1537

URANUS: the first working table SLA (stereolithography) printer

At this time I want to talk about how I became acquainted with the first (as of this writing) to work normally desktop stereolithography printer ( URANUS ) who is in Moscow.

History of 3d-printers began in 1984 with just stereolithography apparatus. Now, these printers are often used by jewelers, since the accuracy of such models print an order of magnitude FDM device (which is printed plastic)

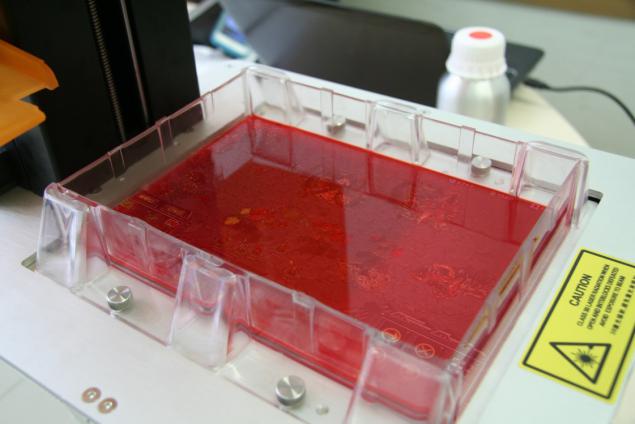

Under the cut a few pictures innards printer and the birth of the Hydralisk "bloody bath»

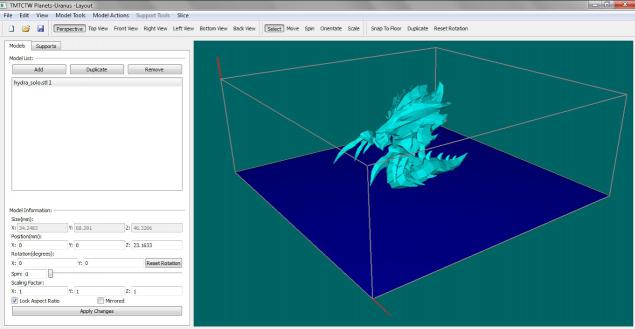

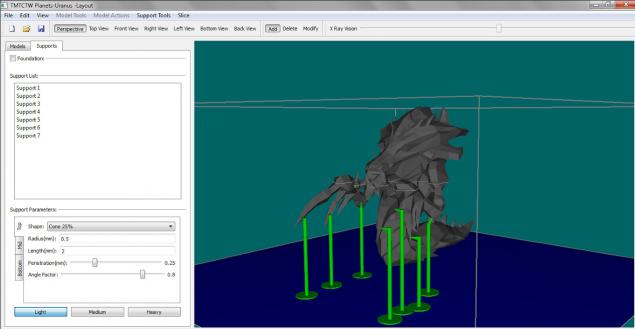

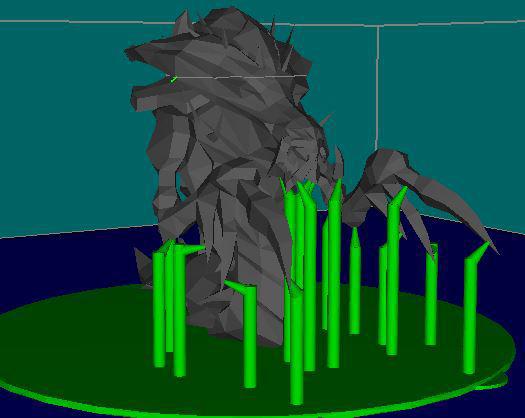

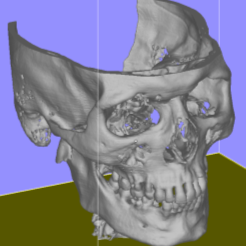

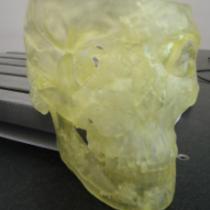

Spawn Hydralisk (H)

Appearance:

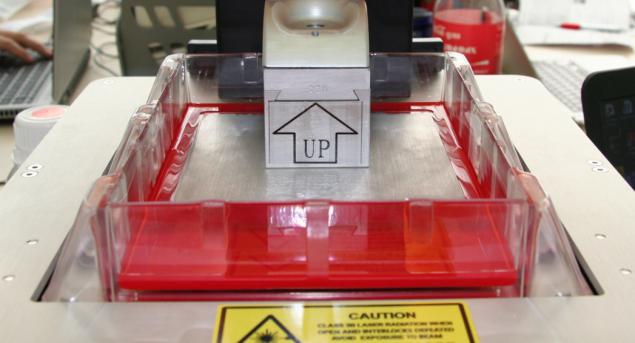

The first impression - like a bucket for papers, but for "homely interface hides a powerful algorithm»

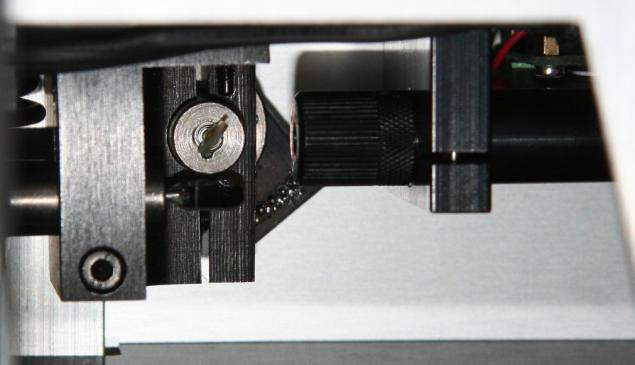

Raw:

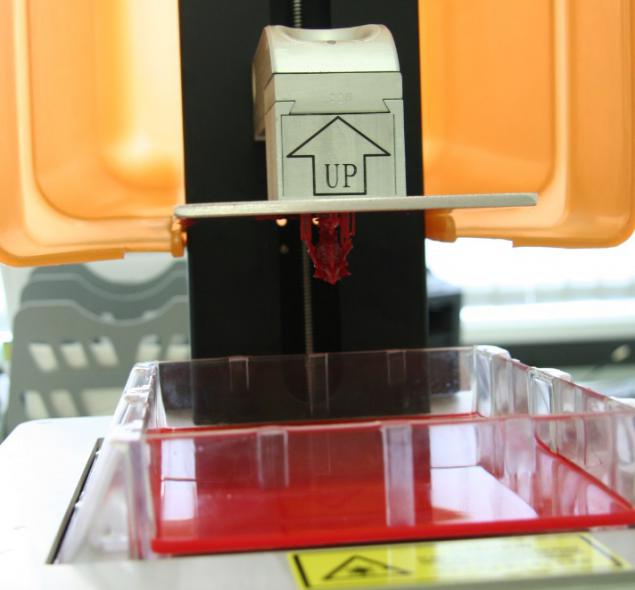

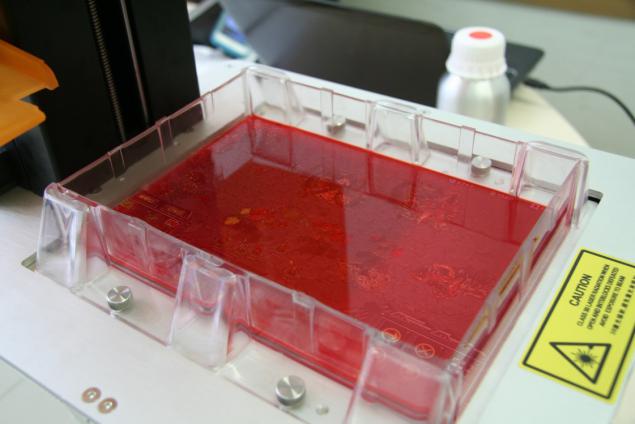

Photopolymer bright red. Included with the printer goes 0.5 liters photopolymer resin photopolymer resin separate volume of 0.5 liters costs 10 000 rubles (already considering a new course), but the printer is not limited to the resin and allows the use of other resins. Ie in fact this SLA printer is versatile for use resins from different vendors.

