1216

IL-62 long-standing project

Greetings to all indifferent to the liner. They say that sometimes dreams do come true. 8 years ago, I made a first attempt to build the Il-62. For various reasons, had to throw this thing, but overall result prototype aircraft was made and hoisted into the air.

20 photos and videos.

via

Dimensions of the model: 1 length, 9m, wingspan 1, 6m, weight 3kg, which is 50% higher than the payment.

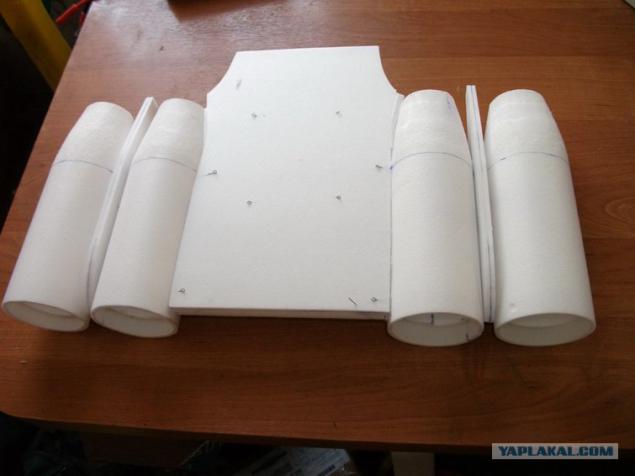

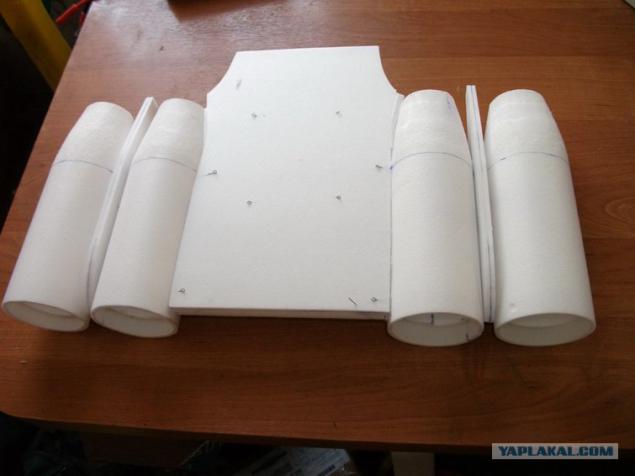

2 photos. Airplane made of potolochki as an established building material at the moment.

3 photos.

4 photos.

5 photos.

6 photos. Engine block. Impeller in it yet.

7 photo. Engine block is made at all, without any force elements. At first there were concerns about the strength of the pylon, but the trial assembly impellers showed sufficient strength of the foam core.

Impellers here are www.parkflyer.ru/33445/product/794492/

Impeller replaced at such www.parkflyer.ru/33445/product/4845/

Replacement impellers reduce the current to 20A and increase traction to 550gramm.

To achieve accuracy in appearance, made 1 trick: the impeller is inserted in a gondola, and then closes the lip.

8 photos. Blanks for gubeshek made so:

9 photos. Wires are displayed as:

10 photo.

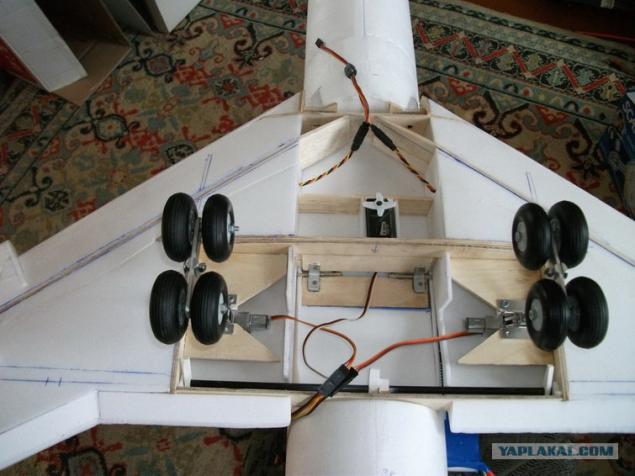

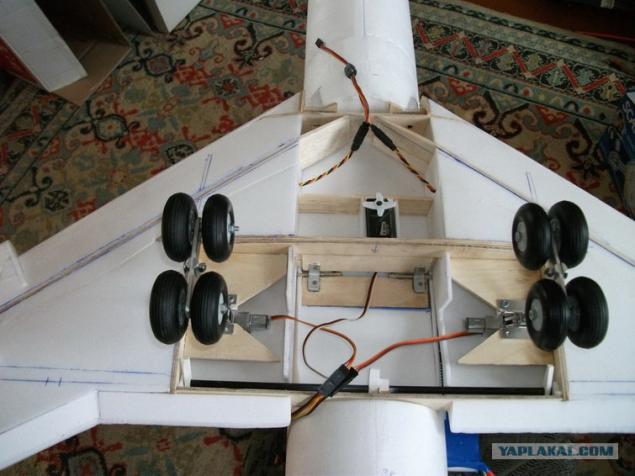

11 photo. The chassis is based on here such retracts www.parkflyer.ru/33445/product/796907/

Stands of this set here www.parkflyer.ru/33445/product/1127220/

Rocker homemade aluminum 3mm, 50mm wheels.

12. photo.

13 photo.

14 photo. Rack-mounting holes are drilled to 4mm. As the A-pillar has been used rack with wheels 35mm without any alterations.

15 photo. What I was most afraid of, because it stands for quality. Still, the weight of the model was marginal, 3kg. Despite everything, racks stood pretty rough landing without deformation.

Next picture will show us the design of center. For obvious reasons, the center-half gone, nowhere else will fold the wheel.

16 photo. Here we see a pipe that is driven by servo 1, located in front of the niche of the chassis. This tube will extend the flaps.

17 photo. Flaps we slotted hanging on remote loop on the pylons. The hinges are made of Mylar strips of width 3mm

18 photo. Stab us all-moving, as it is described here do www.parkflyer.ru/33445/blogs/view_entry/422/

Servite Drive rudder and stabilizer are here www.parkflyer.ru/33445/product/9816/

Placed on the keel here so

19 photo. How to hang wheels, see the link above, nothing new, I did not invent.

Compartment with electronics looks

20 photos. After a trial race impeller was removed all the foam with a plywood box amplification. Otherwise overheating regulators.

Power battery we have such

Posted in [mergetime] 1405928591 [/ mergetime]

The resulting constructs were papered with printer paper on akvalake. This procedure is very strongly weighted aircraft (about 600gramm) and was made for the possibility of spray painting. Moreover, the middle part of the fuselage is further coated with a glass fabric 50 g / m and a further layer of paper to the printer. The middle part is experiencing quite a lot of stress, and the fuselage is quite thin. That he did not break off every detail, the middle part has been strengthened.

That's all. In the manufacture of a prototype of a nuisance: when painting with spray wings, paint penetrated through the paper and devoured foam. For this reason, the airplane is no longer colored.

Today it made its first flight

20 photos and videos.

via

Dimensions of the model: 1 length, 9m, wingspan 1, 6m, weight 3kg, which is 50% higher than the payment.

2 photos. Airplane made of potolochki as an established building material at the moment.

3 photos.

4 photos.

5 photos.

6 photos. Engine block. Impeller in it yet.

7 photo. Engine block is made at all, without any force elements. At first there were concerns about the strength of the pylon, but the trial assembly impellers showed sufficient strength of the foam core.

Impellers here are www.parkflyer.ru/33445/product/794492/

Impeller replaced at such www.parkflyer.ru/33445/product/4845/

Replacement impellers reduce the current to 20A and increase traction to 550gramm.

To achieve accuracy in appearance, made 1 trick: the impeller is inserted in a gondola, and then closes the lip.

8 photos. Blanks for gubeshek made so:

9 photos. Wires are displayed as:

10 photo.

11 photo. The chassis is based on here such retracts www.parkflyer.ru/33445/product/796907/

Stands of this set here www.parkflyer.ru/33445/product/1127220/

Rocker homemade aluminum 3mm, 50mm wheels.

12. photo.

13 photo.

14 photo. Rack-mounting holes are drilled to 4mm. As the A-pillar has been used rack with wheels 35mm without any alterations.

15 photo. What I was most afraid of, because it stands for quality. Still, the weight of the model was marginal, 3kg. Despite everything, racks stood pretty rough landing without deformation.

Next picture will show us the design of center. For obvious reasons, the center-half gone, nowhere else will fold the wheel.

16 photo. Here we see a pipe that is driven by servo 1, located in front of the niche of the chassis. This tube will extend the flaps.

17 photo. Flaps we slotted hanging on remote loop on the pylons. The hinges are made of Mylar strips of width 3mm

18 photo. Stab us all-moving, as it is described here do www.parkflyer.ru/33445/blogs/view_entry/422/

Servite Drive rudder and stabilizer are here www.parkflyer.ru/33445/product/9816/

Placed on the keel here so

19 photo. How to hang wheels, see the link above, nothing new, I did not invent.

Compartment with electronics looks

20 photos. After a trial race impeller was removed all the foam with a plywood box amplification. Otherwise overheating regulators.

Power battery we have such

Posted in [mergetime] 1405928591 [/ mergetime]

The resulting constructs were papered with printer paper on akvalake. This procedure is very strongly weighted aircraft (about 600gramm) and was made for the possibility of spray painting. Moreover, the middle part of the fuselage is further coated with a glass fabric 50 g / m and a further layer of paper to the printer. The middle part is experiencing quite a lot of stress, and the fuselage is quite thin. That he did not break off every detail, the middle part has been strengthened.

That's all. In the manufacture of a prototype of a nuisance: when painting with spray wings, paint penetrated through the paper and devoured foam. For this reason, the airplane is no longer colored.

Today it made its first flight