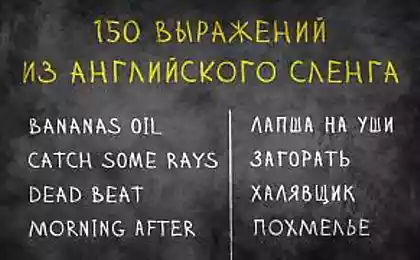

1300

How do gloss

Despite the name, the production is far from the real Pushkin Square, which is in the center of Moscow. Namely in Printers. Huge factory building hit already on the way. Frankly, I thought that typography occupies only part of the hangar ... but no, she takes them all!

We were on Saturday. Production capacity in this day reduced, but nevertheless all work and work to complete the program.

Before we go to production, small safety instruction (do not rush to the machine and under the wheels of passing cars), as well as mandatory painting that you're familiar with everything.

First of all go to the prepress department.

These are sent to all future models of magazines and catalogs. Specialists check them for technical errors, modify if necessary. Then do the test specimen, which is coordinated by the Customer.

Once it has been approved, files are divided into individual color and each color is printed on the special layout of the aluminum plate. With his help, will hereinafter "stamp" already drawing on paper.

Different printing machines need different plates of different sizes.

Next, head to the shop covers.

The main difference lies in the fact that printing is conducted on a paper sheet and not on the roll. Of course, for the cover of the paper is fed better quality, because it is the face of any magazine.

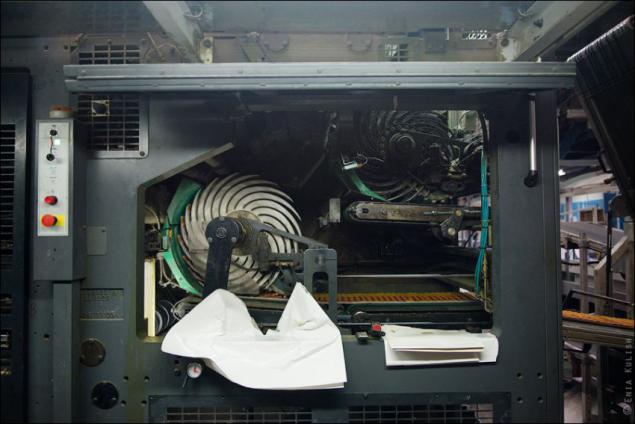

The futuristic-looking machine cleverly bent sheets and submit them to the conveyor.

There they go through several burly compartments, staining each in a specific color!

Performance giant. Just think - 18,000 sheets per hour! HOUR!

Near warehouse with paper. These rolls number in the tens of kilometers ... 60 70 80 ...

Go ahead to the workshop web printing ...

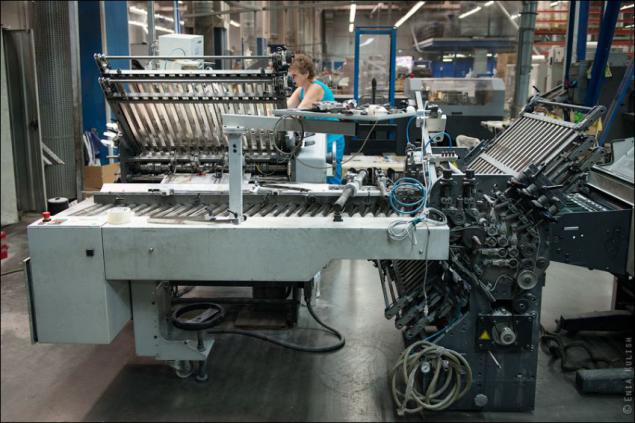

Huge machines are becoming even more by becoming a giant rolls.

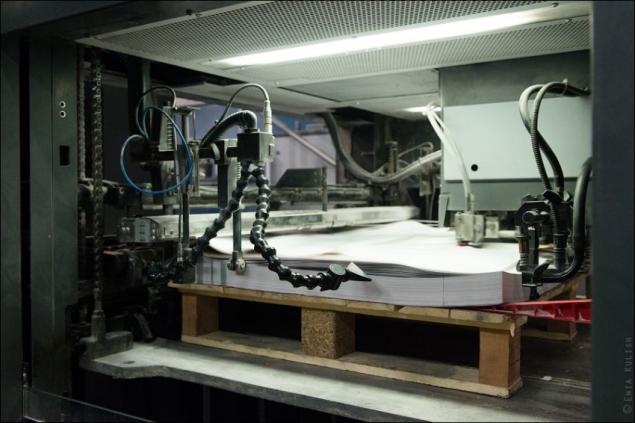

On the assembly line is not just printing. Here the sheets are cut and folded into finished booklets.

They in turn sent to the warehouse on the mechanism of funny.

There they were clamped between pieces of wood (not to brochures bristled).

Marriage is discarded immediately, even before entering the warehouse.

Such conveyors are many printed.

Funny that occurs simultaneously with the print on both sides of the sheet, which flies at a decent speed through these mechanisms ...

Speed 80 000 linear meters per hour!

Generally from the printing remains slight feeling of megalomania. For example, these blue bags - this cartridge.

In this printing mainly produced glossy products. But newspapers are also printed, just in smaller quantities. Newspaper cars look a little less modern ...

Especially beautiful black! =)

There is a very clear timetable, depending on the time of the magazine or newspaper. Where the equipment is not working, yet everything is ready for a new load.

In other halls installed other units at least once this giant.

They do have a whole list of problems. For example logs fastened together with paper of different density (you've seen, for sure, sometimes in magazines across the denser inside page).

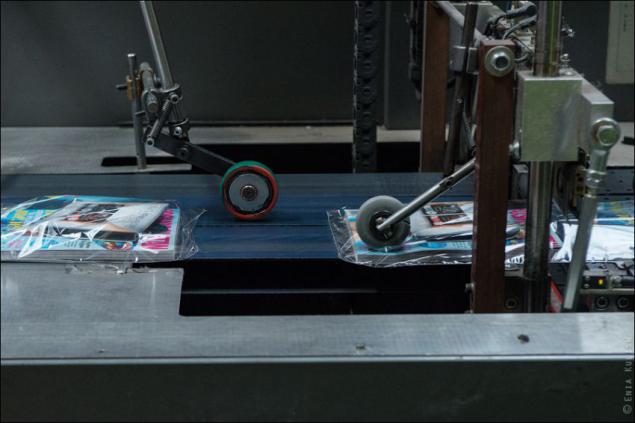

Separate dedicated conveyor packing those journals to which is attached a small gift.

However, in this case, almost all done manually.

Near warehouse already finished products.

Particular attention is paid to any printing humidity. Since we are talking about the paper on which the excess and lack of moisture have a significant impact, air quality monitoring should be the maximum.

For all the halls are special humidifiers.

Well, of course when dealing with printed materials will be a lot of waste. Here they are collected and sent for recycling.

This facility employs more than 1,000 people. And of course, on such production can not do without cute detalek ...

The tour lasted an hour ... But this time, we are constantly told something.

Source: enia.livejournal.com