894

Leica inside. Like going to the camera

Leica M8 early stage of assembly. Many mechanical parts in place, but the viewfinder, lens, and there are no electronic components.

Source: Magazine Wired via fotografov net

Text: Matthew Shechmeister

Photo: Jock Fistick

Translation, adaptation and addition Vlad Kovalenko.

23 photos

Leica Factory is located in the small town of Solms (Solms), in western Germany. Many employees working in the company for over 20 years. Stefan Daniels (Stefan Daniels), who currently heads the factory in Solms, is one of them. He met with a watering can in 15 years and received a technical degree thanks to the work of the company.

The technician inserts a CCD. CCD to Leica manufactured by Kodak. The surface is covered with a plurality of microlenses matrix aimed at altering the incoming light rays so that they fall on the sensor uniformly by one microlens opposite each pixel. Each lens has a thickness of a human hair.

Once inserted into the CCD, a worker assembles lightweight magnesium housing the camera. The body conceals the upper and lower brass plate designed to protect the internal components.

No photograph is an exact copy of the original object. But philosophical objections do not stop photographers to achieve an ideal image, which requires skill and knowledge of the subject. The right tool can make all the difference.

For many generations of photographers working in the center of events, Leica camera was the tool.

Alberto Korda (Alberto Korda) and his portrait of Che Guevara; Vietnamese photographed weeping poop Nick (Nick Ut), how she fled after the attack with napalm; photo sailor kissing a nurse in Times Square shot Eyzenshtedtot Alfred (Alfred Eisenstaedt) - all were made with the help of Leica. In fact, the company can honestly claim that it was she who gave the opportunity to be born this photo. The cameras were compact, unobtrusive and highly reliable under daily wear and tear that can produce high-quality images without any special training.

Software is installed, and the camera can be operated at a basic level, allows technicians to conduct thorough testing on each individual cell. By the end of the test, Leica M8 will consist of 1800 individual parts.

At the turn of the 20th century, an engineer and amateur photographer Oskar Barnack (Oskar Barnack) worked for the company Leitz, a manufacturer of optical instruments, based in the German town of Wetzlar. Barnak studied the mountains nearby, but to document the research had to lug a camera and a few bags of heavy glass plates (the prototype of the modern film). Then he developed a handheld device that used a modified film - the result was the first 35mm camera.

Employers Barnaka new product called «Leica», short for «Leitz camera». The original model, now known as the Ur-Leica, entered into production in 1925. Already in 1928, Rodchenko, Alexander (Alexander Rodchenko), the master of Soviet propaganda, and Andre Kertesz (Andre Kertesz), the father of a photo essay, both acquired Lake. Henri Cartier-Bresson (Henri Cartier-Bresson), whose work the Leica popularized street photography and improvised style of the postwar photojournalism.

Workers are exposed every camera standard system checks: checking shutter rangefinder focusing system, as well as sensitivity and coordination of work of the CCD.

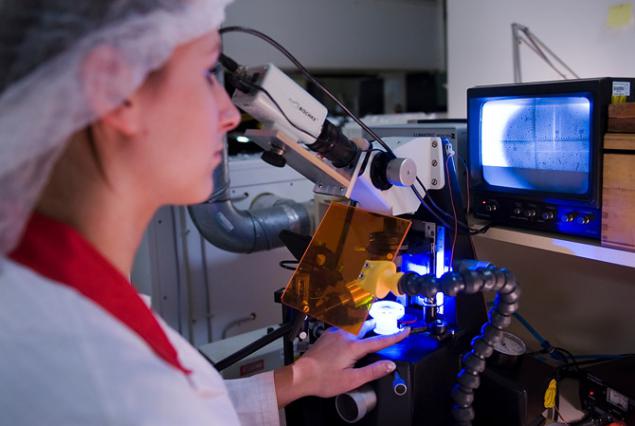

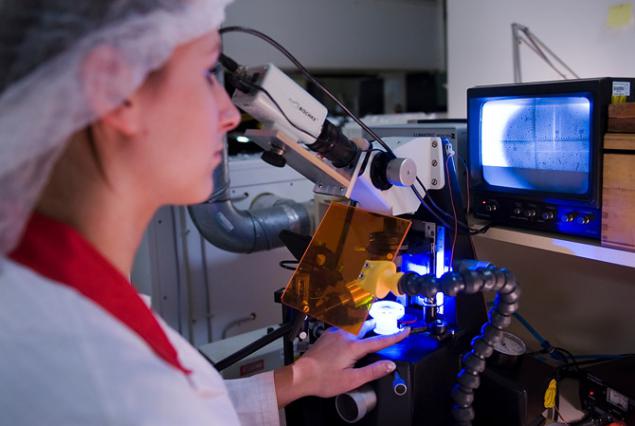

At this stage, quality control, technology determines the accuracy of the camera's viewfinder. Each finder should be adjusted after installation, and Leica requires that the image in the center, visible through the viewfinder is different from the real not more than 0 0001 mm.

The workplace is set to build analog cameras Leica. But as the M8 and M9 are virtually identical to the composition of the items, they are going along with analog cameras. The entire process comprises 35 people, and takes about eight hours at the camera. Tiny dust particles inside the camera can cause serious problems, so Leica factory established rules for access to the workplace. Employees are low-static shoes, to avoid attraction of dust. Dust-absorbing flooring is at the entrances to the assembly plant. All paper products on the conveyor are treated in plastic bags to make sure that even small fibers that can break out of the pages will not be able to get into the room. And employees have to wear special hats.

Shells M7, ready for assembly at any time.

The small size of the camera shutter and quiet allowed Cartier-Bresson and his contemporaries photographed in public without drawing attention to themselves. In addition to mobility, Leica also boasts excellent quality lenses. The combination of precision and portability opened the door to new realism, or as Cartier-Bresson put it, Leica «literally is an optical extension of my eyes."

As Christian Ehrhardt (Christian Erhardt), Deputy Director of Marketing - "The only reason our cameras so carefully made that almost every employee is a user of our products. It's in our blood ».

By order Leica M7 camera can cover ostrich skin. Model «a la carte« allows the user to choose the cosmetic parts of the camera, such as color trim, buttons and leather case. Customers can also customize the size of the viewfinder, and the location of its lines.

The technician makes minor adjustments to the rangefinder cameras to ensure its synchronous operation with the lens.

The bulk of the adjustment is made Leica camera, with the participation of the human eye, rather than computers or sophisticated optical instruments. Here, the technician checks and adjusts the mechanism of manual focus, using the principle of inter-frame strip. The M-series cameras do not have autofocus. Leica is very proud of this line of cameras.

In the photo inside view camera Leica S2. This large-format camera, has 37, 5-megapixel CCD (30 x 45 mm) to 56 per cent more than 24 x 36 mm on a 35 mm frame. Its price is 22,000 $.

Leica M-series launched in 1954 and occupies a special place in the hearts of many famous photographers. Jim Marshall (Jim Marshall) used the camera Leica M-series for shooting Jimi Hendrix (Jimi Hendrix) at the Pop Festival in Monterey and the Beatles (The Beatles) on their last concert.

"I use only Lake for 50 years - says Marshall - From a technical point of view, lens sharpness, better than anyone else."

Haguenauer Ralph (Ralph Hagenauer), head of the Department for the dissemination of the company's products Leica, considering the range of cameras in the lobby of the central office.

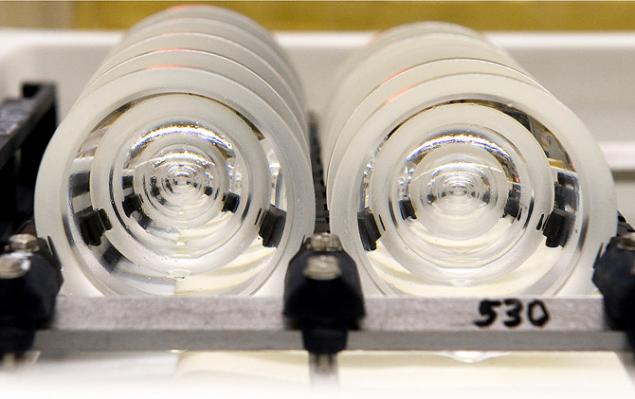

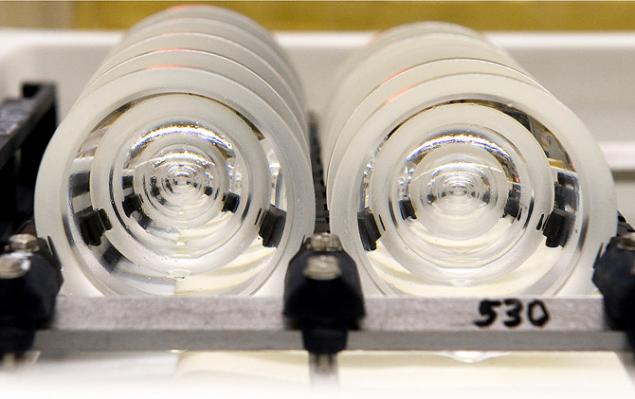

They may look like giant candy cough, but these goals raw glass for grinding and polishing of the lens elements for Leica 21mm f / 1.4. The company buys from the largest glass manufacturers around the world, depending on the optical purity, availability and prices.

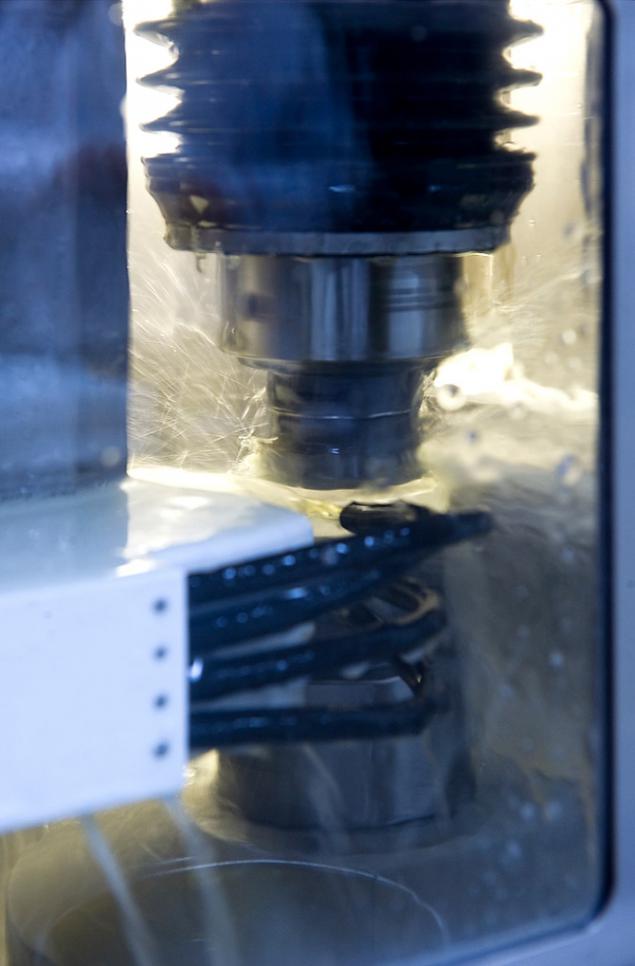

A significant part of the production equipment at the Solms factory made to order, according to the specifications of Leica, and often uses its own processes, which the company keeps a secret.

Glass washer during grinding, which eventually will become the elements of the lens Leica 21mm f / 1.4

Working watching polishing lenses, while the lens-manufacturing process.

Leica lenses are polished with a tolerance of about 1/2, 000 millimeters, about a thousand times thinner than a human hair.

Backview pre grinding and polishing. Then the inspector will determine which of them are suitable for further processing.

The computer displays a graphical representation of the light passing through the lens. He checks on all sides by light transmission and determines whether the lens surface more polished.

Each lens 43 has to coatings, depending on the model of the lens. Glass is placed in an oven where the coating material is applied in aerosol form, and then a strong liking to glass fibers using a patented process. Each layer is designed to improve image quality and produces a color correction, distortion and other inaccuracies.

"Each lens, each piece of glass is unique, we just have to make sure that the end result is always of high quality," - says Ehrhardt.

Finished lenses designed for the lens Leica Noctilux-M 50mm f / 0.95 ASPH. The company claims that this is the bystryya aspherical lens in the world. Priced at $ 11,000 for the lens, this tray is more than 100.000 $

"I would love to came back - said Komenich. - But now it is more business. 20 years ago we had a camera, and the camera is now computers. Of the minuses, I note that the shelf life of digital cameras is much shorter shelf life of the film, and they are inferior in terms of reliability ».

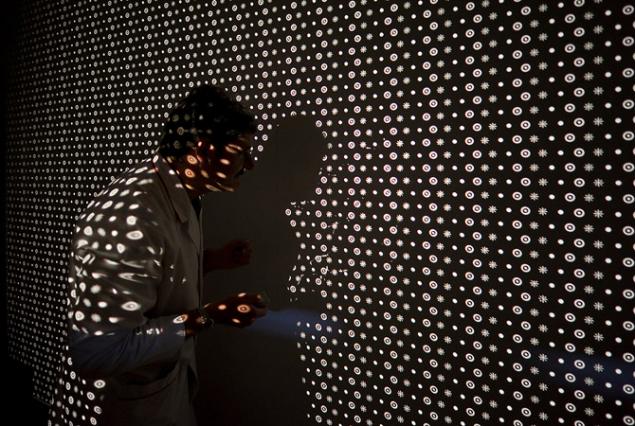

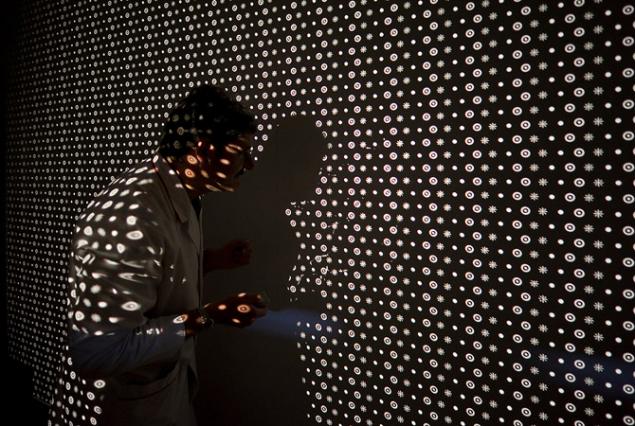

In one of the final stages of quality control technician projects the image through the lens of a homogeneous sample of the wall. Then he makes a visual inspection to make sure that the image is quite sharp.

Tray finished lens Summilux Leica M-21mm F / 1.4.

Source:

Source: Magazine Wired via fotografov net

Text: Matthew Shechmeister

Photo: Jock Fistick

Translation, adaptation and addition Vlad Kovalenko.

23 photos

Leica Factory is located in the small town of Solms (Solms), in western Germany. Many employees working in the company for over 20 years. Stefan Daniels (Stefan Daniels), who currently heads the factory in Solms, is one of them. He met with a watering can in 15 years and received a technical degree thanks to the work of the company.

The technician inserts a CCD. CCD to Leica manufactured by Kodak. The surface is covered with a plurality of microlenses matrix aimed at altering the incoming light rays so that they fall on the sensor uniformly by one microlens opposite each pixel. Each lens has a thickness of a human hair.

Once inserted into the CCD, a worker assembles lightweight magnesium housing the camera. The body conceals the upper and lower brass plate designed to protect the internal components.

No photograph is an exact copy of the original object. But philosophical objections do not stop photographers to achieve an ideal image, which requires skill and knowledge of the subject. The right tool can make all the difference.

For many generations of photographers working in the center of events, Leica camera was the tool.

Alberto Korda (Alberto Korda) and his portrait of Che Guevara; Vietnamese photographed weeping poop Nick (Nick Ut), how she fled after the attack with napalm; photo sailor kissing a nurse in Times Square shot Eyzenshtedtot Alfred (Alfred Eisenstaedt) - all were made with the help of Leica. In fact, the company can honestly claim that it was she who gave the opportunity to be born this photo. The cameras were compact, unobtrusive and highly reliable under daily wear and tear that can produce high-quality images without any special training.

Software is installed, and the camera can be operated at a basic level, allows technicians to conduct thorough testing on each individual cell. By the end of the test, Leica M8 will consist of 1800 individual parts.

At the turn of the 20th century, an engineer and amateur photographer Oskar Barnack (Oskar Barnack) worked for the company Leitz, a manufacturer of optical instruments, based in the German town of Wetzlar. Barnak studied the mountains nearby, but to document the research had to lug a camera and a few bags of heavy glass plates (the prototype of the modern film). Then he developed a handheld device that used a modified film - the result was the first 35mm camera.

Employers Barnaka new product called «Leica», short for «Leitz camera». The original model, now known as the Ur-Leica, entered into production in 1925. Already in 1928, Rodchenko, Alexander (Alexander Rodchenko), the master of Soviet propaganda, and Andre Kertesz (Andre Kertesz), the father of a photo essay, both acquired Lake. Henri Cartier-Bresson (Henri Cartier-Bresson), whose work the Leica popularized street photography and improvised style of the postwar photojournalism.

Workers are exposed every camera standard system checks: checking shutter rangefinder focusing system, as well as sensitivity and coordination of work of the CCD.

At this stage, quality control, technology determines the accuracy of the camera's viewfinder. Each finder should be adjusted after installation, and Leica requires that the image in the center, visible through the viewfinder is different from the real not more than 0 0001 mm.

The workplace is set to build analog cameras Leica. But as the M8 and M9 are virtually identical to the composition of the items, they are going along with analog cameras. The entire process comprises 35 people, and takes about eight hours at the camera. Tiny dust particles inside the camera can cause serious problems, so Leica factory established rules for access to the workplace. Employees are low-static shoes, to avoid attraction of dust. Dust-absorbing flooring is at the entrances to the assembly plant. All paper products on the conveyor are treated in plastic bags to make sure that even small fibers that can break out of the pages will not be able to get into the room. And employees have to wear special hats.

Shells M7, ready for assembly at any time.

The small size of the camera shutter and quiet allowed Cartier-Bresson and his contemporaries photographed in public without drawing attention to themselves. In addition to mobility, Leica also boasts excellent quality lenses. The combination of precision and portability opened the door to new realism, or as Cartier-Bresson put it, Leica «literally is an optical extension of my eyes."

As Christian Ehrhardt (Christian Erhardt), Deputy Director of Marketing - "The only reason our cameras so carefully made that almost every employee is a user of our products. It's in our blood ».

By order Leica M7 camera can cover ostrich skin. Model «a la carte« allows the user to choose the cosmetic parts of the camera, such as color trim, buttons and leather case. Customers can also customize the size of the viewfinder, and the location of its lines.

The technician makes minor adjustments to the rangefinder cameras to ensure its synchronous operation with the lens.

The bulk of the adjustment is made Leica camera, with the participation of the human eye, rather than computers or sophisticated optical instruments. Here, the technician checks and adjusts the mechanism of manual focus, using the principle of inter-frame strip. The M-series cameras do not have autofocus. Leica is very proud of this line of cameras.

In the photo inside view camera Leica S2. This large-format camera, has 37, 5-megapixel CCD (30 x 45 mm) to 56 per cent more than 24 x 36 mm on a 35 mm frame. Its price is 22,000 $.

Leica M-series launched in 1954 and occupies a special place in the hearts of many famous photographers. Jim Marshall (Jim Marshall) used the camera Leica M-series for shooting Jimi Hendrix (Jimi Hendrix) at the Pop Festival in Monterey and the Beatles (The Beatles) on their last concert.

"I use only Lake for 50 years - says Marshall - From a technical point of view, lens sharpness, better than anyone else."

Haguenauer Ralph (Ralph Hagenauer), head of the Department for the dissemination of the company's products Leica, considering the range of cameras in the lobby of the central office.

They may look like giant candy cough, but these goals raw glass for grinding and polishing of the lens elements for Leica 21mm f / 1.4. The company buys from the largest glass manufacturers around the world, depending on the optical purity, availability and prices.

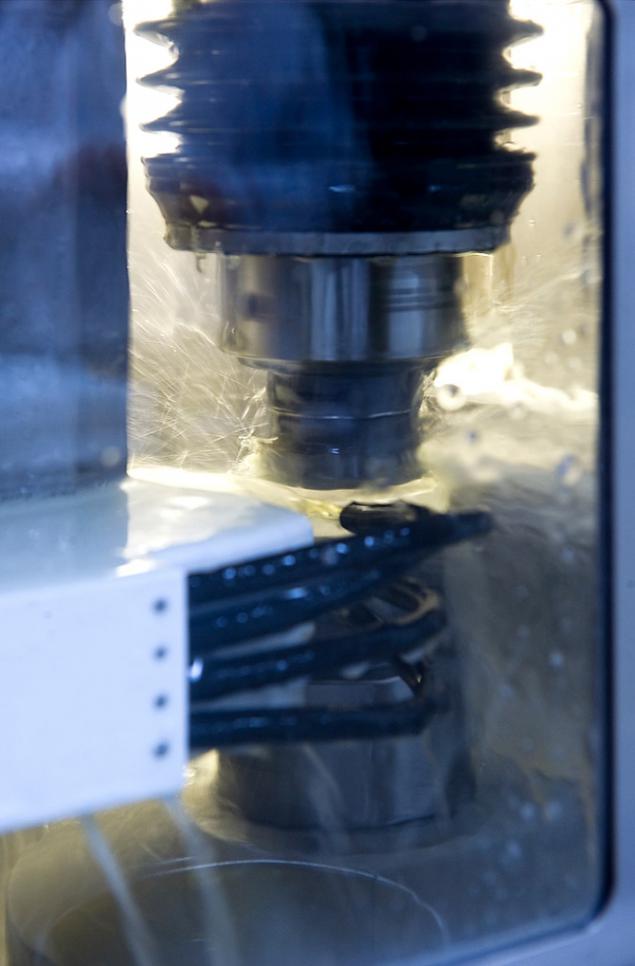

A significant part of the production equipment at the Solms factory made to order, according to the specifications of Leica, and often uses its own processes, which the company keeps a secret.

Glass washer during grinding, which eventually will become the elements of the lens Leica 21mm f / 1.4

Working watching polishing lenses, while the lens-manufacturing process.

Leica lenses are polished with a tolerance of about 1/2, 000 millimeters, about a thousand times thinner than a human hair.

Backview pre grinding and polishing. Then the inspector will determine which of them are suitable for further processing.

The computer displays a graphical representation of the light passing through the lens. He checks on all sides by light transmission and determines whether the lens surface more polished.

Each lens 43 has to coatings, depending on the model of the lens. Glass is placed in an oven where the coating material is applied in aerosol form, and then a strong liking to glass fibers using a patented process. Each layer is designed to improve image quality and produces a color correction, distortion and other inaccuracies.

"Each lens, each piece of glass is unique, we just have to make sure that the end result is always of high quality," - says Ehrhardt.

Finished lenses designed for the lens Leica Noctilux-M 50mm f / 0.95 ASPH. The company claims that this is the bystryya aspherical lens in the world. Priced at $ 11,000 for the lens, this tray is more than 100.000 $

"I would love to came back - said Komenich. - But now it is more business. 20 years ago we had a camera, and the camera is now computers. Of the minuses, I note that the shelf life of digital cameras is much shorter shelf life of the film, and they are inferior in terms of reliability ».

In one of the final stages of quality control technician projects the image through the lens of a homogeneous sample of the wall. Then he makes a visual inspection to make sure that the image is quite sharp.

Tray finished lens Summilux Leica M-21mm F / 1.4.

Source: