11296

Production of pencils

Incidentally, in the production of pencil passes through the 83 process steps used in its manufacture 107 kinds of raw materials and production cycle is 11 days. If all this still look the part of an entire product line, the drawn-established production complex with careful planning and control.

Let's go ...

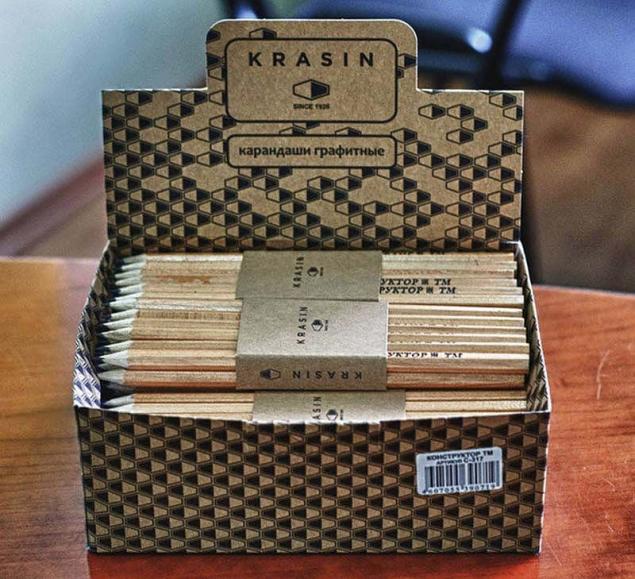

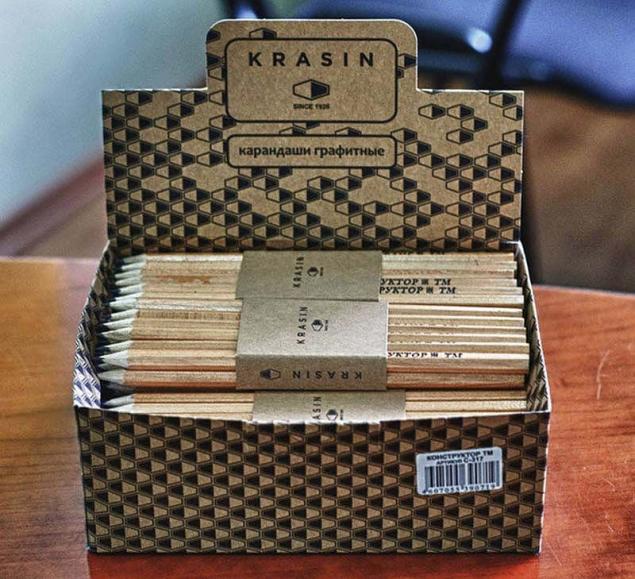

To see with their own eyes the process of production of pencils, we go to the Moscow factory Krasin. This is the oldest pencil production in Russia. The factory was founded in 1926 with the support of the government.

The main task of the government was to eliminate illiteracy in the country, and it was necessary to make the office supplies available. After the collapse of the Soviet Union factory Krasin remained the only manufacturer of pencils in the CIS with a full production cycle. This means that the factory produces all - from the lead up to the final product - pencils. Let's take a closer look at the process of production of pencils.

For the production of pencils in a factory comes specially treated and laid planks of lime. But before they will be involved, it is necessary to make writing rods.

2. Go to the shop fabrication pencil rods. Writing rods are made from a mixture of clay and graphite. Preparation of the necessary mixture begins with just such technological installations, which produces grinding clay. Crushed clay is sent down the pipeline for the next leg of production.

3. At the next station equipped with special mills, where the clay more finely milled and mixed with water.

4. Plants for the preparation of a mixture of clay and graphite. Here the mixture for future rods gets rid of impurities and ready for further processing.

5. It should be noted that the production of handles are used only natural substances, which makes the production of environmentally friendly. Apparatus for compressing the mixture. Obtained from semi-finished products produced rods. Wastes from the production actually not, because they use them again.

6. At the production site is already obtained rods themselves, but that they were in pencil on them would be another series of technological operations.

7. The technology is getting rods - like extrusion. Carefully prepared and blended mass is extruded through a special stamp with holes.

8. Thereafter, for writing the preform rods are placed in special containers.

9. dried in the oven for 16 hours.

10. Thereafter, the rods carefully sorted manually.

11. Here is the workplace for sorting rods. This is a very difficult and laborious work. For a table lamp sleeping cat.

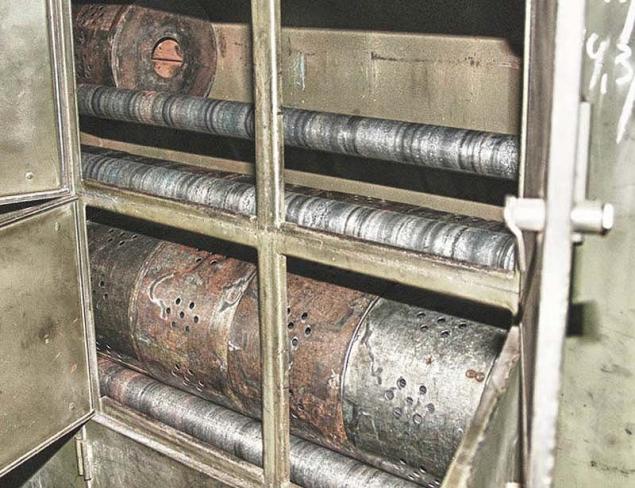

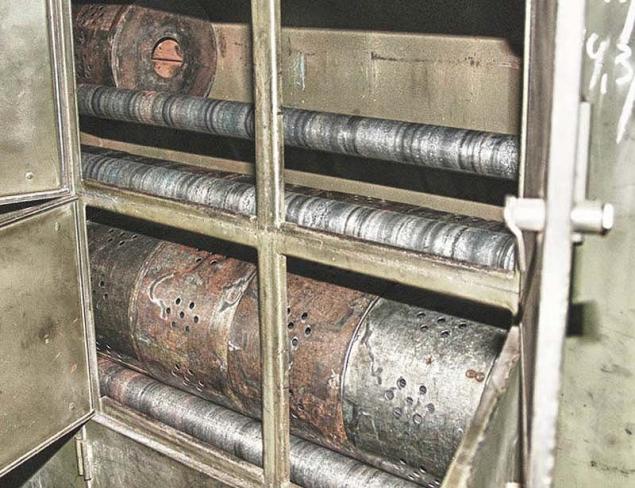

12. After sorting rods are baked in a special cabinet. The annealing temperature ranges from 800 to 1200 degrees centigrade, and directly affects the final properties of the rod. Temperature dependent hardness of the pencil which has graduations 17 - from 8B to 7H.

13. After annealing rods under special pressure and temperature are filled with fat. This is necessary to give them the necessary writing properties: the intensity of features, ease of sliding, grinding quality, ease erase eraser. Depending on the desired hardness of the rod can be applied: salomas, confectionery fat or beeswax and carnauba wax. Outputs manufacturing site rods.

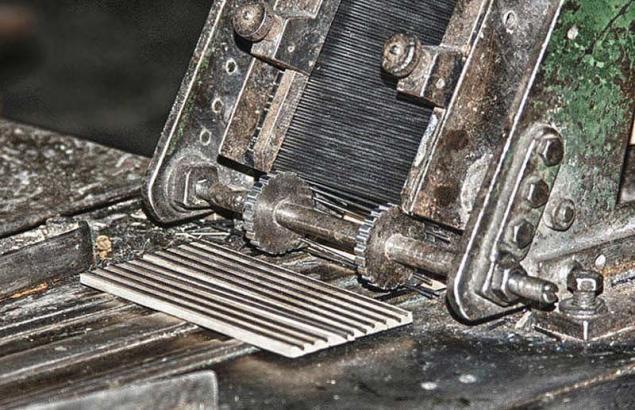

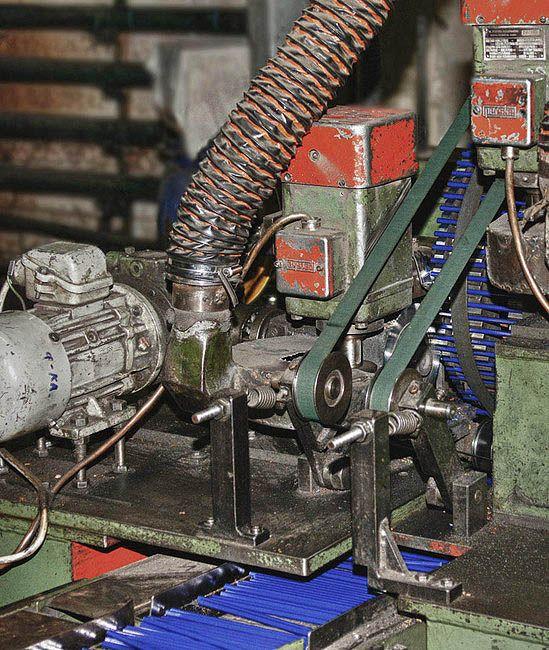

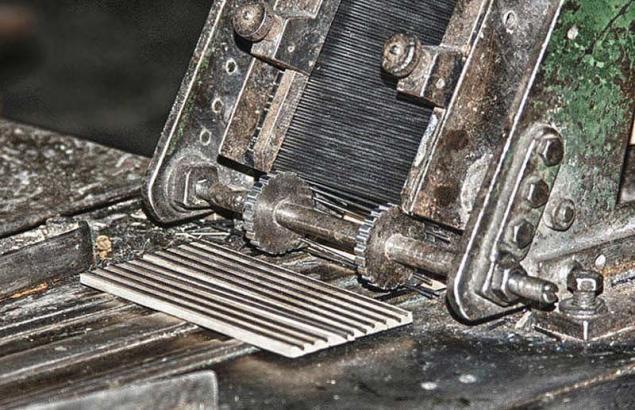

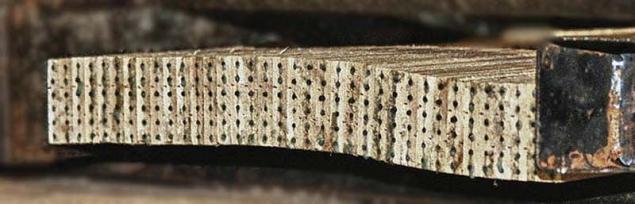

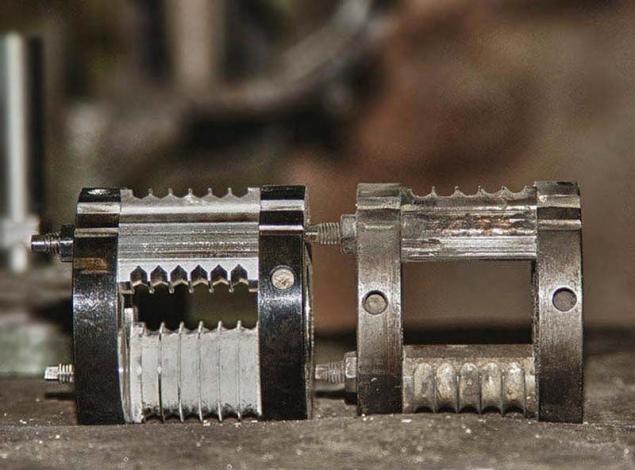

14. After the fall of the rods assembly. Here on these machines are prepared tablets pencil. They are cut grooves for the installation of writing rods.

15. The cutting part of the machine grinds grooves in the tablets.

16. The planks are automatically transferred into a clip here.

17. Thereafter, at another machine rods stacked plates prepared in advance.

18. After laying halves glued together with white glue boards, and they are left to dry under pressure. The essence of this operation is that the rod itself is not glued to the plank. Its diameter is larger than the diameter of the groove, and to design withdrew - press needs. The rod will be held in the same wood is not at the expense of glue, but due to interference wooden shell (specially created so prestressing in the design of a pencil).

19. After drying, the workpiece being cut special cutters to individual pencils.

20. Pencils are cut gradually over several cycles.

21. The output is ready, but not colored pencils.

22. At this stage lays the form of a stick due to the type of profile milling cutter.

23. Further on special lines passes priming the surface of a pencil. When painting pencils used enamel made at the plant. These are made of enamel safe for human components.

24. Line for painting pencils.

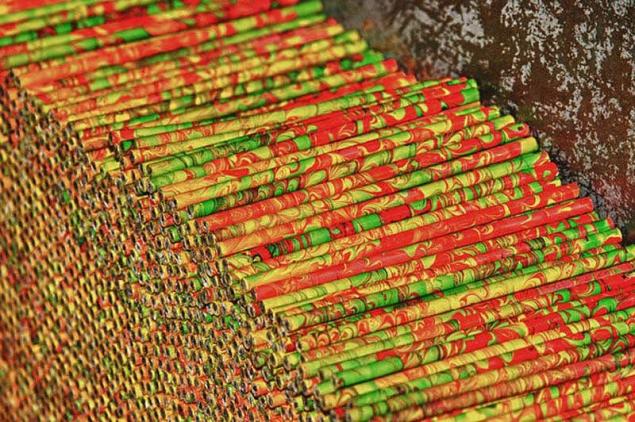

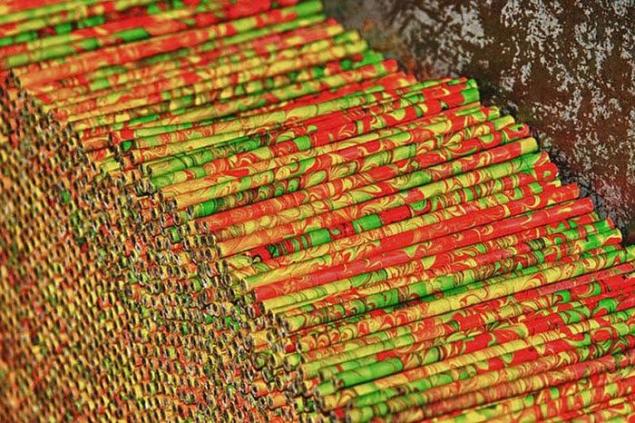

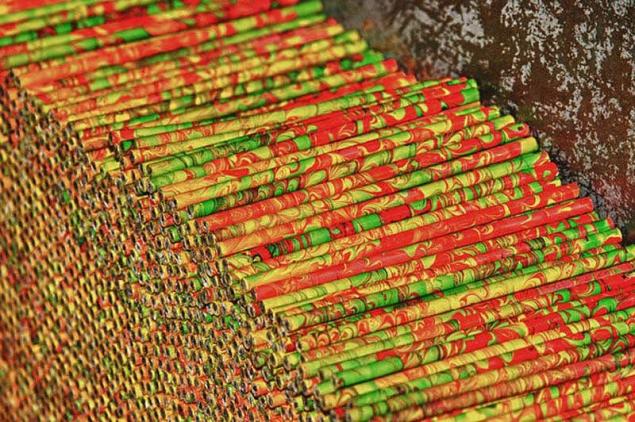

25. I think that in the stores, we saw a lot of gift pencils, colored colorful patches. It turns out that their so-dye, used whole specially developed technology. Here is a small piece of the process of painting.

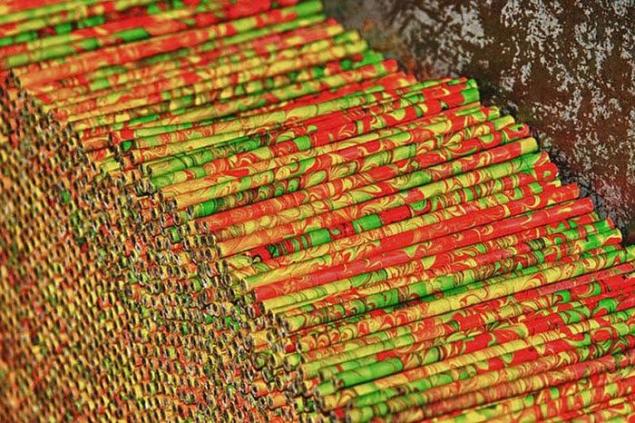

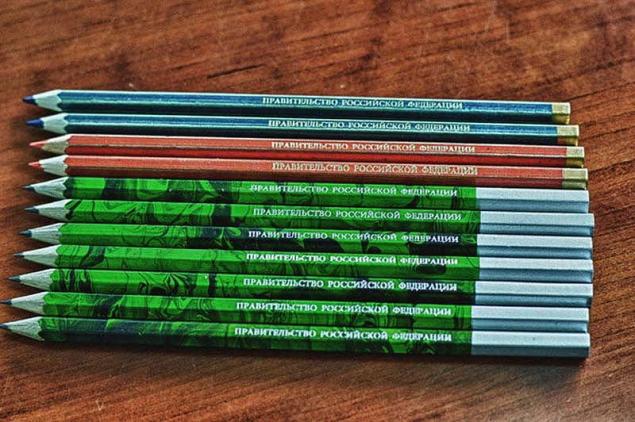

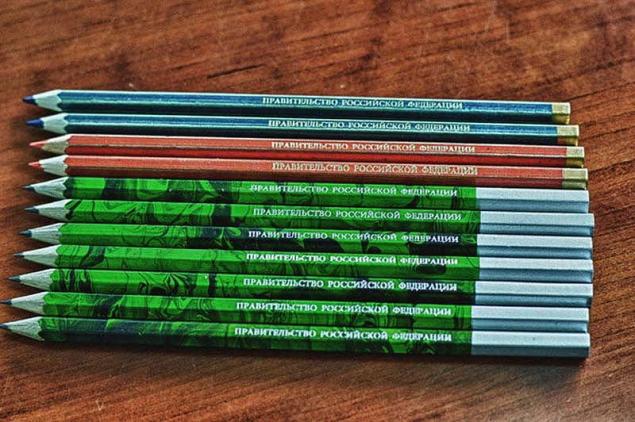

26. Visiting the paint shop I've seen the party pencils for delivery to the Government of the Russian Federation of the new sample. The tip of a pencil symbolizes our national flag. Pencils in special drying technology framework. The regularity of the series looks very unusual and attracts.

27. After painting pencils placed in a batch to be sent to the following sections of the factory.

28. See thousands of pencils, colored by the proprietary technology of the plant, is a great pleasure. This is a very unusual sight.

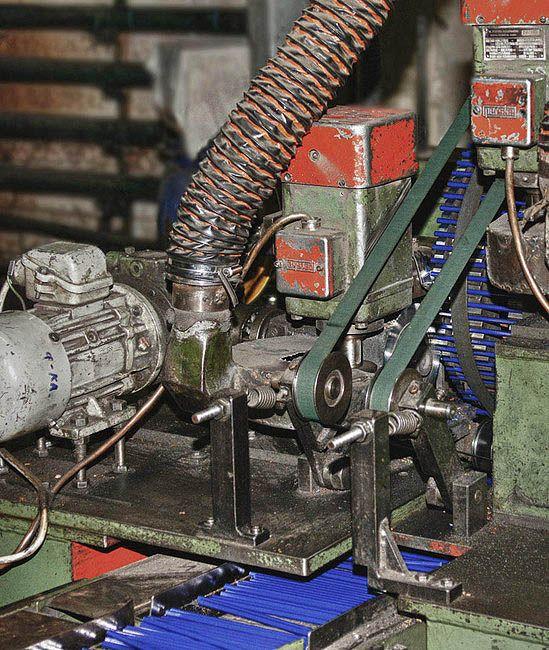

29. Next, on a special machine held the final mechanical operations - processing ends.

30. The production line of surface finish.

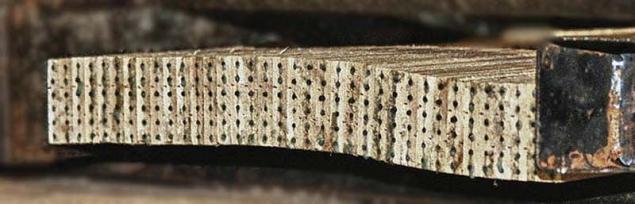

31. Further, in a special machine applied to a pencil marking of a special die which is applied to each foil tape over the pencil.

32. Storage cabinet stamps. Stamps are stored here for the entire range of products.

33. If necessary, before filling pencils sharpened on a special machine. The photograph displayed intermediate stage sharpening. I was struck by the speed of the machine. Pencils fell into the pan a continuous stream. Immediately reminded of all personal unsuccessful attempts to sharpen pencils. From these memories this machine started to inspire even more respect.

34. The factory produces and this is such an interesting pencils oval used in the construction and repair.

35. Arrays stockpiled pencils look very unusual and attracting. This not see anywhere else.

36.

37. In the area of packaging pencils sorted and packed by hand. Here a special atmosphere. People work quietly and silently. Many workers have continuous service at the factory for more than 40 years.

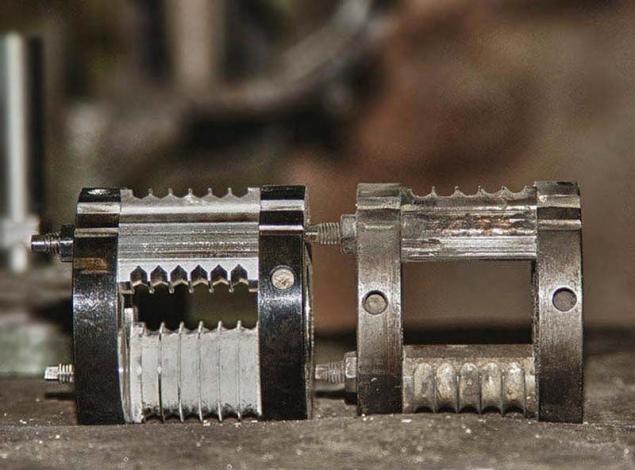

38. The factory has its own equipped laboratory, which tested the product during the production cycle and practiced new production technologies. In the picture - a device for determining the resistance Amsler fracture writing rods.

