821

How to ride the DSG, the variator and machine

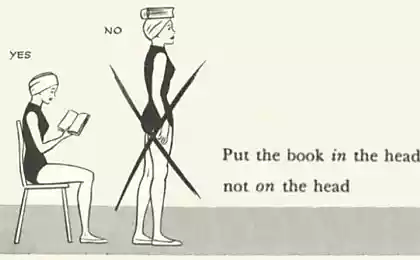

The desire of drivers to comfort led to the fact that other things being equal the client will always prefer a car with two pedals analogue that has the "mechanics". However, only a small portion of buyers is how to exploit a particular box. With the "mechanics" everything is quite simple - it's the cheapest and most reliable way of transmission is sufficient. Yes, during the operation, it requires regular inspection and replacement of consumables (disc basket, clutch release), and in particularly severe cases even repairs. However, with proper treatment, no problem runs half a million kilometers. Such vitality for "alternative" CP is practically inaccessible, however, proper operation and in these cases, can achieve quite comparable indicators.

Single-disk robotized gearbox

Such manual in the mass segment almost outlived its. In fact, this type of boxes on their models persists put only PSA, remaining for the most part, or return to the classic "machine" or preferred variator or developed double disc assemblies. The reason is simple - the transmission, which, as a budget alternative to the "automatic", proved to be quite economical, but not too comfortable, because you need to drive it just as well as the usual "mechanics».

The fact that, technically, is a robotic box INC, which includes the design of servo control or hydraulic clutch operation and gear changes. The main advantage of such transmissions to the classic "handles" - high efficiency, which is achieved by a quick shift, however, smooth acceleration in this case can only be achieved one way - switched manually by gas discharge. For the automatic mode it is often mistaken with a choice of transmission, very long "thinks" in the transition to a low and switches with noticeable jerks.

With regard to rules of use, they, as in the first case, elementary. Regularly check the box for "snotty". Do not forget to put the car on the handbrake in the parking lot. And before towing - to carefully study the relevant section of the operating instructions. All the rest will be built "foolproof».

By the way, repair and maintenance of single-disc "robot" costs in the amount comparable to the repair and maintenance of the ITUC, based on which it is made. And with proper treatment resource box almost as donor resources.

Dual-robotic gearbox

Alas, not all "robots" are equally good. Double disc boxes are usually in operation is far less reliable than single-disk, despite the fact that they are more comfortable and manufacturable. By the way, that last circumstance is the main problem. VW, who decided on the first large-scale implementation of its DSG, originally named the box "robotic AKP", making it clear that the rules and the features of its operation is no different from the operation of the classic "machine».

In the same way he entered, and Ford, when released transmission Powershift. Now manufacturers are trying to blame enough experienced sellers, but those same Americans, when their customers asked the company to clarify how, actually, properly operated dual-box, the answer is simple: as a conventional automatic gearbox. It is noteworthy that in the operating instructions for "folksvagenovskim" truth machines still written: DSG - robotized gearbox.

In general, and DSG, and to PowerShift "automatic" are irrelevant. This is the same mechanical (or, if you single-disk "robots") KP, but with a lot of gear, two wheels and a more complex execution unit. In addition, they are based is not ready to "handle" - all modern boxes of this type are being developed from the ground up.

So, what you need to know and remember in this case?

First. Regardless of the "dry" manual is on the machine, or "wet» (DSG-7, for example, refers to the first, DSG-6 and 7-speed S tronic in the Audi - to the latter), both have wheels and clutch it - consumable. Whatever the manufacturer, every detail is constantly rubbing wear, though the speed of the process depends on many factors, including driving style of the owner. Torn driving and red light race its life, of course, is not extended.

Second. Mechatronic module, the control box - unit is quite delicate, require regular inspection and fearing overheating. By the way, bring to the latter is not so difficult. Patients place some DSG, in particular, are plastic tubes, lead-coolant to the heat exchanger. They crack and break off from the vibration. But even if technically box completely intact, the module to overheat enough to stand in a traffic jam or on the "long" traffic lights, keeping the car brake. With the "automatic" or CVT in this case nothing happens, but the same VAG instructions to their cars says that if the car will be more than a minute, the selector switch must be in "neutral" to just the same to avoid overheating mechatronics. In particular, the "dry» DSG regular "fly" just for this reason.

The problem is that these formal KP in Russia are considered non-performing, and beyond repair. Coupling and mechatronic module change under warranty, the rest - in its entirety. While the warranty valid, but it is worth it to end, the entire burden will fall on the shoulders of the owner. Whereas the amount here is comparable to the price tag on the purchase of an entirely new modern "machine", although the service life at risk and that will remain the same. For this reason, liquidity machines with dual "robot" in the secondary market is very low.

CVT

Or CVT CVT - the youngest box. And if the principles of the ITUC, "robots" and "machine" has long been perfected, in this case, there is still work to do. However, it is the most simple in structure type transmission, wherein at the same high efficiency. Essentially, CVT - a more progressive version of the belt drive, invented by Leonardo da Vinci. Just in this case, the torque transmitted from the engine to the drive wheels by a system of pulleys with different diameters. The simplest visual example - the transmission device or a mountain bike race.

In fact, the most important point about the operation of the variator - preheating. In addition, the owner should forget about the race, as this type of transmission is not intended for this in principle. The fact that the weakest point of the CVT - belt. Today, many manufacturers began to use the chain, but in any case it can not be eternal, especially that the sudden start of the drive slips and new boxes.

Automatic gearbox

In fact, the "automatic" - the most reliable "dvuhpedalnaya" box, the reputation of which at one time seriously impaired a garage unskilled craftsmen, "signed" node when that was not necessary, and the "riders", which did not suit the "dynamics and speed Switching ».

I must say that the old four-speed is really "tupili", so that when the dynamics at stake, and under the hood mounted four-aspirated engine with a small cylinder capacity, such manual - not the best choice. But do not forget that this type of transmission was originally designed as a comfortable alternative to the "handle", which later evolved to its present state. Besides, a truly modern AKP did not concede another box in any speed switching of any economy.

Relative reliable "machine" in the first place due to lack of rigid mechanical connection between the engine and the drive wheels. Of course, this does not mean that there are no such manual rubbing parts, but here the main role played by the working fluid, better known as the ATF, and provides lubrication of parts and assemblies, and cooling, and switching, and communications. So, if you do not flow out of nowhere and you try to follow a few simple enough, in general, the rules of correct operation, the service life of "machine" can be stretched up to 350-400 thousand kilometers.

Rule one. All shift lever between the main modes ("parking", "neutral", "drive") should be standing in the car when the brake pedal is fully depressed.

Second Rule. When you switch to "drive" or "reverse", the movement must begin after the transfer of full inclusion. For this box requires about 1-2 seconds. Inclusion will be accompanied by a characteristic stimulus.

Rule three. "Neutral" - mode intended only for towing. Switching to it, for example at traffic lights, useless and even harmful, since "neutral" box once again reset so that the transition to the "drive" it needs the same 1-2 seconds to activate. The same applies to the overrun. Thus saving fuel still will not work, and the "machine" will wear out faster.

Rule Four. The car with automatic transmission can not be towed. If it is compulsory, the process should take place at a very low speed and make sure the engine is running, because without it the oil pump does not work in the box. Main adhere to the principle "50/50" - not faster than 50 km / h, and no more than 50 kilometers. Ideal - evacuation with full loading.

Rule Five. Do not slip! If this happens, the machine can even shake, but this in the "top dead center" should always use the brake, completely blocking the wheels. Otherwise, there is a high risk to bury the "machine».

The sixth rule. Use the handbrake. When parking the car, before releasing the brake pedal, tighten a manual brake. Will not be superfluous. On the output shaft of the parking box is mechanically locked parking tooth - a pre-tightened handbrake to avoid breakage.

That's all. The rest - the details, which are easier to grasp empirically. To break something, for example, switching gears manually, or often using sports mode, it is difficult - in today's AKP, as a rule, is "foolproof." That does not prevent regular inspection - leaking oil seal - a cheap, in general detail, killing "machine" much faster than the lack of experience.

The original article and the source

Single-disk robotized gearbox

Such manual in the mass segment almost outlived its. In fact, this type of boxes on their models persists put only PSA, remaining for the most part, or return to the classic "machine" or preferred variator or developed double disc assemblies. The reason is simple - the transmission, which, as a budget alternative to the "automatic", proved to be quite economical, but not too comfortable, because you need to drive it just as well as the usual "mechanics».

The fact that, technically, is a robotic box INC, which includes the design of servo control or hydraulic clutch operation and gear changes. The main advantage of such transmissions to the classic "handles" - high efficiency, which is achieved by a quick shift, however, smooth acceleration in this case can only be achieved one way - switched manually by gas discharge. For the automatic mode it is often mistaken with a choice of transmission, very long "thinks" in the transition to a low and switches with noticeable jerks.

With regard to rules of use, they, as in the first case, elementary. Regularly check the box for "snotty". Do not forget to put the car on the handbrake in the parking lot. And before towing - to carefully study the relevant section of the operating instructions. All the rest will be built "foolproof».

By the way, repair and maintenance of single-disc "robot" costs in the amount comparable to the repair and maintenance of the ITUC, based on which it is made. And with proper treatment resource box almost as donor resources.

Dual-robotic gearbox

Alas, not all "robots" are equally good. Double disc boxes are usually in operation is far less reliable than single-disk, despite the fact that they are more comfortable and manufacturable. By the way, that last circumstance is the main problem. VW, who decided on the first large-scale implementation of its DSG, originally named the box "robotic AKP", making it clear that the rules and the features of its operation is no different from the operation of the classic "machine».

In the same way he entered, and Ford, when released transmission Powershift. Now manufacturers are trying to blame enough experienced sellers, but those same Americans, when their customers asked the company to clarify how, actually, properly operated dual-box, the answer is simple: as a conventional automatic gearbox. It is noteworthy that in the operating instructions for "folksvagenovskim" truth machines still written: DSG - robotized gearbox.

In general, and DSG, and to PowerShift "automatic" are irrelevant. This is the same mechanical (or, if you single-disk "robots") KP, but with a lot of gear, two wheels and a more complex execution unit. In addition, they are based is not ready to "handle" - all modern boxes of this type are being developed from the ground up.

So, what you need to know and remember in this case?

First. Regardless of the "dry" manual is on the machine, or "wet» (DSG-7, for example, refers to the first, DSG-6 and 7-speed S tronic in the Audi - to the latter), both have wheels and clutch it - consumable. Whatever the manufacturer, every detail is constantly rubbing wear, though the speed of the process depends on many factors, including driving style of the owner. Torn driving and red light race its life, of course, is not extended.

Second. Mechatronic module, the control box - unit is quite delicate, require regular inspection and fearing overheating. By the way, bring to the latter is not so difficult. Patients place some DSG, in particular, are plastic tubes, lead-coolant to the heat exchanger. They crack and break off from the vibration. But even if technically box completely intact, the module to overheat enough to stand in a traffic jam or on the "long" traffic lights, keeping the car brake. With the "automatic" or CVT in this case nothing happens, but the same VAG instructions to their cars says that if the car will be more than a minute, the selector switch must be in "neutral" to just the same to avoid overheating mechatronics. In particular, the "dry» DSG regular "fly" just for this reason.

The problem is that these formal KP in Russia are considered non-performing, and beyond repair. Coupling and mechatronic module change under warranty, the rest - in its entirety. While the warranty valid, but it is worth it to end, the entire burden will fall on the shoulders of the owner. Whereas the amount here is comparable to the price tag on the purchase of an entirely new modern "machine", although the service life at risk and that will remain the same. For this reason, liquidity machines with dual "robot" in the secondary market is very low.

CVT

Or CVT CVT - the youngest box. And if the principles of the ITUC, "robots" and "machine" has long been perfected, in this case, there is still work to do. However, it is the most simple in structure type transmission, wherein at the same high efficiency. Essentially, CVT - a more progressive version of the belt drive, invented by Leonardo da Vinci. Just in this case, the torque transmitted from the engine to the drive wheels by a system of pulleys with different diameters. The simplest visual example - the transmission device or a mountain bike race.

In fact, the most important point about the operation of the variator - preheating. In addition, the owner should forget about the race, as this type of transmission is not intended for this in principle. The fact that the weakest point of the CVT - belt. Today, many manufacturers began to use the chain, but in any case it can not be eternal, especially that the sudden start of the drive slips and new boxes.

Automatic gearbox

In fact, the "automatic" - the most reliable "dvuhpedalnaya" box, the reputation of which at one time seriously impaired a garage unskilled craftsmen, "signed" node when that was not necessary, and the "riders", which did not suit the "dynamics and speed Switching ».

I must say that the old four-speed is really "tupili", so that when the dynamics at stake, and under the hood mounted four-aspirated engine with a small cylinder capacity, such manual - not the best choice. But do not forget that this type of transmission was originally designed as a comfortable alternative to the "handle", which later evolved to its present state. Besides, a truly modern AKP did not concede another box in any speed switching of any economy.

Relative reliable "machine" in the first place due to lack of rigid mechanical connection between the engine and the drive wheels. Of course, this does not mean that there are no such manual rubbing parts, but here the main role played by the working fluid, better known as the ATF, and provides lubrication of parts and assemblies, and cooling, and switching, and communications. So, if you do not flow out of nowhere and you try to follow a few simple enough, in general, the rules of correct operation, the service life of "machine" can be stretched up to 350-400 thousand kilometers.

Rule one. All shift lever between the main modes ("parking", "neutral", "drive") should be standing in the car when the brake pedal is fully depressed.

Second Rule. When you switch to "drive" or "reverse", the movement must begin after the transfer of full inclusion. For this box requires about 1-2 seconds. Inclusion will be accompanied by a characteristic stimulus.

Rule three. "Neutral" - mode intended only for towing. Switching to it, for example at traffic lights, useless and even harmful, since "neutral" box once again reset so that the transition to the "drive" it needs the same 1-2 seconds to activate. The same applies to the overrun. Thus saving fuel still will not work, and the "machine" will wear out faster.

Rule Four. The car with automatic transmission can not be towed. If it is compulsory, the process should take place at a very low speed and make sure the engine is running, because without it the oil pump does not work in the box. Main adhere to the principle "50/50" - not faster than 50 km / h, and no more than 50 kilometers. Ideal - evacuation with full loading.

Rule Five. Do not slip! If this happens, the machine can even shake, but this in the "top dead center" should always use the brake, completely blocking the wheels. Otherwise, there is a high risk to bury the "machine».

The sixth rule. Use the handbrake. When parking the car, before releasing the brake pedal, tighten a manual brake. Will not be superfluous. On the output shaft of the parking box is mechanically locked parking tooth - a pre-tightened handbrake to avoid breakage.

That's all. The rest - the details, which are easier to grasp empirically. To break something, for example, switching gears manually, or often using sports mode, it is difficult - in today's AKP, as a rule, is "foolproof." That does not prevent regular inspection - leaking oil seal - a cheap, in general detail, killing "machine" much faster than the lack of experience.

The original article and the source