781

Sliding doors with their hands

I decided to share my experience, maybe someone will be interested.

This spring SUDDENLY matured the idea to make a new entry in the country. Old not happy for some reason - the gate swinging, exceedingly miserable for the old as the mammoth shit. Mostly sagged in places fallen off welding. In short, hug and cry. In addition, the width of the gate was small and trucks, of bringing construction material, trying to fix pillars that, in fact, often happened.

As a result, it was decided to remove the whole Gamsakhurdia to coincide with the installation of a new fence installation sliding gates with the opening of 5 meters instead of the old swing for syphilis.

Seeing tags installation sliding gates turnkey slightly fallomikriroval I, for asking for them as something well, not a Communist. 5 meter opening turnkey automation around 110 thousand. I decided to take a chance and do all the work yourself.

A few hours I spent reading the forums, saytik describing the installation. Pitfalls during the installation procedure, "hints" and so on.

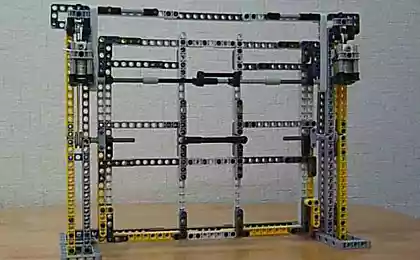

He came to the boutiques of the fittings. Seeking live. This video, for example.

Will be 12 photos + video

In the neighboring dacha cooperative gathered to make sliding doors and has already poured foundation. Photographed "to order» © Xan Ksanych, k / f "Girls".

The first purchase - mortgage element (channel), roller guide 7 meters, traps and other related small epidersiya. All happiness is about 17 rubles delivery by Chekhov (to carry on the roof of a 7-meter-lance guide myself I refused for security reasons, but you can save almost 4000).

Six months before the start of work I bought a welding machine Fubag 163, read the theory in textbooks PTUshnyh up and down, practiced in the garage. By the beginning of work on the gate he was already able confidently to weld thin metal from 1.5mm in any spatial positions with fairly good quality.

Work begins. We place purchase mortgage element and cook under the foundation-frame counterweight. Works for 2 hours (to saw rebar, make, weld).

It is in the process:

Mortgage element frame ready to postpone a pile of sand, so as not to interfere. Pit digging itself with the help of the citizens of former Soviet republics. Work hard, health is not a state-owned. Dig a hole 2.5m * 0.5m depth of 2 meters of the great self-interest was not.

In the evening, as darkness fell, the level posted for welding woodwork. An indispensable thing - Laser builder planes. Looking ahead to say that the "propeller" on the output turned in the range of 1-2 mm by 7 meters long Vorotina. Placing level - a very important step. You should not be guided by the principle of "7 times measure while others have cut off." Check the level as it should.

Start welding the frame. Since Vorotina 7 meters (5 +2 opposed to opening), and standard rental - 6 meters (12 to buy, but you have to wait), we had to piece down 1 meter. Butt welding. Total - 7 meters.

The material for the frame - 60 * 40 * 2mm frame itself, the internal elements - 40 * 20 * 2 mm and 20 * 20 * 1.5mm. Total metal to 4.5 thousand rubles.

Photos during the welding process:

2 photo

3 photo

More photos

The foundation poured. I recommend pouring the foundation of their own, it's hard, but it will guarantee that all leveled. Again, all exhibited the night before with a laser builder planes. Its use is allowed in advance to see the path to 1mm rollback gate and, of course, to put itself in terms of the mortgage.

The frame is welded. We guide rolls, put on top and cook Vorotina to guide 2-3cm seams every 25-35sm. Important - you must cook from the center to the edges of a mortgage in a checkerboard pattern, otherwise there is a risk that the entire structure will lead. Attracts clamps tightened before welding.

It was found welded. Weld the support roller traps. It is important - better to put back post after installing the gate that you protect yourself from the "misses" Vorotina the desired point where there will be a trap. Although you can fathom and gently put a post in advance rollers allow a small adjustment after installing the gate.

Otkrasheno three layers. Joint sealant filled "guide-frame" rust.

Rivet profiled on one side. Dowel - a very convenient form of fasteners. Screws (even the roof) can be rotten, dowel is made of aluminum. Tired badly screws holding dynamic loads and a couple of years may just burst.

It is planned, of course, riveted on both sides.

A week later, it was installed Automatic Nice RB1000. There's nothing particularly complicated there, unless the manual is not always clear. It should be read twice :). From electricians - 2 wires to poles for the photocells (do not want to get in Vorotina Bochin car), 2 wires at the near post to lamp + antenna (I have a special double wire purchased in the same Magazev). For automation 3 * 1.5mm wire. Installed power stabilizer to 1.5kW, as Automation is very sensitive to fluctuations in naprugi and suburban areas it is not uncommon.

Total will be the same if you are interested.

Hardware - 13000 + 4000 Shipping

Metal gates - about 5,000

Foundation - around 5000 (+ cost of digging up cement)

Automation - I think about 17,000

Paint, electrodes, wires, a trifle - 2-3 thousand rubles

Bottom line: Less than 50 thousand. That is doubled. Unlike the factory gates - NEporoshkovaya painting. And yet.

