1870

How do the pencils of Siberian cedar

Today "Siberian pencil factory" - the only in the territory of the former Soviet Union, a manufacturer of pencils and pencil plank of Siberian cedar wood which is used for the manufacture of pencils highest price category.

How to produce pencils, familiar to us from childhood?

Production begins with pencils timber yard where stored harvested cedar. Now it is more than three million cubic meters of wood. The regional authorities have helped the factory to ensure the material and this year it is planning to produce about 85 million pencils.

- The wood that we buy, comes to us as a result of illegal logging, - says Anatoly Lunin, director of the factory. - The vast majority of this stagnate sanitary felling of cedar, which no longer gives a nut. Cedar grows up to 500 years, but it bumps appear somewhere up to 250 years of age, after which it begins to die, its amazing variety of insects. If you cut it down during this period, it will grow a new cedar.

Until the cut logs from compulsory training: each log must be washed to adhering pieces of earth or clay with stones accidentally damaged blade. For this tree with timber yard is placed and kept in a special pool of warm water. In summer, it is kept long, up to twenty minutes, but during the winter log stored in the pool until until thawed - this may take up to three hours. And after 369 hours, or 16, 5 days and 26 different processing steps are obtained from logs pencils ready.

In the sawmill of logs do here such timber:

Production of wooden pencil is extremely demanding on the quality of the material, the cause is just pure straight wood. And if joinery defects such as, for example, knots, not catastrophic, the pencil of this tree is not done. Therefore, to say in advance how many pencils to get from one timber, it is very difficult.

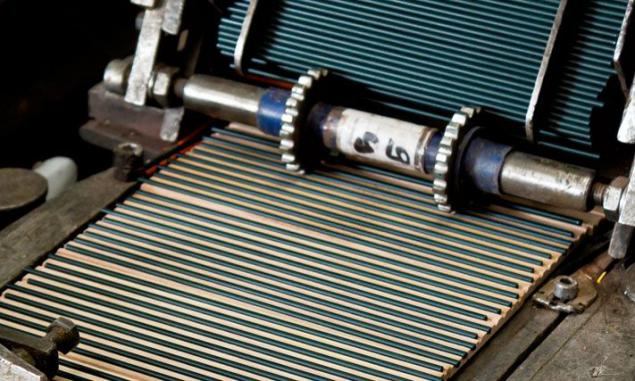

To reduce the amount of waste at the plant looking for different ways to increase the depth of processing of wood. One such method - expanding the range of products. So, from the boards, which is not suitable for the production of a pencil, plan to start production of wooden puzzles, coloring books for children and means of moth. Something is on the production of short pencils for shops «IKEA», as part of the production of such wooden skewers here:

Derived from logs sawn timber on short sections, each of which then dismiss ten boards. To all plates were identical, they need to be calibrated. To do this, they forced through a special machine. At the exit of his plates have the same size and exactly perpendicular to the edge.

Then calibrated plates placed in an autoclave. In appearance it resembles a barrel, which is supplied to the plurality of tubes of different diameters. With these pipes in the chamber is possible to create a vacuum, pressurize and feed into all sorts of solutions.

As a result of these processes is removed from the tablets contained therein, the resin and wood is impregnated (soaked) with paraffin. Today it is not the easiest, but one of the most effective ways to improve important properties of the material and to protect the wood from environmental hazards.

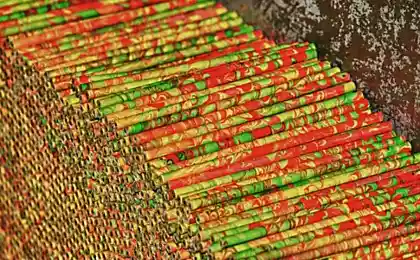

"Sanitized" after autoclaving pencil boards is how to dry, and then - send directly to the pencil production. In this process of manufacturing tablets can be considered complete. So look plank after autoclaving

- Basic principles and production technology since the Tomsk began to make pencils, does not change, - says Anatoly Lunin. - All processes in our factory is well established. Modernization of the equipment expressed in the replacement of some nodes, or switching to more fuel-efficient engines, the use of new mills. Come any new materials, we change something in the acceptance and evaluation, but the technology remains unchanged.