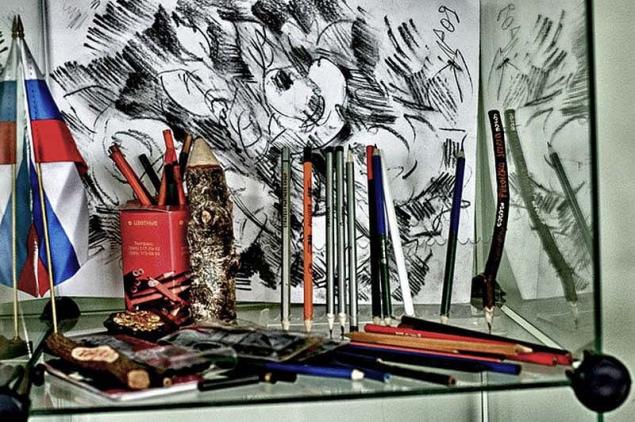

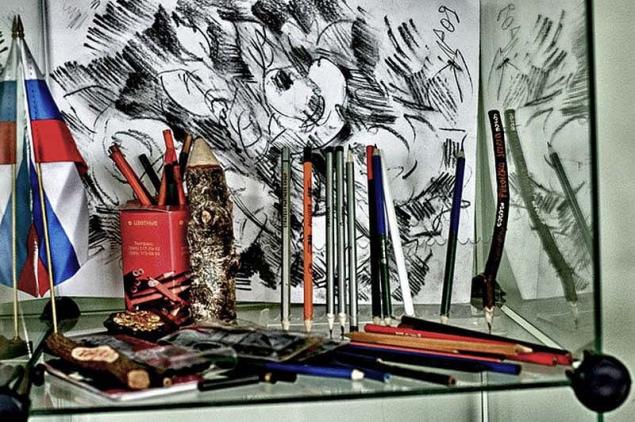

39. Before leaving, I went into the room with display stands factory production. Emblem factory causes some nostalgia. After all, these pencils are familiar to all of us since childhood. The factory produces several product lines. Professional Series pencils for artists, decorators and designers.

40. Samples pencils supplied to the Russian government. For registration pencil drawing is selected in the color of malachite standard desktop devices employees of the Government of the Russian Federation. But other than that, they have other differences from conventional pencils: firstly their shape made with a maximum ergonomically hands of an adult, and in addition they used a special rod type "lyumograf" for marginal notes in the diary, it is not smeared hand but well eraser erased without damaging the paper.

41. Pencils for engineering drawing:

42. The original souvenir factory.

43. Factory visit was very enjoyable and informative. It was very interesting to see how much of the original technology and labor invested in the production of such a seemingly simple object like a pencil.

44. I want to express my gratitude to the main production technology Marina for help and clarification processes in the workplace. At the end of a visit to the factory, its leaders gave their version of Ridus branded pencils, including the Government of the Russian Federation supplied.

Source: sdelano-u-nas.livejournal.com

Let's go ...

To see with their own eyes the process of production of pencils, we go to the Moscow factory Krasin. This is the oldest pencil production in Russia. The factory was founded in 1926 with the support of the government.

The main task of the government was to eliminate illiteracy in the country, and it was necessary to make the office supplies available. After the collapse of the Soviet Union factory Krasin remained the only manufacturer of pencils in the CIS with a full production cycle. This means that the factory produces all - from the lead up to the final product - pencils. Let's take a closer look at the process of production of pencils.

For the production of pencils in a factory comes specially treated and laid planks of lime. But before they will be involved, it is necessary to make writing rods.

2. Go to the shop fabrication pencil rods. Writing rods are made from a mixture of clay and graphite. Preparation of the necessary mixture begins with just such technological installations, which produces grinding clay. Crushed clay is sent down the pipeline for the next leg of production.

3. At the next station equipped with special mills, where the clay more finely milled and mixed with water.

4. Plants for the preparation of a mixture of clay and graphite. Here the mixture for future rods gets rid of impurities and ready for further processing.

5. It should be noted that the production of handles are used only natural substances, which makes the production of environmentally friendly. Apparatus for compressing the mixture. Obtained from semi-finished products produced rods. Wastes from the production actually not, because they use them again.

6. At the production site is already obtained rods themselves, but that they were in pencil on them would be another series of technological operations.

7. The technology is getting rods - like extrusion. Carefully prepared and blended mass is extruded through a special stamp with holes.

8. Thereafter, for writing the preform rods are placed in special containers.

9. dried in the oven for 16 hours.

10. Thereafter, the rods carefully sorted manually.

11. Here is the workplace for sorting rods. This is a very difficult and laborious work. For a table lamp sleeping cat.

12. After sorting rods are baked in a special cabinet. The annealing temperature ranges from 800 to 1200 degrees centigrade, and directly affects the final properties of the rod. Temperature dependent hardness of the pencil which has graduations 17 - from 8B to 7H.