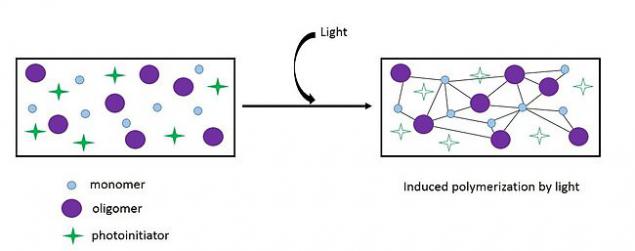

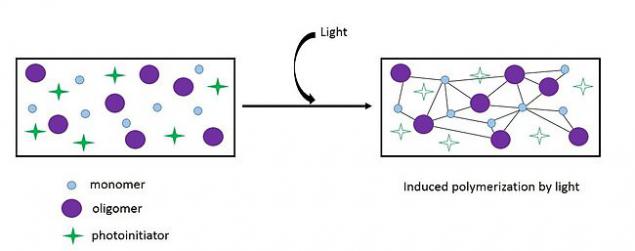

Changing photopolymer under the action of light

How it works SLA

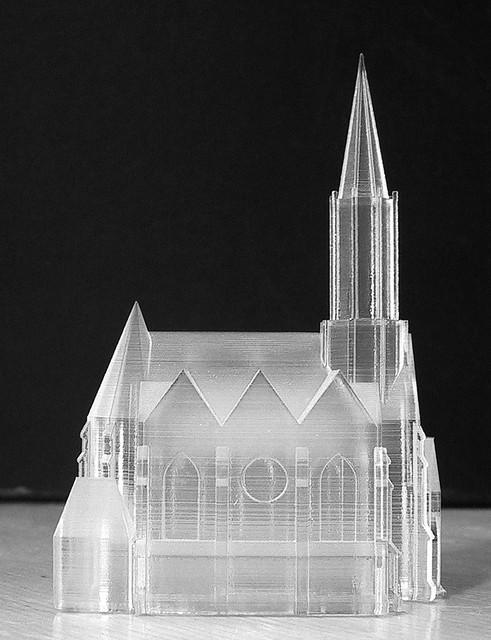

Examples of printing

Manufacturing Hydralisk of bloody bath h4>

Applications h4>

Conclusions. H4> The speed is higher than that FDM

History of 3d-printers began in 1984 with just stereolithography apparatus. Now, these printers are often used by jewelers, since the accuracy of such models print an order of magnitude FDM device (which is printed plastic)

Under the cut a few pictures innards printer and the birth of the Hydralisk "bloody bath»

Spawn Hydralisk (H)

Appearance:

The first impression - like a bucket for papers, but for "homely interface hides a powerful algorithm»

Raw:

Photopolymer bright red. Included with the printer goes 0.5 liters photopolymer resin photopolymer resin separate volume of 0.5 liters costs 10 000 rubles (already considering a new course), but the printer is not limited to the resin and allows the use of other resins. Ie in fact this SLA printer is versatile for use resins from different vendors.

Changing photopolymer under the action of light

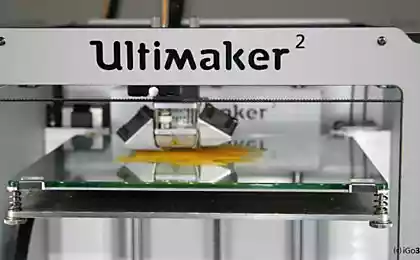

How it works SLA

Examples of printing