783

Production of KIA cars at the plant in Slovakia

The factory is located in Slovakia near the town of Zilina. Construction of the plant began in October 2004 and was completed in December 2005. In June 2006, the plant operated in test mode. The first car came down the conveyor 7 December 2006, it was the Kia cee'd. When I was there (last December), in the production of the model it was four and now five - Add Hyundai ix35. Let's look at a modern car factory.

He writes: russos

45 photos + text

01. Your future Kia car arrives at the plant here in the form of reels of sheet steel.

02. The bale shop dvadtsatitonnye steel rolls are transformed into body parts for future cars. This process is divided into several stages. The first phase includes the preparation of "blanks" for further details of the molding. To do this, cut out from a sheet of steel contour, technological holes and projections of future parts.

03. A vehicle in the shop.

04. Next, the product is formed on the metal racks and using elektrorohli gets into the press machine.

05. Time spent on the production of one part of the order of 20 seconds.

06. Replacement of the molds occurs every 30 minutes.

07. Detail after stamping.

08.

09. Next, the molded parts fall on the shelves stacked and waiting for their turn in the welding shop.

10. If the press shop has a staff that is fully automated warehouse.

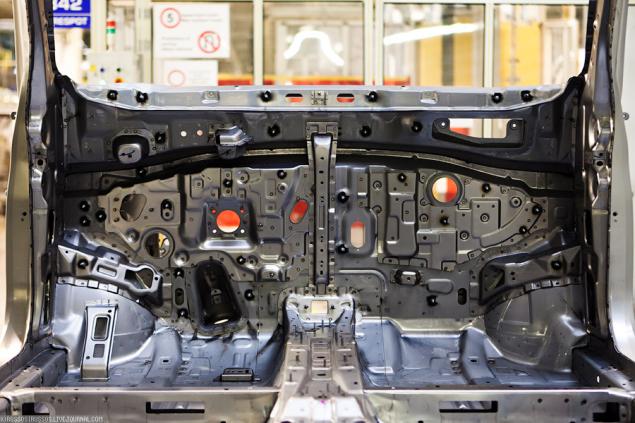

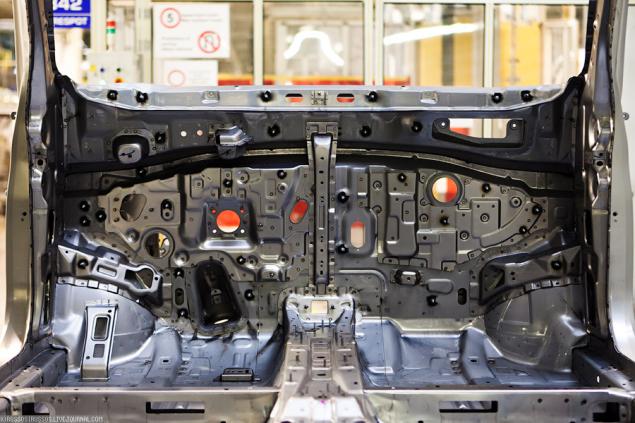

11. After the warehouse body parts fall into the welding shop, which is completely robotized.

12. The workshop is set about 400 robots.

13. The entire process occurs without human intervention, which only controls it.

14. Affected coordinated work of all these mechanisms.

15. The robot methodically picks from the cassette body parts and sends them on to the weld.

16. Suddenly, out of the process "fell out" door, which the employee wrote the date and something else. Then she ducked back. Marriage?

17. And all the robots continued to weld the body.

18.

19.

20.

21. People in this workshop are present only in the area quality assurance (Quality audit area). In the event of deviations in the standard production item or the item is sent back for revision. Quality issues paid a lot of attention - 10% of employees working in this area, both at different stages of production, and the final checks.

22. In such a glass galleries future machines move between shops. Due to the special regime of the paint shop did not show it to us, and we immediately went to the assembly line.

23. Start the assembly line. 2/3 of the operations performed by people here.

24. Suddenly, right-hand drive Siida.

25. In a change to the assembly employs about 500 people.

26. What surprised me - is the lack of sullen or discontented people.

27. What surprised me even more - so that's what on the line going immediately on all models. In order to distinguish them from each other, as well as to protect the LCP, they are put colored protective panel, wherein each color corresponds to a particular model.

28. Even if the work on the assembly line and reminds biorobots, then it's probably happy biorobots

29.

30.

31. And even beautiful.

32. But the small patches of robotics - set collected dashboard.

33. Almost finished car.

34. To complete the assembly need to put the engine and suspension in place.

35. It is all here comes from somewhere on the side of the special trolley.

36. Movement and synchronized ...

37. ... Whack, marriage (as they call) was held.

38. Bitter

39. After that - finish line, where something cool and attached.

40. At the output - quality control.

41. Next, the machine is equipped with almost finished mirrors, windows, seats and other necessary things.

42. Time - and the windshield in place.

43. At different stages of the height of the machine is governed by a lift, which is located under the platform.

44. The process of quality control and ends with filling liquids, after which the machine goes on trial circle.

45. The ring of a few kilometers. On this route simulated various options for covering roads, turns, climbs and descents. Test pilot can prevent the vehicle in the sale, if, in his opinion, in the design of the car has any weaknesses, or in his work there is a deviation (jitter plating is not enough responsive steering, poor suspension, etc.). If deficiencies are found, the car gets parked car ready and waiting for their shipment.

Source:

He writes: russos

45 photos + text

01. Your future Kia car arrives at the plant here in the form of reels of sheet steel.

02. The bale shop dvadtsatitonnye steel rolls are transformed into body parts for future cars. This process is divided into several stages. The first phase includes the preparation of "blanks" for further details of the molding. To do this, cut out from a sheet of steel contour, technological holes and projections of future parts.

03. A vehicle in the shop.

04. Next, the product is formed on the metal racks and using elektrorohli gets into the press machine.

05. Time spent on the production of one part of the order of 20 seconds.

06. Replacement of the molds occurs every 30 minutes.

07. Detail after stamping.

08.

09. Next, the molded parts fall on the shelves stacked and waiting for their turn in the welding shop.

10. If the press shop has a staff that is fully automated warehouse.

11. After the warehouse body parts fall into the welding shop, which is completely robotized.

12. The workshop is set about 400 robots.

13. The entire process occurs without human intervention, which only controls it.

14. Affected coordinated work of all these mechanisms.

15. The robot methodically picks from the cassette body parts and sends them on to the weld.

16. Suddenly, out of the process "fell out" door, which the employee wrote the date and something else. Then she ducked back. Marriage?

17. And all the robots continued to weld the body.

18.

19.

20.

21. People in this workshop are present only in the area quality assurance (Quality audit area). In the event of deviations in the standard production item or the item is sent back for revision. Quality issues paid a lot of attention - 10% of employees working in this area, both at different stages of production, and the final checks.

22. In such a glass galleries future machines move between shops. Due to the special regime of the paint shop did not show it to us, and we immediately went to the assembly line.

23. Start the assembly line. 2/3 of the operations performed by people here.

24. Suddenly, right-hand drive Siida.

25. In a change to the assembly employs about 500 people.

26. What surprised me - is the lack of sullen or discontented people.

27. What surprised me even more - so that's what on the line going immediately on all models. In order to distinguish them from each other, as well as to protect the LCP, they are put colored protective panel, wherein each color corresponds to a particular model.

28. Even if the work on the assembly line and reminds biorobots, then it's probably happy biorobots

29.

30.

31. And even beautiful.

32. But the small patches of robotics - set collected dashboard.

33. Almost finished car.

34. To complete the assembly need to put the engine and suspension in place.

35. It is all here comes from somewhere on the side of the special trolley.

36. Movement and synchronized ...

37. ... Whack, marriage (as they call) was held.

38. Bitter

39. After that - finish line, where something cool and attached.

40. At the output - quality control.

41. Next, the machine is equipped with almost finished mirrors, windows, seats and other necessary things.

42. Time - and the windshield in place.

43. At different stages of the height of the machine is governed by a lift, which is located under the platform.

44. The process of quality control and ends with filling liquids, after which the machine goes on trial circle.

45. The ring of a few kilometers. On this route simulated various options for covering roads, turns, climbs and descents. Test pilot can prevent the vehicle in the sale, if, in his opinion, in the design of the car has any weaknesses, or in his work there is a deviation (jitter plating is not enough responsive steering, poor suspension, etc.). If deficiencies are found, the car gets parked car ready and waiting for their shipment.

Source: