1648

Famous Belarusian condensed milk

The famous delicacy called condensed milk, produced in the Vitebsk region, OJSC "Glubokoye Milk Factory».

Inside reigns complete sterility, which can be compared to the surgical department.

Visitors to this place wear special clothes, painted in the journal of the absence of infectious diseases and are sanitized.

Hands before a visit of the ICC should be washed thoroughly - and not just with liquid soap and water, but with a special antiseptic. Tap water basins fed automatically - there are infrared sensors. This is to ensure that employees and visitors not touch the taps, because if a man touches his dirty hands, and the other - clean, the effect of washing can be reduced to nothing.

But that's not all! At the entrance to the workshop is necessary to put both hands into a special machine, the turnstile, which pour in the palm of a little disinfectant to wipe them. Simultaneously, the shoe soles are handled specially disinfectant. Only after the triggering device to pass the green light, and allows the turnstile to go inside.

Of course, all employees of the company are regularly required medical examination. Hands come into contact directly with the milk and dairy products they do not have, the entire process is automated, but especially food production require full guarantees.

- We introduced the system in the enterprise security production of condensed milk cans of ISO 22000 and the system HASSP requirements which we are obliged to strictly observe, - says the Deputy Director for Operations Ludmila Duc. - First of all incoming milk is tested for antibiotics, as they can seriously affect human health. It uses a special device - HEAT-sensor. If so, for example, tetracycline or other drugs that are sometimes used by veterinarians to treat cows are found in milk - this party under any circumstances, we will not be accepted. If no antibiotics in milk, it undergoes a number of other laboratory tests that should determine the purity of the raw materials group, the percentage of fat mass fraction and, of course, organoleptic properties - in other words, taste, color and smell of the product. According to approved methods, milk before it is heated up to exactly 35 degrees to determine the odor and to the reflux temperature, followed by cooling to identify taste. And bring it to the plant suppliers are required only chilled to 10 degrees, because the bactericidal phase milk is stored for only two hours after its production. The veterinary certificate stating that it was obtained from healthy cows, as required.

According to Lyudmila Georgievna, raw material base of "Glubokoye Dairy Plant" is represented not only native to Glubokoe district enterprise, but also two more - Sharkovshchina and Braslavsky. And, although the suppliers of many years of cooperation with the ICC is more than proven, and the regions themselves - an environmentally clean, each party coming to the company's milk is subjected to strict incoming inspection, because it affects the safety of people.

Irina Vaskovich kindly agreed to conduct a tour of the same route, which passes for admission to the company each batch of raw materials: from the "arrival" in the tank farm, milk tanker sent to consumers in the form of packaged jars of delicious condensed milk.

- There are unloaded or, as we say, "Unrolling" milk tankers, - says Irina Konstantinova. - What you see now - is cleaning tanks after unloading. This means that the party arrived milk passed laboratory tests proved high-quality and has been accepted.

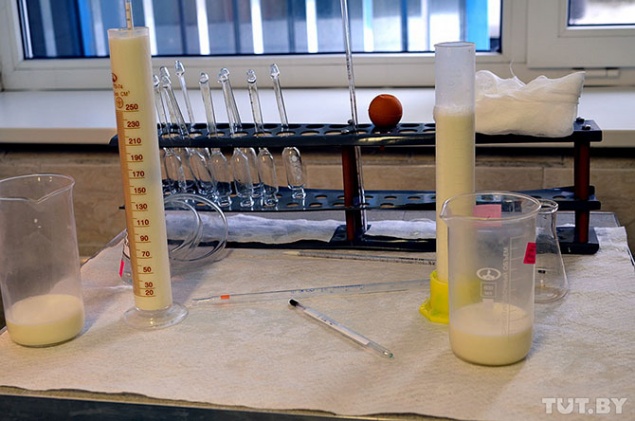

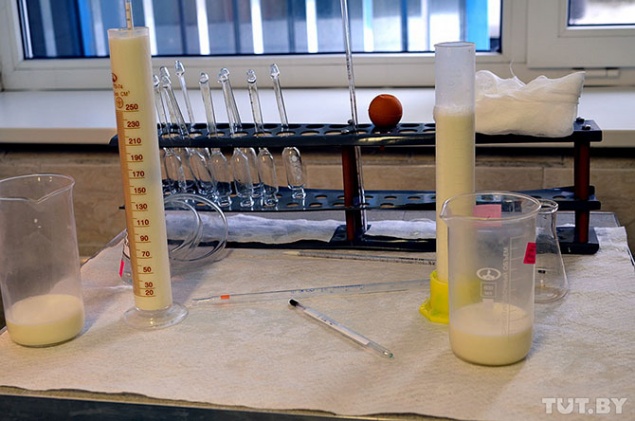

We looked at the receiving laboratory, which, for convenience, the process is close to the area of acceptance. It IWC experts vengeance conjured a cunning devices that can detect even a tiny percentage of content in the milk of antibiotics and other potentially dangerous substances for the consumer. Other devices determines the degree of purity of the product, its richness and variety, and organoleptic qualities were tested by laboratory is very simple: milk is considered closely, sniffed and, of course, tried. Today's raw materials had excellent taste and smell, as it should, the natural fresh milk, and very appetizing.

Meanwhile Newly milk is pumped into the storage compartment - of course, over the counter. In a special window that process could even watch.

Storage tanks for newly arrived materials is also close to the zone of acceptance, only slightly lower, and, of course, the milk they receive only after cooling. Interior storage is a bit like a submarine: the same set of tubes (but only from shining stainless steel food) and round hatches sealed.

How long to keep the milk can not be here, because the sooner the materials go to pasteurization - the better. This process has a great open past biologist Louis Pasteur, milk is heated to a temperature at which kills harmful bacteria and lactic acid, but the raw material is still not boiling, allowing it to retain all the palatability, useful microelements, vitamins and enzymes. Pasteurization is performed in a special section.

Of course, all the threads "rivers of milk" in the enterprise need to somehow manage. This successfully makes fully computerized system, the operator of which may directly from your workstation to manage the process - to open and close the valves manually, as a few decades ago, is no longer required.

But back to the pasteurization. After its passage milk may already be stored for much longer than non-treated using this technology. And store it in special containers, but also very long, because the raw materials are waiting on a plot thickening. However, the "fate" of different batches of milk can vary depending on its purpose: for example, the future of condensed milk without sugar will be immediately directed to evaporation and to the sweetened condensed milk is necessary to add sugar syrup.

And now - the main thing. This syrup - single supplement! Absolutely no preservatives, sweeteners, flavor enhancers and flavor, as well as consumer and other frightening supplements beginning with the letter "E" in the Deep is not used! It is not necessary: a guaranteed and thoroughly tested quality raw material, coupled with modern processing technology make it possible to produce the product is not tasteful flavor and tasteful natural milk from which it is, in fact, done.

Evaporation as pasteurization, made without bringing milk to a temperature of 100 degrees Celsius, which allows you to keep it the whole range of useful qualities of fresh product. However, boiling with removal of "excess" of water molecules in the vapor does not necessarily occur at the same temperature: every schoolboy knows that this is necessary to reduce the pressure. Therefore, the condensed milk is carried out in special devices by evaporation under vacuum. The whole process is carefully controlled - like devices, and visually. And when condensed milk reaches the position according to GOST parameters, it is placed in a special tank.

Meanwhile, from a nearby shop comes cans (still empty) and cover them. Special Machine up to a gram fills cans condensed milk, and then packaging immediately rolled. Filled cans fly out of the car almost like a machine gun at a rate of 300 cans per minute! The assurances of the ICC staff, modern production line of Italian company Zilli & Bellini, and is capable of delivering 450 cans of condensed milk in a minute, just so the speed is not currently used.

Next, the filled, but not yet "unnamed" with condensed milk cans are sent on a conveyor that delivers them directly to the machine for labeling. Like all processes in Glubokoye ICC, this is fully automated: intelligent equipment itself and the sticker, and obozhmet her, and scroll to the bank during this process.

The road continues with condensed milk cans, already decorated with the traditional blue and white label that goes to a machine that assembles them in the proper amount and placed in the box. Sami cardboard boxes are also made another machine. The filled and taped boxes arrive on the conveyor belt, which takes them to the warehouse of finished products, and from there they go directly to the stores. However, for a long time on this stock goods do not lie - condensed milk, as well as other products Glubokoye Dairy Judging by scurrying to and fro branded trucks, in great demand among consumers.

In conclusion, it showed a kind of "Hall of Fame" Glubokoye Dairy, indicated, however, relatively modest signboard "Our achievements". Awards received in the quality of products, already struggling to fit on the wall!

And there are among them not only the Belarusian diplomas of winners of various contests and exhibitions, quality certificates and various prizes, but also international. That, however, is not surprising: after all, Dairy products Glubokoe comes in a variety of countries. This clearly shows the map placed here. "Conquer" condensed milk Hlybokae state marked with special icons on it, and the markets of other Glubokoe milkmen have yet to conquer.

Source: tinepoverish.livejournal.com

Inside reigns complete sterility, which can be compared to the surgical department.

Visitors to this place wear special clothes, painted in the journal of the absence of infectious diseases and are sanitized.

Hands before a visit of the ICC should be washed thoroughly - and not just with liquid soap and water, but with a special antiseptic. Tap water basins fed automatically - there are infrared sensors. This is to ensure that employees and visitors not touch the taps, because if a man touches his dirty hands, and the other - clean, the effect of washing can be reduced to nothing.

But that's not all! At the entrance to the workshop is necessary to put both hands into a special machine, the turnstile, which pour in the palm of a little disinfectant to wipe them. Simultaneously, the shoe soles are handled specially disinfectant. Only after the triggering device to pass the green light, and allows the turnstile to go inside.

Of course, all employees of the company are regularly required medical examination. Hands come into contact directly with the milk and dairy products they do not have, the entire process is automated, but especially food production require full guarantees.

- We introduced the system in the enterprise security production of condensed milk cans of ISO 22000 and the system HASSP requirements which we are obliged to strictly observe, - says the Deputy Director for Operations Ludmila Duc. - First of all incoming milk is tested for antibiotics, as they can seriously affect human health. It uses a special device - HEAT-sensor. If so, for example, tetracycline or other drugs that are sometimes used by veterinarians to treat cows are found in milk - this party under any circumstances, we will not be accepted. If no antibiotics in milk, it undergoes a number of other laboratory tests that should determine the purity of the raw materials group, the percentage of fat mass fraction and, of course, organoleptic properties - in other words, taste, color and smell of the product. According to approved methods, milk before it is heated up to exactly 35 degrees to determine the odor and to the reflux temperature, followed by cooling to identify taste. And bring it to the plant suppliers are required only chilled to 10 degrees, because the bactericidal phase milk is stored for only two hours after its production. The veterinary certificate stating that it was obtained from healthy cows, as required.

According to Lyudmila Georgievna, raw material base of "Glubokoye Dairy Plant" is represented not only native to Glubokoe district enterprise, but also two more - Sharkovshchina and Braslavsky. And, although the suppliers of many years of cooperation with the ICC is more than proven, and the regions themselves - an environmentally clean, each party coming to the company's milk is subjected to strict incoming inspection, because it affects the safety of people.

Irina Vaskovich kindly agreed to conduct a tour of the same route, which passes for admission to the company each batch of raw materials: from the "arrival" in the tank farm, milk tanker sent to consumers in the form of packaged jars of delicious condensed milk.

- There are unloaded or, as we say, "Unrolling" milk tankers, - says Irina Konstantinova. - What you see now - is cleaning tanks after unloading. This means that the party arrived milk passed laboratory tests proved high-quality and has been accepted.

We looked at the receiving laboratory, which, for convenience, the process is close to the area of acceptance. It IWC experts vengeance conjured a cunning devices that can detect even a tiny percentage of content in the milk of antibiotics and other potentially dangerous substances for the consumer. Other devices determines the degree of purity of the product, its richness and variety, and organoleptic qualities were tested by laboratory is very simple: milk is considered closely, sniffed and, of course, tried. Today's raw materials had excellent taste and smell, as it should, the natural fresh milk, and very appetizing.

Meanwhile Newly milk is pumped into the storage compartment - of course, over the counter. In a special window that process could even watch.

Storage tanks for newly arrived materials is also close to the zone of acceptance, only slightly lower, and, of course, the milk they receive only after cooling. Interior storage is a bit like a submarine: the same set of tubes (but only from shining stainless steel food) and round hatches sealed.

How long to keep the milk can not be here, because the sooner the materials go to pasteurization - the better. This process has a great open past biologist Louis Pasteur, milk is heated to a temperature at which kills harmful bacteria and lactic acid, but the raw material is still not boiling, allowing it to retain all the palatability, useful microelements, vitamins and enzymes. Pasteurization is performed in a special section.

Of course, all the threads "rivers of milk" in the enterprise need to somehow manage. This successfully makes fully computerized system, the operator of which may directly from your workstation to manage the process - to open and close the valves manually, as a few decades ago, is no longer required.

But back to the pasteurization. After its passage milk may already be stored for much longer than non-treated using this technology. And store it in special containers, but also very long, because the raw materials are waiting on a plot thickening. However, the "fate" of different batches of milk can vary depending on its purpose: for example, the future of condensed milk without sugar will be immediately directed to evaporation and to the sweetened condensed milk is necessary to add sugar syrup.

And now - the main thing. This syrup - single supplement! Absolutely no preservatives, sweeteners, flavor enhancers and flavor, as well as consumer and other frightening supplements beginning with the letter "E" in the Deep is not used! It is not necessary: a guaranteed and thoroughly tested quality raw material, coupled with modern processing technology make it possible to produce the product is not tasteful flavor and tasteful natural milk from which it is, in fact, done.

Evaporation as pasteurization, made without bringing milk to a temperature of 100 degrees Celsius, which allows you to keep it the whole range of useful qualities of fresh product. However, boiling with removal of "excess" of water molecules in the vapor does not necessarily occur at the same temperature: every schoolboy knows that this is necessary to reduce the pressure. Therefore, the condensed milk is carried out in special devices by evaporation under vacuum. The whole process is carefully controlled - like devices, and visually. And when condensed milk reaches the position according to GOST parameters, it is placed in a special tank.

Meanwhile, from a nearby shop comes cans (still empty) and cover them. Special Machine up to a gram fills cans condensed milk, and then packaging immediately rolled. Filled cans fly out of the car almost like a machine gun at a rate of 300 cans per minute! The assurances of the ICC staff, modern production line of Italian company Zilli & Bellini, and is capable of delivering 450 cans of condensed milk in a minute, just so the speed is not currently used.

Next, the filled, but not yet "unnamed" with condensed milk cans are sent on a conveyor that delivers them directly to the machine for labeling. Like all processes in Glubokoye ICC, this is fully automated: intelligent equipment itself and the sticker, and obozhmet her, and scroll to the bank during this process.

The road continues with condensed milk cans, already decorated with the traditional blue and white label that goes to a machine that assembles them in the proper amount and placed in the box. Sami cardboard boxes are also made another machine. The filled and taped boxes arrive on the conveyor belt, which takes them to the warehouse of finished products, and from there they go directly to the stores. However, for a long time on this stock goods do not lie - condensed milk, as well as other products Glubokoye Dairy Judging by scurrying to and fro branded trucks, in great demand among consumers.

In conclusion, it showed a kind of "Hall of Fame" Glubokoye Dairy, indicated, however, relatively modest signboard "Our achievements". Awards received in the quality of products, already struggling to fit on the wall!

And there are among them not only the Belarusian diplomas of winners of various contests and exhibitions, quality certificates and various prizes, but also international. That, however, is not surprising: after all, Dairy products Glubokoe comes in a variety of countries. This clearly shows the map placed here. "Conquer" condensed milk Hlybokae state marked with special icons on it, and the markets of other Glubokoe milkmen have yet to conquer.

Source: tinepoverish.livejournal.com