819

Dumplings: how to make the "A to Z"

Blogger Santa Makhorka recently visited the plant where the dumplings are made and shared pictures of the whole process

37 photos

2. Be sure to wash their hands before entering the production halls.

3. The first point of our route - the room agrofleksov bectarnogo for storage of flour. It contains flour for the whole production, it automatically screened. In line modeling ravioli Dominioni meal served by pipelines to other areas in special containers.

4. Line sculpting Dominioni produces up to 25 tons per day. Via line to line served flour, which is mixed into the dough automata. The program includes a variety of recipes are included automatic test, the operator monitors the ripening ratio of ingredients.

5. Automatic trolley gives the dough on all machines. The dough is rolled out in layers, cut blank, molded product (supplied filling machine and turns into a dough).

6. The operator of this line regularly reviews products in the fullness filling.

7. The final product of the tape sent to the chamber spiral quick freezing. The temperature in the chambers -30 -32.

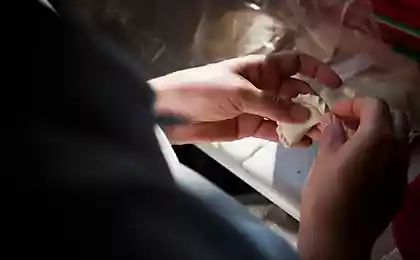

8. Line manual modeling ravioli produces about 10 tonnes per day. On this line blank obtained automatically lepschitsey appears to have carved out a circle of dough with filling. Task lepschitsy form dumpling manually prolepit joint and connect the ends.

9. Dumplings manual molding made from less dense dough and a juicy stuffing.

In this area special attention to sanitary standards.

10. After the freezer product carefully sorted, selected nekonditsiya appearance and compliant product is packed.

11.

12. The next phase of the line - mulitigolovochny feeder, which separates and dispenses products, they can be packaged immediately two types of products.

13. After packing the products formed in boxes on pallets and then quickly sent for temporary storage in refrigerators. In the finished product is in the form of zero temperature in minutes. This is done to preserve the appearance and quality.

14. Packing tape

15. The temperature of 13 C in the shops

16. The whole process from the refrigerator before packing

17. Immediately adjacent to make dumplings and meatballs

khinkali

18. The product comes in a freezer

19. Minced used in khinkali

20. cutlets.

21. Before loading the stuffing into the machine for the production of hamburgers.

22. packer

23. When the product is packaged, transported to its refrigeration and logistics terminal, which has a capacity of 600-700 tons, this volume is realized in less than 2 weeks.

24. The terminal constant temperature of minus 18 degrees. In the area of shipping there is a special entrances for refrigerated so as to maintain a low temperature. The close proximity of the terminal and the production site, a comfortable temperature for the frozen semi-finished products (products are also transported at a temperature of minus 18 ⁰S) allow to maintain the quality of products.

25. Warehouse on pallets 3200 \ place

For many, the most interesting will be how to make the stuffing for semifinished products? I, too, was the most interesting thing is this stage, but in fact nothing unusual I have not seen. Dumplings made of real meat. I asked a question about the soy plant - whether to add it? I was told that soy is added only in the beef, which comes in cheap dumplings. All those dumplings that cost more than 150 rubles are made of 100% of the stuffing.

Ie if soy is in the dumpling, the only cheap and for the sake of saving the consumer. Therefore, all those who complain that there is no stuffing dumplings, simply stingy to buy a normal product.

26.

27. In the area of beef carcasses deboned meat is cut. Raw materials are purchased mainly from local producers and from some of the European.

28. After separating the meat from the bones, it is sorted to the highest, the first and second grade. For each type of product used a variety of beef and pork.

29. Acceptance of meat raw materials occurs in the presence of the state veterinary service (by the Veterinary Inspectorate) and technology. If the meat does not comply with the required degree of fatness, it is returned. Raw meat stored at low temperatures in special chambers. Meat raw materials technology must be stored at least 24 hours. This is done for the "maturing" of meat during this period it gets a proper taste.

30.

31. briquettes purchased frozen bacon European manufacturers. This is done out of necessity, as the raw materials of local manufacturers is not enough. This fat, as well as all raw materials, is thoroughly laboratory.

32. Luke, who goes to ground beef.

33. The next step of preparing a minced - mixing the ingredients. The ground on blokoreze to 5 mm raw meat pour into mixers where it is mixed with onions and spices. After kneading mixers in minced ripens in a special clean room with a low temperature, which requires the formulation.

34. At the enterprise there is a quality of service which carries out quality control at all stages of production. This service includes quality control department, whose task is to monitor quality at every stage: from the entrance of raw materials to the finished product.

For the control of incoming raw materials "Siberian Gourmet" purchased unique equipment in the Urals - Body Fat Analyzer. The cost of this equipment 5 million rubles, origin Germany. Fat analyzer allows to determine the percentage of fat with high accuracy, eliminating the human factor. This point is important because the fat content of meat raw materials largely determines the taste of the finished product, which the company aims to standardize.

35. It is also a laboratory, where the laboratory tests of samples of raw materials and products at all stages of production. For maximum control revealed the stages of production, which are subject to change quality. At these stages occur sampling each batch of products for laboratory research.

36. All studies are recorded in a special electronic database.

37. Without the permission of the laboratory, raw materials and products in production is not used.

Source:

37 photos

2. Be sure to wash their hands before entering the production halls.

3. The first point of our route - the room agrofleksov bectarnogo for storage of flour. It contains flour for the whole production, it automatically screened. In line modeling ravioli Dominioni meal served by pipelines to other areas in special containers.

4. Line sculpting Dominioni produces up to 25 tons per day. Via line to line served flour, which is mixed into the dough automata. The program includes a variety of recipes are included automatic test, the operator monitors the ripening ratio of ingredients.

5. Automatic trolley gives the dough on all machines. The dough is rolled out in layers, cut blank, molded product (supplied filling machine and turns into a dough).

6. The operator of this line regularly reviews products in the fullness filling.

7. The final product of the tape sent to the chamber spiral quick freezing. The temperature in the chambers -30 -32.

8. Line manual modeling ravioli produces about 10 tonnes per day. On this line blank obtained automatically lepschitsey appears to have carved out a circle of dough with filling. Task lepschitsy form dumpling manually prolepit joint and connect the ends.

9. Dumplings manual molding made from less dense dough and a juicy stuffing.

In this area special attention to sanitary standards.

10. After the freezer product carefully sorted, selected nekonditsiya appearance and compliant product is packed.

11.

12. The next phase of the line - mulitigolovochny feeder, which separates and dispenses products, they can be packaged immediately two types of products.

13. After packing the products formed in boxes on pallets and then quickly sent for temporary storage in refrigerators. In the finished product is in the form of zero temperature in minutes. This is done to preserve the appearance and quality.

14. Packing tape

15. The temperature of 13 C in the shops

16. The whole process from the refrigerator before packing

17. Immediately adjacent to make dumplings and meatballs

khinkali

18. The product comes in a freezer

19. Minced used in khinkali

20. cutlets.

21. Before loading the stuffing into the machine for the production of hamburgers.

22. packer

23. When the product is packaged, transported to its refrigeration and logistics terminal, which has a capacity of 600-700 tons, this volume is realized in less than 2 weeks.

24. The terminal constant temperature of minus 18 degrees. In the area of shipping there is a special entrances for refrigerated so as to maintain a low temperature. The close proximity of the terminal and the production site, a comfortable temperature for the frozen semi-finished products (products are also transported at a temperature of minus 18 ⁰S) allow to maintain the quality of products.

25. Warehouse on pallets 3200 \ place

For many, the most interesting will be how to make the stuffing for semifinished products? I, too, was the most interesting thing is this stage, but in fact nothing unusual I have not seen. Dumplings made of real meat. I asked a question about the soy plant - whether to add it? I was told that soy is added only in the beef, which comes in cheap dumplings. All those dumplings that cost more than 150 rubles are made of 100% of the stuffing.

Ie if soy is in the dumpling, the only cheap and for the sake of saving the consumer. Therefore, all those who complain that there is no stuffing dumplings, simply stingy to buy a normal product.

26.

27. In the area of beef carcasses deboned meat is cut. Raw materials are purchased mainly from local producers and from some of the European.

28. After separating the meat from the bones, it is sorted to the highest, the first and second grade. For each type of product used a variety of beef and pork.

29. Acceptance of meat raw materials occurs in the presence of the state veterinary service (by the Veterinary Inspectorate) and technology. If the meat does not comply with the required degree of fatness, it is returned. Raw meat stored at low temperatures in special chambers. Meat raw materials technology must be stored at least 24 hours. This is done for the "maturing" of meat during this period it gets a proper taste.

30.

31. briquettes purchased frozen bacon European manufacturers. This is done out of necessity, as the raw materials of local manufacturers is not enough. This fat, as well as all raw materials, is thoroughly laboratory.

32. Luke, who goes to ground beef.

33. The next step of preparing a minced - mixing the ingredients. The ground on blokoreze to 5 mm raw meat pour into mixers where it is mixed with onions and spices. After kneading mixers in minced ripens in a special clean room with a low temperature, which requires the formulation.

34. At the enterprise there is a quality of service which carries out quality control at all stages of production. This service includes quality control department, whose task is to monitor quality at every stage: from the entrance of raw materials to the finished product.

For the control of incoming raw materials "Siberian Gourmet" purchased unique equipment in the Urals - Body Fat Analyzer. The cost of this equipment 5 million rubles, origin Germany. Fat analyzer allows to determine the percentage of fat with high accuracy, eliminating the human factor. This point is important because the fat content of meat raw materials largely determines the taste of the finished product, which the company aims to standardize.

35. It is also a laboratory, where the laboratory tests of samples of raw materials and products at all stages of production. For maximum control revealed the stages of production, which are subject to change quality. At these stages occur sampling each batch of products for laboratory research.

36. All studies are recorded in a special electronic database.

37. Without the permission of the laboratory, raw materials and products in production is not used.

Source: