I want to finish the kitchen and the toilet. So we made it, and we put it behind everything that was already there. Then the kitchen was made, and again - placed it on the back. Next, the same with the bedroom. That’s how our house appeared in a week, says architect Oep Schilling, founder of the manufacturer Fiction Factory.

Building material for a 3D printed paper house

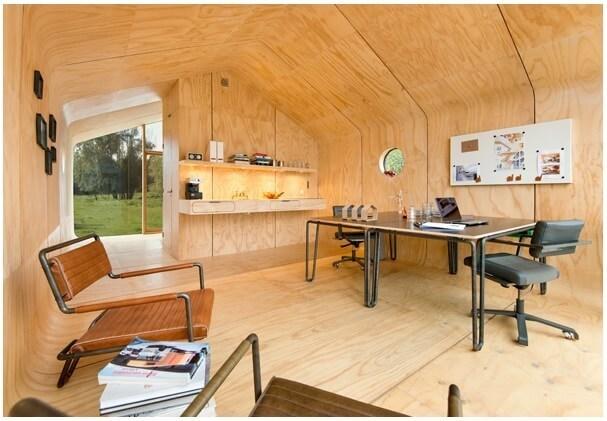

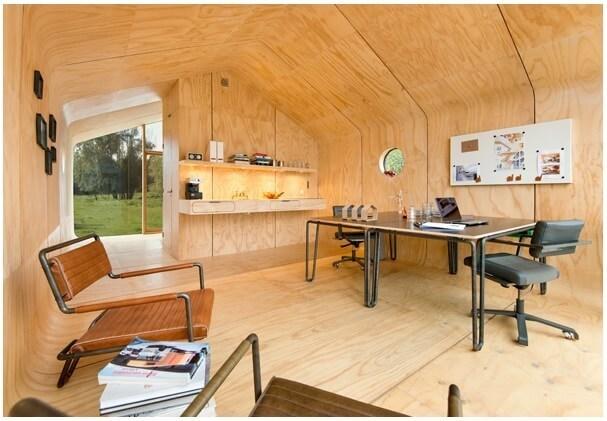

This is what Wikkelhouse looks like from the inside out.

The cost of one module is three and a half thousand euros. However, the concrete foundation and additional, manufactured in advance, structural elements increase the cost of the eco-house to 70 thousand euros. According to the developers, the construction of the cardboard house does not exceed ten days.

These elements are manufactured on a three-dimensional printer MX3D. The printer is equipped with an industrial robot manipulator, and its “advanced” welding machine is controlled by software. Because of this, it is able to print a wide range of complex multistructured items. This, according to the manufacturer, its advantage over a conventional 3D printer.

The company plans to 3D-print a pedestrian bridge for Amsterdam by the end of the year.

“Regular three-dimensional printers have to work on a building scale like this, and we’ve been able to go a little further. Therefore, the construction of the bridge is a really powerful step forward compared to the capabilities of current technology. This is a real innovation, explains MX3D founder Gis van der Velden.

The exhibition of houses built using three-dimensional printing, FabCity is available for public viewing from April 18 to June 26.

At the FabCity campus on the island of Java in the Dutch capital, visitors can explore new technologies designed to create a green future. In total, there are 50 installations and prototypes developed by students and professional designers.

For example, this tiny mobile house called Woonpioners is built with environmentally friendly materials. House half-timbered (framework) under a steel roof and on wheels.

The 18-meter interior includes a small living room, kitchen, toilet and shower room, it also has a double bed, which can only be reached by “overcoming” a coffee table.

The cost of a prototype mini-house on wheels is 35 thousand euros.

“People are very surprised that such a small house is so spacious. In addition, we used a lot of glass, so it looks amazingly open and harmoniously interacts with the environment, says project manager Gelte Glas.

A module called Wikkelhouse is a concept home built entirely of cardboard. Its plaster-covered "walls" are made of 24 layers of compressed cardboard, each glued to the previous one.

The structure is covered with wooden frames to protect against external influences, in particular, ultraviolet radiation.

“I could already live in this little house, but now I want to finish the kitchen and the toilet. So we made it, and we put it behind everything that was already there. Then the kitchen was made, and again - placed it on the back. Next, the same with the bedroom. That’s how our house appeared in a week, says architect Oep Schilling, founder of the manufacturer Fiction Factory.

Building material for a 3D printed paper house

This is what Wikkelhouse looks like from the inside out.

The cost of one module is three and a half thousand euros. However, the concrete foundation and additional, manufactured in advance, structural elements increase the cost of the eco-house to 70 thousand euros. According to the developers, the construction of the cardboard house does not exceed ten days.

These elements are manufactured on a three-dimensional printer MX3D. The printer is equipped with an industrial robot manipulator, and its “advanced” welding machine is controlled by software. Because of this, it is able to print a wide range of complex multistructured items. This, according to the manufacturer, its advantage over a conventional 3D printer.

The company plans to 3D-print a pedestrian bridge for Amsterdam by the end of the year.

“Regular three-dimensional printers have to work on a building scale like this, and we’ve been able to go a little further. Therefore, the construction of the bridge is a really powerful step forward compared to the capabilities of current technology. This is a real innovation, explains MX3D founder Gis van der Velden.

The exhibition of houses built using three-dimensional printing, FabCity is available for public viewing from April 18 to June 26.

There is nothing right or wrong. Everything depends on your point of view

The infinitely small is infinitely large