Finished tablet enters the shop white pencil where to start in the machine it is cut groove, where the rods are then stacked (the word "white" in this case means that the pencil at this stage is not colored). Plates are served with a side of the machine, the road surface is ground for their gluing, a special cutter in it are cut recess. At the proximal edge of the machine boards automatically stacked in a pile. The thickness of the polished plates with cut grooves is 5 mm, which is equal to half the thickness of a pencil the future.

The next step boards are glued in pairs with each other, to get one pencil unit.

The machine continuously delivers the first tablet and puts pins in her groove. Following this, from another device "leaves" the second plank, already oiled water-soluble glue and gently rests on the first. The resulting pencil blocks clamped in the pneumatic press and tightening the clamps.

If the tablet is manufactured in a factory on their own, then the rod, mostly bought in China. There he began to produce for the "dry" technology that does not require baking in the oven at a high temperature.

Consequently, the cost of the rod was so low that the lion's share of pencil manufacturers passed just such a rod.

To lead pencil did not break inside the body, the technology used in the factory additional sizing rod special adhesive system. After this operation, the glued blocks maintained in a special oven for several hours.

The camera is quite hot. Hot air blower, maintaining the temperature at about 35-40 degrees. Timber should be dry well, to continue to pencil in one pass he became smooth and got the desired geometry. Pencil with "simple" pencil drying is not less than two hours, and color - at least four. Due to the fact that the color contains more fatty substances, it requires more time to dry.

After this time, the blocks disassembled, placed in a trolley with an indication of all further parameters and sent to the next machine, which divide them into individual pencils.

Its shape is similar to the machine, which makes grooves in the boards, but it has its own peculiarities. The blanks are placed in the hopper.

They are on the transport hubs, butt saw off and the output is the usual wooden pencil, but not yet painted.

Dual cutter that separates blocks, sets and shape the future of the pencil, and does it all in a single pass. That is the type of profile milling cutter depends on what will be a pencil - hexagonal or round.

Most recently, the factory mastered the production of triangular pencil. It turned out that the demand for this form of growing. Buyers are attracted ergonomics and natural location on the edges of the fingers, which certainly facilitates learning letter children.

Near the machine is desktop sorter. Its mission - to sort out in pencil, select the "fit" and to separate defective. Defects are chipped at the end of the rod, roughness, burning wood, and the like. Above the table hangs a memo with the rules of marriage. Each standing on the table tray is put in 1440 pencils.

Sorted pencils on a special elevator to ascend to the next floor, where they will be painted.

Buy paint in dry form and diluted to the desired thickness in the laboratory paints. Painting itself is fast enough.

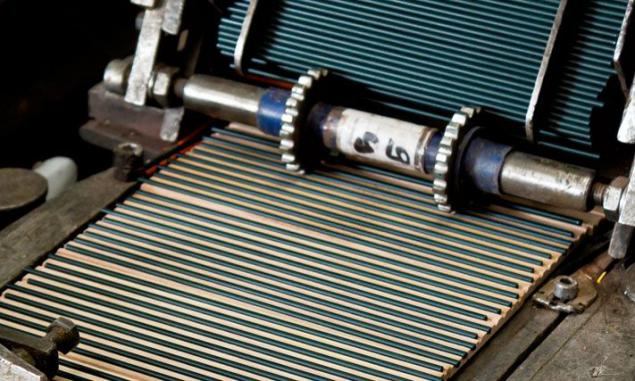

The device continually pushes the colored pencils on the conveyor. The length and speed of the conveyor belt are designed so that the pen drying out while it is moving.

Before reaching the opposite end of the conveyor, pencils fall into one of three receivers where they are sent back to the next coating.

On average, each pen is covered by three layers of paint and two coats of varnish - it all depends on the willingness of the customer. You can also paint the pencil in almost any color. The factory produces a set of six, twelve, eighteen and twenty-four colors. Some pencils only cover varnish.

After painting, pencils sent to the finishing department. At this point they acquire the final form in which reach the consumer. On the stamp is applied to pencils, eraser and put sharpened.

A method of applying a lot of punches, but the "Siberian pencil factory" This is done using different colors of foil. This method is called the incubation. The working part of the machine is heated, and the stamp is transferred through the foil on a pencil - so it will not peel, and dirty hands. Sam stamp can be anything, it is specially ordered from the engraver. Depending on the complexity, for its production it takes about five days.

On the part of the pencil, if necessary, wear an eraser.

The last operation - is sharpening. To sharpen pencils on emery paper placed over the drum and moving with great speed. This happens very quickly, in just a few seconds.

Besides sharpening machine can be configured to perform rolling - the back end processing of the pen at a slight angle. Now the pencils are ready for packaging, they are sent to the next room. There's pencils are collected in a set, put in a box and sent to the consumer.

The packaging for the right amount of pencils printed in Novosibirsk. It comes in a flat form, so make sure you give it volume. Then after picking machines, the required number of pencils laid out in a predetermined color. Special machine allows you to collect a set of twelve colors. At the end of pencils laid out on the cases a.

When asked whether the factory plans, following the example of Chinese enterprises to switch to the production of a pencil from cheaper wood or plastic Anatoly Lunin recognized:

- I was thinking to try to make an economical pencil from low-grade aspen, but it is another technology, and let alone the Chinese are engaged. I'm more interested in the topic of increasing the useful output by improving the quality of processing of wood. And from the point of view of ecology, to produce anything better from renewable raw materials. Plastic pencil never rot and wood for several years completely decompose.

One can only wish that in the age of global computerization was a place simple wooden pencils.

--img40--

Source: obzor.westsib.ru

How to produce pencils, familiar to us from childhood?

Production begins with pencils timber yard where stored harvested cedar. Now it is more than three million cubic meters of wood. The regional authorities have helped the factory to ensure the material and this year it is planning to produce about 85 million pencils.

- The wood that we buy, comes to us as a result of illegal logging, - says Anatoly Lunin, director of the factory. - The vast majority of this stagnate sanitary felling of cedar, which no longer gives a nut. Cedar grows up to 500 years, but it bumps appear somewhere up to 250 years of age, after which it begins to die, its amazing variety of insects. If you cut it down during this period, it will grow a new cedar.

Until the cut logs from compulsory training: each log must be washed to adhering pieces of earth or clay with stones accidentally damaged blade. For this tree with timber yard is placed and kept in a special pool of warm water. In summer, it is kept long, up to twenty minutes, but during the winter log stored in the pool until until thawed - this may take up to three hours. And after 369 hours, or 16, 5 days and 26 different processing steps are obtained from logs pencils ready.

In the sawmill of logs do here such timber:

Production of wooden pencil is extremely demanding on the quality of the material, the cause is just pure straight wood. And if joinery defects such as, for example, knots, not catastrophic, the pencil of this tree is not done. Therefore, to say in advance how many pencils to get from one timber, it is very difficult.

To reduce the amount of waste at the plant looking for different ways to increase the depth of processing of wood. One such method - expanding the range of products. So, from the boards, which is not suitable for the production of a pencil, plan to start production of wooden puzzles, coloring books for children and means of moth. Something is on the production of short pencils for shops «IKEA», as part of the production of such wooden skewers here:

Derived from logs sawn timber on short sections, each of which then dismiss ten boards. To all plates were identical, they need to be calibrated. To do this, they forced through a special machine. At the exit of his plates have the same size and exactly perpendicular to the edge.

Then calibrated plates placed in an autoclave. In appearance it resembles a barrel, which is supplied to the plurality of tubes of different diameters. With these pipes in the chamber is possible to create a vacuum, pressurize and feed into all sorts of solutions.

As a result of these processes is removed from the tablets contained therein, the resin and wood is impregnated (soaked) with paraffin. Today it is not the easiest, but one of the most effective ways to improve important properties of the material and to protect the wood from environmental hazards.

"Sanitized" after autoclaving pencil boards is how to dry, and then - send directly to the pencil production. In this process of manufacturing tablets can be considered complete. So look plank after autoclaving

- Basic principles and production technology since the Tomsk began to make pencils, does not change, - says Anatoly Lunin. - All processes in our factory is well established. Modernization of the equipment expressed in the replacement of some nodes, or switching to more fuel-efficient engines, the use of new mills. Come any new materials, we change something in the acceptance and evaluation, but the technology remains unchanged.

Finished tablet enters the shop white pencil where to start in the machine it is cut groove, where the rods are then stacked (the word "white" in this case means that the pencil at this stage is not colored). Plates are served with a side of the machine, the road surface is ground for their gluing, a special cutter in it are cut recess. At the proximal edge of the machine boards automatically stacked in a pile. The thickness of the polished plates with cut grooves is 5 mm, which is equal to half the thickness of a pencil the future.

The next step boards are glued in pairs with each other, to get one pencil unit.