The final version of the video:

(FLASH MOVIE)

(FLASH MOVIE)

Posted in [mergetime] 1381905508 [/ mergetime]

While all!

Source:

This spring SUDDENLY matured the idea to make a new entry in the country. Old not happy for some reason - the gate swinging, exceedingly miserable for the old as the mammoth shit. Mostly sagged in places fallen off welding. In short, hug and cry. In addition, the width of the gate was small and trucks, of bringing construction material, trying to fix pillars that, in fact, often happened.

As a result, it was decided to remove the whole Gamsakhurdia to coincide with the installation of a new fence installation sliding gates with the opening of 5 meters instead of the old swing for syphilis.

Seeing tags installation sliding gates turnkey slightly fallomikriroval I, for asking for them as something well, not a Communist. 5 meter opening turnkey automation around 110 thousand. I decided to take a chance and do all the work yourself.

A few hours I spent reading the forums, saytik describing the installation. Pitfalls during the installation procedure, "hints" and so on.

He came to the boutiques of the fittings. Seeking live. This video, for example.

Will be 12 photos + video

In the neighboring dacha cooperative gathered to make sliding doors and has already poured foundation. Photographed "to order» © Xan Ksanych, k / f "Girls".

The first purchase - mortgage element (channel), roller guide 7 meters, traps and other related small epidersiya. All happiness is about 17 rubles delivery by Chekhov (to carry on the roof of a 7-meter-lance guide myself I refused for security reasons, but you can save almost 4000).

Six months before the start of work I bought a welding machine Fubag 163, read the theory in textbooks PTUshnyh up and down, practiced in the garage. By the beginning of work on the gate he was already able confidently to weld thin metal from 1.5mm in any spatial positions with fairly good quality.

Work begins. We place purchase mortgage element and cook under the foundation-frame counterweight. Works for 2 hours (to saw rebar, make, weld).

It is in the process:

Mortgage element frame ready to postpone a pile of sand, so as not to interfere. Pit digging itself with the help of the citizens of former Soviet republics. Work hard, health is not a state-owned. Dig a hole 2.5m * 0.5m depth of 2 meters of the great self-interest was not.

In the evening, as darkness fell, the level posted for welding woodwork. An indispensable thing - Laser builder planes. Looking ahead to say that the "propeller" on the output turned in the range of 1-2 mm by 7 meters long Vorotina. Placing level - a very important step. You should not be guided by the principle of "7 times measure while others have cut off." Check the level as it should.

Start welding the frame. Since Vorotina 7 meters (5 +2 opposed to opening), and standard rental - 6 meters (12 to buy, but you have to wait), we had to piece down 1 meter. Butt welding. Total - 7 meters.

The material for the frame - 60 * 40 * 2mm frame itself, the internal elements - 40 * 20 * 2 mm and 20 * 20 * 1.5mm. Total metal to 4.5 thousand rubles.

Photos during the welding process:

2 photo

3 photo

More photos

The foundation poured. I recommend pouring the foundation of their own, it's hard, but it will guarantee that all leveled. Again, all exhibited the night before with a laser builder planes. Its use is allowed in advance to see the path to 1mm rollback gate and, of course, to put itself in terms of the mortgage.

The frame is welded. We guide rolls, put on top and cook Vorotina to guide 2-3cm seams every 25-35sm. Important - you must cook from the center to the edges of a mortgage in a checkerboard pattern, otherwise there is a risk that the entire structure will lead. Attracts clamps tightened before welding.

It was found welded. Weld the support roller traps. It is important - better to put back post after installing the gate that you protect yourself from the "misses" Vorotina the desired point where there will be a trap. Although you can fathom and gently put a post in advance rollers allow a small adjustment after installing the gate.

Otkrasheno three layers. Joint sealant filled "guide-frame" rust.

Rivet profiled on one side. Dowel - a very convenient form of fasteners. Screws (even the roof) can be rotten, dowel is made of aluminum. Tired badly screws holding dynamic loads and a couple of years may just burst.

It is planned, of course, riveted on both sides.

A week later, it was installed Automatic Nice RB1000. There's nothing particularly complicated there, unless the manual is not always clear. It should be read twice :). From electricians - 2 wires to poles for the photocells (do not want to get in Vorotina Bochin car), 2 wires at the near post to lamp + antenna (I have a special double wire purchased in the same Magazev). For automation 3 * 1.5mm wire. Installed power stabilizer to 1.5kW, as Automation is very sensitive to fluctuations in naprugi and suburban areas it is not uncommon.

Total will be the same if you are interested.

Hardware - 13000 + 4000 Shipping

Metal gates - about 5,000

Foundation - around 5000 (+ cost of digging up cement)

Automation - I think about 17,000

Paint, electrodes, wires, a trifle - 2-3 thousand rubles

Bottom line: Less than 50 thousand. That is doubled. Unlike the factory gates - NEporoshkovaya painting. And yet.

The final version of the video:

(FLASH MOVIE)

(FLASH MOVIE)

Posted in [mergetime] 1381905508 [/ mergetime]

While all!

Source: