911

Klavdievskaya factory Christmas tree decorations (40 photos)

Klavdievskaya factory is one of the leading factories in the former USSR, which produce Christmas decorations (except for her best known factory "Herringbone" in Vysokovsk Moscow Region.).

Factory was established in 1949 in the village near Kiev Klavdiyevo and initially engaged in the production of various products from laboratory glass. In the 50's and its redeveloped since the factory engaged in the production of Christmas decorations.

For the most part - a Christmas tree balls, but are not limited to the factory and can produce a sufficiently large glass ornaments ease.

The Union factory occupies the 1st place in terms of volume of production and area (if the factory included two more enterprises in Kiev - on Svyatoshino and at the hem). The performance of all enterprises in the day reached a volume of flat cars. Now there is only one company in the village Klavdiyevo (he recently migrated in part with. Lubyanka), which operates at 25% of the "allied" power.

In the past, the factory employed about 600 people, now there are only a tenth.

Almost all the decorations (about 96%) are now being exported (Germany, Belgium, Holland, France, UK, USA and others.) And only 4% are in Ukraine.

Let's see what it looks like factory and process of making Christmas tree decorations.

Externally (and internally) factory creates the impression of neglect. Indeed, after the collapse of the Soviet Union for 5 years from the factory carried everything handed down, and when he finally has a new owner, it took more than a year to restore operability at least to the minimum level.

One of the shops:

The first stage of the production of ornaments - glass-blowing from a height of about 1, 5 m bead or other decoration. For different uses of glass ornaments of its diameter and wall thickness with his.

Here we demonstrate a tube head of the board factory:

Mechanized blowing with customers out of favor: at low tide ball remains on the shape of the seam, so the entire production process manual.

To start the tube is heated over a gas burner, the temperature of which reaches 1, 5 thousand. Deg., And drawn into long, thin tubes at intervals of pristine original tube diameter:

The stocks for future decorations; where the original left tube diameter, and will receive balls:

Next is heated and blown gap untouched ball or other decoration:

The subtlety of this work lies in the fact that the glass blower must dial in light air as much as you need to create the required diameter of the ball:

In this case, the ball should always rotate around its axis, or simply droop glass still hot from previous:

Despite the ease of the process, glassblowers easily blown balls, lying in the tolerance of 0, 2 mm.

When we blew balls 80 mm in diameter:

However, after blowing each ball he checked on a special template:

For a change master can blow up to 200 balls. And this is familiar to many born tip for trees:

The second stage - silvering. It is performed with the help of such a straightforward installation: container with reagents yes bath with hot water

Inside decoration injected silver oxide, ammonia and distilled water in a certain proportion.

Christmas toy with this mixture is placed in hot water, the reaction takes place and the silver is deposited (this reaction is called "silver mirror reaction"), attached to the inside walls. Decoration is shaken several times to evenly cover the walls of silver. After that, the remaining solution poured:

The third stage - painting.

Silver plated beads and wiped with a cloth dipped in paint. At the same time it is very important consistency: if the paint is too thick, on the ball will begin to flow, if too thin - spaces:

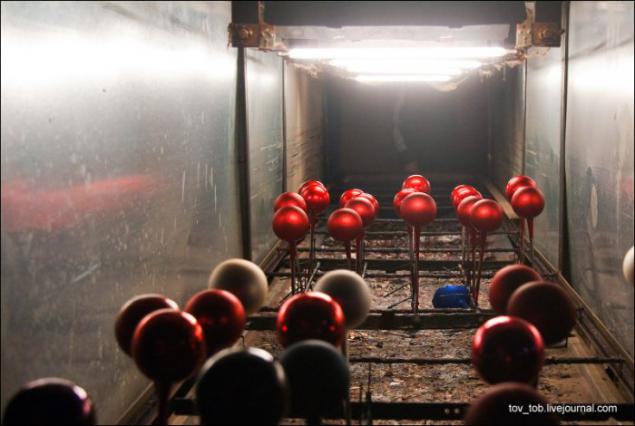

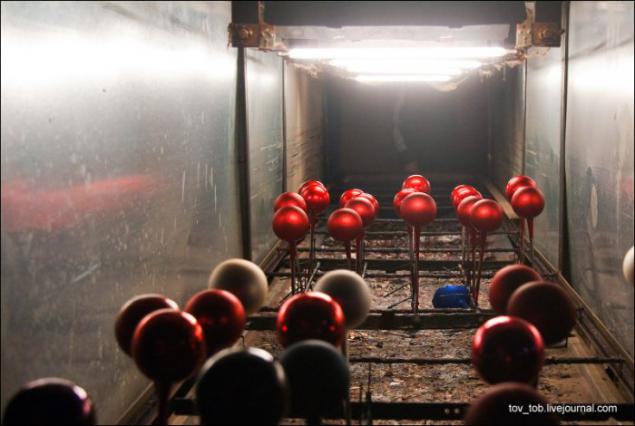

Painted balls are sent to the oven - they dry out here under the lights. Rheostat regulated voltage supplied to the lamp, and accordingly, temperature:

The fourth stage - decoration. If it is not required, the ball can pass this step and leave immediately for pruning.

When making the artist applied to the toy figure required:

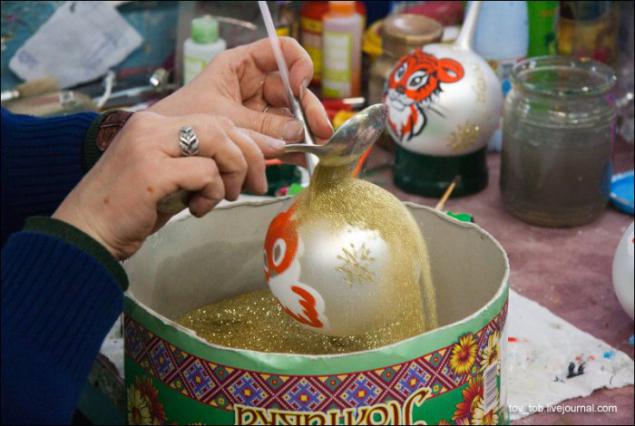

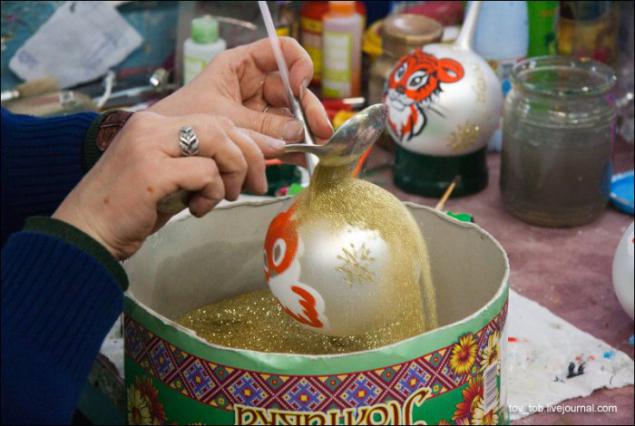

The process of drawing a tiger:

To put on a ball pattern of sequins, its pre-coated with glue and then sprinkle with glitter ball:

Tigers ready beside still unfinished brothers:

Artist can cause picture for every taste:

Each artist can paint 50 to 100 balls a day.

The fifth stage - trimming the tip, the remainder of the glass blowers. Done with a diamond wheel:

Bzdyn! Tip flies towards:

It only remains to put all caps familiar with a loop:

... And pack toys:

Finally a few examples of the diversity of the New Year, which produces factory:

Author

Factory was established in 1949 in the village near Kiev Klavdiyevo and initially engaged in the production of various products from laboratory glass. In the 50's and its redeveloped since the factory engaged in the production of Christmas decorations.

For the most part - a Christmas tree balls, but are not limited to the factory and can produce a sufficiently large glass ornaments ease.

The Union factory occupies the 1st place in terms of volume of production and area (if the factory included two more enterprises in Kiev - on Svyatoshino and at the hem). The performance of all enterprises in the day reached a volume of flat cars. Now there is only one company in the village Klavdiyevo (he recently migrated in part with. Lubyanka), which operates at 25% of the "allied" power.

In the past, the factory employed about 600 people, now there are only a tenth.

Almost all the decorations (about 96%) are now being exported (Germany, Belgium, Holland, France, UK, USA and others.) And only 4% are in Ukraine.

Let's see what it looks like factory and process of making Christmas tree decorations.

Externally (and internally) factory creates the impression of neglect. Indeed, after the collapse of the Soviet Union for 5 years from the factory carried everything handed down, and when he finally has a new owner, it took more than a year to restore operability at least to the minimum level.

One of the shops:

The first stage of the production of ornaments - glass-blowing from a height of about 1, 5 m bead or other decoration. For different uses of glass ornaments of its diameter and wall thickness with his.

Here we demonstrate a tube head of the board factory:

Mechanized blowing with customers out of favor: at low tide ball remains on the shape of the seam, so the entire production process manual.

To start the tube is heated over a gas burner, the temperature of which reaches 1, 5 thousand. Deg., And drawn into long, thin tubes at intervals of pristine original tube diameter:

The stocks for future decorations; where the original left tube diameter, and will receive balls:

Next is heated and blown gap untouched ball or other decoration:

The subtlety of this work lies in the fact that the glass blower must dial in light air as much as you need to create the required diameter of the ball:

In this case, the ball should always rotate around its axis, or simply droop glass still hot from previous:

Despite the ease of the process, glassblowers easily blown balls, lying in the tolerance of 0, 2 mm.

When we blew balls 80 mm in diameter:

However, after blowing each ball he checked on a special template:

For a change master can blow up to 200 balls. And this is familiar to many born tip for trees:

The second stage - silvering. It is performed with the help of such a straightforward installation: container with reagents yes bath with hot water

Inside decoration injected silver oxide, ammonia and distilled water in a certain proportion.

Christmas toy with this mixture is placed in hot water, the reaction takes place and the silver is deposited (this reaction is called "silver mirror reaction"), attached to the inside walls. Decoration is shaken several times to evenly cover the walls of silver. After that, the remaining solution poured:

The third stage - painting.

Silver plated beads and wiped with a cloth dipped in paint. At the same time it is very important consistency: if the paint is too thick, on the ball will begin to flow, if too thin - spaces:

Painted balls are sent to the oven - they dry out here under the lights. Rheostat regulated voltage supplied to the lamp, and accordingly, temperature:

The fourth stage - decoration. If it is not required, the ball can pass this step and leave immediately for pruning.

When making the artist applied to the toy figure required:

The process of drawing a tiger:

To put on a ball pattern of sequins, its pre-coated with glue and then sprinkle with glitter ball:

Tigers ready beside still unfinished brothers:

Artist can cause picture for every taste:

Each artist can paint 50 to 100 balls a day.

The fifth stage - trimming the tip, the remainder of the glass blowers. Done with a diamond wheel:

Bzdyn! Tip flies towards:

It only remains to put all caps familiar with a loop:

... And pack toys:

Finally a few examples of the diversity of the New Year, which produces factory:

Author