437

LEGO crazy hands + + iron = GATES

A tendency to brag YaPovtsev process and results rukozhopstva, decided to try his luck and present to the public their product. It will be some photos and videos, the completion will tell.

It all started with the fact that after moving out of the apartment to the house I had an urgent need to replace the gate to the courtyard, as the old wooden little open, and were, to put it mildly, in Khrenovoe state.

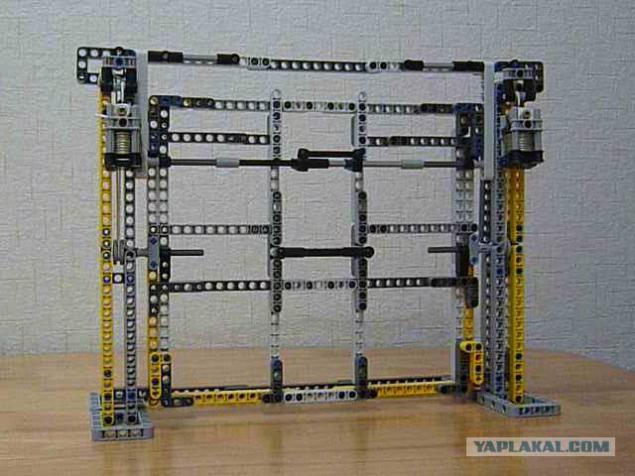

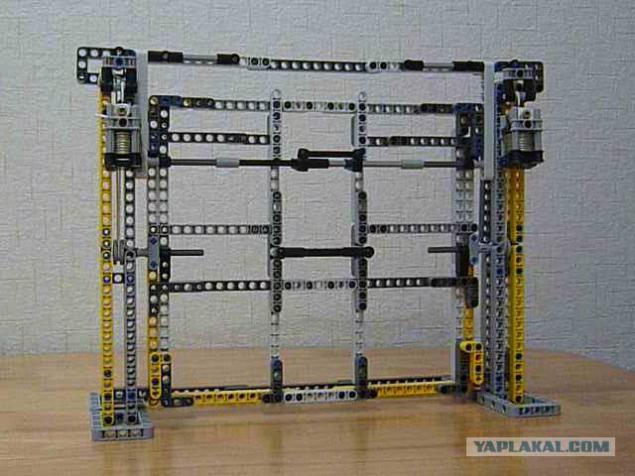

The first step had to consider the design and make a prototype to make sure that the structure is efficient. Oddly enough, but the designer LEGO Technic was the easiest and best tool for simulation. I spent a few nights, tried different options and stop at the most successful.

That's what I got:

Meditate for a while, I decided that conventional swing gates I do not fit in many ways. In particular, I did not like that for opening swing gates winter had to be constantly clearing the snow in front of them, or raise the gates structurally above the ground, and figure out how to close the gap under the gate from curious dogs and cats. Ready role-gates were too expensive, so it was decided to build their own gates. At the same time there was one small problem - the almost complete absence of drawings and any useful information about the design of lifting the gate. The standard scheme, in which the flap is lifted, turned and went back under the roof of the garage, came not for the simple reason that there is a garage behind the gate and is not planned. The only possible design in my case - lifting and turning gates with counterweights, which do not require any additional elements, but two of the pillars on the sides of the gate.

Naturally, the prototype had to show that the basic idea I understood correctly. The model is valid, and tolerably well demonstrated kinematics design.

The sea trials of the prototype has shown that it is invented kinematics design viable, and you can begin to implement the idea of "iron". Of course, it had been previously drawn sketch of the gate, and count all geometry. After acquiring the necessary materials have only to saw everything in size, cook, tie and put in place.

Putting the gate leaf:

If not for his wife's brother, the hell with the two I own everything so neatly welded

Professional cooks from any position and in any condition)))

Putting racks:

The process of final assembly proved to be tedious and time consuming, the camera decided that he had had enough, and passed out. Therefore, the final result has pictures.

Inside:

Posted in [mergetime] 1397766265 [/ mergetime]

Are any glitches with the addition of the last post sticks together with the penultimate (((

And to hell with him, so I decorated.

Well, to fully understand the results, with the video demonstration of the process of opening-closing:

I have everything, thank you for your attention.

Outside view: (sorry, a little gate zasrali birds)

Source:

It all started with the fact that after moving out of the apartment to the house I had an urgent need to replace the gate to the courtyard, as the old wooden little open, and were, to put it mildly, in Khrenovoe state.

The first step had to consider the design and make a prototype to make sure that the structure is efficient. Oddly enough, but the designer LEGO Technic was the easiest and best tool for simulation. I spent a few nights, tried different options and stop at the most successful.

That's what I got:

Meditate for a while, I decided that conventional swing gates I do not fit in many ways. In particular, I did not like that for opening swing gates winter had to be constantly clearing the snow in front of them, or raise the gates structurally above the ground, and figure out how to close the gap under the gate from curious dogs and cats. Ready role-gates were too expensive, so it was decided to build their own gates. At the same time there was one small problem - the almost complete absence of drawings and any useful information about the design of lifting the gate. The standard scheme, in which the flap is lifted, turned and went back under the roof of the garage, came not for the simple reason that there is a garage behind the gate and is not planned. The only possible design in my case - lifting and turning gates with counterweights, which do not require any additional elements, but two of the pillars on the sides of the gate.

Naturally, the prototype had to show that the basic idea I understood correctly. The model is valid, and tolerably well demonstrated kinematics design.

The sea trials of the prototype has shown that it is invented kinematics design viable, and you can begin to implement the idea of "iron". Of course, it had been previously drawn sketch of the gate, and count all geometry. After acquiring the necessary materials have only to saw everything in size, cook, tie and put in place.

Putting the gate leaf:

If not for his wife's brother, the hell with the two I own everything so neatly welded

Professional cooks from any position and in any condition)))

Putting racks:

The process of final assembly proved to be tedious and time consuming, the camera decided that he had had enough, and passed out. Therefore, the final result has pictures.

Inside:

Posted in [mergetime] 1397766265 [/ mergetime]

Are any glitches with the addition of the last post sticks together with the penultimate (((

And to hell with him, so I decorated.

Well, to fully understand the results, with the video demonstration of the process of opening-closing:

I have everything, thank you for your attention.

Outside view: (sorry, a little gate zasrali birds)

Source: