1801

How to make chocolate

Let's look at a chocolate bar or any product made of chocolate and think, how is it that we love so much, and often we eat in large quantities? What is this delicacy? How is white chocolate? What is the origin of cocoa beans? If you can not immediately answer these questions, let's try to understand together. Today we go to the chocolate museum, once a chocolate factory manufacturer Shtolverk (it. Stollwerck) in the German city of Cologne.

So, where does all begins. All obviously cocoa tree - tree species of the genus Theobroma (lat. Theobroma). In the wild these trees grow in the tropical forests of Central and South America, in Mexico, but at the moment the cocoa is cultivated in all tropical countries.

The fruits of cocoa, like lemons rough elongated shape, mature for 4-7 months, after which the workers are cut off (before most of the slaves). One such fruit weighs 300 grams. up to 1 kg.

Inside fruit in the five rows of the longitudinal groove situated cocoa beans surrounded by pulp. That they are necessary for the production of chocolate. Inside the fruit may range from about 20 to 60 seeds. Depending on the formulation of a fetus can be made from half to three bars (100 g).

However, it must first be profermentirovat and dry. Cocoa beans are put into wooden boxes and covered with banana tree leaves. Thanks to this fermented fruit under heat and release aroma becomes less bitter. After that, the cocoa beans are dried in the sun for about a week.

Then the cocoa beans are checked, sorting, classification types, cleaning, weighing process, packaged and transported to the customer. The main producers of cocoa are: Ivory Coast, Indonesia, Ghana, Nigeria, Cameroon, Brazil, Ecuador.

In the next step the cocoa beans are roasted to disclose specific fragrance.

In special installations separated hulls, after which they were crushed to form a chocolate liquor (or cocoa mass which occurs upon heating)

In the next step, the cocoa mass is placed under a press and squeeze made of cocoa butter. The remaining mass is ground into cocoa powder. You can start the production of chocolate.

After a few technical steps, performed so-called conching - mixing the ingredients.

For example, a milk chocolate bar comprises the following components: 40% sugar, 25% milk powder, 20% cocoa butter, 14% cocoa mass, 0, 5% lecithin and 0, 5% vanillin (total: 34% cocoa) . The white chocolate cocoa mass is not at all.

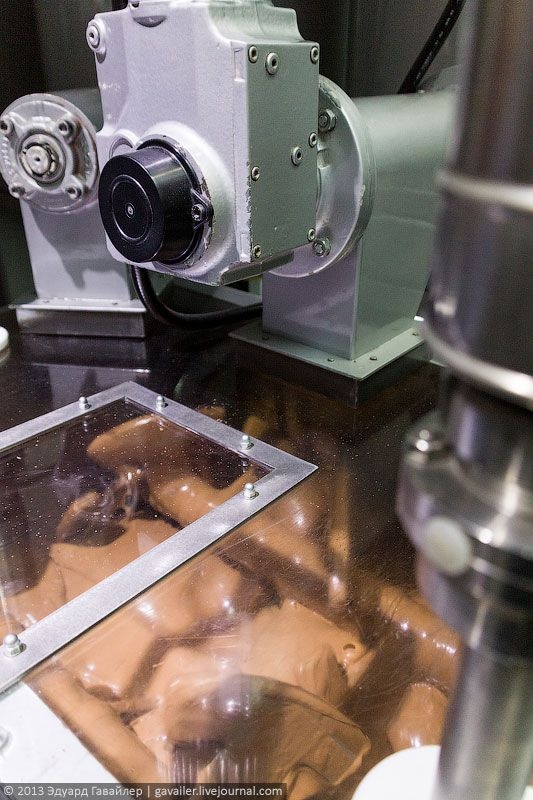

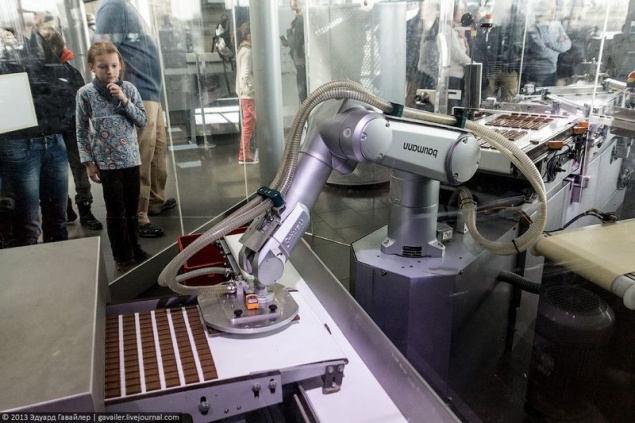

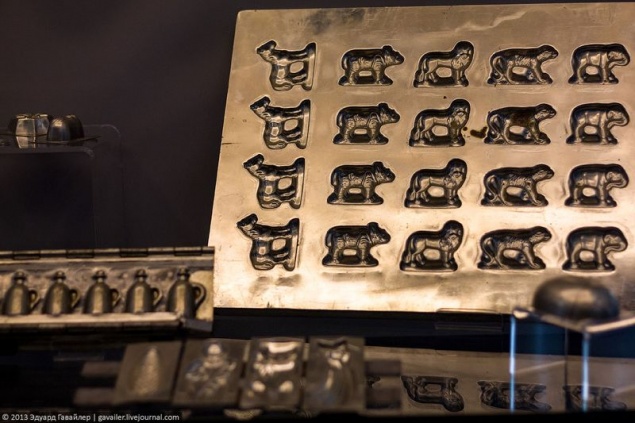

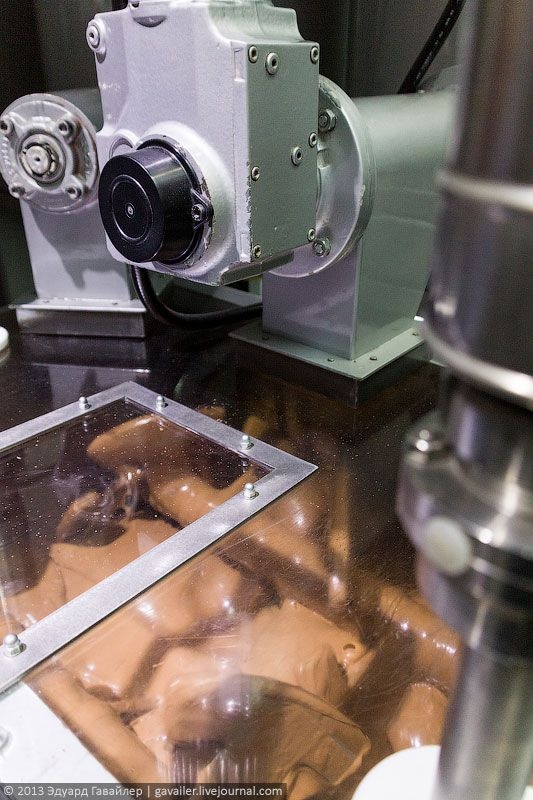

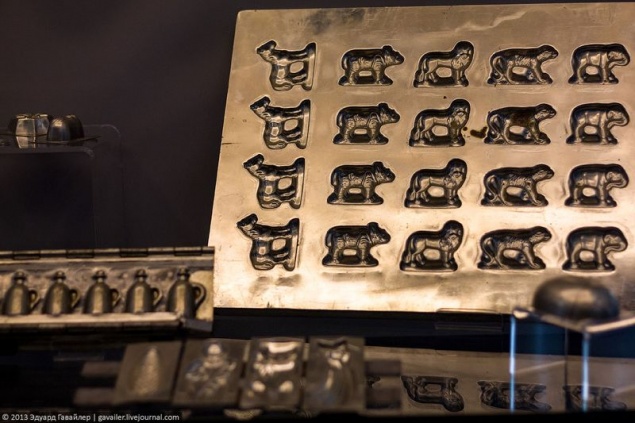

At the final stage, the tempering chocolate several times heated and cooled. In practice, the finished product remains on the forms and pour over cooled.

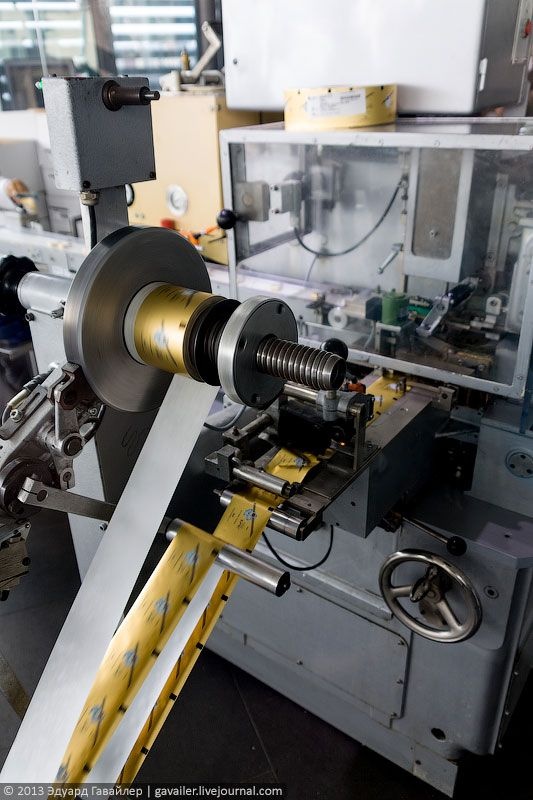

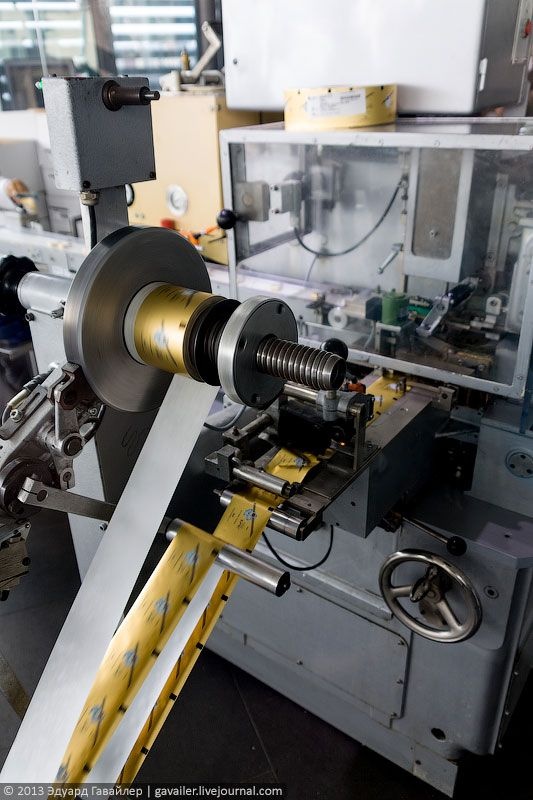

The last stage of packing and packaging.

These were the main stages of the production of chocolate. Of course, depending on the variety and type of products, new steps and stages.

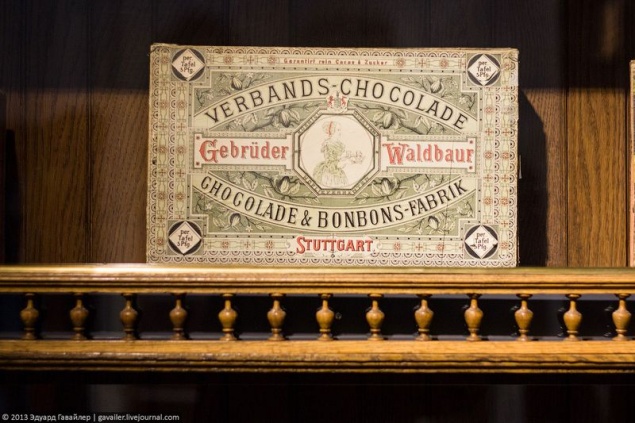

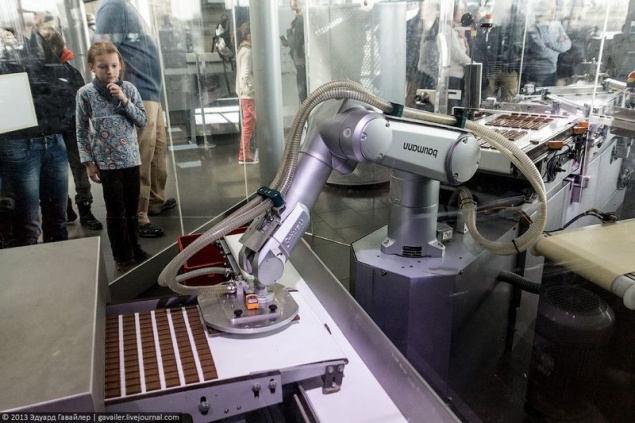

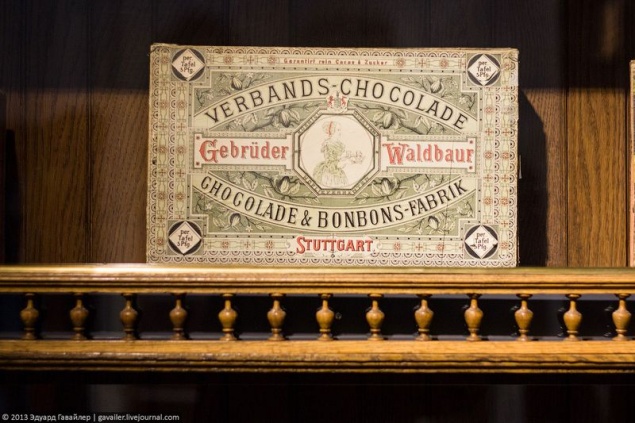

A few photos from the Cologne Chocolate Museum.

Source: gavailer.livejournal.com

So, where does all begins. All obviously cocoa tree - tree species of the genus Theobroma (lat. Theobroma). In the wild these trees grow in the tropical forests of Central and South America, in Mexico, but at the moment the cocoa is cultivated in all tropical countries.

The fruits of cocoa, like lemons rough elongated shape, mature for 4-7 months, after which the workers are cut off (before most of the slaves). One such fruit weighs 300 grams. up to 1 kg.

Inside fruit in the five rows of the longitudinal groove situated cocoa beans surrounded by pulp. That they are necessary for the production of chocolate. Inside the fruit may range from about 20 to 60 seeds. Depending on the formulation of a fetus can be made from half to three bars (100 g).

However, it must first be profermentirovat and dry. Cocoa beans are put into wooden boxes and covered with banana tree leaves. Thanks to this fermented fruit under heat and release aroma becomes less bitter. After that, the cocoa beans are dried in the sun for about a week.

Then the cocoa beans are checked, sorting, classification types, cleaning, weighing process, packaged and transported to the customer. The main producers of cocoa are: Ivory Coast, Indonesia, Ghana, Nigeria, Cameroon, Brazil, Ecuador.

In the next step the cocoa beans are roasted to disclose specific fragrance.

In special installations separated hulls, after which they were crushed to form a chocolate liquor (or cocoa mass which occurs upon heating)

In the next step, the cocoa mass is placed under a press and squeeze made of cocoa butter. The remaining mass is ground into cocoa powder. You can start the production of chocolate.

After a few technical steps, performed so-called conching - mixing the ingredients.

For example, a milk chocolate bar comprises the following components: 40% sugar, 25% milk powder, 20% cocoa butter, 14% cocoa mass, 0, 5% lecithin and 0, 5% vanillin (total: 34% cocoa) . The white chocolate cocoa mass is not at all.

At the final stage, the tempering chocolate several times heated and cooled. In practice, the finished product remains on the forms and pour over cooled.

The last stage of packing and packaging.

These were the main stages of the production of chocolate. Of course, depending on the variety and type of products, new steps and stages.

A few photos from the Cologne Chocolate Museum.

Source: gavailer.livejournal.com