983

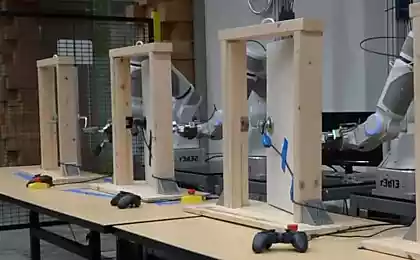

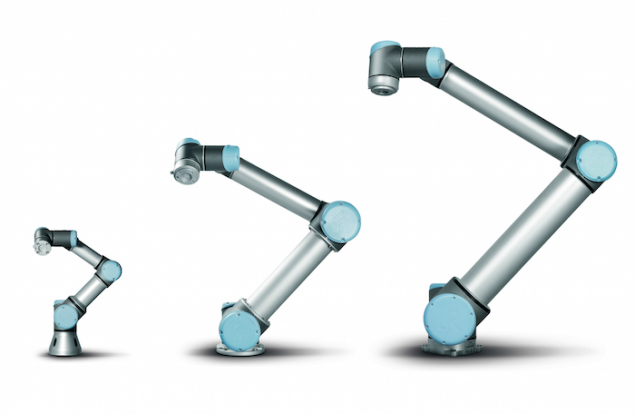

Compact and agile robotic arm helps to make copies of itself

The Danish company Universal Robots представила his new robot UR3 . This youngest possible to load a model in a number of other models, UR5 and UR10. The product is a robotic arm blue-gray color for industrial use. And this roboruki quite unusual characteristics.

Manipulator lightweight (11 kg maximum load - 3 kg), compact and inexpensive ($ 23,000). Each of the three joints - a servo motor that can rotate 360 degrees. Developers particular focus on facilitating the task of programming the robot. For example, in the "learning" a person can arbitrarily moving parts of a robotic arm, literally leading the robot "the handle" - after which the robot exactly repeat these movements. To work with the robot attached to it tablet device and software of its own design. Robot controls the system based on Linux, as an interface for programming the robot is made to Java.

Programming a robot can learn in just a few minutes instead of several days or even weeks, you need to configure other complex industrial robots. 10 minutes journalist who first demonstrated the robot was able to make a simple program to transfer a plastic cup on the table in an urn.

Another feature of UR robots is the high security and the ability to work in the same room with people. The sensors of the robot pick up resistance in a collision with an obstacle and immediately stop the movement. Similar sensors help robot at work to follow the shape of the part - for example, when applied to her sealant. In this case, it is not necessary to program the movement for several different parts - it will just follow the contours of each of them.

The manipulator is able to move at a speed of 2.5 m / s and at the same time to be precise movements to a few hundredths of a millimeter. In-house Universal Robots have been using their robots, which thus help to create new copies of themselves.

Source: geektimes.ru/post/247460/

Travis Dzhenk - Bitcoin or the evolution of money

Electron microscope to distinguish between individual atoms, appeared in the British National Laboratory SuperSTEM