1117

Your windmill pipe stagger, or a new way to extract energy from the wind

The inventors on the verification models in the field i>

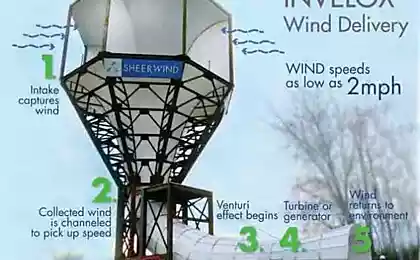

Spanish startup Vortex Bladeless offers устройство to a fundamentally new method of collecting wind energy, in which no rubbing against each other or parts of the rotating blades. The device gets its energy from the turbulence generated by the wind around a vertical cylinder, fortified on the mast.

Standard wind turbines have a huge size, their screws are not only expensive to make and difficult to deliver and assemble - they still are a source of noise and danger to birds. And if about the danger to birds animal advocates still are at odds with the manufacturers of wind turbines, the doubts about the presence of noise, no one, it seems, does not occur - once every two years, even carried out Conference on reduction of noise from wind turbines .

Furthermore, the moving parts of the engine windmill require periodic maintenance. A moving part of the generator from the VB interact using magnets and therefore do not require lubrication. As a result, the assurances of the founders of the company, the manufacturing cost of the windmill is half the usual cost, and maintenance costs - five times less.

Vortex Bladeless works to the known effect of vortex formation in which the air flows around a solid body, forms a periodic twist. With this effect for a long time, engineers are fighting - brutal lesson about the destructive vortex was obtained for example Такомского Bridge , which was destroyed by the wind just four months after opening. And said start-up using it to extract useful energy.

Hollow and sufficiently flexible fiberglass cylinder fortified through the generator on a fixed mast. Its geometry is designed in such a way as to maximize the effect of turbulence. Wind rocks the cylinder, whereby the generator produces electricity. The computer adjusts the work force transmitting electromagnets under varying wind force to obtain the maximum energy in any of its speed.

Startup four years of its existence has passed the way from an idea to a working prototype. Engineers tested prototypes of its devices in the wind tunnel, and now the work is checked by scale models in the field. Not more than a year, they are planning to submit the finished version for commercial use.

The first version will have a size of 12.5 meters and weigh about 100 kg and produce about 4 kW of energy. Also plans to create a miniature version of the device, 3 meters tall and weighing 10 kg, which should give 100 watts. According to calculations, the inventors, in spite of the fact that their device collects 30% less energy than traditional windmill VB extremely low cost makes the collected energy to 40% cheaper than conventional. Furthermore, the device takes up much less space and can be installed on the roofs and in other places, where the area is in short supply.

The project has collected about one million euros from the various European funds. Also recently сообщалось about moving companies in Boston, USA. In addition, it has received funding in the amount of nearly 300 million euros from the Spanish oil company Repsol (contrary to popular belief that the oil is sent inventors of new ways of getting energy to feed the fish). Oil companies are sponsoring inventors, because they will not only receive an additional benefit in the case of the successful market launch of new devices, but also to improve the social contribution to society.

Source: geektimes.ru/post/250262/

Translator in Skype became available to everyone with the latest versions of Windows

The Federal Trade Commission has supported Tesla in question direct sales to buyers of electric cars