674

The conveyor of money

Goznak, leading its history from the Department of State securities, established by the decree of Emperor Alexander I in 1818, produces not only rubles and kopecks. It produces banknotes for many other countries, including Belarus, Lebanon, Laos, Malaysia, Guatemala, Syria. Banknote paper Goznak supplies in more than 20 countries, including Indonesia and Nigeria. Recently it became known about a major contract with Angola Goznak - Russian company has developed a design for her nine denominations of banknotes and coins of the four denominations.

Chasing a ten coins at the Moscow Mint

31 Photo Source

Preparations for the small coins to be issued in the Moscow Mint

Upload coin blanks in one of the workshops of the Mint

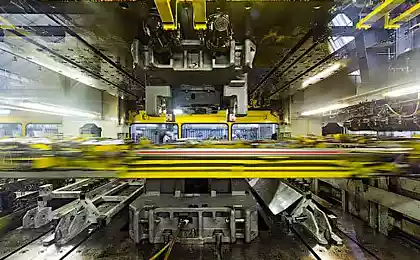

Chasing a ten coins

Chasing a ten coins

Employees Moscow Mint coins are packaged ready

The reverse side of the silver collector coin with the image of three rubles George in the shop coinage

The shop coinage to Moscow Mint

Silver collectible coins (reverse side) face value of three rubles depicting George

The shop coinage to Moscow Mint

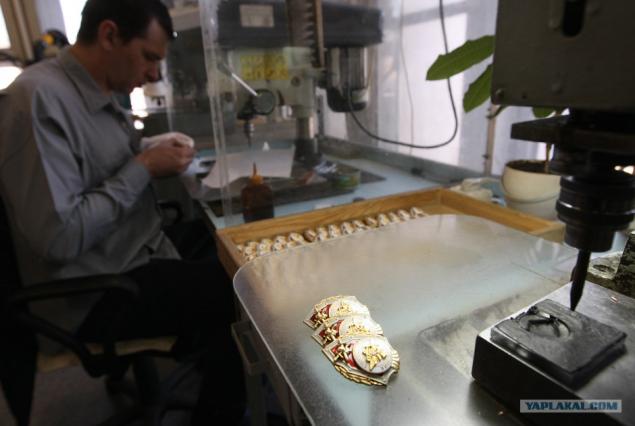

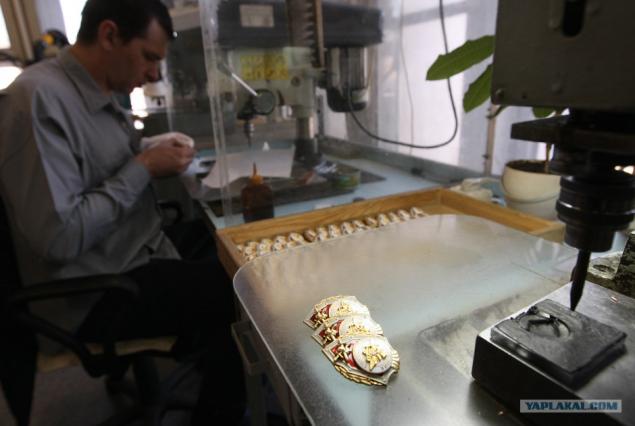

Manufacturing of badges "Excellent ground forces»

Manufacturing of badges "Excellent ground forces»

Form for the coinage. Manufacturing orders and medals at the Moscow Mint

Manufacturing orders and medals at the Moscow Mint

Minting of icons at the Moscow Mint

The application of paint

Icons State Duma deputy

Exclusive watches, gathered at Moscow Mint

Production of commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Production of commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Commemorative coin dedicated to the Olympic Winter Games 2014 in Sochi

Commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Checking printed blanks before sending the line cutting and packing factory Federal State Unitary Enterprise "Goznak" Perm

Checking printed blanks before sending the line cutting and packing

The driver line cutting and packing pack products puts the drum for cutting

The employees of the same factory converted products before packing

Factory employee examines the banknotes printed on site sampling quality printing, cutting and packaging

That's done sampling the print quality of banknotes

Storekeepers check the integrity of the packaging and converted products

Ready money is going into the pantry

Employee recalculates and checks the integrity of packaging at the site of sampling quality printing, cutting and packaging

I have all

Source:

Chasing a ten coins at the Moscow Mint

31 Photo Source

Preparations for the small coins to be issued in the Moscow Mint

Upload coin blanks in one of the workshops of the Mint

Chasing a ten coins

Chasing a ten coins

Employees Moscow Mint coins are packaged ready

The reverse side of the silver collector coin with the image of three rubles George in the shop coinage

The shop coinage to Moscow Mint

Silver collectible coins (reverse side) face value of three rubles depicting George

The shop coinage to Moscow Mint

Manufacturing of badges "Excellent ground forces»

Manufacturing of badges "Excellent ground forces»

Form for the coinage. Manufacturing orders and medals at the Moscow Mint

Manufacturing orders and medals at the Moscow Mint

Minting of icons at the Moscow Mint

The application of paint

Icons State Duma deputy

Exclusive watches, gathered at Moscow Mint

Production of commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Production of commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Commemorative coin dedicated to the Olympic Winter Games 2014 in Sochi

Commemorative coins dedicated to the Olympic Winter Games 2014 in Sochi

Checking printed blanks before sending the line cutting and packing factory Federal State Unitary Enterprise "Goznak" Perm

Checking printed blanks before sending the line cutting and packing

The driver line cutting and packing pack products puts the drum for cutting

The employees of the same factory converted products before packing

Factory employee examines the banknotes printed on site sampling quality printing, cutting and packaging

That's done sampling the print quality of banknotes

Storekeepers check the integrity of the packaging and converted products

Ready money is going into the pantry

Employee recalculates and checks the integrity of packaging at the site of sampling quality printing, cutting and packaging

I have all

Source: