740

Make a new clock mechanism with a vintage

A small sketch of the life of a watchmaker and restorer.

It's a hobby, like to restore the old timers with history.

Gradually, the hobby has grown in the production of new with old clock mechanism.

Will be 16 photos

A little history of restoration mechanism of gold pocket watch. However, gold in the review will not, because the body of hours a long time ago in the melted gold teeth trendy and stylish thick-ring seals Orphaned mechanism remains lie in a box watchmaker, and lay there for several decades.

In the picture our patient, traded one greedy watchmaker into a number of pieces of paper money. Judging by the layers of dirt, lying without housing since before the war. Poor guy.

Most likely, the car was stored in long oiled paper. Oil for half a century has grown to the metal layer of solid resin.

The case is heavy. Usually old mechanisms are much cuter than this chumazik.

Little about the origin of the mechanism, because it is important to understand what you're dealing with. We in the hands of the Swiss net early XX century, with a barely perceptible incomprehensible inscription Labrador Depose. But under the dial there was a small round mark of the famous Swiss company OMEGA. These timepieces are now known to all connoisseurs watch threads and therefore a good price.

Actually, in our hands very early mechanism manufactory OMEGA, when they were still working under the old name «Labrador». In the history of the company this fact can be found, but live like the clock is very rare even among experienced collectors of the topic. So our patient collector, about 1905-1908 model years. These samples illustrate the early history of the factory, and is usually valued even higher than usual Swiss "Omega».

In addition to the collection value mechanism, he played the role of a good enamel dial (it immediately took off and hid from possible damage, see photo at the end), and of all the desire to preserve the machine from disassembly to detail, to identify its potential and return to a new life.

First dismantle all screw up. Remove from the main board all the details of the mechanism. Conventional mechanisms are cleaned in an ultrasonic cleaning, but this modern technology will not help. Therefore, soaked for 10 minutes in gasoline, and a good clean manually with a brush, with the jewelry cleaning solution and tooth powder (by the way, tooth powder nowadays already a rarity).

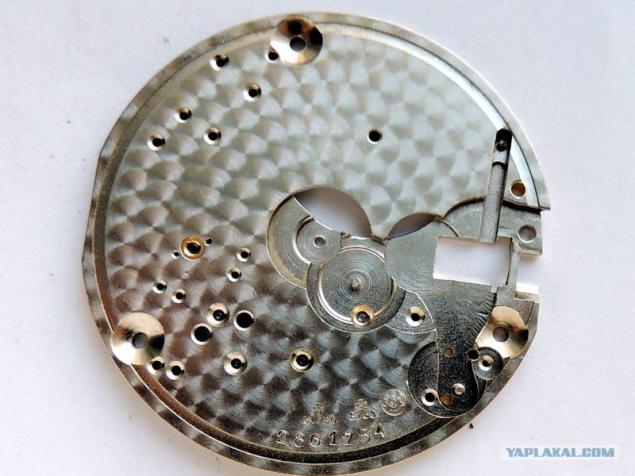

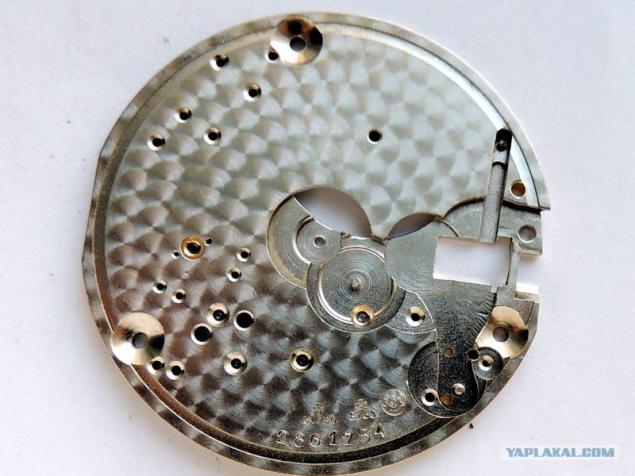

After a simple magic of the old oil crust peels, oxides are cleaned to bare metal with polished shining and polishing fasochkami "Perlage" (circular graining).

Now the mark and patent numbers can be seen much better light and shadow play in the reflections.

On the reverse side are making the same purity, there will be mounted the whole wheel system. We pay special attention to cleaning the jewels, which will rotate the wheel mechanism. They have to be perfect, spotlessly clean and otterty sharpened wooden sticks from the remnants of dirt. Wheel speed nothing should prevent.

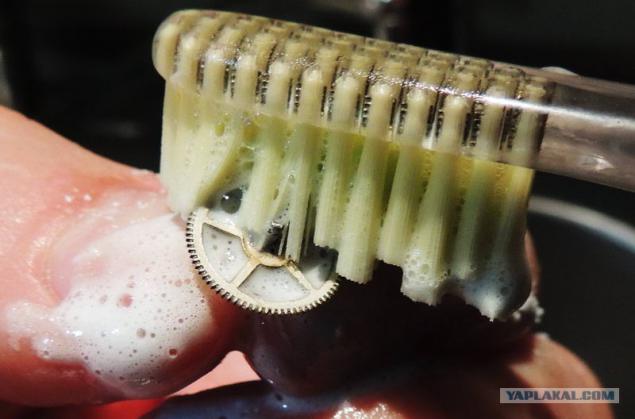

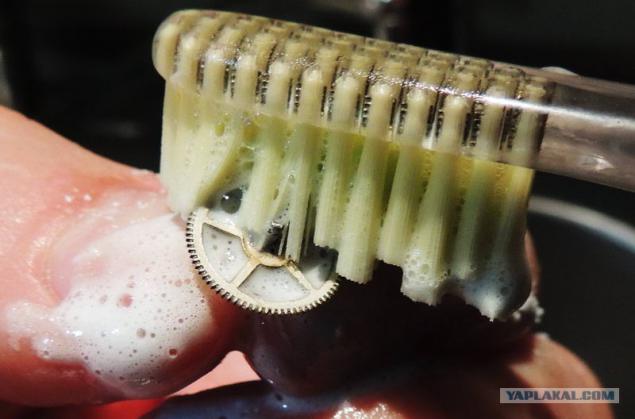

Each item is soaked, and separate, also manually cleaned with foam powder to the same luminous state. The wheels between the teeth black patina, it then additionally finely honed scour solid bamboo stick.

After rinsing in clean gasoline "Shoe" collecting mechanism. Wink and glistening polished gold-insert bezels with ruby stones, began to play in the rays of a wavy pattern grinding, they are seen more clearly. The mechanism once earned, but was tightly soured.

Before cleaning hours for future housing was produced from a blank here. Material - hypoallergenic stainless steel 316L. On a lathe chiseled landing sizes, fasteners.

Orphaned by a mechanism old pocket "bulbs" step by step it turns into a new wristwatch.

Go to the main - face future hours. Speech about the dial and hands. With dial handled very carefully, we put it at the very end of the project. This dial is very afraid of cracks.

Material of the dial - hot enamel, ceramic on a copper substrate. The age-old age does not affect the saturation of colors, they are baked in the ceramic layer at 900-degree temperatures, and are not afraid of household pollution. Only cracks and chips may mar the appearance of the enamel dials, and even if there was a crack, it is not clear. Therefore it is necessary to handle with care. It was lucky, all in perfect condition, just a little at the figure Scratchy 60. All present the original, older than 100 years.

After assembly, grease and tune the mechanism. Fortunate that the technical condition of the axes and jewels turned out very good.

Ready hours after a week of testing show scatter accuracy of the 10-20 seconds / day. This error fit even in modern standards, so that the project can be considered a success. Machine-quality, well-known brand with a decent story, so that she was wrong to lie idle.

A little more magic strap with buckle and you're done - you can wear and carry. Close brutal size is now in vogue. Front watch all as new, and only on the mechanism can determine the age.

An important detail - the case with a transparent back cover, so you can admire the 100-year-old ticking mechanism. By the way, it's pretty loud ticking.

That's from the "ugly duckling" managed to make a nice modern clock with a 100-year-old heart, which is again reliably and accurately counts the time.

In conclusion, it should be noted that this project was one of the really difficult cases, and only took half a day to clean parts of pure time.

Usually the initial arrangements for such watches are chosen deliberately perfect safety to recovery time was not spent in vain (because all the work is not done, so you do not know - they zatikayut well and reliably, or do not want). However, in the project "Labrador" the risk was justified, and the contrast of "before" and "after" speaks for itself.

THANK YOU !!!

Taken from here: german242.com/souscription/project165/labrador.htm

All finished!

I hope not tired, something many letters turned out =)

Source:

It's a hobby, like to restore the old timers with history.

Gradually, the hobby has grown in the production of new with old clock mechanism.

Will be 16 photos

A little history of restoration mechanism of gold pocket watch. However, gold in the review will not, because the body of hours a long time ago in the melted gold teeth trendy and stylish thick-ring seals Orphaned mechanism remains lie in a box watchmaker, and lay there for several decades.

In the picture our patient, traded one greedy watchmaker into a number of pieces of paper money. Judging by the layers of dirt, lying without housing since before the war. Poor guy.

Most likely, the car was stored in long oiled paper. Oil for half a century has grown to the metal layer of solid resin.

The case is heavy. Usually old mechanisms are much cuter than this chumazik.

Little about the origin of the mechanism, because it is important to understand what you're dealing with. We in the hands of the Swiss net early XX century, with a barely perceptible incomprehensible inscription Labrador Depose. But under the dial there was a small round mark of the famous Swiss company OMEGA. These timepieces are now known to all connoisseurs watch threads and therefore a good price.

Actually, in our hands very early mechanism manufactory OMEGA, when they were still working under the old name «Labrador». In the history of the company this fact can be found, but live like the clock is very rare even among experienced collectors of the topic. So our patient collector, about 1905-1908 model years. These samples illustrate the early history of the factory, and is usually valued even higher than usual Swiss "Omega».

In addition to the collection value mechanism, he played the role of a good enamel dial (it immediately took off and hid from possible damage, see photo at the end), and of all the desire to preserve the machine from disassembly to detail, to identify its potential and return to a new life.

First dismantle all screw up. Remove from the main board all the details of the mechanism. Conventional mechanisms are cleaned in an ultrasonic cleaning, but this modern technology will not help. Therefore, soaked for 10 minutes in gasoline, and a good clean manually with a brush, with the jewelry cleaning solution and tooth powder (by the way, tooth powder nowadays already a rarity).

After a simple magic of the old oil crust peels, oxides are cleaned to bare metal with polished shining and polishing fasochkami "Perlage" (circular graining).

Now the mark and patent numbers can be seen much better light and shadow play in the reflections.

On the reverse side are making the same purity, there will be mounted the whole wheel system. We pay special attention to cleaning the jewels, which will rotate the wheel mechanism. They have to be perfect, spotlessly clean and otterty sharpened wooden sticks from the remnants of dirt. Wheel speed nothing should prevent.

Each item is soaked, and separate, also manually cleaned with foam powder to the same luminous state. The wheels between the teeth black patina, it then additionally finely honed scour solid bamboo stick.

After rinsing in clean gasoline "Shoe" collecting mechanism. Wink and glistening polished gold-insert bezels with ruby stones, began to play in the rays of a wavy pattern grinding, they are seen more clearly. The mechanism once earned, but was tightly soured.

Before cleaning hours for future housing was produced from a blank here. Material - hypoallergenic stainless steel 316L. On a lathe chiseled landing sizes, fasteners.

Orphaned by a mechanism old pocket "bulbs" step by step it turns into a new wristwatch.

Go to the main - face future hours. Speech about the dial and hands. With dial handled very carefully, we put it at the very end of the project. This dial is very afraid of cracks.

Material of the dial - hot enamel, ceramic on a copper substrate. The age-old age does not affect the saturation of colors, they are baked in the ceramic layer at 900-degree temperatures, and are not afraid of household pollution. Only cracks and chips may mar the appearance of the enamel dials, and even if there was a crack, it is not clear. Therefore it is necessary to handle with care. It was lucky, all in perfect condition, just a little at the figure Scratchy 60. All present the original, older than 100 years.

After assembly, grease and tune the mechanism. Fortunate that the technical condition of the axes and jewels turned out very good.

Ready hours after a week of testing show scatter accuracy of the 10-20 seconds / day. This error fit even in modern standards, so that the project can be considered a success. Machine-quality, well-known brand with a decent story, so that she was wrong to lie idle.

A little more magic strap with buckle and you're done - you can wear and carry. Close brutal size is now in vogue. Front watch all as new, and only on the mechanism can determine the age.

An important detail - the case with a transparent back cover, so you can admire the 100-year-old ticking mechanism. By the way, it's pretty loud ticking.

That's from the "ugly duckling" managed to make a nice modern clock with a 100-year-old heart, which is again reliably and accurately counts the time.

In conclusion, it should be noted that this project was one of the really difficult cases, and only took half a day to clean parts of pure time.

Usually the initial arrangements for such watches are chosen deliberately perfect safety to recovery time was not spent in vain (because all the work is not done, so you do not know - they zatikayut well and reliably, or do not want). However, in the project "Labrador" the risk was justified, and the contrast of "before" and "after" speaks for itself.

THANK YOU !!!

Taken from here: german242.com/souscription/project165/labrador.htm

All finished!

I hope not tired, something many letters turned out =)

Source: