2775

Report from the best Latvian sprat production plant

Salacgriva offseason - in mid-June, just in time for our arrival, the company is finalizing the last few days. Brīvais Vilnis is about to be closed for long summer vacation. On the line are the last batch of fish. Process Controller Henry Babris leads us to the pier. Just Sea plays with the sun, and now loaded the rain. In the Baltic unstable - it happens here a heavy storm.

We are at the point of reference of a large canning way. Independently fish caught in the enterprise is not to buy from private owners. Fresh pilchards and herring deliver small fishing companies - fish live in local waters. Herring, mackerel, Sardinella and other "Atlantic" is obtained in frozen containers from abroad.

- Classic sprats made of sprats - immediately says Henry Babris. - But you can do from the small Baltic herring. The taste, however, they can be easily distinguished. Sprat taste differs from winter and summer sprat, fresh and frozen. Top - winter, from fresh catch.

On the "input" check all raw materials, take samples for laboratory. If the fish is fresh, the part goes into the shop on line sorting, and some frozen at minus 18 degrees. So it can be stored up to 9 months.

Sprat in the cells are thawed thawing - the temperature rises to 10 degrees plus.

The next step - and one of the most important - sorting. For sprat taken almost perfect fish. Whole, not battered, without damage. Suitable carcass size 11-13 inches.

Our guide makes a small digression. What is it all about - Riga sprats? In the mid-1990s in Latvia was established association of the same name, which brings together the largest fish processing companies of the country. The Association is the holder of the collective trademark "Riga Sprats in oil" and controls the quality of products. Requirements to him very hard. That is why the sorting is carried out entirely by hand - not to hurt the fish. There have been attempts to automate the process. But the efficiency of female hands was higher than that of the mechanical "robot».

Do workers have no time to look around and pose for pictures. Before them in the pan fish. A lot of fish. Master gives the command: "stringing small!" And they strung, putting a major in a separate box, as the smoke of different sizes simultaneously pilchards impossible. Soon master shout: "stringing big!" And so during the entire shift.

This is a difficult process. We are told that at any time a worker can stand and rest. Each is given a certain amount of contradiction. Fill in all - you will receive a token. The more tokens a day, the more salary. One who gives a lot of marriage may depremirovat. Sorting of raw materials for the production of elite plant - "Royal sprats" - are only the most experienced.

Skewered fish ready for smoking. Though not quite. Employees leave it on time to the glass moisture. Pilchards need to push that little fish from sticking together. When smoking it can lead to marriage.

Prepare the mixture for smoking - the smoke we will alder.

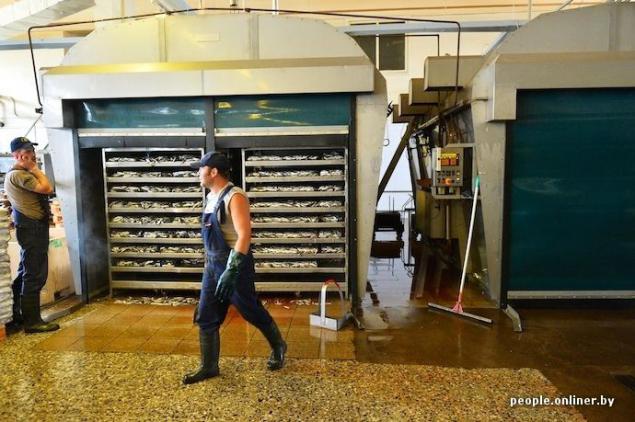

Fish moves through the tunnels, where the various stages of smoking - about 15 degrees. It prepares the smoke steam is there. Curer regulates the flow of the mixture and the temperature in each zone. Monitors the degree of moisture. All workers with experience, mostly men. On their ability largely depends on the quality of the product that the buyer will acquire the store.

Before us is almost ready semis - smoked sprats characteristic golden color. Next fishes cut off the head, and sent to the carcass chilling. Head sold as recyclables.

Laying. Already during smoking wizard will determine what raw materials go to the Riga sprats, and what to simple. Or, for example, on the pate. Or maybe on pilchards in tomato sauce.

Each worker laying there scales. Sprat trying to fit beautifully skaters. To look aesthetically pleasing and presentable. Henry says:

- Open the jar, you can determine the manufacturer faked or not. If the fish is laid bellies up - a good sign. After all, if the raw material of poor quality or badly smoked, it is usually put back up. Bellies opened the first "hack" need to hide it. Importantly, there is in the first row of the damage. By our standards, they should not be.

And here the work is standardized - the number of cans.

- We have people who are working families - continues the source. - In the surrounding area there are practically no places where they can get middle-aged women. But in this situation, it is impossible to dial another shift workers. We, however, do not need the volume and quality.

Right spell some! In general, it seems to us, is otherworldly idealism - to lay the fish in the bank at a price of € 1, as if she were not golden, and gold. Especially under the tin cover all the effort of workers Salacgrīva potential buyers do not see it. At the factory realized this long ago. Compete with producers who throw in their banks battered precooked and dumping, say workers, it became impossible:

- Both in Russia and in the Ukraine and in Belarus try to make sprats from the damaged fish. As a result, consumer confidence in the product disappears. We went the other way.

Several years ago, there have implemented know-how - the banks with a transparent lid. Now the buyer sees exactly what he wants to sell. No more canned secrets. For "fair" package, albeit more expensive, consider here - canning future.

Different variations of sardines in tomato sauce. Tomato sauce is cooked in the enterprise itself, not using cheap powder substitutes. It turns out expensive. The cost price of a quality thick sauce - almost like a fish net cost.

- Save makes no sense. A curious thing: in Ukraine, our sprats in tomato sauce five times more local, but buy it perfectly. So people are willing to pay for quality - says Henry.

And we return to the sprats. Banks have already rolled up. They are washed, and then sent to the autoclaves for sterilization.

- No preservatives and antioxidants we do not add: there is no need. The product is completely sterilized, airtight jars. For each species has its own formula for sterilization of canned food. Thus, and up to 2-3-year shelf life.

Most of the equipment at the plant - Soviet era. Does not look very presentable, perfume does not smell. Equipment regularly mend, kept in good condition. Something bought for the European money. Strange thing: to modernize the look a bit different here than in Belarus. It turns out that the meaning is not in the new lines for the millions who are so nice to get into the account. Essence cram us in ideas and innovations - that's the same as in a blister pack.

- No matter how hard the same Kaliningrad, get the same high quality, they can not. Even at the new ultramodern equipment. Our curer experience - decades, and the top bosses do not cry, Give us the cost price - that's the view of Henry.

After sterilization, the banks again washed, dried and sent to the ferry pasting label. All can be shipped to the warehouse and send with a convenient opportunity to counter.

- In fact, the production technology in the Soviet times have changed little - says comptroller. - Is it only looked no where to save and where to steal. Now all the company's employees are well aware, will survive only through quality work. Outperformed - rot. No one will not help us.

Chairman of the Board Brīvais Vilnis Babris Arnold tells how the company manages to stay afloat.

- Was a difficult period. The banker gave money - starting capital. Negotiations with the team, chose a niche - to provide the highest quality on the market. And start working. Optimized to the maximum that could. In 2004, all chasing the price, and we decided to take the theme of exclusive, expensive segment. Began to produce "The Royal sprats." First started working with plastic. The detachable lid - also our invention. And many of these innovations.

In 2006, whether from the sea foam, or from secret cavities appeared Baltic water. His name Onishchenko, and he liked to find things that are hidden. In the Latvian sprats chief supervisor of the Russian Federation found benzopyrene - and the delivery of products to the Russian market prohibited.

Here, in this very room, showing us Babris Arnold, he put in place Onishchenko.

- Right after I ordered sounded accusations of Russian products and sent to the control in Germany. Was a terrible picture. Called the TV people, show: Look, where this most benzopyrene. Show Onishchenko to know. For several years in the delivery of RF ceased. But the plant is built on a model that at any moment we can without loss of "close" any country, go to another market. Now signed a contract with China - the minimum monthly party in the amount of not less than € 250 thousand. And without Russia not perish.

The traditional weekly tasting: managers and staff assess the quality of output. Besides sprat is a few dozen different kinds of canned

And that Belarus? At one time the company Brivais Vilnis supplied the RB about 12% of total production. After the collapse of the 2011 figures are not as pleasant.

- I have to be sure that the return of the product obtained without puffs money. Everything is simple. The level of profitability on preserves - 5% of the turnover. Only! We can not afford to risk - says Arnold Babris.

Plenty natrudivshis, Salacgriva resting. Fish factory - forming enterprise. Here 450 people employed. Lie Plant - immediately zagnetsya town. And so he did not zhiruet. Because of the abundance of manual labor-third the cost of a can - wage workers. Good handler gets on your hands, on average € 300. And this is the biggest salary in the industry. People want more. But while this is the ceiling. Nobody said that the market easily.

Here, of course, there is an important detail. Whatever the storm Whatever happens, occupy a niche plant is unlikely to lose position. There have learned to live within our means and count every penny. Without any public podpitok - somehow, but survive.

Source: people.onliner.by

The most astounding rules and prohibitions in the US

Yevgeny Leonov: The tragic comedian, comic tragedian ..