13. After annealing rods under special pressure and temperature are filled with fat. This is necessary to give them the necessary writing properties: the intensity of features, ease of sliding, grinding quality, ease erase eraser. Depending on the desired hardness of the rod can be applied: salomas, confectionery fat or beeswax and carnauba wax. Outputs manufacturing site rods.

14. After the fall of the rods assembly. Here on these machines are prepared tablets pencil. They are cut grooves for the installation of writing rods.

15. The cutting part of the machine grinds grooves in the tablets.

16. The planks are automatically transferred into a clip here.

17. Thereafter, at another machine rods stacked plates prepared in advance.

18. After laying halves glued together with white glue boards, and they are left to dry under pressure. The essence of this operation is that the rod itself is not glued to the plank. Its diameter is larger than the diameter of the groove, and to design withdrew - press needs. The rod will be held in the same wood is not at the expense of glue, but due to interference wooden shell (specially created so prestressing in the design of a pencil).

19. After drying, the workpiece being cut special cutters to individual pencils.

20. Pencils are cut gradually over several cycles.

21. The output is ready, but not colored pencils.

22. At this stage lays the form of a stick due to the type of profile milling cutter.

23. Further on special lines passes priming the surface of a pencil. When painting pencils used enamel made at the plant. These are made of enamel safe for human components.

24. Line for painting pencils.

25. I think that in the stores, we saw a lot of gift pencils, colored colorful patches. It turns out that their so-dye, used whole specially developed technology. Here is a small piece of the process of painting.

26. Visiting the paint shop I've seen the party pencils for delivery to the Government of the Russian Federation of the new sample. The tip of a pencil symbolizes our national flag. Pencils in special drying technology framework. The regularity of the series looks very unusual and attracts.

27. After painting pencils placed in a batch to be sent to the following sections of the factory.

28. See thousands of pencils, colored by the proprietary technology of the plant, is a great pleasure. This is a very unusual sight.

29. Next, on a special machine held the final mechanical operations - processing ends.

30. The production line of surface finish.

31. Further, in a special machine applied to a pencil marking of a special die which is applied to each foil tape over the pencil.

32. Storage cabinet stamps. Stamps are stored here for the entire range of products.

33. If necessary, before filling pencils sharpened on a special machine. The photograph displayed intermediate stage sharpening. I was struck by the speed of the machine. Pencils fell into the pan a continuous stream. Immediately reminded of all personal unsuccessful attempts to sharpen pencils. From these memories this machine started to inspire even more respect.

34. The factory produces and this is such an interesting pencils oval used in the construction and repair.

35. Arrays stockpiled pencils look very unusual and attracting. This not see anywhere else.

36.

37. In the area of packaging pencils sorted and packed by hand. Here a special atmosphere. People work quietly and silently. Many workers have continuous service at the factory for more than 40 years.

38. The factory has its own equipped laboratory, which tested the product during the production cycle and practiced new production technologies. In the picture - a device for determining the resistance Amsler fracture writing rods.

39. Before leaving, I went into the room with display stands factory production. Emblem factory causes some nostalgia. After all, these pencils are familiar to all of us since childhood. The factory produces several product lines. Professional Series pencils for artists, decorators and designers.

40. Samples pencils supplied to the Russian government. For registration pencil drawing is selected in the color of malachite standard desktop devices employees of the Government of the Russian Federation. But other than that, they have other differences from conventional pencils: firstly their shape made with a maximum ergonomically hands of an adult, and in addition they used a special rod type "lyumograf" for marginal notes in the diary, it is not smeared hand but well eraser erased without damaging the paper.

41. Pencils for engineering drawing:

42. The original souvenir factory.

43. Factory visit was very enjoyable and informative. It was very interesting to see how much of the original technology and labor invested in the production of such a seemingly simple object like a pencil.

44. I want to express my gratitude to the main production technology Marina for help and clarification processes in the workplace. At the end of a visit to the factory, its leaders gave their version of Ridus branded pencils, including the Government of the Russian Federation supplied.

Source: sdelano-u-nas.livejournal.com