The machine continuously delivers the first tablet and puts pins in her groove. Following this, from another device "leaves" the second plank, already oiled water-soluble glue and gently rests on the first. The resulting pencil blocks clamped in the pneumatic press and tightening the clamps.

If the tablet is manufactured in a factory on their own, then the rod, mostly bought in China. There he began to produce for the "dry" technology that does not require baking in the oven at a high temperature.

Consequently, the cost of the rod was so low that the lion's share of pencil manufacturers passed just such a rod.

To lead pencil did not break inside the body, the technology used in the factory additional sizing rod special adhesive system. After this operation, the glued blocks maintained in a special oven for several hours.

The camera is quite hot. Hot air blower, maintaining the temperature at about 35-40 degrees. Timber should be dry well, to continue to pencil in one pass he became smooth and got the desired geometry. Pencil with "simple" pencil drying is not less than two hours, and color - at least four. Due to the fact that the color contains more fatty substances, it requires more time to dry.

After this time, the blocks disassembled, placed in a trolley with an indication of all further parameters and sent to the next machine, which divide them into individual pencils.

Its shape is similar to the machine, which makes grooves in the boards, but it has its own peculiarities. The blanks are placed in the hopper.

They are on the transport hubs, butt saw off and the output is the usual wooden pencil, but not yet painted.

Dual cutter that separates blocks, sets and shape the future of the pencil, and does it all in a single pass. That is the type of profile milling cutter depends on what will be a pencil - hexagonal or round.

Most recently, the factory mastered the production of triangular pencil. It turned out that the demand for this form of growing. Buyers are attracted ergonomics and natural location on the edges of the fingers, which certainly facilitates learning letter children.

Near the machine is desktop sorter. Its mission - to sort out in pencil, select the "fit" and to separate defective. Defects are chipped at the end of the rod, roughness, burning wood, and the like. Above the table hangs a memo with the rules of marriage. Each standing on the table tray is put in 1440 pencils.

Sorted pencils on a special elevator to ascend to the next floor, where they will be painted.

Buy paint in dry form and diluted to the desired thickness in the laboratory paints. Painting itself is fast enough.

The device continually pushes the colored pencils on the conveyor. The length and speed of the conveyor belt are designed so that the pen drying out while it is moving.

Before reaching the opposite end of the conveyor, pencils fall into one of three receivers where they are sent back to the next coating.

On average, each pen is covered by three layers of paint and two coats of varnish - it all depends on the willingness of the customer. You can also paint the pencil in almost any color. The factory produces a set of six, twelve, eighteen and twenty-four colors. Some pencils only cover varnish.

After painting, pencils sent to the finishing department. At this point they acquire the final form in which reach the consumer. On the stamp is applied to pencils, eraser and put sharpened.

A method of applying a lot of punches, but the "Siberian pencil factory" This is done using different colors of foil. This method is called the incubation. The working part of the machine is heated, and the stamp is transferred through the foil on a pencil - so it will not peel, and dirty hands. Sam stamp can be anything, it is specially ordered from the engraver. Depending on the complexity, for its production it takes about five days.

On the part of the pencil, if necessary, wear an eraser.

The last operation - is sharpening. To sharpen pencils on emery paper placed over the drum and moving with great speed. This happens very quickly, in just a few seconds.

Besides sharpening machine can be configured to perform rolling - the back end processing of the pen at a slight angle. Now the pencils are ready for packaging, they are sent to the next room. There's pencils are collected in a set, put in a box and sent to the consumer.

The packaging for the right amount of pencils printed in Novosibirsk. It comes in a flat form, so make sure you give it volume. Then after picking machines, the required number of pencils laid out in a predetermined color. Special machine allows you to collect a set of twelve colors. At the end of pencils laid out on the cases a.

When asked whether the factory plans, following the example of Chinese enterprises to switch to the production of a pencil from cheaper wood or plastic Anatoly Lunin recognized:

- I was thinking to try to make an economical pencil from low-grade aspen, but it is another technology, and let alone the Chinese are engaged. I'm more interested in the topic of increasing the useful output by improving the quality of processing of wood. And from the point of view of ecology, to produce anything better from renewable raw materials. Plastic pencil never rot and wood for several years completely decompose.

One can only wish that in the age of global computerization was a place simple wooden pencils.

--img40--

Source: obzor.westsib.ru