2773

Oak table with their hands

Will post a bit like the style how to draw an owl, but I fotkal only when he thought about it.

So went

On the street "is not summer" weather - rain charged. I will begin work on the spot where there will be a table, good tool allows not much litter.

So we need:

Planer, Saw, sander belt and eccentric, screwdrivers, angle, usually a pencil, a lot of different sanding paper from 60 to 320. At vskidku like everything.

And a lot of light :)

Begin to lead the board in order. What krasotischa then under the clothes ... a pleasure to look expensive.

"Helicopters", "bridges" and slabs tortured. Hard for it all align.

Then select less travel boards countertops and the remaining forest on the connection and support.

A little distracted from the topic ...

Since oak planing is a sin not to use sawdust for aging wine until no drums.

Used about 1-2 grams per liter. Pre-brew 3-4 times in hot water and dry in a skillet until the smell of vanilla.

If you do not do something with tannic wine broth will not be able to drink. And wine maturation occurs rather quickly.

In wine sawdust added 3 weeks before the new year, as well as bentonite clay 1 g per liter of pre-diluted it in a small amount of wine.

Bentonite clay (aka white) was added to remove all of the wines from the yeast slurry.

And send wine cellar to defend.

The weather improved, and crawl out into the street. Board on the rasp and now beginning to cut into blanks.

Creative mess

Begin collecting blank, be sure to check the squareness in three planes.

Saw off the vertical support exactly perpendicular as it was not so easy. had to saw off with a stock and then belt sander to bring to a right angle.

Support for semi-assembled table

On support fasten boards, which were intended for countertops.

We boards remained small curvature and they need to be aligned together. Started with a belt sander.

Grain 60 as it simulates it is possible to remove the layer of wood thicker align all the boards as needed.

Then go through the tape 120. The direction of motion machine ususchestvlyaem along the grain.

We proceed to the eccentric grinding machine. Started with a grain of 120, 240, 320.

The tree then becomes very smooth well. By taktilnomu feeling fingers and can not say that this tree.

The most important thing is sanding before painting. The better part is ground the better the product will look like.

So the case is suitable for painting. We have to completely disassemble the table.

The room in which the board began to tighten film plane.

Mount the forced extraction. On the floor of the stele out of thick cardboard packaging machinery, all fastened with tape, trying to fix the maximum quality.

Prepare your desktop with the ingredients for painting.

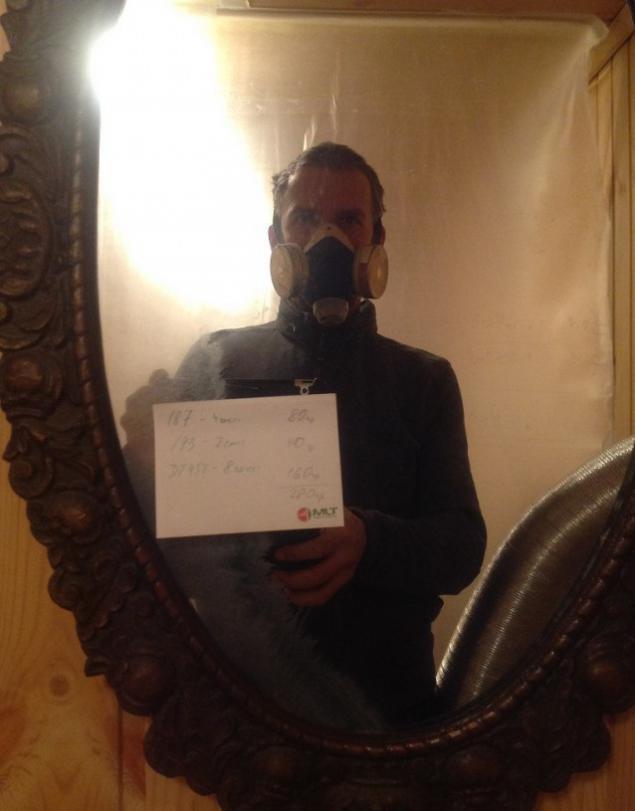

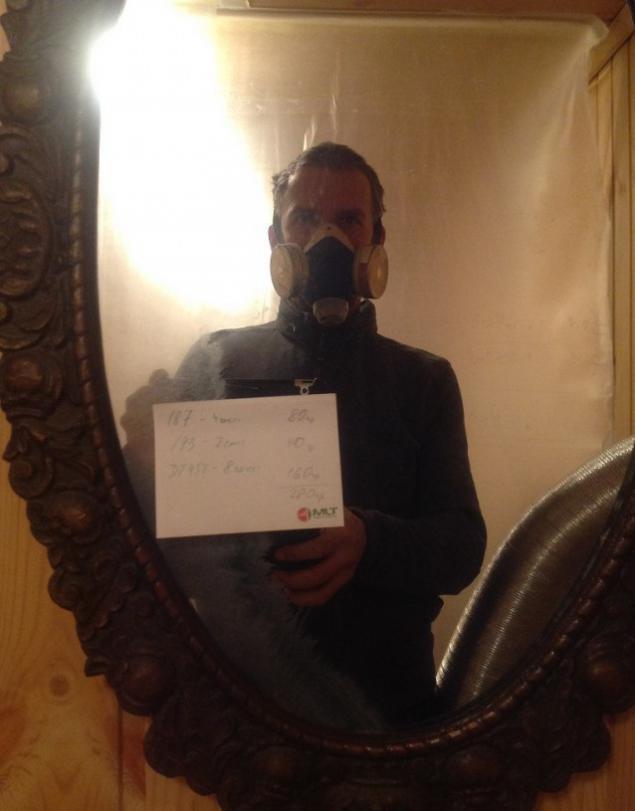

Do not forget about personal safety measures. Use a gas mask. After painting the table, he was almost completely clogged.

The mirror is attached to the recipe stain color mixing.

And in the mirror looking at me stalker :)

I paint the second time in my life this lacquer furniture, I like the result. Without special skills get very decent things.

So that we use for painting:

Stain sayerlack XM 8000/87 - 4 parts

Stain sayerlack XM 8000/93 - Part 2

The solvent DT452 - 8 parts.

Measure out on electronic scales and a gun. Used for painting the cheapest gun matrix for 650 rubles.

He justified his price by 100%. The only thing that he had torn gum quickly. I had to make my.

stain dries fairly quickly because after half an hour already, you can cover the ground.

Toyzhe firm polyurethane primer TU-20

Mix it according to the instructions with of.sayta. Applied very well, and we can pre-evaluate the color of the finished product.

2 coats of soil with a break of 20 minutes.

And then a few hours of drying

When the ground is dry, I walked around him 400 sandpaper, made it matte. At the same time removed all the drips that were.

To make the patina of antiquity, I used HR1950 / 94 on the edges of workpieces.

Next began to prepare a varnish. Polyurethane varnish TZ6235. Gloss 35% believe that the matte finish. Scratch-resistant.

For most that table. Knead 3 components and airbrush.

The only thing that I did not have any goats and adapted for painting. Used an old bench and stool. And in order to minimize skip paint and sprayed with paint I started nelitsevoy hand, and in the end took place on the front side.

If it was sprayed in the joints and was on the back side under the bracket.

After prokraski and primers I sent my billet to dry the steam room which protopit degrees to 40.

This greatly accelerated the drying process.

The next day, could not resist and started to collect table. We must be very careful, because the varnish dries a few days and can be easily damaged.

But in general, then this Hand made :)

Happy New Year! Rejoice yourself and your loved ones!

PS And wine I'll tell you the cancellation is very tasty!

© antaid

So went

On the street "is not summer" weather - rain charged. I will begin work on the spot where there will be a table, good tool allows not much litter.

So we need:

Planer, Saw, sander belt and eccentric, screwdrivers, angle, usually a pencil, a lot of different sanding paper from 60 to 320. At vskidku like everything.

And a lot of light :)

Begin to lead the board in order. What krasotischa then under the clothes ... a pleasure to look expensive.

"Helicopters", "bridges" and slabs tortured. Hard for it all align.

Then select less travel boards countertops and the remaining forest on the connection and support.

A little distracted from the topic ...

Since oak planing is a sin not to use sawdust for aging wine until no drums.

Used about 1-2 grams per liter. Pre-brew 3-4 times in hot water and dry in a skillet until the smell of vanilla.

If you do not do something with tannic wine broth will not be able to drink. And wine maturation occurs rather quickly.

In wine sawdust added 3 weeks before the new year, as well as bentonite clay 1 g per liter of pre-diluted it in a small amount of wine.

Bentonite clay (aka white) was added to remove all of the wines from the yeast slurry.

And send wine cellar to defend.

The weather improved, and crawl out into the street. Board on the rasp and now beginning to cut into blanks.

Creative mess

Begin collecting blank, be sure to check the squareness in three planes.

Saw off the vertical support exactly perpendicular as it was not so easy. had to saw off with a stock and then belt sander to bring to a right angle.

Support for semi-assembled table

On support fasten boards, which were intended for countertops.

We boards remained small curvature and they need to be aligned together. Started with a belt sander.

Grain 60 as it simulates it is possible to remove the layer of wood thicker align all the boards as needed.

Then go through the tape 120. The direction of motion machine ususchestvlyaem along the grain.

We proceed to the eccentric grinding machine. Started with a grain of 120, 240, 320.

The tree then becomes very smooth well. By taktilnomu feeling fingers and can not say that this tree.

The most important thing is sanding before painting. The better part is ground the better the product will look like.

So the case is suitable for painting. We have to completely disassemble the table.

The room in which the board began to tighten film plane.

Mount the forced extraction. On the floor of the stele out of thick cardboard packaging machinery, all fastened with tape, trying to fix the maximum quality.

Prepare your desktop with the ingredients for painting.

Do not forget about personal safety measures. Use a gas mask. After painting the table, he was almost completely clogged.

The mirror is attached to the recipe stain color mixing.

And in the mirror looking at me stalker :)

I paint the second time in my life this lacquer furniture, I like the result. Without special skills get very decent things.

So that we use for painting:

Stain sayerlack XM 8000/87 - 4 parts

Stain sayerlack XM 8000/93 - Part 2

The solvent DT452 - 8 parts.

Measure out on electronic scales and a gun. Used for painting the cheapest gun matrix for 650 rubles.

He justified his price by 100%. The only thing that he had torn gum quickly. I had to make my.

stain dries fairly quickly because after half an hour already, you can cover the ground.

Toyzhe firm polyurethane primer TU-20

Mix it according to the instructions with of.sayta. Applied very well, and we can pre-evaluate the color of the finished product.

2 coats of soil with a break of 20 minutes.

And then a few hours of drying

When the ground is dry, I walked around him 400 sandpaper, made it matte. At the same time removed all the drips that were.

To make the patina of antiquity, I used HR1950 / 94 on the edges of workpieces.

Next began to prepare a varnish. Polyurethane varnish TZ6235. Gloss 35% believe that the matte finish. Scratch-resistant.

For most that table. Knead 3 components and airbrush.

The only thing that I did not have any goats and adapted for painting. Used an old bench and stool. And in order to minimize skip paint and sprayed with paint I started nelitsevoy hand, and in the end took place on the front side.

If it was sprayed in the joints and was on the back side under the bracket.

After prokraski and primers I sent my billet to dry the steam room which protopit degrees to 40.

This greatly accelerated the drying process.

The next day, could not resist and started to collect table. We must be very careful, because the varnish dries a few days and can be easily damaged.

But in general, then this Hand made :)

Happy New Year! Rejoice yourself and your loved ones!

PS And wine I'll tell you the cancellation is very tasty!

© antaid